You might see a bench grinder and wonder about using it for a wood project. While a bench grinder is essential in woodworking, its role is specific. Direct grinding of wood is dangerous and ineffective. The machine’s true purpose involves sharpening tools. This critical grinding task ensures your chisels and blades stay in perfect shape for clean, precise cuts.

Key Takeaways

- Do not use a bench grinder to shape wood. It is dangerous and can burn the wood.

- A bench grinder is good for sharpening metal tools like chisels. It keeps them sharp for clean cuts.

- Using the wrong wheel on a bench grinder can damage tools. Use special wheels for hard materials like carbide.

- Always use the right tool for the job. Use sanders or rasps for shaping wood, not a bench grinder.

Risks of using a bench grinder on wood

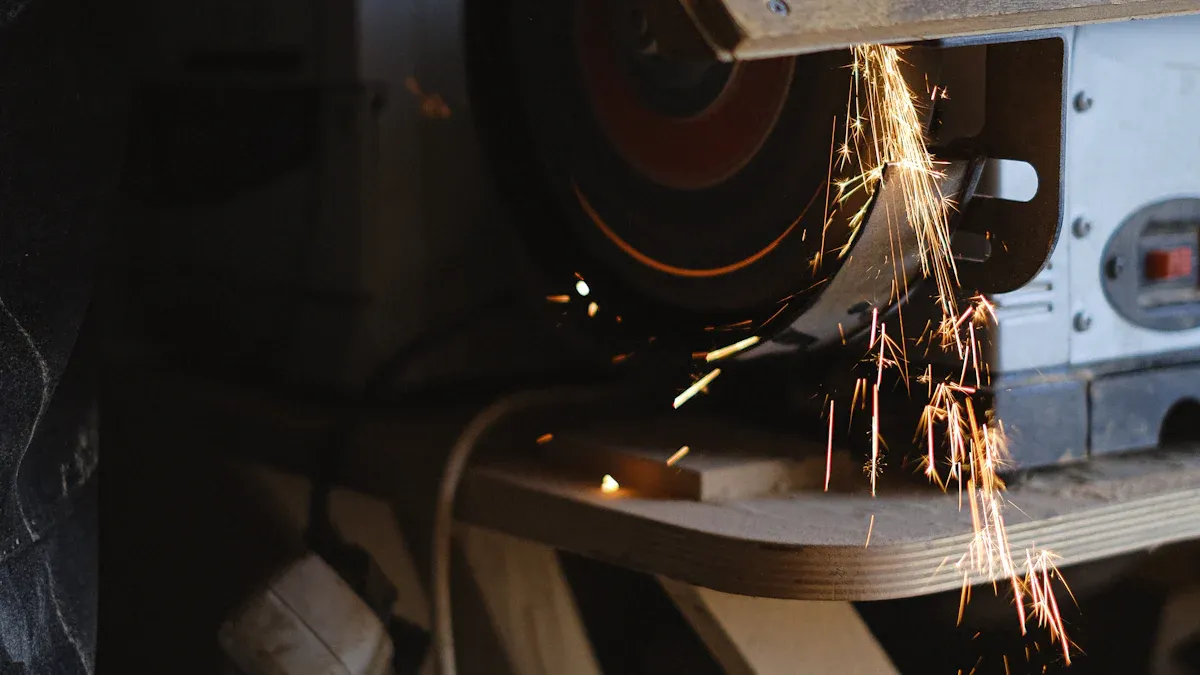

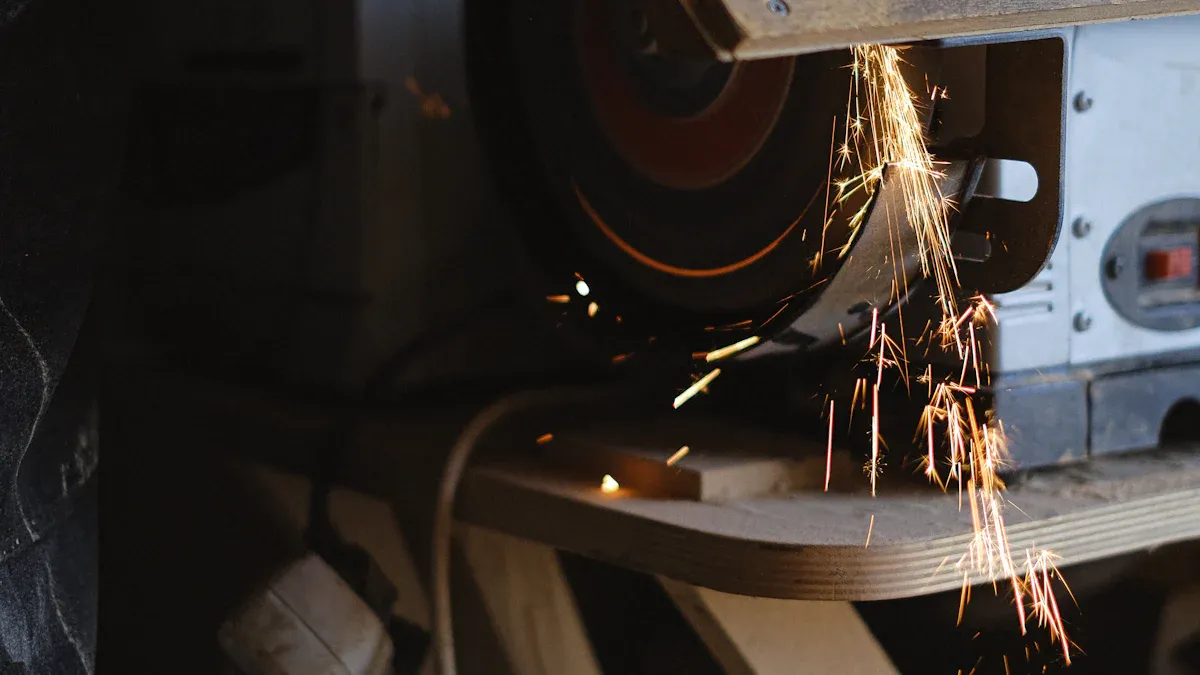

Using a standard bench grinder for shaping wood is a recipe for disaster. The tool is designed for hard metals, not soft, fibrous materials. You will encounter several serious risks that make this a dangerous and ineffective practice. Understanding these hazards will help you choose the right tool for your project.

Wood burning and scorching

A bench grinder spins at a very high speed, often over 3,000 RPM. This speed creates immense friction when the grinding wheel touches a surface. For metal, this action removes material. For wood, it generates intense heat that burns the material instead of cutting it. You will see black scorch marks and smell smoke almost immediately.

