Following safe storage procedures is a critical safety measure. It prevents damage that can lead to dangerous wheel failures.

A Note on Safety 📝

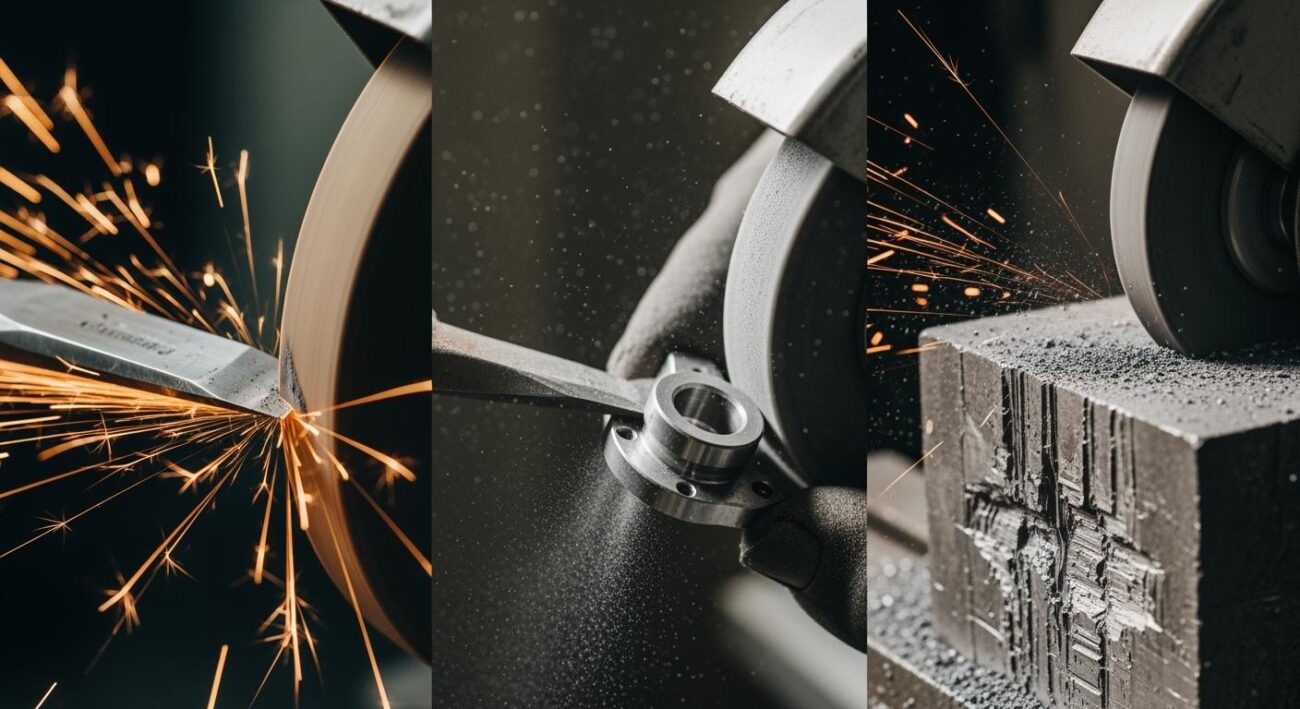

- Over 5,000 documented injuries from angle grinder use occur annually in the US.

- The vast majority of these incidents are caused by a shattering abrasive wheel.

Proper storage means you must keep your grinding wheels in a dry, temperature-controlled area, away from sunlight and extreme temperature changes. The best way to store abrasives depends on the wheel’s specific type and size, which dictates the correct physical orientation.

Key Takeaways

- Store grinding wheels in a dry, stable place. Keep them away from sunlight and big temperature changes. This stops damage and keeps them safe to use.

- Match the storage method to the wheel type. Small wheels go in bins. Large wheels need special racks. Thin discs must lie flat. Cup wheels stack in pairs.

- Always check grinding wheels before you use them. Look for cracks or chips. Do a ‘ring test’ for vitrified wheels. A clear ring means it is safe.

- Use older wheels first. Resinoid wheels last two years. Vitrified wheels need re-testing after two years. Break and throw away old or damaged wheels safely.

Ideal Storage Environment

You must create the right environment to protect your grinding wheels. The American National Standards Institute (ANSI) B7.1 standard offers guidelines for safe handling and storage. A controlled space prevents damage and ensures your wheels perform correctly and safely.

