You must sharpen carbide tools with an abrasive harder than carbide itself. This makes diamond wheels your only effective choice. A common aluminum oxide wheel is too soft. This wheel damages your expensive tools. The wrong wheel creates excess heat. It also produces a poor surface finish. You need a quality wheel to protect your investment in these tools. The carbide tool market is growing fast, making proper care essential.

| Attribute | Statistics |

|---|---|

| Market Value in 2023 | USD 11.03 Billion |

| Market Forecast in 2032 | USD 18.41 Billion |

| CAGR (2024 to 2032) | 6.0% |

Using the right wheel gives your tools a superior surface finish. A poor wheel creates a bad surface finish and a dull surface. A great wheel ensures a sharp surface and an excellent finish.

Key Takeaways

- Diamond wheels are the only good choice for sharpening carbide tools. Carbide is very hard, so you need an even harder material to sharpen it.

- Using the wrong grinding wheel can damage your carbide tools. Softer wheels create too much heat and cause cracks, which ruins the tool’s edge.

- Diamond wheels cut carbide cleanly and keep tools cool. This helps your tools last longer and gives a much smoother finish.

- Choosing the right diamond wheel grit size is important. Use a coarse grit for big repairs and a fine grit for a smooth, final finish.

- Diamond wheels save money over time. They last longer and protect your expensive carbide tools from damage.

Why Standard Wheels Fail on Carbide

You might think any grinding wheel can sharpen your tools. This is a costly mistake when working with tungsten carbide. Standard wheels, like the common gray aluminum oxide ones, are simply not up to the task. Using the wrong wheel will not only fail to sharpen your tools but will actively damage them, costing you time, money, and quality.

The Hardness Mismatch in Grinding Tungsten Carbide

The core principle of grinding is simple: the abrasive must be harder than the material you are cutting. If it is not, the abrasive itself wears away instead of the workpiece. When grinding tungsten carbide, you are dealing with one of the hardest materials used in modern tooling.

On the Mohs scale of hardness, aluminum oxide and tungsten carbide appear deceptively close.

