Proper maintenance is the key to maximizing the performance and lifespan of your high-value metal bond grinding wheel. Good maintenance practices extend the life of your grinding wheels. This smart investment ensures consistent results and reduces long-term costs. Poor maintenance, however, leads to expensive problems.

- Costs of Neglect: Premature replacement causes unnecessary downtime and requires more frequent wheel changes.

- Benefits of Care: Daily cleaning and regular maintenance restore grinding performance and extend the tool’s service life.

Key Takeaways

- Use the right speed and feed for your grinding wheel. This helps the wheel last longer and works better.

- Always use enough clean coolant. Coolant keeps the wheel cool and prevents damage.

- Do not push too hard when grinding. Too much pressure can break the wheel and the material.

- Clean and dress your grinding wheel often. This keeps it sharp and working well.

- Store your grinding wheels carefully and check them for damage. This prevents accidents and makes them last.

Mastering Grinding Operations

Your daily grinding operations directly impact the lifespan of your tools. Following best practices is the most effective form of maintenance. You can optimize productivity and achieve high-quality grinding results by mastering a few key techniques.

Set Correct Speeds and Feeds

You must operate your metal bond grinding wheel at the manufacturer’s recommended speed. Incorrect speeds can cause poor performance or damage the wheel. Always consider the application when setting your parameters. A slower feed rate often improves surface finish and extends the wheel’s life. Finding the right balance between speed and feed will optimize wheel life and ensure efficient metal grinding.

Extend Wheel Life with Proper Coolant

Proper coolant application is essential for extending the life of diamond grinding wheels. A steady flow of clean coolant keeps the grinding zone cool. This action prevents the metal workpiece from burning and reduces wheel loading. Research shows that efficient coolant delivery lowers grinding forces, which helps maintain the wheel’s cutting ability. Insufficient or dirty coolant leads to problems that shorten the tool’s life. Good coolant allows your metal bond wheels to perform at their best, ensuring a long operating life. This simple maintenance step is crucial for effective grinding.

Use Moderate Grinding Pressure

Applying the right amount of pressure is key to successful grinding. Too much force can damage both the workpiece and the diamond grinding wheels. It causes premature wear on the diamond abrasives and can even fracture the wheel. You should let the wheels do the work. Listen for changes in sound and look for signs of excessive pressure. This helps you protect your investment and extend its life.

Alert: Signs of Excessive Grinding Pressure

Watch for these common problems. They often indicate that your grinding pressure or other settings need adjustment.

| Problem (Sign of Excessive Pressure) | Possible Cause(s) |

|---|---|

| MATERIAL BURNING | Wheel speed is too high; Insufficient coolant. |

| WHEEL GLAZING | Bond is too hard for the material; Coolant flow is poor. |

| MATERIAL MICRO CRACKS | Excessive grinding pressure; Poor coolant direction. |

| PREMATURE DIAMOND FRACTURE | Too much pressure during grinding; Wheel speed is too high. |

Essential Cleaning and Dressing Maintenance

Proper maintenance extends the life of your grinding tools. Regular cleaning and dressing are two essential practices that keep your diamond grinding wheels in top condition. These steps prevent problems and ensure consistent performance.

Routine Cleaning to Prevent Loading

Regular cleaning is your first line of defense against wheel loading. After each use, you should use a soft brush to remove loose swarf and debris from the wheel’s surface. This simple cleaning habit prevents buildup that can affect grinding quality.

For more stubborn loading, a simple brush is not enough. You will need a proper dressing stick to effectively clean the wheel.

- Make sure the wheel face is clean of old coolant and grinding swarf.

- Use a dressing stick made of aluminum oxide or silicon carbide.

- This level of cleaning prepares your diamond grinding wheels for more intensive maintenance.

