Are you using cut-off wheels correctly? Proper use means matching the wheel to your material and using the right tool RPM. You must apply a 90-degree cutting angle with light pressure for every cut-off task. These simple guidelines are critical for both efficiency and safety.

Did you know? Angle grinders rank as the third most dangerous tool, causing over 5,000 injuries annually. Most accidents happen from shattering cut-off wheels or tool kickback.

Following expert cutting advice ensures professional cutting results. It also helps you prevent dangerous accidents. Your personal safety is paramount.

Key Takeaways

- Always pick the right cut-off wheel for your material and tool speed. This helps you cut well and stay safe.

- Wear safety gear like a face shield, gloves, and a special mask. Also, check your wheel for damage before every use.

- Cut at a straight 90-degree angle to your material. Do not push too hard; let the wheel do the work.

- Always clamp your material tightly. This stops it from moving and keeps your hands safe.

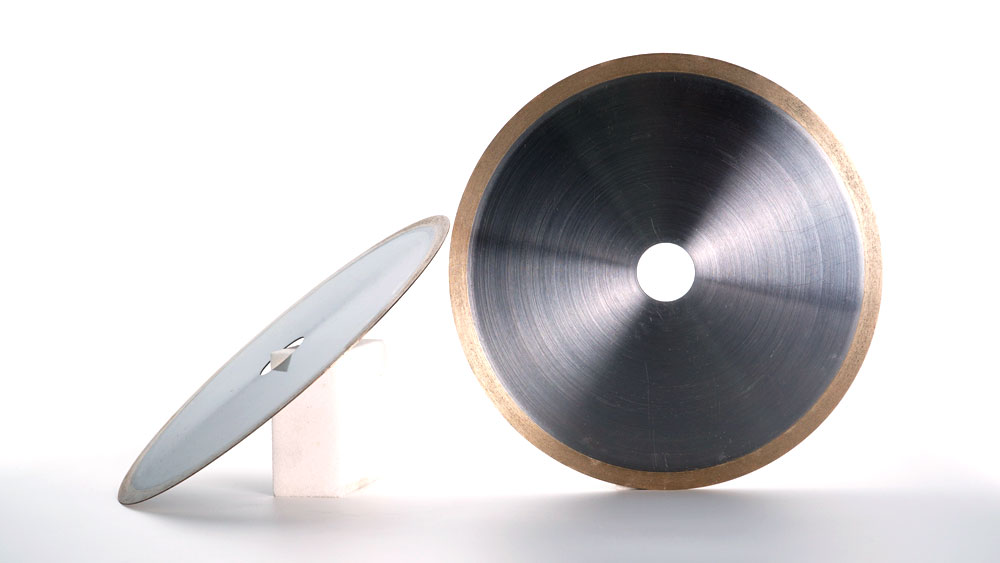

Selecting the Correct Cut-Off Wheels

Choosing the right wheel is the first step toward a safe and successful cut-off. A mismatched wheel can lead to poor results, rapid wear, and dangerous failures. You can ensure a clean cut every time by understanding a few key factors.

Match the Wheel to Your Material

Different abrasive materials are designed for specific jobs. Using the wrong one will make your work harder and less effective. For cutting metal, you have several common options.

| Abrasive Type | Best For | Key Feature |

|---|---|---|

| Aluminum Oxide | General-purpose ferrous metals, alloys | A cost-effective choice for many tasks. |

| Zirconia Alumina | Steel, structural steel, iron | Self-sharpens under high pressure for fast cutting. |

| Ceramic Alumina | Stainless steel, titanium, hard alloys | Cuts cooler and lasts longer on tough metals. |

For non-ferrous metals like aluminum or copper, you need a different approach.

- Silicon Carbide is a great choice. It is very sharp and prevents the soft metal from clogging the wheel.

- Wheels with a special stearate coating also help prevent this loading issue when cutting metal.

Verify RPM and Size Compatibility

Safety is your top priority. You must always check the wheel’s maximum operating speed, which is printed on its label. This RPM rating must be higher than the RPM of your angle grinder. Using a wheel on a tool that spins too fast can cause it to shatter. Also, ensure the wheel’s arbor hole fits your tool’s spindle perfectly. A loose fit is a major safety hazard. Proper matching ensures safe operation and consistent cutting performance.

