You optimize metal bond grinding wheel performance by mastering three key areas: selecting the right wheel, setting precise parameters, and performing diligent maintenance. These pillars are your solution for better efficiency, longer wheel life, and achieving the fine surface finishes your work demands. Effective grinding optimization delivers significant gains in precision and productivity. For example, focusing on cycle time can reduce costs far more than simply finding a cheaper wheel.

Optimization Impact on Cost Per Part

Strategy Impact on Cost 18% decrease in cycle time Over 14% reduction 30% discount on wheel price Less than 1% reduction

Key Takeaways

- Pick the right grinding wheel for your job. This means choosing the correct abrasive material, grit size, and bond hardness.

- Set your machine’s speed and feed rates carefully. This helps you get the best results for both speed and finish.

- Keep your grinding wheel in good shape. Make sure it is true, sharp, and clean. This makes it last longer and work better.

- Use coolant correctly. It stops your workpiece from getting too hot and damaged.

- Following these steps helps you save money and make better parts.

Selecting the Right Grinding Wheel

Your journey to optimal performance begins with selecting the correct wheel. This choice is the foundation for all subsequent steps. A mismatched wheel leads to poor results, no matter how well you tune your machine. At Aimgrind, we specialize in personalized formula design for materials like hard alloys and ceramics, ensuring your metal bond grinding wheel is perfectly suited for your unique precision grinding needs.

Choosing the Abrasive Material

The abrasive material does the actual cutting. Your choice depends entirely on the material you are grinding. The two primary superabrasives are Diamond and Cubic Boron Nitride (CBN). Each abrasive has distinct properties. Diamond is extremely hard but reacts with iron at high temperatures. CBN offers superior thermal stability, making it ideal for grinding ferrous metals.

Diamond vs. CBN: A Quick Comparison

Feature Diamond Abrasive CBN Abrasive Best For Carbides, ceramics, glass, non-ferrous metals Hardened steels, superalloys, cast irons Weakness Reacts with ferrous metals at high heat Less effective on non-ferrous materials

Determining Grit Size

Grit size determines the balance between your material removal rate and surface finish.

- Coarse grits (lower numbers) remove material quickly but leave a rougher finish.

- Fine grits (higher numbers) remove material slowly but produce a much smoother surface.

Using a smaller, sharp abrasive grit can improve your surface finish. It also lowers grinding energy, which reduces heat and allows for faster feed rates. This makes your precision grinding process more efficient.

Specifying Abrasive Concentration

Abrasive concentration refers to the amount of abrasive grit in the wheel’s bond matrix. A higher concentration provides more cutting points, which can extend wheel life and improve form holding. However, a lower concentration may be better for some grinding operations, as it allows for better chip clearance and coolant flow. This choice impacts both performance and cost.

Matching Bond Hardness

The bond holds the abrasive particles in place. For a metal bond, its hardness must match your application. A softer bond wears away faster, exposing new, sharp abrasive grains. This self-sharpening action is ideal for grinding very hard materials. In contrast, harder bonds are used for softer materials. This principle also applies to other wheel types, like vitrified bond grinding wheels. The right bond ensures consistent cutting and high precision, just as with vitrified bond grinding wheels.

Setting Optimal Operating Parameters

After selecting your wheel, you must dial in your machine’s operating parameters. The right settings unlock the full potential of your metal bond grinding wheel. They ensure you achieve both efficiency and precision. This step transforms a good setup into a great one.

Adjusting Wheel Speed

Your wheel speed directly impacts the grinding result. Higher speeds often reduce subsurface damage and create a better surface finish. You will see fewer and smaller micro-pits on the workpiece. The grinding process generates heat from friction and material deformation. Managing this heat is vital. You must balance speed with heat generation to protect the workpiece surface integrity. A faster wheel can make each abrasive particle do less work, which lowers grinding forces.

Controlling Feed and Traverse Rates

Feed and traverse rates control how quickly the workpiece moves past the abrasive wheel.

