Hybrid bond grinding wheels are advanced abrasives that combine different bonding materials, such as resin with metal bonds. This engineered hybrid bond creates a unique balance of properties. It offers superior cutting efficiency and extends the life of the grinding wheel. These tools are designed for high-performance, precision grinding in demanding industrial jobs. Hybrid bonding technologies are gaining traction for their stability in high-speed grinding operations, making the hybrid grinding wheel a key innovation for modern manufacturing.

Key Takeaways

- Hybrid bond grinding wheels mix different materials. This gives them strong cutting power and a long life.

- These wheels cut faster and last longer than regular wheels. They also make parts smoother and keep the grinding process cooler.

- Hybrid wheels cost more at first. But they save money over time because they work better and last longer.

- These special wheels work best for tough jobs. They are great for making tools and parts for airplanes.

Understanding the Hybrid Bond

A hybrid bond is an engineered mixture of different bonding materials. It combines the best features of each type to create a superior grinding wheel. To understand this technology, we first need to look at the individual bonds.

Resin, Metal, and Vitrified Bonds

Manufacturers use three primary bond types for a superabrasive grinding wheel. Each has unique strengths.

- Resin Bonds: These use plastic polymers like phenolic or polyimide resin. The resin holds the abrasive grains together. This bond offers some flexibility, which helps achieve a fine surface finish during grinding operations.

- Metal Bonds: These bonds use metal powders like bronze or cobalt. They are extremely strong and wear-resistant. This makes them ideal for heavy-duty grinding and cutting hard materials.

- Vitrified Bonds: These are made from ceramic materials, creating a hard, porous structure. The pores help with cooling and clearing away material during grinding.

Key Takeaway: Metal bonds provide strength, resin bonds offer flexibility and finish, and vitrified bonds give a cool, fast-cutting action.

Resulting Wheel Properties

Hybrid bond grinding wheels merge these distinct properties into one tool. For example, a resin-metal hybrid bond combines the strength of metal with the finishing ability of resin. This combination creates a unique structure with excellent grain retention, meaning the abrasive particles stay locked in place longer.

This improved structure allows for aggressive material removal without sacrificing the wheel’s shape. The hybrid bond also manages porosity effectively. It provides enough space for coolant to flow and chips to clear out. This leads to a cooler grinding process and better performance. The result is a versatile tool that excels at precision grinding tasks.

Advantages of a Hybrid Grinding Wheel

A hybrid grinding wheel offers significant benefits over traditional single-bond wheels. The engineered combination of bonding materials creates a tool with enhanced performance. These advantages lead to greater efficiency, higher quality parts, and lower operational costs in demanding grinding applications.

Aggressive Cutting Action

The unique structure of a hybrid bond allows for a more aggressive cutting action. It combines the strength of a metal bond with the finishing properties of a resin bond. This synergy enables the wheel to remove more material in less time. The result is a dramatic increase in productivity. Operators can complete grinding tasks faster, which reduces overall cycle times.

