You can reduce burning when grinding stainless steel by managing heat. The friction from grinding creates intense heat, causing the metal to burn. Successful cutting and grinding stainless steel depends on controlling this temperature.

Quick Tip: To prevent burning, focus on these four key actions:

- Use the correct abrasives for the job.

- Apply light, consistent pressure.

- Reduce your grinder’s speed.

- Use a grinding lubricant or coolant.

Key Takeaways

- Choose the right abrasives. Use ceramic or zirconia discs. They cut cooler and prevent heat buildup.

- Use light pressure and keep the grinder moving. This stops heat from staying in one spot. It prevents burn marks.

- Grind at a lower speed. High speeds create too much heat. A slower speed gives a cleaner cut.

- Use lubricants or coolants. They reduce friction and cool the metal. This helps avoid burning.

- Work in short bursts. Let the metal cool between passes. This is good for thin stainless steel.

Select the Right Abrasive for Grinding Stainless Steel

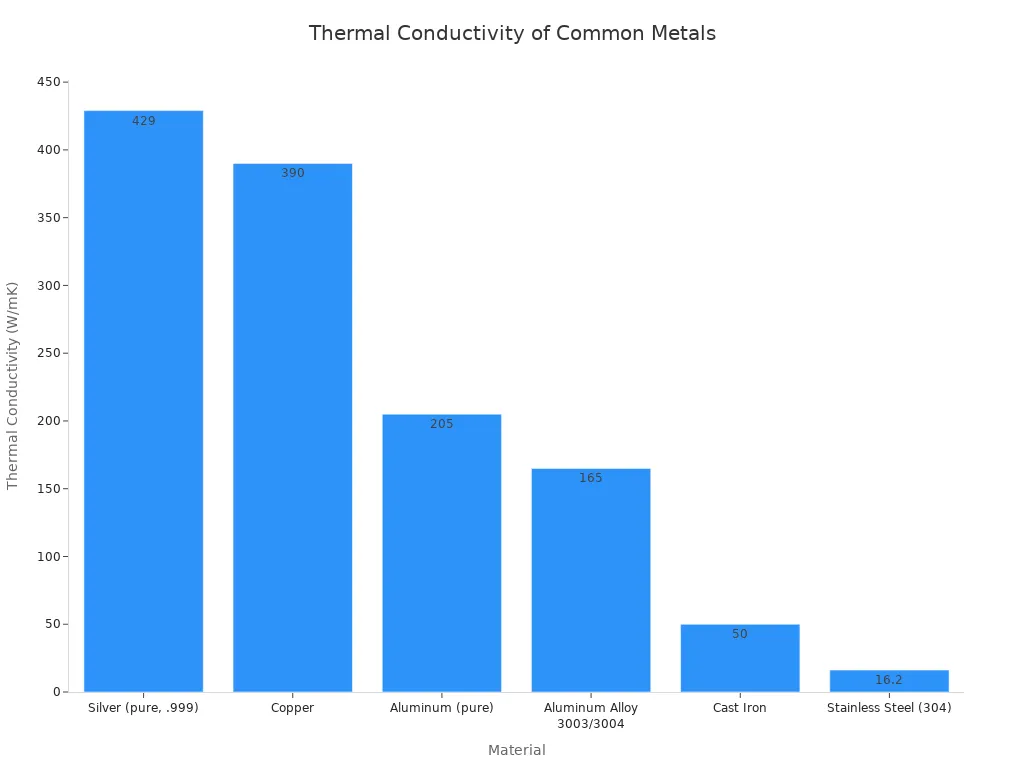

Your choice of abrasive is the single most important factor in preventing burning. Stainless steel is a poor conductor of heat. This means heat builds up quickly at the point of contact instead of spreading out. Proper abrasives selection is essential to manage this heat.

Metals like aluminum and copper transfer heat efficiently. Stainless steel traps it. The chart below shows just how low its thermal conductivity is compared to other common metals. This low conductivity is the primary reason you see discoloration and warping.

