Abrasive technology is a process using hard abrasives to machine materials that resist traditional cutting. This abrasive method shapes difficult materials like superalloys, advanced ceramics, and composites, some of which are used as a cutting tool material themselves. Key techniques include waterjet cutting, wire sawing, and high-precision grinding. The industry’s significant growth highlights its importance in modern manufacturing.

| Metric | Value |

|---|---|

| Market Size (2024) | USD 72.98 billion |

| Projected Market Size (2032) | USD 110.32 billion |

| CAGR (2024-2032) | 5.30% |

Key Takeaways

- Abrasive technology cuts hard materials. It uses methods like waterjet, wire sawing, and grinding. This helps make things like superalloys and ceramics.

- Waterjet cutting uses high-pressure water and sand. It cuts materials without heat. This is good for things sensitive to heat, like aerospace metals.

- Wire sawing uses a thin wire with diamonds. It cuts brittle materials with little waste. This is important for making parts for electronics.

- Grinding uses super hard wheels. It makes surfaces very smooth and precise. Diamond and CBN wheels are used for different hard materials.

- Choosing the right method depends on the material. It also depends on how precise you need the cut to be. Consider the cost and speed for your project.

Abrasive Waterjet Cutting

Abrasive waterjet cutting is a cold-cutting process that erodes material rather than shearing or melting it. This technology excels at cutting materials that are sensitive to the high temperatures generated by other methods.

How Waterjet Cutting Works

This process uses a high-pressure pump to create an extremely powerful stream of water, often reaching pressures over 60,000 psi. The system directs this water through a tiny nozzle. At the nozzle, a granular abrasive like garnet mixes into the stream. This mixture of water and hard particles creates a powerful cutting tool capable of slicing through very hard materials. A computer-controlled system guides the cutting head along a precise path, allowing for intricate shapes and designs.

Best Materials for Waterjet

Waterjet technology is incredibly versatile. It is an excellent choice for cutting heat-sensitive superalloys that are common in the aerospace industry. These include:

- Inconel

- Hastelloy

- Waspaloy

It also works well on composites like fiberglass and Garolite. Because it is a cold-cutting process, it avoids melting, warping, or creating a heat-affected zone (HAZ).

Did You Know? 💡

Waterjet cutting is so gentle that it can slice through materials like glass, rubber, and even food without causing cracks, deformation, or damage.

Key Advantages and Limitations

The primary advantage of waterjet cutting is its ability to cut without heat. This preserves the material’s structural integrity. The process achieves very high precision, with some machines holding tolerances as tight as ±0.001 inches.

However, there are limitations. The material removal rate can be slower than other methods, especially for very thick sections. Operational costs are also a consideration. The hourly cost can range from $15 to $30, with the abrasive material accounting for a significant portion of that expense.

Abrasive Wire Sawing

Abrasive wire sawing is a precision cutting method ideal for slicing hard and brittle materials. This technique minimizes material waste and is essential in industries where every micrometer counts, such as semiconductor manufacturing.

How Wire Sawing Works

Wire sawing uses a very thin steel wire that moves at high speed. In modern diamond wire sawing, the wire is coated with fixed diamond particles. This diamond-coated wire performs a true cutting action as it slides over the workpiece. The hard diamond particles on the wire abrade the material, creating a precise cut.

Older methods used a bare wire with a separate abrasive slurry. The new diamond wire technology offers significant improvements.

| Feature | Slurry Wire Saw | Diamond Wire Saw |

|---|---|---|

| Abrasive | Loose grit in a fluid | Diamonds fixed to the wire |

| Action | Erodes the material | Cuts the material |

| Speed | Slower removal rate | Faster material removal |

| Environment | Less eco-friendly | Cleaner, water-based fluids |

This advanced process allows for much faster wire speeds and better heat dissipation, resulting in a more efficient and cleaner operation.

Best Materials for Wire Sawing

Wire sawing excels at cutting expensive, brittle, and hard crystalline materials. Its precision is critical for producing thin wafers for the electronics and optics industries. Ideal materials include:

- Monocrystalline Silicon: Used to create wafers for semiconductor devices.

- Sapphire: Sliced into thin substrates for LEDs and other optical components.

- Multi-crystal Silicon: Cut for use in photovoltaic solar cells.

The technology’s ability to produce smooth surfaces with minimal subsurface damage makes it perfect for these high-value applications.

Key Advantages and Limitations

The most significant advantage of wire sawing is its minimal material waste. The cut, or “kerf,” is extremely narrow, which maximizes the number of parts from a single block of material.

Precision in Action ⚙️

- Diamond Wire Saw Kerf: 120-200µm

- Traditional Slurry Saw Kerf: 180-220µm

This reduction in kerf loss directly improves cost efficiency and material yield. However, the process can be slower than other cutting methods. It also requires careful management of wire tension and debris to maintain cut quality.

Grinding with Super Hard Abrasives

Grinding is a precision machining process that achieves superior surface finishes and tight dimensional tolerances. It is essential for shaping materials that are too hard for other methods. This high-performance grinding technique is critical in applications demanding extreme accuracy, such as gear grinding and micro thread grinding.

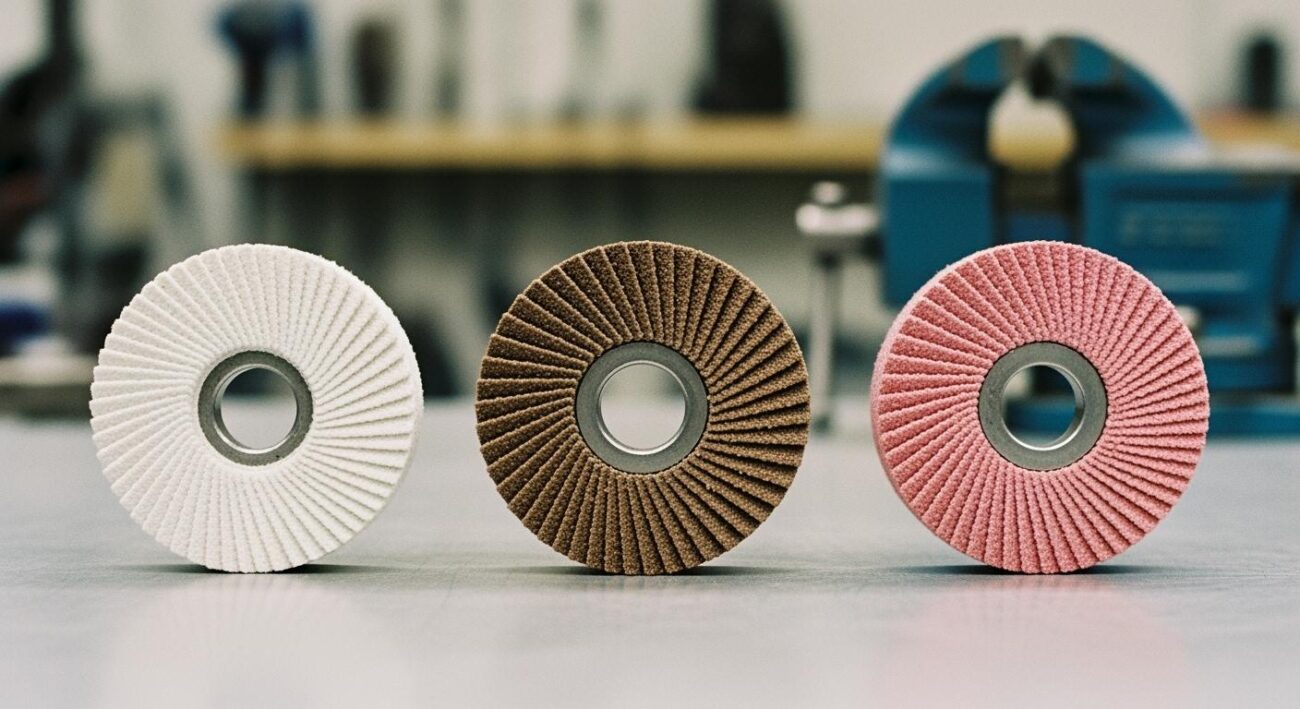

How Grinding Works

The grinding process uses a rapidly rotating bonded abrasive wheel to remove material from a workpiece. For the toughest materials, manufacturers rely on superabrasive grinding wheels. These wheels contain super hard abrasives like diamond or Cubic Boron Nitride (CBN). The abrasive particles act as microscopic cutting tools, shearing away tiny chips of material. For specialized tasks, a provider like Aimgrind offers customized grinding solutions. Their super hard abrasives are engineered for the high-precision grinding of hardened steels, tungsten carbide, and advanced ceramics. Aimgrind’s superabrasive grinding products deliver exceptional durability, superior surface finish, and longer tool life, which enhances overall productivity.

Best Materials for Grinding

Choosing the right abrasive is critical for successful grinding. The material of the workpiece dictates whether to use diamond or CBN superabrasives.

| Grinding Wheel Type | Suitable Materials | Unsuitable Materials |

|---|---|---|

| Diamond | Ceramics, Carbides, Glass, Stone | Steel, Cast Iron |

| CBN | Hardened Steels, Tool Steels, Cast Iron | N/A |

Diamond superabrasive grinding tools excel on extremely hard non-ferrous materials. However, diamond reacts chemically with iron at high temperatures, causing rapid wear. CBN is the ideal choice for grinding hard ferrous metals. Its thermal stability makes it perfect for high-speed applications like gear grinding on hardened steel components in the automotive and aerospace industries.

Key Advantages and Limitations

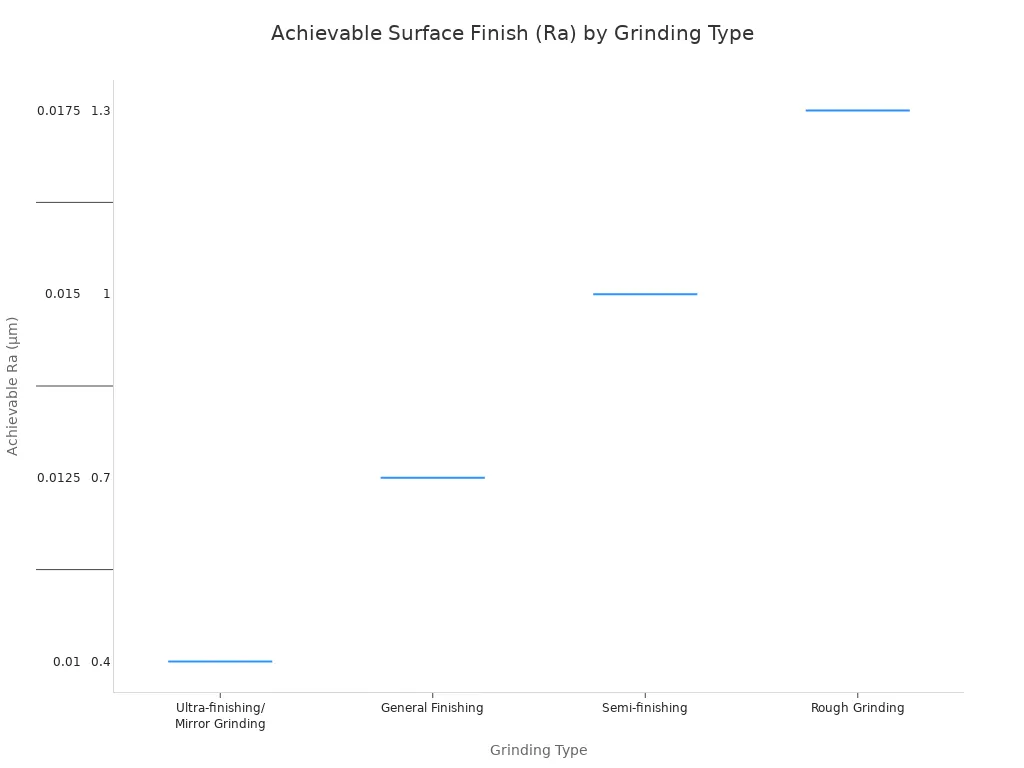

The primary advantage of grinding with superabrasives is the outstanding surface quality it produces. The process can achieve mirror-like finishes that are impossible with other cutting methods. The level of finish depends on the type of grinding operation.

Another key benefit is the long life of superabrasive grinding wheels. Their exceptional wear resistance means less frequent replacement and dressing, reducing machine downtime. However, effective grinding requires careful control of parameters and a robust grinding machine tool design. The initial cost of superabrasive grinding tools can also be higher than conventional abrasive tools, though this is often offset by longer life and increased productivity.

Emerging Trends in Advanced Abrasive Technology

The field of advanced abrasive technology is constantly evolving. New developments in materials and processes are pushing the boundaries of what is possible in precision cutting and shaping. These trends promise greater efficiency, higher accuracy, and improved performance.

Innovations in Bonding and Abrasives

Innovations in how superabrasives are bonded to tools are creating major performance gains.

- P.B.S.® braze technology is one such advancement. This system offers precise control over diamond particle placement. It allows for more space between particles, which helps clear away material debris efficiently. This is especially useful for creating very small, intricate geometries.

- 3M™ Trizact™ abrasives use microreplication to create tiny, three-dimensional pyramids of abrasive material. As these structures wear down during grinding, they continuously expose fresh, sharp mineral. This self-renewing action ensures a consistent finish and cooler operation, which is ideal for hard-to-grind metals.

Did You Know? 💡

Modern ceramic abrasives are also playing a key role. Their unique structure allows them to fracture in a way that creates new sharp edges, significantly increasing cutting speeds and the efficiency of the grinding process.

The Future of Precision Cutting

The future of precision cutting combines powerful new techniques with smart technology. Laser-assisted grinding (LAG) is a hybrid process that uses a high-energy laser to preheat a material’s surface. This heating softens the material, making it easier to remove. The method reduces grinding forces and improves the final surface quality.