Dressing Diamond Grinding Wheels

Dressing restores the cutting surface of your diamond grinding wheels. The process erodes the metal bond to expose fresh, sharp diamond grains. This action is crucial for maintaining the wheel’s grinding ability. You should apply a dressing tool with light to medium pressure against the rotating wheel until you feel it pull the tool away. Repeat this process until the diamond surface feels sharp again.

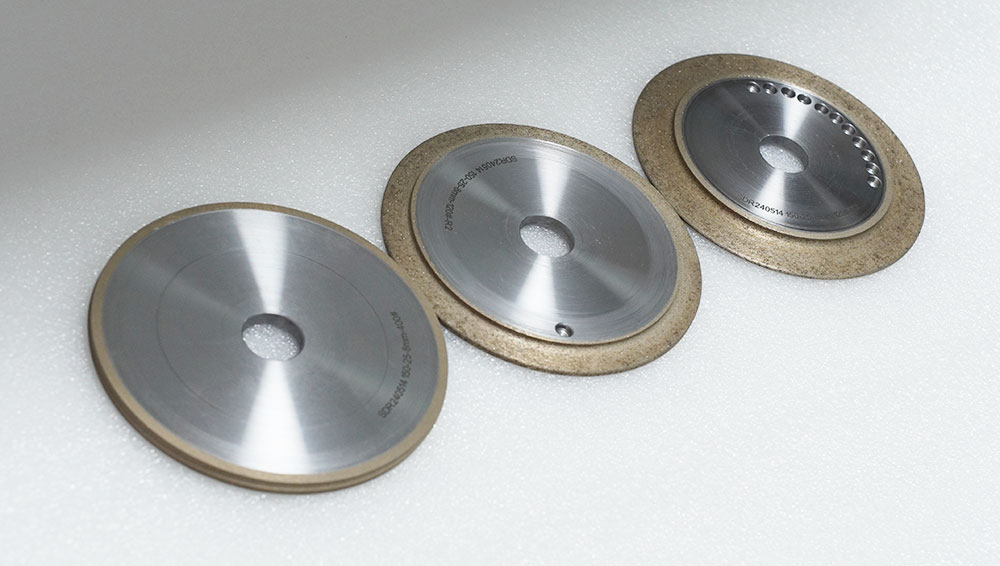

A Note on Quality and Maintenance

High-quality wheels, like those from Aimgrind, feature excellent wear resistance. Their durable construction means they may require less frequent dressing than other wheels. This superior wear resistance saves you time and reduces long-term maintenance costs, extending the lifespan of your metal bond grinding wheel.

Dressing these durable wheels requires the right tools. A standard dressing stick may not be effective. You often need a more aggressive tool, like an impregnated diamond wheel dresser, to properly expose the diamond abrasives. This ensures your wheels continue to deliver precise grinding results and a long service life.

Proper Metal Bond Grinding Wheel Storage

Proper storage and handling protect your investment. A dropped or improperly stored metal bond grinding wheel can develop hidden cracks, creating a serious safety hazard. You should treat your wheels with care from the moment they arrive until they are retired from service.

Safe Handling and Mounting

Your primary focus on safety begins with correct handling. Never roll or drop your grinding wheels. When you are ready to mount a wheel, a precise procedure is essential for both performance and safety. This process ensures the wheel runs true and reduces the risk of failure during a grinding operation.

Follow these key steps for safe mounting:

- Always use the correct size blotters, which are the compressible washers between the wheel and the flange.

- Use matching flanges that are clean, flat, and free of burrs.

- Tighten the bolts using the manufacturer’s recommended sequence and torque, much like mounting a car wheel.

This careful attention to detail guarantees a secure fit and is a critical part of your overall safety protocol.

The Ideal Storage Environment

The right storage environment prevents physical damage and protects your tools from extreme temperatures and humidity. You should store your wheels in a dry, organized area away from vibrations. A well-designed storage system makes it easy to find the right wheel for your next grinding job.

For best results, organize your storage space with these practices:

- Stack most plain wheels on their edge in racks.

- Make sure racks provide two-point cradle support to keep wheels from rolling.

- Arrange your storage so you can remove one wheel without disturbing others.

- Use strong racks, bins, or drawers that can handle the weight of your metal tools.

Proper storage is a simple but effective way to extend the life of your equipment and ensure consistent grinding results.

The Importance of Routine Inspection

Regular inspection is a simple yet powerful form of maintenance. You can catch small problems before they become serious safety risks or lead to costly damage. Making routine maintenance checks a part of your workflow protects your investment and ensures your tools are always ready for the next grinding job.

Perform Visual Checks for Damage

You should always inspect your grinding wheels before mounting them. Look closely for any visible cracks, chips, or signs of excessive wear. A damaged wheel can fail during operation, creating a dangerous situation.

Sometimes, a wheel can have a hidden crack that you cannot see. The “ring test” is a simple procedure to check a wheel’s structural soundness. It helps you find internal defects before you start a grinding task.

How to Perform the Ring Test 📝

- Make sure the wheel is clean and dry. Suspend it from its center hole using a pin or your finger.

- Gently tap the wheel with a nonmetallic object, like a screwdriver handle. Tap it about one to two inches from the edge.

- Listen to the sound. A healthy wheel will produce a clear, ringing tone. A dull thud suggests a hidden crack or defect.

- Rotate the wheel 45 degrees and tap it again to confirm the sound. Never use a wheel that sounds dull or damaged.

Listen for Operational Changes

Your ears are an excellent tool for monitoring your equipment. During a grinding operation, you should listen for any unusual sounds. A sudden change in noise, like a new vibration or rattling sound, often indicates a problem. It could mean the wheel is out of balance, has come loose, or is showing signs of wear.

Pay attention to how the machine feels and sounds. If you notice anything out of the ordinary, stop the machine immediately. Investigate the cause to prevent damage to the workpiece or the wheels. This careful attention helps you maintain safe and efficient operations.

You can extend the life of your metal bond grinding wheel with four key habits. Master your operations, clean and dress the wheel, store it safely, and inspect it regularly. This proper maintenance extends the tool’s lifespan and delivers a great return on investment by reducing scrap and downtime. A proactive approach to maintenance ensures your tools perform consistently. Combining this care with premium products from a brand like Aimgrind is the best way to optimize wheel life and achieve professional results. Your commitment to care protects the tool’s life.

FAQ

What is wheel loading and how do I fix it?

Wheel loading happens when grinding debris clogs your wheel’s surface. This reduces its cutting ability. You can fix minor loading with a soft brush. For stubborn buildup, you must use a proper dressing stick to clean the wheel face and restore its performance.

How often should I dress my metal bond wheel?

You should dress your wheel when you notice a drop in cutting performance or see signs of glazing. The frequency depends on your application. High-quality wheels, like those from Aimgrind, have superior wear resistance and often require less frequent dressing, saving you time.

What is the “ring test” for?

The ring test helps you find hidden cracks inside a grinding wheel. You gently tap the suspended wheel and listen for the sound. A clear ring means the wheel is safe to use. A dull thud indicates a defect, and you should not use the wheel.

Why is coolant so important for metal bond wheels?

Coolant is essential for protecting your wheel and workpiece. It keeps the grinding zone cool, preventing burns and reducing wheel wear. A clean, steady flow of coolant also washes away debris, which helps maintain the wheel’s cutting efficiency and extends its service life.

See Also

Selecting the Optimal Metal Grinding Wheel for Your Specific Project

Picking the Best Bench Grinding Wheel Material for Your Requirements

Identifying the Perfect Grinding Wheel for Your Carbide Tool Sharpening

Guidance on Selecting the Correct Grinding Wheel for Stainless Steel

Mastering Safe and Effective Usage of Your Dremel Grinding Wheel

Contact Us

For More Grinding Solution or Customized Abrasive Tools