Because of this, you need abrasives that cut quickly and coolly.

Choose Ceramic or Zirconia Abrasives

You should avoid standard aluminum oxide abrasives for stainless steel. They dull quickly and generate too much heat. Instead, you can choose ceramic or zirconia abrasives. These materials are self-sharpening.

As you apply pressure, the abrasive grains fracture. This process exposes new, sharp cutting edges. This continuous renewal allows the disc to maintain a cool, consistent cutting action throughout its life, which is crucial for successful grinding.

This self-sharpening action means less friction and less heat, giving you a cleaner result without the burn marks.

Opt for Aimgrind Super Hard Abrasives

For the best performance when cutting and grinding stainless steel, you can upgrade to a premium solution. Aimgrind‘s super hard abrasives are specifically engineered for tough, heat-sensitive materials.

Our resin bond grinding wheels use Cubic Boron Nitride (CBN) grains. CBN is one of the hardest materials available, second only to diamond. This allows our wheels to slice through stainless steel with minimal friction and heat generation. This technology helps you to reduce burning and achieve a flawless finish. These advanced abrasives offer exceptional durability and efficiency, reflecting our commitment to quality.

Use a Coarser Grit for Heavy Grinding

When you need to remove a lot of material, you should use a coarser grit. A lower grit number (e.g., 36, 40, 60) means larger abrasive particles. These larger particles cut more aggressively and create wider channels for material to escape. This reduces friction and heat buildup. Finer grits require more time to remove the same amount of material, which leads to more heat and potential burning.

For heavy stock removal, a coarser grit is always more efficient.

| Application | Recommended Grit Range |

|---|---|

| Heavy Stock Removal | 36 – 60 grit |

| General Purpose Grinding | 60 – 80 grit |

Keep Your Abrasives Sharp and Clean

A sharp, clean disc is a cool disc. Over time, your grinding disc can become “loaded” with metal particles. This clogging prevents the abrasive grains from cutting effectively. Instead of cutting, the disc starts to rub against the metal. This rubbing action creates massive amounts of friction and heat.

You should regularly check your abrasives. If a disc is loaded or feels dull, replace it immediately. Using high-quality, self-sharpening abrasives for stainless steel helps solve this problem by keeping the cutting surface fresh and clean.

Master Your Grinding Technique to Reduce Burning

Choosing the right abrasives is your first step. Now, you need to master your technique. How you handle the grinder directly impacts heat generation. Your goal is to let the tool do the work. Proper technique will help you reduce burning and achieve a professional finish when grinding stainless steel.

Apply Light and Consistent Pressure

Pushing too hard is a common mistake that creates excess heat. You should apply just enough pressure to let the abrasive grains cut effectively. Forcing the grinder into the metal causes friction, not faster removal. This intense pressure and heat can cause metallurgical damage.

Heads Up: Excessive grinding pressure creates high mechanical stress within the steel. This stress can lead to micro-cracks and weaken the workpiece, even if you can’t see the damage immediately.

You can spot the signs of too much pressure by observing your workpiece and your tools. Look for these visual cues:

- Discoloration: Blue, brown, or black marks on the steel are clear signs of burning.

- Uneven Wear: Check your grinding disc for uneven wear patterns or chipping. This indicates you are applying pressure inconsistently.

- Workpiece Warping: Too much heat in one area can cause the thin stainless steel to warp or bend.

To avoid these issues, secure your workpiece firmly. A good tip is to tap it with a hammer before you start. If it vibrates or moves, clamp it down more securely. A stable setup helps you apply smooth, even pressure throughout the grinding process.

Keep the Grinder in Constant Motion

You should never hold the grinder still on one spot. Lingering in a single area concentrates an immense amount of heat, which is the fastest way to cause burning.

Instead, use long, steady, and overlapping strokes. Move the grinder continuously across the surface of the metal. This technique distributes the heat over a larger area, preventing it from building up in one spot. Think of it like painting a wall—you want smooth, even coverage to get a uniform result. Constant motion ensures a more consistent finish and keeps the temperature under control.