Choose Quality Aimgrind Cutting Wheels

Your choice of brand matters. Aimgrind provides specialized cutting wheels designed for superior results. We offer advanced solutions like Cubic Boron Nitride (CBN) wheels, which excel at cutting hardened steels and superalloys. These wheels offer long life and high precision, generating less heat to protect your workpiece. At Aimgrind, we focus on matching the right wheel to your specific process. This ensures you get the best cut-off wheels for your unique cutting application, enhancing both productivity and safety.

Essential Safety and Inspection Protocols

Selecting the right wheel is only half the battle. Your personal safety depends on the protocols you follow before and during every cut-off task. These steps are not suggestions; they are essential rules to prevent serious accidents and ensure you work with confidence. Ignoring these protocols introduces unnecessary hazards.

Wear Non-Negotiable PPE

You must protect yourself from flying debris, sparks, and harmful dust. Your personal protective equipment (PPE) is your first and most important line of defense. OSHA regulations mandate proper protection for your eyes, face, and hands.

Your non-negotiable PPE checklist includes:

- Full-Face Shield over Safety Glasses: A face shield protects your entire face from sparks and shattering wheel fragments. You must wear safety glasses underneath it for complete eye safety.

- High-Dexterity Gloves: You need gloves that protect your hands without sacrificing control. Look for gloves with an ANSI/ISEA Cut Level 3 rating. An 18-gauge knit with a nitrile coating offers excellent durability and puncture protection while letting you feel the tool.

- Respiratory Protection: Metal cutting creates fine dust and fumes that are dangerous to inhale. You should use a respirator with P100 filters. These filters block at least 99.97% of all particles and are ideal for industrial environments.

Safety Tip: Never start a cutting job without your full PPE. A few seconds of preparation can prevent a lifetime of injury. Your safety is always the top priority.

Inspect the Wheel Before Each Use

A damaged wheel can explode when it reaches operating speed. You must inspect every wheel for damage before you mount it on your grinder. This simple check is a critical safety measure.

First, perform a visual inspection. Look for any signs of trouble:

- Cracks or Chips: Even a small crack can cause the wheel to fail under pressure.

- Glazing: A shiny or smooth surface means the abrasive is clogged and will not cut effectively.

- Discoloration: Blue or brown spots indicate the wheel has been damaged by heat.

- Missing Metal Ring: The stamped metal ring in the center reinforces the arbor hole. Do not use a wheel if it is missing.

If you find any of these issues, you must discard the damaged or chipped wheel immediately.

Next, perform the “ring test” on new wheels to find hidden cracks.

- Make sure the wheel is dry and clean.

- Suspend the wheel freely on your finger or a small pin through the arbor hole.

- Gently tap the wheel with a non-metallic object, like a plastic screwdriver handle. Tap about one or two inches from the edge.

- Listen to the sound. A solid, undamaged wheel will produce a clear ringing sound. A cracked wheel will make a dull “thud.”

If you hear a thud, the wheel is unsafe. Do not use it. It is time to replace a cut-off wheel when it fails this test or shows any visual damage.

Use the Correct Tool and Guard

The safety guard on your angle grinder is not optional. OSHA regulations require you to use a guard for all cut-off operations. It is designed to contain fragments if a wheel breaks and to deflect sparks away from you. Your safety depends on it.

You must also use the correct type of guard for your wheel.

- Type 1 Wheels are flat cut-off wheels. They require a Type 1 guard, which is more enclosed to provide maximum protection during a straight cut-off.

- Type 27 Wheels have a depressed center and are often used for grinding. Using a Type 27 guard with a Type 1 wheel for cutting is extremely dangerous because it does not provide adequate coverage.

Mismatched guards create significant safety risks. Always ensure your guard is designed specifically for the type of cutting wheel you are using. Never remove or modify the guard on your tool. Proper equipment matching is a fundamental part of job site safety.

Best Practices for Using Cut-Off Wheels

You have the right wheel and your full PPE. Now, your focus must shift to technique. The proper application of the tool is critical for achieving a clean, precise cut-off and preventing accidents. Mastering these best practices will protect you and ensure professional results on every job.

Maintain a Strict 90-Degree Angle

Your most important rule when using cut-off wheels is to keep the tool at a 90-degree angle to the workpiece. You must only perform straight, direct cuts. Never bend, twist, or apply pressure to the side of the wheel.