| Material | Mohs Hardness |

|---|---|

| Tungsten Carbide | Approximately 9 |

| Aluminum Oxide | 9 |

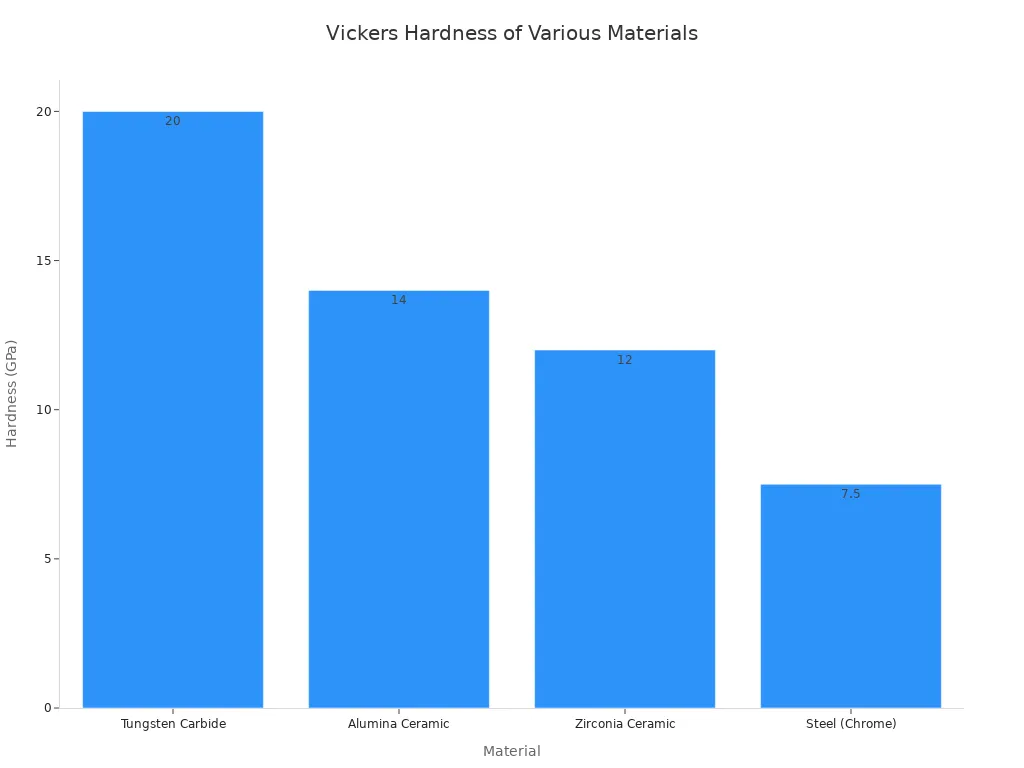

However, the Mohs scale is not precise enough for industrial applications. A more accurate measure is the Vickers hardness test, which reveals a massive difference. Tungsten carbide has a Vickers hardness of around 20 GPa, making it significantly harder than standard abrasives.

When you attempt grinding tungsten carbide with a softer wheel, you trigger a losing battle.

- The softer abrasive wheel cannot effectively cut the carbide surface.

- Your wheel wears down at an incredible rate, losing its shape and balance.

- You achieve minimal material removal, destroying your efficiency.

- The wheel glazes over, becoming smooth and useless for any further work.

This fundamental mismatch makes standard wheels completely ineffective for grinding tungsten carbide. You waste the wheel, you waste your time, and you fail to get a sharp edge.

The Dangers of Heat and Tool Damage

The problems with using the wrong wheel go beyond poor efficiency. The intense friction from a soft wheel rubbing against a hard carbide surface generates a tremendous amount of heat. This heat is the enemy of your expensive tools.

Note: Causes of Grinding Cracks

Micro-cracks in carbide tools often result from improper sharpening. Key factors include using a wheel with the wrong material or grit size, providing inadequate cooling, and being too aggressive with the grinding process.

This excessive heat can cause thermal shock, leading to microscopic fractures within the carbide. These tiny cracks weaken the cutting edge, making it brittle and prone to chipping during use. You may not even see the damage at first, but you will see its effects.

Signs of thermal damage on your tools include:

- Thermal Cracking: Small cracks appear on the cutting edge, which can lead to pieces of the tool breaking off (spalling).

- Thermal Deformation: The tool’s shape changes as high temperatures soften the binder material holding the carbide particles together.

- Discoloration: A blue or straw-colored tint on the tool surface is a clear sign of overheating and a ruined temper.

A damaged tool cannot produce a quality finish. Chipping on the cutting face creates a rough, marred surface on your workpiece. This damage compromises the accuracy of your parts and the overall longevity of your tools. A poor finish reflects poorly on your work. You need a sharp, clean edge for a professional finish. Ultimately, using the wrong wheel for grinding carbide leads to a poor surface finish and a cycle of replacing both your wheel and your tools.

The Diamond Advantage: Maximize Performance

Switching to diamond wheels is the single most important upgrade you can make for grinding carbide. You will unlock a new level of efficiency, precision, and tool longevity. Diamond wheels offer key advantages over other abrasive types that help you maximize performance and protect your valuable tools. They are the superior choice for grinding carbide because they work with the material, not against it.

Superior Hardness for a Fast, Clean Cut

You already know that your abrasive must be harder than your workpiece. Diamond is the hardest material on Earth, making it uniquely qualified for this job. While tungsten carbide is incredibly hard, diamond is in a class of its own.

| Material | Mohs Hardness |

|---|---|

| Diamond | 10 |

| Tungsten Carbide | 9 to 9.5 |

This superior hardness allows a diamond grinding wheel to slice cleanly through carbide. Instead of rubbing and creating friction, the diamond particles shear the material away. This results in aggressive stock removal when you need it and delicate precision finishing when you don’t. The outcome is a faster, more controlled process that gives you a far better surface finish. A quality wheel produces a quality finish.