Use a Lower Grinder Speed (RPM)

Speed kills your finish when it comes to stainless steel. A higher grinder speed (RPM) creates more friction, which generates more heat. While a high RPM might seem faster, it often leads to “blue chips and smoke,” damaging both your workpiece and your tool. More importantly, running a grinding wheel faster than its rated speed is extremely dangerous. The centrifugal force can cause the wheel to shatter.

For successful cutting and grinding stainless steel, you should use a variable-speed grinder and set it to a lower RPM. A slower speed reduces friction and allows for a cooler, more controlled cut. While it may remove material slightly slower, it protects the integrity of the steel.

This table shows how speed affects grinding performance:

| Grinder Speed (RPM) | Effect on Grinding |

|---|---|

| Lower Speed | Reduces heat buildup, prolongs abrasive life, results in a slightly rougher initial finish. |

| Higher Speed | Increases heat and burning risk, wears out abrasives faster, can provide a smoother finish if heat is managed. |

Ultimately, managing your machine’s parameters, including spindle speed and pressure, is essential. A lower speed gives you more control and is the safest way to get a clean, burn-free result.

Manage Heat to Prevent Burning

Even with the right abrasive and technique, active heat management is your final line of defense. You must control the temperature at the point of contact to prevent burning. These two methods will help you keep the workpiece cool and achieve a perfect finish when grinding stainless steel.

Use Grinding Lubricants or Wax

You can use grinding lubricants to significantly reduce friction and cool the workpiece. These products create a barrier between the abrasive and the metal, which helps dissipate heat. For stainless steel, you have several effective options:

- Oil-Based Fluids: These offer excellent lubricity and are ideal for heavy-duty grinding.

- Water-Soluble Coolants: These are great for cooling and help keep your grinding wheels clean.

- Grinding Wax Sticks: You can apply these directly to the abrasive. The wax melts during grinding, providing lubrication where you need it most.

Safety First! ⚠️

When you use lubricants, always work in a well-ventilated area. Wear your personal protective equipment (PPE), including safety glasses and gloves. You should also clean up any spills immediately to prevent slips and fire hazards.

Work in Short Bursts to Allow Cooling

A simple yet powerful technique to reduce burning is to manage your work rhythm. Instead of grinding continuously, you should work in short bursts. This method gives the metal time to cool down between passes.

Grind an area for a few seconds, then pull the tool away. You can touch the surface (carefully!) or visually inspect it for signs of overheating. This pause allows the heat to dissipate naturally. This approach is especially important for thin pieces of stainless steel, which can warp easily. By controlling the temperature through this stop-and-go process, you prevent heat from building up to a damaging level.

You can successfully reduce burning during stainless steel grinding. Your success starts with selecting the right tools. Choose advanced abrasives like ceramic or Aimgrind’s super hard abrasives for a cooler cut. You should also master your technique by applying light pressure and using a lower grinder speed. Finally, manage temperature actively with lubricants or by pausing your work. Mastering these methods will help you achieve a clean, professional finish every time.

FAQ

Why does stainless steel burn so easily?

Stainless steel does not spread heat well. The friction from grinding creates intense heat that gets trapped in one spot. This concentrated heat causes the metal to discolor and burn. You must manage this temperature to get a clean finish.

What is the best abrasive for stainless steel?

You should use abrasives that cut coolly. Ceramic and zirconia are good choices. For the best results, you can use Aimgrind’s super hard abrasives with CBN grains. They are designed specifically for heat-sensitive metals like stainless steel.

Is a faster grinder speed better for stainless steel?

No, a faster speed is not better. High speeds create more friction and heat, which leads to burning. You should use a variable-speed grinder and set it to a lower RPM. This gives you more control and a cooler cut.

How do I know if I’m applying too much pressure?

You can look for visual signs on your workpiece. If you see blue, brown, or black discoloration on the steel, you are pushing too hard. This is a clear sign of burning caused by excessive pressure and heat.

Contact Us

For More Grinding Solution or Customized Abrasive Tools