This burning is not just ugly; it’s a significant fire hazard. The fine dust created during grinding can ignite at surprisingly low temperatures.

Did You Know? The ignition temperature for wood dust can be very low, making it a serious fire risk during high-friction operations like grinding.

Wood Dust Type Minimum Ignition Temperature (°C) Oak 280 Spruce 300 Beech 330 (in a 5 mm layer)

Kickback and safety hazards

Kickback is one of the most severe dangers. Wood has an inconsistent grain pattern with hard and soft areas. The fast-spinning grinding wheel can easily catch on a tough part of the grain. When this happens, the machine will violently throw the workpiece from your hands.

This can cause serious injury. The piece of wood can be launched at high speed, hitting you or others in your workshop. Your hands could also be pulled toward the spinning wheel. Never underestimate the force of a bench grinder; it is not designed to handle the unpredictability of wood grain.

Grinding wheel clogging

Standard grinding wheels have a porous structure designed to let metal particles fall away. Wood fibers and resins behave differently. They are soft and sticky, and they quickly clog these pores. This issue is known as “loading” or “clogging.”

A clogged wheel presents multiple problems:

- Reduced Effectiveness: The wheel stops grinding because the abrasive surface is covered.

- Increased Heat: The clogged material creates even more friction, increasing the risk of burning the wood and overheating the motor.

- Fire Hazard: The trapped wood dust and resin can ignite from the friction, turning your grinding wheel into a potential fire starter.

Poor finish and lack of control

Even if you avoid burning and kickback, the result of grinding wood will be disappointing. A bench grinder is a blunt instrument for this task. It tears and shreds the wood fibers rather than shearing them cleanly.

You will be left with a rough, gouged surface that is difficult to fix. The tool offers very little control for creating a smooth or precise shape. You cannot achieve a clean edge or a flat surface. For any woodworking task that requires a good finish, you must use tools designed specifically for shaping and sanding wood.

Sharpening woodworking tools with a bench grinder

You have learned the dangers of grinding wood directly. Now, let’s explore the true value of a bench grinder in your workshop. Its most important job is sharpening tools. A sharp tool is a safe tool. It cuts cleanly, reduces effort, and gives you professional results. This section provides essential bench grinder tips for keeping your tools in top condition.

Sharpening chisels and lathe tools

Your chisels and lathe tools will become dull with use. A bench grinder quickly restores a keen edge to these high-speed steel (HSS) instruments. The key is using the right wheel and controlling heat. Standard gray wheels can work, but specialized wheels offer better performance.

I use white and pink wheels for HSS tool grinding… I think the grit is around 60-80 grit and 100-120 grit for the two wheels.

Many woodworkers prefer white or pink aluminum oxide wheels. These wheels cut faster and run cooler than gray wheels. This reduces the risk of overheating your tool. Overheating can ruin the steel’s temper, making it unable to hold a sharp edge.

| Wheel Type | Characteristics |

|---|---|

| Aluminum Oxide | Gray wheels are for general purposes. White wheels are purer, cut faster, and stay cooler, making them ideal for HSS tools. |

| Silicon Carbide | This is best for grinding non-ferrous metals and very hard non-metals like carbide. |

| Ceramic Aluminum Oxide | A premium abrasive that is very durable. It cuts fast and is great for heavy-duty grinding. |

| Diamond and CBN | These are the hardest abrasives. Diamond wheels grind carbide. CBN wheels are best for HSS. |

Proper technique during grinding is crucial to prevent heat damage. You must keep the tool cool.

- Keep a container of water nearby. Dip the tool in the water every few seconds to cool it down.

- Use a low-speed grinder (around 1,750 RPM) if possible. High speeds build heat much faster.

- Dress your wheel often. A dressing tool cleans the wheel and exposes fresh abrasive grit. This helps it cut efficiently and stay cool.

- Watch the sparks. When sparks start to roll over the top of the tool, the edge is getting thin and sharp. Be extra careful at this stage.

For lathe tools like gouges, you can use a jig to maintain a consistent angle. You swing the tool smoothly from side to side to create the desired “fingernail” shape. The process of sharpening chisels and other tools requires patience and control.

Grinding primary bevels

When sharpening chisels, you are often re-establishing the primary bevel. The primary bevel is the main angle ground onto the tool. For most woodworking chisels, this angle is 25 degrees. This angle makes the tool strong and easy to sharpen. After grinding, you will create a slightly steeper secondary bevel (or “micro-bevel”) at 30 degrees using a honing stone. This two-bevel system makes future sharpening much faster.

Setting the correct angle on your bench grinder is simple.

- Use a protractor to draw a 25-degree angle on a piece of cardboard.

- Cut the cardboard to create an angle guide.

- Adjust the grinder’s tool rest until it matches your cardboard guide.

With the tool rest set, you can confidently perform the grinding to create a perfect primary bevel. This preparation ensures you remove steel consistently and efficiently.

Using Aimgrind wheels for saw blades

What about sharpening saw blades? Your standard bench grinder wheels are not suitable for modern saw blades. Many circular saw and band saw blades have tungsten carbide teeth. This material is extremely hard and brittle. A standard aluminum oxide wheel will not effectively sharpen it. The wheel will wear down quickly and can even damage the carbide teeth.

For these specialized jobs, you need a specialized solution. Companies like Aimgrind provide customized grinding solutions for hard materials. They offer high-quality abrasive tools, such as diamond grinding wheels, designed specifically for tungsten carbide. Diamond is one of the few materials hard enough to grind carbide effectively.

Using a purpose-built wheel from a provider like Aimgrind ensures a precise and clean sharpening process. Their expertise helps you select the perfect wheel for your equipment and the specific material you are grinding. This approach protects your investment in expensive saw blades and restores them to factory-sharp condition. For serious woodworking, choosing the right abrasive is just as important as choosing the right tool.

Other uses and safer alternatives

You now know a bench grinder is not for shaping wood. However, you can adapt it for some finishing tasks. This section covers those uses and introduces much better tools for working with wood. Always choose the safest and most effective tool for your project.

Rough shaping and buffing

You can outfit a bench grinder with buffing wheels for polishing wood. This is a good way to apply a final sheen to a finished project. You can use compounds like White Diamond or Green Rouge to enhance shine. While not a primary use, it can also help with tasks like removing rust or paint from hardware. However, safety is critical.

Safety First: A bench grinder converted for buffing can be dangerous. The motor housing is often too close to the wheels, limiting your access.

- Always wear a face shield and safety glasses.

- Never start the machine with your workpiece touching the wheel.

- Wait for the grinder to reach full speed before you begin.

- Clean dust away from the machine regularly to prevent fire hazards.

Belt and spindle sanders

For shaping and smoothing wood, you should use a sander. A belt sander is perfect for flattening a large surface or smoothing rough edges. A spindle sander excels at smoothing curved cuts, both inside and outside curves. These tools are designed specifically for wood. They give you excellent control and a much better finish than any grinding wheel could.

Rasps and angle grinders

Hand tools also offer great control. Rasps have been used for thousands of years to quickly remove wood. Ancient woodworkers in Egypt and Assyria used early versions of these tools. You can use a rasp for aggressive shaping and then follow up with a file for a smoother surface.

An angle grinder is another powerful option. You can fit it with a flap disc for wood. Zirconia flap discs are great for rapid shaping, blending, and even removing rust or paint from reclaimed wood. This tool offers a different kind of control for shaping a sharp edge or contour.

Rotary tools for detail work

For fine detail, a rotary tool is your best choice. These small, high-speed tools are perfect for carving, engraving, and intricate sanding. You can use many different accessories for detailed woodworking.

- Carbide bits are excellent for carving.

- Cutting wheels help you make small, precise cuts.

- Diamond-point wheels can etch and engrave an edge on your projects.

These tools give you the precision needed for tasks that larger machines cannot handle. They are essential for any detailed grinding or finishing work.

Remember this key rule: never use a bench grinder to shape your projects. Its true value in woodworking is sharpening steel tools.

For specialized items like carbide saw blades, using the correct wheel from an expert supplier like Aimgrind is crucial for safety and success. Always choose the right tool for the job. You should use sanders, rasps, or other specific tools for shaping wood. This ensures a great finish and keeps you safe.

FAQ

What wheel should I use for sharpening chisels?

You should use a white or pink aluminum oxide wheel. These wheels run cooler than standard gray wheels. This helps prevent overheating and ruining the temper of your steel tools. A cooler wheel protects your tool’s ability to hold a sharp edge.

Why does wood burn on a bench grinder?

Wood burns because the grinder spins too fast. The high speed creates intense friction and heat. This heat scorches the wood instead of cutting it. This process creates a fire hazard and damages your workpiece. 🔥

Can I sharpen carbide saw blades on my grinder?

You cannot use standard wheels for carbide. Tungsten carbide is too hard. You need a specialized diamond grinding wheel. A supplier like Aimgrind can provide the correct wheel to sharpen these blades safely and effectively.

Is a low-speed or high-speed grinder better for tools?

A low-speed grinder (around 1,750 RPM) is much better for sharpening woodworking tools. It generates less heat. This reduces the risk of overheating the steel and ruining its temper. You have more control and a safer sharpening experience.

Contact Us

For More Grinding Solution or Customized Abrasive Tools