- Feed Rate: The speed at which the workpiece is fed into the wheel.

- Traverse Rate: The speed at which the wheel moves across the workpiece surface.

Slower rates generally produce a finer finish. Faster rates allow for high stock removal rates but may compromise surface quality. Your goal is to find the fastest rates that still meet your precision grinding specifications. This optimizes your cycle time without sacrificing quality.

Establishing Depth of Cut

Depth of cut is how deep the abrasive wheel cuts into the material on each pass. This parameter directly affects the grinding force and the power your machine uses. A deeper cut requires more power. Precision grinding applications use very shallow depths, often between 0.01 mm and 0.1 mm. This small depth is key to achieving extreme precision and a fine finish. You must set a depth that the abrasive can handle without excessive wear or heat.

Managing Grinding Pressure

You must manage the pressure between the wheel and the workpiece. Excessive pressure strains your machine’s spindle and can cause damage. Modern systems use advanced monitoring to manage this.

Pro Tip: Use Acoustic Emission (AE) Monitoring

AE sensors detect the high-frequency stress waves created during the grinding process. These signals come directly from the deformation zone where the abrasive cuts the material. This technology allows you to “listen” to the cutting action in real-time. You can identify small variations and prevent problems before they cause damage, ensuring a stable precision grinding operation.

Maintaining Your Metal Bond Grinding Wheel

Proper maintenance unlocks the full value of your metal bond grinding wheel. You must keep the wheel true, sharp, and clean. Good maintenance habits extend wheel life and ensure consistent, high-quality results in every grinding operation.

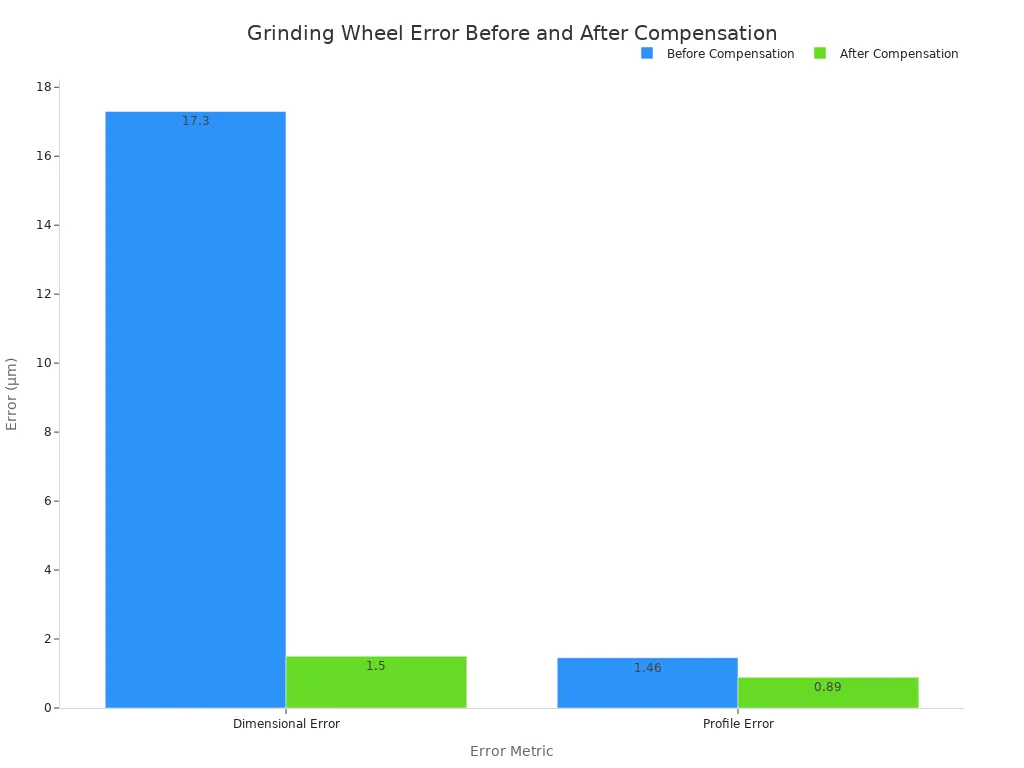

Mastering the Truing Process

Truing makes your wheel perfectly round and concentric with the machine’s spindle. This step is critical for precision grinding. A true wheel minimizes vibration and dimensional errors. You can choose from several effective methods.