A sharp, clean edge is not just for looks. It directly impacts your work by producing smoother cuts and holding tighter tolerances. This often eliminates the need for secondary finishing steps, saving you time and improving your overall efficiency.

Using the wrong wheel creates a jagged, inconsistent edge. A diamond wheel, however, delivers a flawless surface. The difference in the final finish is dramatic.

| Grinding Wheel Type | Surface Finish Quality on Carbide |

|---|---|

| Diamond Wheel | Produces a far smoother edge |

| Green Silicon Carbide Wheel | Produces a serrated edge |

A smooth finish on your tools translates to a smooth surface on your workpiece. This level of quality and efficiency helps you maximize performance with every project.

Cooler Grinding for Precision and Safety

Heat is the enemy of precision. As you saw earlier, excessive heat from the wrong wheel can cause micro-cracks and ruin your carbide tools. Diamond wheels solve this problem because diamond is an excellent thermal conductor. It pulls heat away from the cutting surface and into the body of the wheel, keeping your tool cool.

This cooler grinding process is essential for several reasons:

- Prevents Thermal Expansion: It stops your tool from expanding due to heat, which prevents dimensional inaccuracies and ensures your sharpened tools meet exact specifications.

- Preserves Surface Integrity: A cooler process protects the carbide’s internal structure, maintaining its hardness and strength for a longer service life.

- Eliminates Surface Defects: You avoid burns, discoloration, and cracks on the tool’s surface, which compromise its performance and longevity.

By preventing heat damage, you create a sharper, more durable edge. This allows for high-efficiency grinding and precision finishing without risking the integrity of your tools. A cool grinding process is a safe and effective process that helps you extend the life of your equipment.

Long-Term Value and Cost-Effectiveness

A diamond grinding wheel may have a higher initial cost, but it delivers an incredible return on investment. The extreme durability of diamond means your wheel lasts significantly longer than conventional abrasives. While a standard wheel wears down quickly against carbide, a diamond wheel maintains its shape and cutting ability, giving you consistent grinding performance. This superior longevity means you spend less time and money replacing your wheel.

This is one of the key advantages over other abrasive types. For example, some shops find that a brazed diamond wheel can last over 500 hours, while a traditional wheel might need replacement after just 120 hours. This longer wheel life dramatically reduces downtime and material costs.

The benefits extend directly to your tools. Because diamond wheels provide a clean, cool cut, they do not inflict the thermal damage that shortens tool life. You will sharpen your tools less often and replace them far less frequently. This helps you extend the life of your entire tool inventory.

