Regular inspection is the most important step for extending wheel life and ensuring safety. You can get more value from your silicon carbide grinding wheel with a few simple tips. Proper maintenance improves your grinding results and boosts workshop productivity. Good care of your silicon carbide wheels maintains part accuracy and enhances overall safety. This guide provides a practical checklist to maximize the life of your grinding tools.

Note: Consistent maintenance is the key to quality output and a safer work environment.

Key Takeaways

- Always inspect your grinding wheel before use. Check for cracks with a ‘ring test.’ Look for chips and verify the speed rating. This prevents accidents and ensures good work.

- Choose the right silicon carbide wheel for your job. Match the abrasive type and bond hardness to the material you grind. Proper storage also keeps wheels safe and effective.

- Maintain your grinding wheel regularly. Mount and balance it correctly. Dress and true the wheel to keep it sharp and round. Clean your machine daily and use dust extraction.

- Use correct grinding practices. Run the wheel at the right speed (SFPM). Apply gentle pressure. Use coolant to reduce heat. These steps make your wheels last longer and improve results.

Essential Pre-Use Wheel Inspection

Before you start any grinding job, a thorough inspection of your wheel is essential. This simple routine protects you and ensures the quality of your work. These safety precautions take only a few moments but can prevent serious accidents. Following these tips will help you get the most out of your grinding wheels.

Perform the “Ring Test” for Cracks

The ring test is a quick way to check for hidden cracks inside a vitrified wheel. You should perform this test each time you mount a new wheel.

- Make sure the wheel is dry and clean. Suspend it freely on your finger or a small pin through the center hole.

- Gently tap the side of the wheel with a non-metallic object, like a screwdriver handle. Tap it about one or two inches from the edge.

- Listen to the sound. A healthy wheel will make a clear, high-pitched ringing sound.

- If you hear a dull thud or a flat sound, the wheel is likely cracked. You must discard it immediately. Do not use a wheel that fails the ring test.

Visually Inspect for Chips and Damage

Next, perform a careful visual inspection. Look over the entire surface of the wheel for any visible damage. Check for chips, gouges, or large cracks that could compromise its structure. Pay close attention to the edges and the area around the arbor hole. Any sign of damage means the wheel is unsafe for use.

Check Blotter Condition and Speed Rating

The blotter is the paper disc on the side of the wheel. It provides important information and helps distribute mounting pressure.

Safety Tip: Always verify that your grinder’s operating speed (RPM) does not exceed the maximum speed printed on the wheel or its blotter. Exceeding this speed is a major safety hazard.

Ensure the blotter is in good condition and not damaged. These simple safety precautions are vital for safe grinding operations.

Verify the Wheel’s Expiration Date

Many grinding wheels, especially resin-bonded types, have an expiration date. Over time, the bonding material can degrade, weakening the wheel’s structure. Using an expired wheel increases the risk of it breaking apart during use. Always check for an expiration date printed on the wheel or its packaging. This simple check helps extend the life of your equipment and ensures your safety.

Choosing the Right Wheel for a Longer Life

Selecting the right wheel from the start is a powerful way to ensure a long lifespan and better performance. The specifications of your silicon carbide grinding wheel directly impact its durability and efficiency. Following these tips will boost your productivity and extend the tool’s life.