Artificial intelligence (AI) and automation are also transforming abrasive technology. AI algorithms can optimize cutting paths for waterjets and other CNC machines. This reduces waste and programming time. Smart systems also enable predictive maintenance for tools with superabrasives. They can alert operators before a tool wears out, minimizing downtime. This integration of smart technology makes the entire abrasive cutting process more efficient and reliable.

How to Choose the Right Abrasive Technology

Selecting the correct abrasive technology is crucial for project success. The choice depends on the material, required precision, and budget. Each method offers unique strengths for different applications. A careful evaluation ensures optimal results in terms of quality, speed, and cost.

Comparison Table for Decision-Making

This table provides a quick overview to help guide your decision. It compares the three main technologies across several important factors.

| Feature | Abrasive Waterjet | Abrasive Wire Saw | Grinding with Superabrasives |

|---|---|---|---|

| Primary Action | Cold erosion with water and abrasive | Slicing with a diamond-coated wire | Shearing with a bonded wheel |

| Best For Materials | Heat-sensitive metals, composites, glass | Brittle, expensive crystalline materials | Hardened steels, ceramics, carbides |

| Heat-Affected Zone | None | Minimal to none | Can occur; requires coolant |

| Precision Level | High (±0.001″) | Very High (minimal kerf loss) | Extremely High (±0.0001″) |

| Surface Finish | Good, slightly rough | Excellent, smooth | Superior, mirror-like finish |

| Typical Cutting Speed | Moderate (e.g., 3-5 ipm on Titanium) | Slower, high precision | Variable, high removal rate |

| Material Waste | Low | Very Low (thinnest kerf) | Moderate (depends on process) |

Key Selection Criteria

Engineers and fabricators should consider several key factors before choosing an abrasive technology. Answering these questions will point to the most effective method for a specific job.

What is the material?

The material’s properties are the most important factor. Waterjet cutting is versatile for heat-sensitive metals and composites. Wire sawing excels with brittle materials like silicon or sapphire. High-performance grinding is the best choice for extremely hard materials like hardened tool steels and advanced ceramics.What level of precision is required?

The required dimensional accuracy often dictates the process. Precision grinding is essential for parts that demand extremely tight tolerances. Some products require dimensions within one-thousandth of an inch, while others need accuracy up to +/-0.0001 inches. Grinding consistently delivers this level of precision.What surface finish is needed?

The final surface quality is a critical outcome. Waterjet leaves a good but noticeably textured finish. Wire sawing produces a very smooth surface. Grinding provides the best possible finish, often achieving a mirror-like quality that other methods cannot match.What are the project’s speed and cost constraints?

Operational factors play a big role. Waterjet offers a good balance of speed and versatility. Wire sawing is slower but minimizes waste of expensive materials. Grinding can be very fast in terms of material removal, but the initial tooling cost for superabrasive wheels can be higher.

Pro Tip 💡

Always consider the total cost of operation. A slower process like wire sawing might save money by preserving expensive material. A faster grinding process might increase throughput and reduce labor costs, justifying the investment in advanced tooling.

Choosing the right abrasive technology depends on the material, desired finish, and cost. A final recommendation helps guide this decision.

Final Recommendations 🎯

- Select waterjet cutting for its versatility. It is ideal for heat-sensitive metals and composites used in aerospace and automotive manufacturing.

- Opt for wire sawing to cut brittle, expensive materials where minimizing waste is the top priority.

- Use grinding for the highest precision. High-quality super hard abrasives, like those from Aimgrind, make precision grinding and finish grinding possible. This abrasive method uses the best abrasives for the job.

FAQ

What makes a material “difficult” to cut?

Difficult materials possess extreme properties. These include exceptional hardness, high strength, brittleness, or sensitivity to heat. Superalloys, advanced ceramics, and composites are common examples that challenge traditional machining methods and require specialized abrasive technologies for effective cutting.

Which abrasive technology is the most cost-effective?

The most cost-effective technology depends on the project’s goals.

- Waterjet is versatile for many materials.

- Wire sawing saves money by minimizing waste on expensive materials.

- Grinding with superabrasives offers long tool life, increasing productivity.

Why use CBN instead of diamond for grinding steel?

Diamond reacts chemically with iron in steel at high temperatures. This causes the diamond abrasive to wear down quickly. Cubic Boron Nitride (CBN) is thermally stable with ferrous metals, making it the superior choice for grinding hardened steels. ⚙️

How do customized grinding wheels improve performance?

Customized grinding wheels match the abrasive, grit, and bond to a specific material and application. This optimization, offered by specialists like Aimgrind, ensures maximum cutting efficiency, superior surface finish, and longer tool life, boosting overall productivity.

Contact Us

For More Grinding Solution or Customized Abrasive Tools