| Method | Description | Advantages |

|---|---|---|

| Brake-controlled truing | Uses a conventional abrasive wheel on a braking system to scrub and erode the bond. | Versatile and quickly establishes the correct wheel geometry. |

| Grinding to truth | Mounts the wheel in the work position and grinds its face with another abrasive wheel. | A fast and highly effective method used by wheel manufacturers. |

Proper truing dramatically improves accuracy. It corrects profile errors and ensures your wheel runs true.

Executing Effective Wheel Dressing

Dressing exposes new, sharp abrasive particles on your wheel’s surface. Frequent dressing is key to keeping the wheel cool and sharp. A common method involves using a silicon carbide dressing stick, often with a medium 220 grit, to re-expose the diamond abrasive. How you dress the wheel affects its performance. More frequent, lighter dressing passes can improve the grinding ratio by a factor of four. For specialized applications, advanced methods like Electrolytic In-Process Dressing (ELID) continuously expose the abrasive during grinding, enabling mirror finishes on hard ceramics.

Optimizing Coolant Application

Coolant is essential for managing heat during the grinding process. Incorrect application can cause thermal damage to your workpiece.

- Flow Rate: Aim for 1.5 to 2 gallons per minute (gpm) for each horsepower of your spindle.

- Pressure: Use a low pressure of 60 to 300 psi for general cooling. This ensures the coolant effectively removes heat.

Proper coolant flow prevents rehardening burn and thermal softening. It helps you maintain the integrity of your finished part.

Proper Cleaning and Storage

You must keep your wheel clean. Use a dressing stick to remove swarf and debris from the wheel’s pores. This action keeps the abrasive surface ready for the next grinding task. Proper storage is also important.

Storage Best Practices 📝

These conditions prevent the abrasive wheel from degrading over time.

Your metal bond grinding wheel’s peak performance comes from combining selection, operation, and maintenance. A systematic grinding approach delivers proven economic benefits and superior quality.

Your Final Checklist for Success 📝

- Choose Correctly: Select the right wheel to reduce scrap and achieve fine surface finishes.

- Operate Precisely: Dial in your parameters to ensure consistent precision.

- Maintain Diligently: Use proper truing and dressing to extend wheel life.

Apply these principles to your grinding process. You will reduce costs and improve quality. Grind with passion, and you will achieve your aim.

FAQ

What materials can you grind with metal bond wheels?

You use metal bond wheels for grinding very hard materials. These include hard alloys, ceramics, and superhard materials. They deliver excellent performance and precision for demanding applications in industries like aerospace and tool manufacturing.

Why is wheel dressing so important?

You dress the wheel to expose sharp, new abrasive grains. This action keeps your wheel cutting efficiently and prevents heat buildup. Frequent dressing extends wheel life and improves your part’s surface finish.

How do you choose between diamond and CBN abrasives?

You choose diamond for non-ferrous materials like carbide, glass, and ceramics. You should select CBN for its superior heat stability when grinding ferrous metals like hardened steel. Each abrasive excels on specific material types.

What makes metal bond wheels good for heavy-duty jobs?

Metal bond wheels offer high wear resistance and thermal stability. This durability makes them ideal for tough grinding tasks. They provide a long service life and consistent performance, reducing downtime and replacement costs.

See Also

Selecting the Perfect Metal Grinding Wheel for Your Specific Project

Picking the Ideal Bench Grinding Wheel Material for Your Requirements

Finding the Best Grinding Wheel for Your Stainless Steel Applications

Optimal Grinding Wheel Selection for Sharpening Your Carbide Tools

Discovering the Most Effective Grinding Wheel Dresser for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools