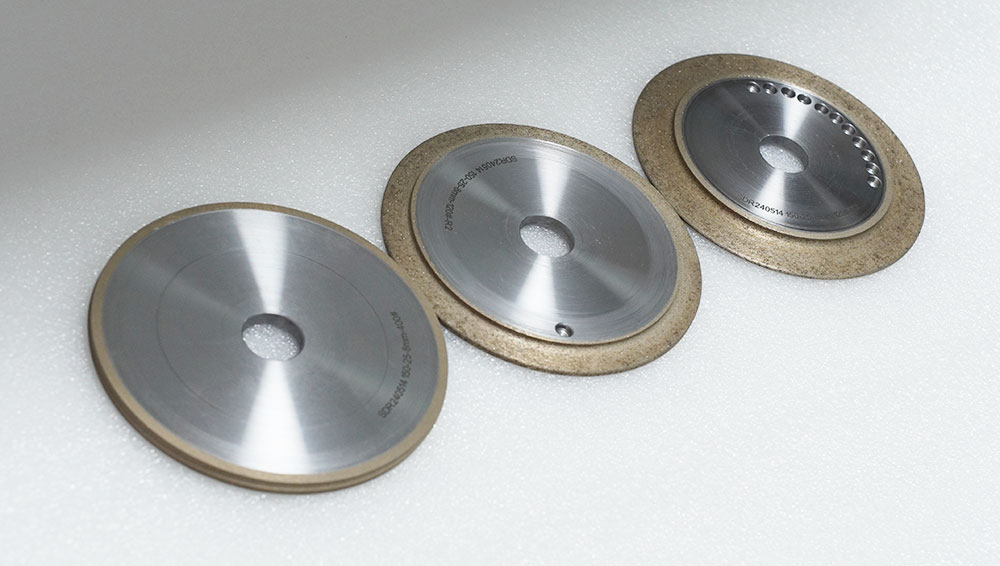

The metal bond grinding wheel is the premier choice for working with hard materials. This type of grinding wheel provides exceptional bond strength and superior wear resistance. These qualities hold abrasive particles securely in place. They also help the grinding wheel keep its shape over long periods. This is critical for achieving excellent performance in precision grinding tasks. Aimgrind stands as a specialized provider of customized grinding solutions, demonstrating deep expertise in this field.

Key Takeaways

- Metal bond grinding wheels are very strong. They hold abrasive particles tightly. This helps them work well on hard materials.

- These wheels last a long time. They keep their shape even when used a lot. This means less time is spent fixing them.

- Metal bond wheels move heat away quickly. This stops the material being ground from getting too hot. It prevents damage to the workpiece.

Superior Bond Strength and Abrasive Retention

The bond in a grinding wheel acts as the glue holding the abrasive grains. A strong bond is essential for good performance. The metal bond grinding wheel excels in this area, providing a powerful grip that ensures reliability during demanding tasks.

The Mechanics of a Strong Metallic Grip

Manufacturers create a metal bond grinding wheel through a process called sintering. This method involves heating powdered metals and superhard abrasives like diamond or CBN. The materials reach very high temperatures, causing them to fuse together into a solid, strong mass. This process creates an extremely durable metallic structure. The resulting grinding wheel has excellent toughness and strength, which are key to its superior performance.

Securing Abrasives in the Grinding Wheel

The primary job of the bond is to hold the abrasive grains securely. The strong metallic matrix in a metal bond grinding wheel or in metal bond cbn wheels achieves this better than many other types. While resin bonds offer advantages, they can wear more quickly in heavy-duty jobs, causing grains to fall out. Metal bonds, however, create a rigid structure that resists wear and deformation.

The bond’s strength is a careful balance. A weak bond causes the grinding wheel to wear out fast. A bond that is too strong prevents dull grains from falling away, which reduces the grinding wheel’s cutting efficiency.

This secure grip is engineered at the interface between the bond and the abrasive. It ensures each grain remains in place, contributing to the overall performance of the grinding wheel.

Importance for Grinding Hard Materials

Secure abrasive retention is critical for high-performance grinding on hard materials. When a grinding wheel works on materials like tungsten carbide or ceramics, it faces immense pressure and heat. A weak bond would fail, leading to rapid wear and inconsistent results. The strong grip of a metal bond grinding wheel maintains the tool’s shape and cutting ability. This stability allows the grinding wheel to deliver a high surface finish consistently. Operators see fewer wheel changes and better productivity, making this grinding wheel a top choice for precision work.

The Aimgrind Metal Bond Grinding Wheel Advantage

Aimgrind delivers a significant advantage with its metal bond grinding wheel solutions. The brand’s focus on wear resistance and form holding directly enhances customer productivity. This commitment results in a superior grinding wheel with consistent, long-lasting performance.

Unmatched Durability of the Metal Matrix

The durability of a grinding wheel comes from its metal matrix. Aimgrind wheels, using diamond or CBN abrasives, offer exceptional wear resistance. Metal bonds are much harder than resin bonds. This means a metal bond grinding wheel wears down far more slowly under the same conditions. The design of the matrix composition is key to achieving this durability and high-quality performance. Different metal mixtures create specific properties for the grinding wheel.

| Metal Matrix Composition | Effect on Durability and Wear Resistance |

|---|---|

| Fe-Mn-Cu-Sn-C mixture | Provides high resistance to abrasive wear. |

| Cobalt and its alloys | Offer excellent abrasive retention and wear resistance. |

| Iron-based with boron | Improves mechanical and tribological properties. |

This careful engineering ensures each grinding wheel, including metal bond cbn wheels, delivers optimal durability for its intended task.

Critical Role of Form Holding in Precision Work

Form holding is the ability of a grinding wheel to keep its exact shape during use. This is vital for precision grinding tasks. Industries like aerospace and tool manufacturing demand extremely tight tolerances. A grinding wheel must meet these strict standards to ensure safety and reliability.

Precision in Aerospace Aerospace manufacturing follows strict quality standards to ensure component integrity. These include:

- AS9100 Quality Management System

- Original Equipment Manufacturer (OEM) Specifications

- Military Standards (MIL-SPEC)

Aimgrind’s metal bond cbn wheels excel at form holding. The strong metal matrix resists deformation from heat and pressure. This superior form holding means the grinding wheel maintains its profile for longer periods. Operators spend less time on wheel dressing and truing. This reduction in maintenance leads to less downtime and a longer useful life for the grinding wheel. The result is consistent performance and greater efficiency on the production floor.

High Thermal Conductivity for Workpiece Protection

Managing heat is a major challenge in high-performance grinding. Excessive heat can ruin the workpiece, compromising its integrity and finish. Metal bond grinding wheels offer an excellent solution because of their high thermal conductivity. This property helps protect sensitive materials from thermal damage, ensuring a high-quality outcome and superior performance.

How Metal Bonds Dissipate Heat

Metals are natural conductors of heat. The metallic matrix of a grinding wheel acts like a heat sink. During grinding, intense friction generates a large amount of heat at the point of contact. The metal bond quickly draws this heat away from the workpiece surface. The heat then spreads throughout the body of the wheel, dissipating into the surrounding environment and coolant. This rapid heat transfer keeps the grinding zone cooler. A cooler operation prevents the workpiece from overheating, which is essential for maintaining its structural properties and achieving a precise finish. This efficient heat management is a key factor in the wheel’s overall performance.

Preventing Thermal Damage to Materials

When grinding hard materials, uncontrolled heat can cause serious defects. These issues compromise the quality and strength of the finished part. The superior thermal conductivity of a metal bond wheel directly prevents these problems. By keeping the workpiece cool, the wheel minimizes the risk of thermal damage.

Common Types of Thermal Damage:

- Oxidation burn, which appears as discoloration on the surface.

- Microcracks and broken pits that weaken the material.

- A reduction in surface hardness.

- Changes in the material’s internal metallurgical structure.

- High residual tensile stress, which can lead to future cracking.

Protecting against these defects is crucial in industries like aerospace and tool manufacturing, where component failure is not an option. The reliable thermal performance of metal bond wheels ensures that parts meet strict quality standards every time.

A metal bond grinding wheel provides a powerful combination of benefits for demanding applications. Its performance rests on three core pillars:

- Superior bond strength for secure abrasive retention.

- Exceptional wear resistance for long-lasting form holding.

- High thermal conductivity to prevent workpiece damage.

This trio makes the grinding wheel the most reliable choice for high-stress grinding. Aimgrind partners with businesses to achieve grinding excellence, offering a customized grinding wheel that delivers on these promises.

Grind with Passion, Achieve with Aim.

FAQ

How do metal bonds compare to other bond types?

Metal bonds offer the highest durability. Other types of grinding wheels, like resin bond cbn wheels, offer faster cutting. Vitrified bond cbn wheels provide cool grinding. Electroplated cbn wheels are excellent for intricate shapes. The best choice depends on the specific grinding task.

What are the main types of grinding wheels?

The primary types of grinding wheels use metal, resin, vitrified, or electroplated bonds. Each bond, such as in vitrified bond cbn wheels or electroplated cbn wheels, holds abrasives differently. This variety allows operators to select the perfect tool for their material and desired finish.

When should someone choose a different bond type?

Tip: Match the bond to the job.

- Resin bond cbn wheels are great for high material removal.

- Vitrified bond cbn wheels offer cool, precise cutting.

- Electroplated cbn wheels excel at profile grinding.

- Hybrid bond cbn wheels balance cutting speed and wheel life.

What are some common grinding wheel applications?

Different types of grinding wheels serve unique purposes. Metal bonds excel at heavy-duty grinding on hard materials. Resin bond cbn wheels are often used for tool sharpening. This variety in grinding wheel applications ensures there is a solution for nearly every industrial need.

See Also

Selecting Optimal Bench Grinding Wheel Materials for Specific Applications

Picking the Perfect Metal Grinding Wheel for Your Fabrication Project

Identifying the Ideal Grinding Wheel for Sharpening Carbide Tooling

Finding the Appropriate Grinding Wheel for Stainless Steel Fabrication

Discovering the Most Effective Grinding Wheel Dresser for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools