The difference between truing and dressing is simple. Truing restores a grinding wheel’s geometric shape. Dressing, however, cleans and sharpens the cutting surface.

Think of truing as reshaping a warped car tire. Dressing is like cleaning mud from its treads. ⚙️

Understanding dressing and truing is vital for precision work. Operators must use the correct process and tools, such as a diamond truing tool, to ensure both safety and accuracy in every grinding operation.

Key Takeaways

- Truing makes a grinding wheel perfectly round. It fixes the wheel’s shape and balance.

- Dressing cleans and sharpens the wheel’s surface. It helps the wheel cut materials better.

- Truing fixes the wheel’s shape, like making a tire round. Dressing sharpens the wheel, like cleaning mud from a tire’s treads.

- Always dress a wheel after truing it. Truing shapes the wheel, but dressing makes it ready to cut well.

- Use good diamond tools for both truing and dressing. This helps you get precise and high-quality results.

What is Truing?: Restoring Wheel Shape

Truing is the process of making a grinding wheel perfectly round and concentric with its spindle. This operation corrects any geometric errors, ensuring the wheel spins without wobble or runout.

Goal of Truing: Perfect Geometry

The main goal of truing is to achieve perfect geometry. It corrects the wheel’s profile and restores its concentricity. This process is essential because wheels can wear unevenly over time. Proper truing ensures the entire face of the wheel makes uniform contact with the workpiece. This precision is the foundation for accurate grinding results.

When is Truing Necessary?

Operators should perform truing whenever the wheel’s shape is compromised. A new wheel always requires truing after it is mounted. Other signs indicate truing is needed:

- The wheel runs out of true or is not concentric with the bearings.

- A measurable deviation occurs, such as the wheel being 1/8″ out of round.

- Forced vibration appears, often caused by an unbalanced rotating body.

- Internal density variations or a loose fit on the shaft cause imbalance.

The Truing Process Explained

The truing process uses a fixed tool, like a diamond truing tool, to remove material from the spinning wheel. The basic steps for truing grinding wheel are straightforward.

- Securely mount the diamond truing tool on the machine bed.

- Position the tool slightly off-center from the wheel.

- Start the machine and slowly bring the wheel down until it just touches the tool.

- Make careful passes across the wheel’s face, removing small amounts of material.

- Continue until the wheel is perfectly round and runs true.

Tip: Always use coolant during wet grinding operations to manage heat and dust. For dry grinding, the truing should also be done dry.

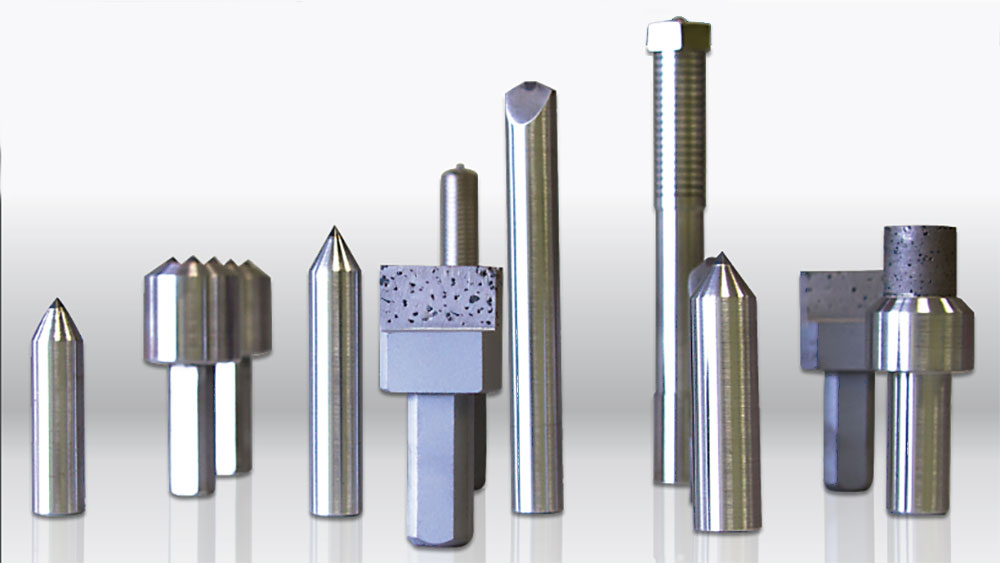

The Role of a Diamond Truing Tool

A diamond truing tool is critical for effective truing. Diamond is the hardest known material, making it the only substance that can effectively cut and reshape abrasive grains. A quality diamond truing tool precisely shaves away the high spots on the wheel. This action helps restore the grinding wheel’s original shape. Using a durable diamond truing tool ensures accuracy and a high-quality surface finish. For any precision work, a reliable diamond truing tool is not just a recommendation; it is a necessity.

What is Dressing?: Sharpening the Cutting Surface

Dressing is the process of cleaning and sharpening a grinding wheel‘s cutting surface. While truing corrects the wheel’s shape, dressing restores its ability to cut efficiently. This maintenance is crucial for achieving a fine surface finish and preventing damage to the workpiece.

Goal of Dressing: Restored Cutting Ability

The primary goal of grinding wheel dressing is to restore the wheel’s cutting performance. Over time, a wheel’s surface can become dull in two main ways:

- Glazing: The abrasive grains wear down and become smooth, losing their sharp cutting edges. This often happens when the wheel’s bond is too hard for the material.

- Loading: Metal particles from the workpiece get stuck in the pores of the wheel, clogging the cutting surface. This can be caused by incorrect wheel selection or a lack of coolant.

Dressing removes this dull or loaded layer, exposing fresh, sharp abrasive grains underneath.

When is Dressing Necessary?

An operator knows dressing is necessary when the grinding wheel stops cutting effectively. Several signs indicate it is time for a grinding wheel dressing.

A loud, high-pitched screeching sound is a common sign that a wheel is glazed and needs attention. 👂

Other indicators include:

- Burn marks or discoloration on the workpiece from excess heat.

- A poor surface finish with visible scratch patterns.

- Shiny metallic streaks on the wheel’s face, showing it is loaded.

The Dressing Process Explained

The dressing process involves moving a dressing tool across the face of the spinning wheel. The operator makes several light passes to shear away the worn abrasive layer. This action fractures dull grains and removes clogged material. The depth of cut for each pass is very small, ensuring only the damaged surface is removed. Proper dressing grinding wheel technique creates a sharp, open-pored surface ready for efficient grinding.