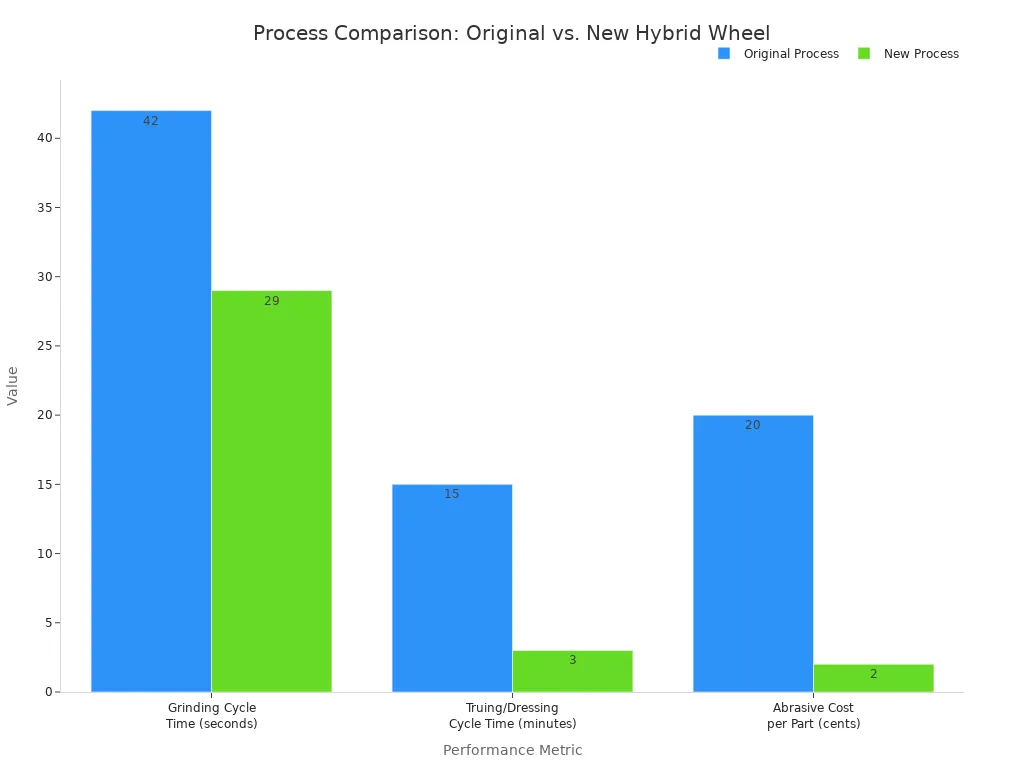

A case study comparing a standard resin-bond wheel to a hybrid wheel highlights these gains. The data shows a significant reduction in grinding time and tooling costs.

| Metric | Original Process (Resin-bond wheel) | New Process (Hybrid G-Force wheel) |

|---|---|---|

| Grinding Cycle Time | 42 seconds | 29 seconds |

| Truing/Dressing Cycle Time | 15 minutes | 3 minutes |

| Dress Depth | 0.010 “ | 0.0005 “ |

| Parts per Dress | 40 | 40 |

| Abrasive Cost per Part | 20 cents | 2 cents |

| Overall Process Savings | N/A | 31 seconds per part (48% reduction) |

| Tooling Cost Reduction | N/A | 90% |

| Total Cost Reduction | N/A | 53% |

This aggressive grinding capability directly translates to higher output and lower costs per part.

Superior Form Holding

Precision grinding requires a wheel that maintains its shape. Hybrid bond grinding wheels excel at form holding. The hard bond components, like metal or vitrified materials, provide exceptional strength and wear resistance. This robust structure prevents the wheel’s edge from breaking down quickly, even during high-stress grinding operations.

Key Benefit: Excellent form holding means the grinding wheel needs less frequent dressing and truing. This reduces machine downtime and increases the wheel’s usable life, contributing to more consistent part quality.

Improved Surface Finish

An aggressive cut often comes at the expense of surface finish. However, a hybrid grinding wheel balances stock removal with a high-quality finish. The resin component in the bond matrix provides a slight cushioning effect. This flexibility allows the abrasive grains to produce a smoother surface on the workpiece. This dual-action performance makes it possible to achieve fast grinding cycles without needing a separate finishing step, saving valuable production time.

Cooler Grinding Process

Heat is a major challenge in any grinding process. Excessive heat can cause thermal damage, such as burns or microcracks, to the workpiece. The hybrid bond is engineered with controlled porosity. This structure creates channels for coolant to flow efficiently to the grinding zone.

This improved cooling action accomplishes two things:

- It washes away metal chips and debris effectively.

- It keeps both the wheel and the workpiece at a lower temperature.

A cooler grinding process protects sensitive materials and ensures the final part meets strict quality standards. It minimizes scrap rates and improves overall operational reliability.

Limitations and Considerations

Hybrid bond grinding wheels offer many benefits. However, users should consider a few key points before adopting them. Understanding these factors ensures that the wheels deliver their full potential and provide a positive return on investment.

Higher Initial Investment

The most notable consideration is the upfront cost. Hybrid wheels are more expensive than traditional single-bond wheels. This higher price comes from their complex manufacturing process and advanced materials. The engineering required to combine different bond types creates a superior tool, but it also increases production costs.

However, it is important to look beyond the initial purchase price. The total cost of ownership is often lower.

- Longer wheel life means fewer replacements.

- Faster cycle times increase overall productivity.

- Reduced dressing frequency minimizes machine downtime.

These factors can lead to significant long-term savings that outweigh the higher initial investment.

Application-Specific Performance

Hybrid wheels are not a universal solution for every grinding task. Their performance is highly specialized. A wheel designed for one material or operation may not work well in another. The specific blend of bonds is engineered for a particular purpose.

Note: Success with hybrid wheels depends on matching the right wheel to the job. Factors like the workpiece material, machine parameters, and desired finish all play a crucial role in the selection process.

Choosing the wrong wheel can lead to poor results and negate its advantages. This makes expert consultation essential. Working with a knowledgeable supplier ensures the selected wheel is optimized for your specific grinding needs, guaranteeing the best possible performance and efficiency.

Applications for Hybrid Bond Grinding Wheels

Hybrid bond grinding wheels are not for every job. They are specialized tools for high-value, precision industries. Their unique properties make them the top choice for applications where performance and accuracy are critical. These wheels solve tough challenges in modern manufacturing.

Key Industrial Uses

The tool and cutter manufacturing industry heavily relies on hybrid wheels. These tools perform essential tasks like fluting and gashing. Fluting is the process of creating the spiral grooves on drill bits and end mills. These grooves help clear away material during cutting. The hybrid bond structure allows for faster material removal. This makes the flute grinding process more efficient.

Expert Tip: For these demanding sectors, partnering with a specialist is key. A provider like Aimgrind offers customized solutions, using deep experience with advanced materials to match the right wheel to the specific grinding operation.

The aerospace industry also benefits from this technology. Aerospace components often use superalloys like Inconel or titanium. These materials are extremely difficult to machine. The grinding process generates immense heat, which can damage the part. A hybrid grinding wheel offers a cooler grinding action. It also uses advanced abrasives like Cubic Boron Nitride (CBN) for grinding hard metals. This combination ensures precision without causing thermal damage.

Key applications for hybrid wheels include:

- Fluting: Creating grooves in carbide and HSS end mills or drill bits.

- Gashing: Making the initial rough tooth profiles on cutters.

- Relief Grinding: Grinding the clearance angles behind a tool’s cutting edge.

- Cylindrical OD Grinding: Precision grinding of the outside diameter of a part.

- Cut-Off: Slicing through hard materials with high accuracy.

Hybrid vs. Traditional Wheels

Choosing the right grinding wheel involves balancing performance, life, and cost. A hybrid bond offers a unique mix of benefits compared to traditional metal or resin bonds. The table below shows a simple comparison.

| Factor | Hybrid Bond | Metal Bond | Resin Bond |

|---|---|---|---|

| Cutting Speed | Very High | High | Moderate |

| Wheel Life | Long | Very Long | Short to Moderate |

| Surface Finish | Excellent | Good | Excellent |

| Dressing Frequency | Very Low | Low | High |

| Initial Cost | High | High | Low |

This comparison shows that a hybrid bond merges the best qualities of other bonds. It delivers the aggressive cutting of a metal bond with the fine finish of a resin bond. The extended wheel life and reduced need for dressing, similar to vitrified CBN wheels, lead to less machine downtime. While the initial cost is higher, the gains in productivity and tool life often provide a better return on investment for high-production grinding environments.

Hybrid bond grinding wheels are a specialized solution for modern manufacturing. They merge the properties of different bonds to achieve superior results. This hybrid bond delivers enhanced productivity and exceptional precision in challenging grinding applications. The technology’s market growth shows its importance in advanced grinding. A hybrid grinding wheel offers longer tool life where traditional wheels fall short. Partnering with an expert like Aimgrind helps businesses unlock the full potential of this innovative grinding wheel for their specific grinding needs.

FAQ

What makes a hybrid wheel different from a metal bond wheel?

A hybrid bond mixes different materials, like resin and metal, for balanced performance. A pure metal bond wheel uses only metal powders. This gives it extreme durability. Hybrid wheels combine that strength with the finishing ability of other bonds for a unique result.

Are hybrid wheels worth the higher cost?

Yes, for many high-production jobs. The higher initial cost is often offset by major long-term savings. Users benefit from faster grinding cycles, longer wheel life, and less machine downtime. This increases overall productivity and lowers the cost per part.

Can I use a hybrid wheel for any grinding job?

No, hybrid wheels are highly specialized. Their performance depends on the specific application.

Expert Tip: Always consult a specialist like Aimgrind. They can help you select the perfect wheel formula for your material and machine parameters to ensure optimal results.

What industries use hybrid grinding wheels the most?

Tool manufacturing and aerospace industries are major users. These sectors require high precision for tasks like fluting carbide end mills or grinding tough superalloys. Hybrid wheels provide the necessary performance and accuracy for these demanding jobs.

Contact Us

For More Grinding Solution or Customized Abrasive Tools