Temperature and Humidity

You should maintain a stable climate in your storage area. The ideal temperature is between 18°C and 26°C (64°F and 79°F). You also need to control the moisture in the air. Aim for a relative humidity of around 45%. These conditions prevent condensation from forming on the wheels. Water can weaken the bonds holding the abrasive grains together, leading to wheel failure.

Pro Tip 🌡️

Extreme changes in temperature or humidity are the biggest threats. A dry, stable room is far more important than hitting an exact number. Avoid damp basements or unheated sheds.

Location and Placement

Your storage location is just as important as the climate. Always keep wheels indoors in a dedicated area. You must protect them from several environmental hazards.

- Direct Sunlight: Never leave wheels exposed to sunlight. UV rays and heat can degrade the wheel’s structural integrity.

- Heat Sources: Keep wheels away from radiators, furnaces, and hot pipes. Heat can cause damage and affect the humidity around the wheel.

- Moisture and Frost: Store wheels away from open windows, leaky pipes, or areas prone to dampness. Frost and moisture are direct threats to the wheel’s safety.

Proper storage is a simple but vital step. It protects your investment and, more importantly, ensures a safer work environment every time you grind.

The Best Way to Store Abrasives by Type

Not all abrasive wheels are the same, so you cannot store them all the same way. The best way to store abrasives is to match the physical storage method to the wheel’s size, shape, and type. This protects the wheel from physical damage and preserves its structural balance.

Small Wheels, Cones, and Plugs

You should handle small abrasive products with care. This includes items like cones, plugs, and wheels up to 80mm (about 3 inches) in diameter. Proper storage for these smaller tools is simple but important.

- Use appropriate bins, boxes, or compartmented drawers.

- Keep them organized to prevent them from rolling around and chipping.

- This method protects their delicate shapes and ensures they are ready for use.

Large Diameter Wheels

Large grinding wheels require a more robust storage solution to prevent warping and damage. You should never stack them flat or lean them against a wall.

Rack ‘Em Right ⚙️ Use specially designed racks for large wheels. These racks should have:

- Vertical Partitions: These keep the wheels separate and upright.

- Cushioned Supports: Each wheel should rest on a cushioned, two-point cradle support at its base. This prevents the wheel from rolling and protects its edge.

This vertical storage method supports the wheel correctly and prevents stress that could lead to cracks.

Thin Cutting Discs

Thin, organic-bonded cutting discs are very susceptible to warping. You must store them flat to maintain their shape.

| Do ✅ | Don’t ❌ |

|---|---|

| Lay discs flat on a rigid, perfectly level surface like steel. | Stack them directly on top of each other. |

| Place a steel plate or other heavy, flat object on top of the stack. | Store them in a place with excessive heat or moisture. |

Placing packing material between stacked discs is not recommended unless they came with attached blotters. Proper flat storage is essential for safety and performance.

Cup Wheels

Cup wheels have a unique shape that requires a specific stacking technique to prevent chipping their rims. You should stack them in pairs.

- Place the first wheel with its base down.

- Place the second wheel on top, with its base facing up.

- This creates a “base-to-base and rim-to-rim” stack.

- Always place a layer of cushioning material, like corrugated cardboard, between each pair of wheels for extra protection.

Aimgrind Diamond Grinding Wheels

High-value, precision tools demand the highest level of care. As experts in specialized abrasives, we at Aimgrind know that the longevity of a diamond wheel depends heavily on its storage. Improper storage is a major cause of premature wheel failure.

An Industry Fact 📈

The Industrial Grinding Journal (2023) reported that nearly 12% of premature wheel failures in small manufacturing settings are due to poor storage conditions.

To protect your investment and ensure peak performance, you must keep high-performance tools like Aimgrind Diamond Grinding Wheels in their original protective packaging. This packaging is specifically designed to shield the delicate diamond surfaces from nicks, scratches, and impact. This careful storage maintains the integrity of the cutting edge and ensures a long service life.

Inspecting Grinding Wheels Before Use

Proper storage protects your wheels, but you must always perform a final inspection before mounting one on a machine. This quick check is your last line of defense against using a damaged wheel, which can prevent serious injury. You should make this inspection a mandatory part of your routine.

Visual Checks for Damage

Your first step is a thorough visual check. You need to carefully examine the entire surface of the wheel with your eyes. This direct examination helps you spot obvious defects that make a wheel unsafe for use.

You should look for several key signs of damage:

- Cracks: Search for any visible cracks on the surface. These can be large, obvious fractures or tiny hairline cracks.

- Chips: Check the edges and faces for any missing pieces. A chip is a clear sign of impact damage.

- Uneven Wear: Look for any areas on the surface that appear worn down more than others.

- Glazing: Notice if the wheel has a glassy, smooth buildup on its surface, which indicates it is loaded and may not cut effectively.

If you see any of these issues, do not use the wheel.

The Ring Test for Vitrified Wheels

Some damage, like internal cracks, is not visible to the naked eye. For vitrified grinding wheels, you must perform the “ring test” to detect these hidden flaws. This simple test uses sound to verify the wheel’s structural integrity.

Follow these steps to perform the test correctly:

- Make sure the wheel is dry and clean.

- Suspend the wheel on your finger or a small pin through its center hole so it can hang freely.

- Gently tap the side of the wheel with a non-metallic object, like a screwdriver handle. Tap it about 1-2 inches from the edge.

- Listen carefully to the sound it makes.

Listen for the Sound 👂

A healthy wheel will produce a clear, sharp ringing sound. A dull thud or a muffled sound means the wheel is cracked. You must immediately discard any wheel that produces a dull thud.

If the wheel passes both the visual check and the ring test, it is safe to mount.

Managing Wheel Lifespan and Disposal

Properly managing your abrasives from arrival to disposal completes the safety cycle. A good system ensures you always use wheels within their effective lifespan and dispose of old ones safely.

First-In, First-Out System

You should use a “First-In, First-Out” (FIFO) system for your inventory. This method ensures you use the oldest products first, reducing the risk of using a degraded wheel. When new shipments arrive, you should label them with the date and place them behind your existing stock. This simple practice prevents newer abrasives from being used prematurely.

Know Your Shelf Life 🗓️ The bond in a wheel has a limited lifespan. Proper storage is key, but time is also a factor.

- Resinoid Wheels: You should use these within two years of their manufacture date.

- Vitrified Wheels: These are more durable, but you should re-inspect and re-test any wheel that is two years or older.

The FIFO strategy is crucial for managing your grinding wheels and minimizing waste.

Safe Disposal of Old Wheels

You must dispose of old, damaged, or expired wheels correctly. Never throw them in a regular trash bin where someone might mistakenly try to use them. You should first break the wheel into several smaller pieces. This action makes it unusable and prevents accidental reuse.

For final disposal, you need to consult local regulations. Some areas have strict rules for what can go into a landfill. The Environmental Protection Agency (EPA) also provides guidelines for industrial waste. If a wheel was used on materials that left hazardous residue, you must treat it as hazardous waste. This often requires using a licensed disposal company. Always check your local rules to ensure you are compliant.

Your most critical responsibility is proper storage. You must keep grinding wheels in a dry, stable environment and use the correct physical storage method for each type. Always perform a visual check and the ring test before use as a final safety measure. This commitment protects you and ensures peak performance.

Your professional responsibility is to Grind with Passion, Achieve with Aim.

FAQ

What is the single most important rule for storing grinding wheels?

You must store your wheels in a dry, stable environment. Keep them away from extreme temperature changes, direct sunlight, and moisture. This prevents the bonding material from weakening, which is the top priority for safety.

Do grinding wheels have an expiration date?

Yes, their bonding agents degrade over time. 🗓️

You should use resinoid wheels within two years of their manufacture date. Vitrified wheels are more durable, but you should always re-test any wheel that is over two years old before using it.

What should I do if I drop a grinding wheel?

You must not use a dropped wheel, even if it looks undamaged. The impact can create internal cracks you cannot see. You should perform a ring test. If it fails or you have any doubts, break it and dispose of it safely.

Why is it important to keep diamond wheels in their original packaging?

Protection is key for precision tools. 💡

High-value tools like Aimgrind Diamond Grinding Wheels have delicate cutting edges. Their original packaging protects them from impact and damage. This ensures they maintain their precision and deliver a long service life, protecting your investment.

Contact Us

For More Grinding Solution or Customized Abrasive Tools