Cut-off wheels are thin and designed to handle forces only on their cutting edge. Applying side pressure creates intense friction and heat. This weakens the wheel‘s internal structure, making it likely to shatter under the stress of high-speed rotation. Grinding on the side of a flat wheel is extremely dangerous and can cause it to break apart from centrifugal force alone.

You may have felt your angle grinder try to “wriggle” out of your hands. This is a physical force called gyroscopic precession. When you twist a spinning object, it creates a powerful torque at a right angle to your movement. This makes the tool unstable and difficult to control, increasing the risk of an accident during the cutting process. A straight, 90-degree approach keeps this force in check.

Let the Wheel Do the Work

You should never force a cut-off wheel through material. Your job is to guide the tool with light, steady pressure and let the wheel’s speed do the cutting. Forcing the tool is inefficient and creates serious safety hazards. Pushing too hard causes the wheel to bind or pinch in the material. This can trigger a violent kickback, where the tool is thrown up and back toward you.

Pro Tip: For cutting medium-hard metals like mild steel, experts advise an operating pressure between 10 and 15 PSI. This is just enough force to be effective without damaging the wheel or workpiece.

Pay attention to the signs that you are applying too much pressure. Your tool and workpiece will give you clear warnings:

- Glazing: The wheel’s surface becomes smooth and shiny because the abrasive grains are clogged. A glazed wheel will not cut.

- Burn Marks: Blue or brown discoloration on your workpiece indicates excessive heat buildup.

- Smell of Burning: This is a clear sign of too much friction and heat.

- Tool Overheating: The grinder itself becomes excessively hot to the touch.

If you notice any of these signs, ease up on the pressure immediately. Remember, cut-off wheels are for cutting only. Never use them for grinding, sanding, or deburring surfaces. Their thin structure is not built for those side loads and can fail catastrophically.

Secure the Workpiece Firmly

A stable workpiece is essential for a safe and accurate cut-off. You must secure your material firmly before you begin cutting. Never attempt to hold a small workpiece by hand. If the wheel catches, the piece can spin violently and pull your hand into the blade, causing severe injury.

The right clamping method depends on your material.

| Material Type | Recommended Clamping Method |

|---|---|

| Flat Stock | Use a heavy-duty bench vise or strong parallel clamps. A cast iron vise provides excellent stability and holds the metal securely in place. |

| Pipes & Round Stock | Clamp the pipe securely in a vise designed for round objects. You can also block it with heavy wood timbers to prevent any rotation during the cut. |

Always double-check that your material is completely immobile before you start the grinder. A few extra seconds spent securing your workpiece is a critical investment in your safety while using cut-off wheels.

Your safety while using cut-off wheels for any cutting job depends on a simple pre-cut-off checklist. Following these guidelines is your first defense against accidents. For every cutting task, remember:

- Right Wheel & RPM

- Full PPE & Pre-Use Inspection

- Strict 90-Degree Cutting Angle

- Light, Steady Pressure

This ensures a perfect cut-off. Adopting these practices when using cut-off wheels makes every cut-off safe and efficient. For specialized cutting wheels that improve your cutting process and overall safety, explore the solutions at Aimgrind.

FAQ

What is the difference between a cutting wheel and a grinding wheel?

You use a cut-off wheel for making straight cuts. It is very thin. A grinding wheel is much thicker. You use it to remove material from a surface. Never use a cut-off wheel for grinding. This is extremely dangerous and can cause the wheel to shatter.

Can I use one cut-off wheel for all materials?

No, you must match the wheel to the material. Using the wrong wheel is unsafe and inefficient. For example, you need a diamond wheel for masonry or a CBN wheel for hardened steel. Aimgrind offers specialized wheels for your specific cutting needs.

How do I know when to replace my cut-off wheel?

You should replace a wheel immediately if you find any damage. Look for cracks, chips, or discoloration. You can also perform the “ring test” on a new wheel. If it makes a dull thud instead of a clear ring, do not use it.

Remember: A damaged wheel can explode at high speed. Your safety depends on regular inspection.

Why is the 90-degree cutting angle so important?

Cut-off wheels are thin and strong only on their edge. Applying pressure to the side of the wheel can cause it to bend and break apart. A strict 90-degree angle keeps the force on the cutting edge, ensuring a safe and clean cut every time.

Contact Us

For More Grinding Solution or Customized Abrasive Tools