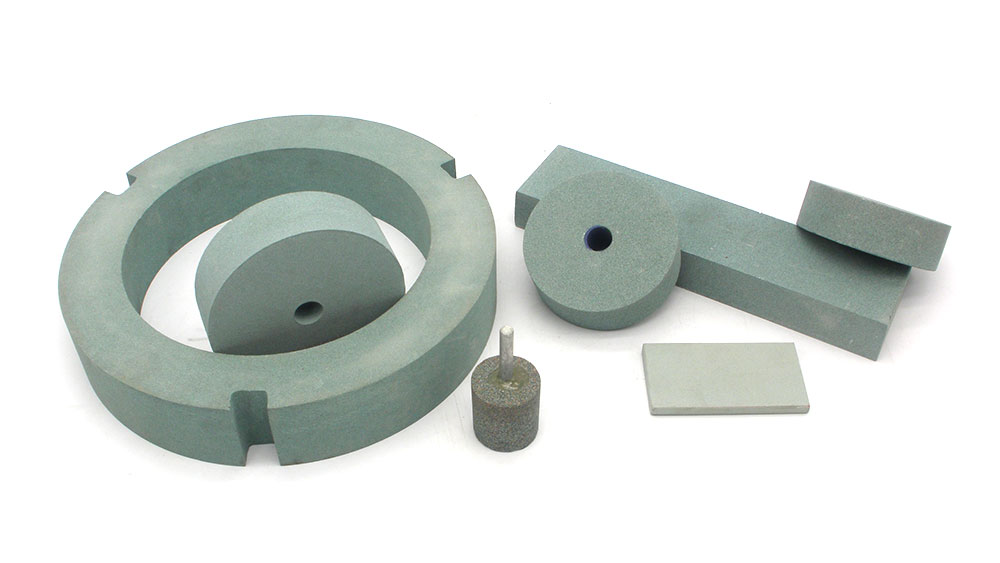

Select the Correct Abrasive Specification

The type of silicon carbide abrasive you choose matters. Your selection should match the material you are grinding and your desired surface finish. For general-purpose grinding on softer materials like cast iron or non-ferrous metals, a standard silicon carbide abrasive works well.

Pro Tip: Consider the two main types of silicon carbide for optimal results:

- Black Silicon Carbide: This is a tough and economical choice. It is great for grinding metals and other demanding jobs.

- Green Silicon Carbide: This type is purer and sharper. You should use it for precision grinding on hard materials like ceramics.

Choosing the correct grit size also affects wheel life. Coarser grits remove material quickly, while finer grits create a smoother finish. Matching the grit to the job prevents unnecessary wear on your wheels.

Choose the Right Bond Hardness

The bond holds the abrasive grains together. A harder bond holds grains tightly, which is ideal for grinding soft materials. A softer bond releases dull grains more easily, exposing fresh, sharp ones. This self-sharpening action is perfect for grinding hard materials and improves productivity. Choosing the right bond prevents the wheel from glazing over or wearing down too fast. A correct match between the bond, material, and grinding operation is essential for a long life.

Ensure Proper Storage and Handling

How you store your wheels is just as important as how you use them. Improper storage can damage wheels before they even touch a grinder.

Follow these simple storage tips:

- Store wheels in a dry area, away from extreme heat or cold.

- Use proper racks that support the wheels and prevent them from rolling.

- Never stack heavy objects on top of your grinding wheels.

- Handle wheels carefully to avoid dropping or bumping them.

Proper handling and storage protect your investment and ensure the wheels are safe and effective when you need them.

Core Grinding Wheel Maintenance Practices

Beyond inspection, your daily habits determine the performance and life of your wheels. Good grinding wheel maintenance is not just about cleaning; it involves a set of core practices that ensure precision, safety, and efficiency. Following these maintenance tips will boost your productivity and protect your investment.

Correct Mounting and Balancing

Properly mounting your wheel is the first step to safe grinding. You must ensure the flanges are clean, correctly sized, and tightened just enough to hold the wheel securely without causing stress. However, balancing is equally critical. An unbalanced wheel creates vibrations that can cause numerous problems.

An out-of-balance wheel can lead to:

- Poor Surface Finish: Vibrations cause chatter marks or waves on your workpiece. You will not achieve a perfect surface finish with an unbalanced wheel.

- Premature Tool Wear: The constant vibration accelerates the wear on your grinding wheels, forcing you to replace them more often.

- Increased Machine Stress: An unbalanced load puts extra strain on your machine’s spindle bearings, which can lead to costly repairs and downtime.

Proper balancing is essential for extending machine life and achieving high-quality results in every grinding job.

Effective Dressing and Truing

Over time, your wheel’s surface will either become loaded with material or lose its shape. Dressing and truing are two distinct but vital grinding wheel maintenance processes to correct these issues.

Truing restores the wheel’s shape, making it perfectly round and concentric with the spindle. Dressing cleans and sharpens the wheel’s cutting surface by removing clogged material and exposing fresh abrasive grains.

Here is a simple breakdown of the two processes:

| Aspect | Truing | Dressing |

|---|---|---|

| Purpose | Restores the wheel’s original shape and corrects imbalance. | Cleans the wheel’s surface and exposes new abrasive grains. |

| Procedure | Uses a diamond tool to reshape the wheel to its correct profile. | Uses a dressing tool to cut away worn or loaded sections. |

| Frequency | Performed less often, only when the wheel loses its shape. | A more frequent operation needed when cutting efficiency drops. |

| Outcome | Ensures grinding accuracy with minimal runout. | Improves cutting performance and surface finish. |

You can use several tools for dressing, including single-point diamond dressers, multi-point dressers, and rotary dressers. Choosing the right tool helps you perform this maintenance task effectively and restore your wheel’s cutting ability.

Daily Maintenance and Cleaning

A consistent daily maintenance routine is one of the best tips for ensuring safety and longevity. Before starting work, you should perform a quick check of your grinding machine and wheel. This simple habit of grinding disc maintenance prevents unexpected failures and keeps your equipment in top condition.

Your daily checklist should include:

- Wipe Down the Machine: Clean away dust and debris from all surfaces.

- Inspect the Wheel: Look for any new signs of wear, damage, or glazing.

- Check the Spindle: Ensure it rotates smoothly without any unusual noise or looseness.

- Verify Safety Guards: Make sure all guards are in place and functioning correctly.

- Check Coolant System: Inspect the coolant level and check hoses for any leaks.

- Test Emergency Stops: Confirm all safety features, like the e-stop button, are working.

These daily safety precautions are simple yet powerful ways to maintain a safe and productive workshop.

Using Dust Extraction Equipment

Grinding creates fine dust that poses serious health and safety risks. The dust from a silicon carbide grinding wheel can be harmful if inhaled. Additionally, some metal dusts can be combustible, creating a fire or explosion hazard. Using proper dust extraction equipment is not just a good practice—it is often a regulatory requirement.

OSHA provides clear guidelines for dust control in grinding operations. A proper dust collection system should have a filter with 99% or greater efficiency and a mechanism for cleaning the filter. The system must also provide enough airflow, often specified as cubic feet per minute (CFM) per inch of the wheel’s diameter. Investing in a quality dust extraction system protects your health, ensures a cleaner workspace, and keeps you compliant with safety standards.

Optimal Operational Practices

Your daily habits during a grinding job directly control the lifespan and performance of your wheels. Following the right operational practices ensures you get the most from your investment. These tips will improve your results, boost productivity, and extend the life of your tools.

Use Correct Wheel Speeds (SFPM)

Running your grinder at the correct speed is crucial for both safety and efficiency. Instead of just looking at RPM (Revolutions Per Minute), you should focus on SFPM (Surface Feet Per Minute). SFPM measures how fast the abrasive grains on the wheel’s edge travel. It gives you a more accurate picture of the grinding action.

You can calculate SFPM with a simple formula:

SFPM = RPM x 0.262 x Wheel Diameter (in inches)

Operating your wheel within its recommended SFPM range is essential. Running it outside this range can cause problems.

- Running too fast: This makes the wheel act harder. It can lead to glazing, where the wheel surface becomes smooth and stops cutting. In the worst case, exceeding the safe speed can cause the wheel to break apart from the force.

- Running too slow: This makes the wheel act softer. While it can remove material faster, it also causes the wheel to wear down quickly and can lead to “loading,” where the wheel gets clogged with material.

Finding the right speed prevents these issues and is a key part of good maintenance.

Apply Appropriate Infeed and Pressure

You might think that pushing harder will get the job done faster, but this is a common mistake. Applying too much infeed or pressure during grinding is counterproductive. It forces the abrasive grains to break down too quickly and can even cause micro-cracks in your workpiece.

Pro Tip: Let the wheel do the work. Excessive pressure leads to premature wheel wear, poor surface finishes, and can even cause the wheel to break. Using a steady, appropriate infeed rate reduces stress on both the wheel and your machine.

Gentle, consistent pressure ensures the wheel wears evenly, improves its durability, and gives you a much better result. This simple change in technique can significantly increase your productivity.

The Role of Coolant in Extending Wheel Life

Grinding generates a lot of heat. This heat can damage your workpiece and drastically shorten your wheel life. This is where coolant plays a vital role. Proper coolant use reduces heat and friction, protecting both the tool and the material.

Using a high-quality synthetic coolant is an excellent choice for grinding with a silicon carbide grinding wheel. These fluids are engineered for great heat transfer and lubrication. For best results, you must maintain the right coolant concentration and flow rate.

- Clean Coolant: Contaminated coolant is less effective and can cause more heat.

- Optimal Flow: A steady flow directed at the grinding point washes away debris and keeps temperatures stable.

Studies show that a high-performance coolant can increase wheel life by 30% or more. Effective coolant management is one of the best ways to improve your grinding process.

Optimizing Your Silicon Carbide Grinding Wheel

Combining all these practices will help you achieve peak grinding wheel performance. You can optimize productivity and get a longer lifespan from your wheels by paying attention to the details.

Here are two final tips to bring it all together:

- Start with a Pull Motion: When using a brand-new wheel, initiate the first few passes with a gentle “pull motion.” This helps break in the edge of the wheel smoothly and prevents it from gouging the workpiece.

- Watch for Glazing and Loading: If you see shiny, smooth spots on your wheel (glazing) or notice it feels clogged (loading), it is a sign that your speed or pressure is wrong. You will need to dress the wheel to expose fresh abrasive grains and adjust your technique.

Consistent operational excellence is the key to extending the life of your grinding tools and achieving superior results.

Upgrading for Maximum Life: Aimgrind Super Hard Abrasives

While silicon carbide wheels are excellent for many jobs, some industries require performance beyond their limits. If you work in aerospace, medical device manufacturing, or precision tooling, you may need to upgrade. This move ensures you meet the highest standards for quality and efficiency.

When to Upgrade from Silicon Carbide

You should consider an upgrade when your current grinding process falls short. A standard silicon carbide abrasive is brittle. This property causes it to wear quickly when grinding high-toughness steel. It also struggles with certain non-ferrous metals like copper and brass, which can clog the wheel and reduce its effectiveness.

You know it is time to upgrade when you need:

- Higher grinding efficiency and performance

- Longer tool life and greater durability

- Better precision and surface quality on hard materials

If you work with advanced ceramics or superalloys, you need a tool designed for the job.

Benefits of Diamond and CBN Wheels

Super hard abrasive wheels, using Diamond or Cubic Boron Nitride (CBN), offer unmatched performance. These wheels provide a much longer life and superior finishes.

- Diamond Wheels: These are perfect for grinding hard, brittle materials like ceramics, glass, and carbide. However, you should not use them on steel because the carbon in the diamond reacts with iron.

- CBN Wheels: These are the ideal choice for grinding hardened ferrous materials. On hardened steel, a CBN tool can last for hundreds or thousands of parts. A carbide tool might fail after just a few. This incredible durability boosts your productivity.

The right super hard abrasive wheels deliver the precision needed for critical parts like aerospace turbine blades and medical implants.

Aimgrind’s Custom Grinding Solutions

Choosing the right wheel is only part of the solution. Your entire grinding process must be optimized for your specific material and goals. Aimgrind specializes in providing custom grinding solutions. We do more than sell wheels; we diagnose problems and design a process that matches your equipment. Our expertise helps you achieve higher productivity and superior results, especially when working with hard coatings or exotic alloys.

For applications demanding the ultimate in performance and durability, explore Aimgrind’s super hard abrasives. Let us help you achieve your grinding goals with passion.

Consistent grinding wheel maintenance is the key to getting the most from your tools. These tips improve your grinding results, boost safety, and save money. Proper maintenance and the right wheel choice lead to better quality and lower costs in your grinding operations. Implement these tips for your silicon carbide grinding wheel. For your toughest grinding challenges, explore Aimgrind’s custom solutions to achieve your goals with passion.

FAQ

What is the difference between dressing and truing?

Truing restores your wheel’s perfect round shape for accuracy. Dressing cleans the wheel’s surface and exposes sharp new grains. You true the wheel for shape and dress it for sharpness. This ensures both precision and good cutting action.

Why did my grinding wheel crack?

A wheel can crack from being dropped or bumped during handling. Incorrect mounting also creates stress fractures. You should always perform the “ring test” on a new wheel to check for hidden damage before you use it.

What is wheel “glazing” and how do I fix it?

Glazing happens when the wheel’s surface becomes smooth and stops cutting. This is often caused by using the wrong speed or pressure. You can fix a glazed wheel by dressing it to expose fresh, sharp abrasive grains.

How often should I dress my grinding wheel?

You should dress your wheel whenever you notice a drop in cutting performance. If the wheel seems clogged or produces a poor surface finish, it is time to dress it. Regular dressing maintains cutting efficiency and extends the wheel’s life.

See Also

Selecting Optimal Grinding Wheels for Precision Carbide Tool Sharpening

Picking the Perfect Grinding Wheel for Your Circular Saw Blade

Mastering Your Dremel Grinding Wheel: Safe and Effective Techniques

Exploring Various Grinding Wheel Types and Their Real-World Uses

Selecting the Ideal Bench Grinding Wheel Material for Specific Tasks