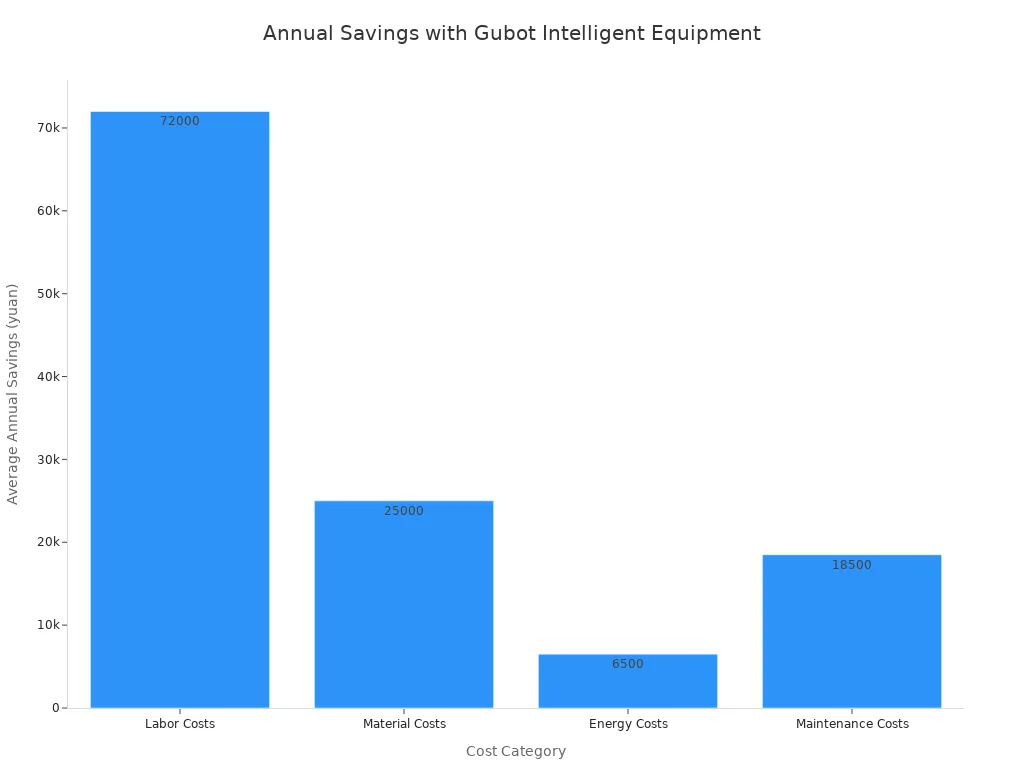

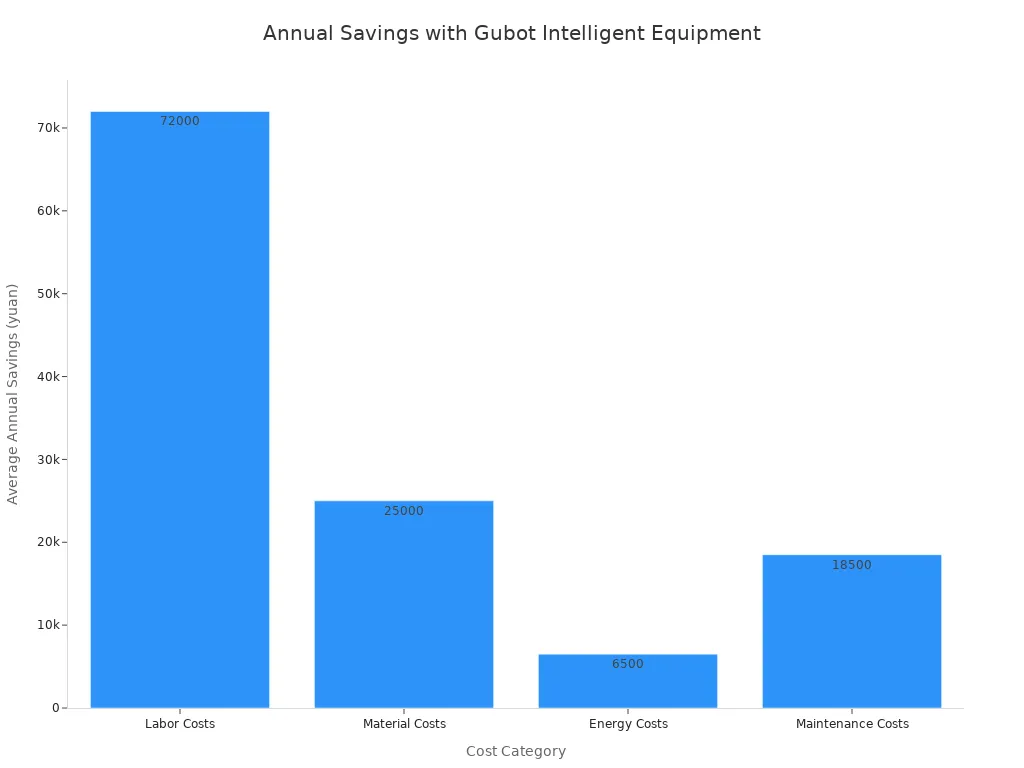

For any workshop, the investment in diamond technology pays for itself. Consider the savings:

By reducing labor, material waste, and maintenance, you can save thousands annually. This makes a diamond wheel the superior choice for grinding, not just for performance but for your bottom line. You achieve aggressive stock removal for roughing and perfect precision finishing for your final pass, all while boosting your shop’s efficiency and profitability. Optimal carbide grinding is smart business.

Choosing the Right Diamond Grinding Wheel

Selecting the right diamond grinding wheel is crucial for achieving optimal carbide grinding. The correct wheel ensures you get the best performance from your tools. Your choice of wheel directly impacts efficiency, the quality of the surface finish, and the longevity of your tools. Making an informed decision will help you extend the life of your equipment and produce a superior finish.

Matching Grit Size to Your Task

You must match the grit size of your diamond grinding wheel to your specific task. Grit size determines the wheel’s cutting speed and the final surface finish. A coarse grit wheel allows for aggressive stock removal, while a fine grit wheel produces a smooth, mirror-like surface. Using the wrong grit will compromise your efficiency and the quality of your finish.

Pro Tip: Start with a coarser grit for repairing chips or for significant reshaping. Then, switch to a finer grit wheel for the final precision finishing pass. This two-step process gives you the best combination of speed and a flawless surface.

This table will help you choose the right grit for grinding carbide tools.

| Grit Size | Application | Outcome |

|---|---|---|

| 70-120 | Aggressive Stock Removal | Fast cutting, rough surface finish |

| 150-320 | General Sharpening & Finishing | Good balance of speed and a clean finish |

| 400-1200+ | Honing & Precision Finishing | Excellent, smooth surface; slower removal |

Choosing the correct grit ensures your wheel delivers the expected grinding performance and a better surface finish. This simple choice has a big impact on your final product.

Wheels for Sharpening Saw Blades and Tools

When it comes to sharpening saw blades and other carbide tools, not all diamond wheels are created equal. You need a wheel designed for the job. For nearly two decades, Aimgrind has specialized in customized grinding solutions. We understand the unique demands of working with carbide.

Aimgrind’s resin bond diamond grinding wheels are perfect for sharpening carbide-tipped saw blades and tools. These common types of diamond wheels offer excellent cutting action while generating less heat. This protects your tools from thermal damage and ensures a high-quality finish. A cooler process also contributes to longer wheel life and less diamond wheel wear. We provide personalized selection to match the perfect diamond grinding wheel to your equipment and specific tools. Whether you are in woodworking or tool manufacturing, we help you achieve high-efficiency grinding and a perfect surface.

Explore our range of common types of diamond wheels and find the ideal solution for your needs. You can find the right wheel for your tools on our diamond grinding wheels product page.

The physics of sharpening is clear. You need a harder material to cut a softer one. This makes a diamond grinding wheel your only real choice for carbide. A quality wheel delivers a faster, cooler cut for a perfect surface finish. This wheel protects your expensive tools. The right wheel gives you a superior surface finish. Your wheel choice affects the final surface finish. A great wheel ensures a sharp surface and an excellent finish. This wheel also saves you money over time. The correct wheel produces a better surface finish.

Stop gambling with the wrong wheel. Invest in a diamond grinding wheel from the experts at Aimgrind. We help you make the proper selection for a flawless surface finish. It is the only correct decision for your workshop.

FAQ

What makes a diamond wheel better than a standard wheel?

A diamond wheel is much harder. This hardness lets the wheel cut carbide cleanly. A standard wheel is too soft and wears out fast. You need the right wheel.

How do I choose the right diamond wheel?

You match the wheel grit to your task. A coarse grit wheel is for fast cutting. A fine grit wheel gives a smooth finish.

Can I use one diamond wheel for everything?

You should use a specific wheel for each material. A diamond wheel is for hard materials like carbide. Using this wheel on soft steel can clog the wheel.

How do I maintain my diamond wheel?

You can use a dressing stick to clean the wheel surface. This simple step keeps your wheel cutting effectively for a long time.

Contact Us

For More Grinding Solution or Customized Abrasive Tools