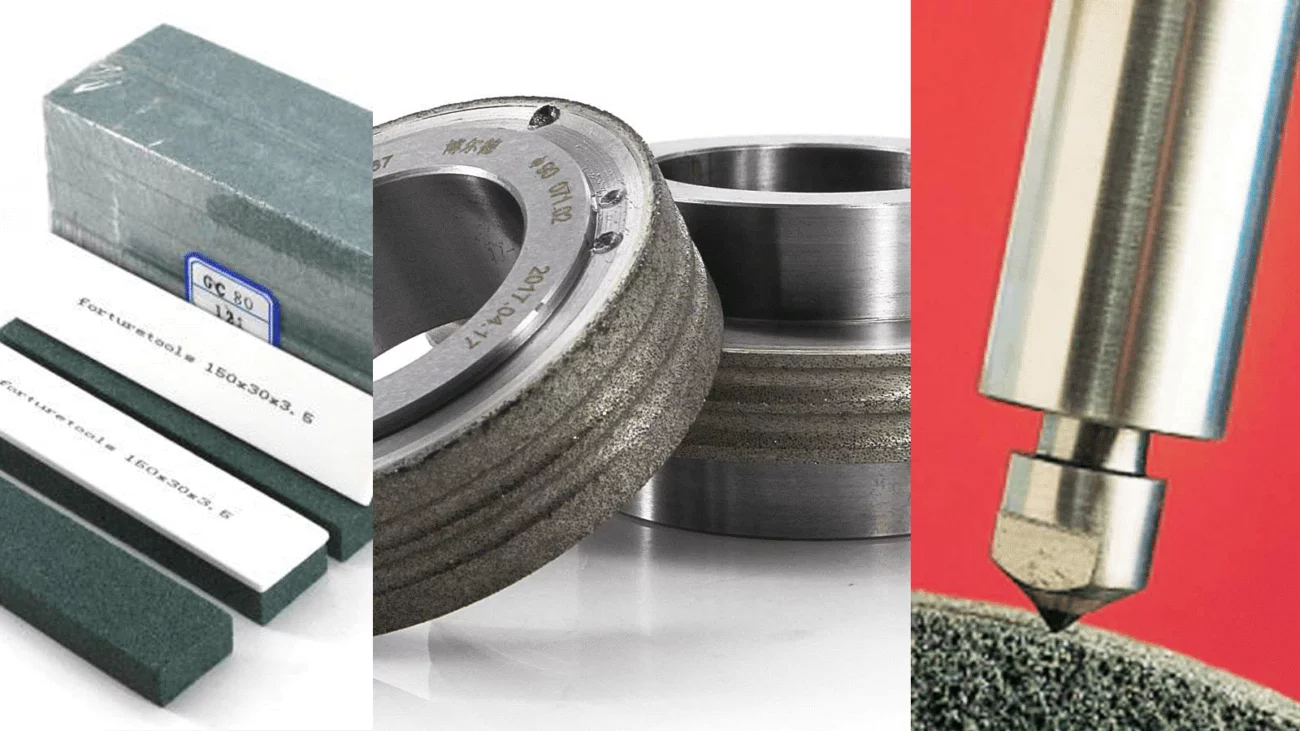

Common Tools for Wheel Dressing

Operators use several tools for dressing grinding wheel surfaces. The choice depends on the wheel type and desired finish.

- Abrasive Sticks: These are simple, inexpensive sticks made from materials like aluminum oxide. They are effective for light dressing on conventional wheels.

- Star Dressers: These tools have free-spinning, star-shaped cutters. They are good for quickly removing heavy loading from coarse-grained wheels but can leave a rough finish.

- Diamond Dressers: For precision and a superior finish, diamond dressers are the best choice. Their hardness allows them to dress any wheel type quickly and accurately, making them a versatile and cost-effective solution for professional results.

Key Difference Between Truing and Dressing

While people often use the terms interchangeably, the difference between truing and dressing is significant. Truing focuses on the wheel’s geometry, while dressing focuses on its surface condition. Understanding this distinction is key for any operator aiming for precision and efficiency. Both truing and dressing are essential maintenance, but they solve different problems.

Goal: Shape vs. Sharpness

The primary goal of each process is fundamentally different. Truing is a geometric operation, while dressing is a sharpening operation.

- Truing manipulates the grinding wheel’s geometry. The process creates a specific profile on the wheel and ensures that profile is perfectly concentric with the spindle. An operator performs truing to correct its form and restore its original shape.

- Dressing restores the wheel’s cutting ability. This operation exposes fresh abrasive crystals and creates chip clearance. It sharpens the wheel by removing loaded material and fracturing dull grains.

The following table breaks down the core purpose and outcome of each process.

| Aspect | Truing | Dressing |

|---|---|---|

| Purpose | Restores the wheel’s shape, ensuring it is concentric and balanced. | Cleans and sharpens the wheel’s surface, removing clogs and exposing fresh abrasive grains. |

| Outcome | Guarantees geometric accuracy for precise grinding with minimal runout. | Enhances cutting performance and improves the workpiece surface finish. |

Frequency: Occasional vs. Frequent

The frequency of each operation also highlights their different roles. Truing is an occasional task, whereas dressing is a frequent, routine part of the grinding process.

An operator performs truing only when necessary, such as when mounting a new wheel or after an accident causes visible runout. It is a corrective measure for significant geometric flaws.

In contrast, dressing is a regular maintenance task. The need for it depends on several factors.

- Material Type: Hardened steels like D-2 generate more heat, which can cause the wheel to glaze faster.

- Wheel Hardness: A wheel that is too hard for a job will dull quickly and require more frequent dressing.

- Grinding Aggressiveness: Removing a large amount of material generates more heat and load, causing the dressed surface to wear off sooner.

Outcome: Concentricity vs. Cutting Power

The results of truing and dressing are distinct and measurable. Truing produces a wheel that is perfectly round and true, while dressing produces a wheel that cuts efficiently.

The outcome of truing is concentricity. A trued wheel spins without wobble, making uniform contact with the workpiece. This precision is essential for achieving tight dimensional tolerances and preventing vibration that could harm the surface finish.

The outcome of dressing is restored cutting power. A freshly dressed wheel has a sharp, open-pored surface. This allows it to remove material at an optimal rate. Dressing directly impacts the material removal rate by:

- Exposing new, sharp abrasive grains.

- Removing glazed areas and metal particles (loading).

- Improving chip clearance for better cooling.

Proper dressing restores the grinding process to its expected performance, reduces thermal stress on the workpiece, and maximizes productivity.

Tool Selection: Correcting Form vs. Exposing Grain

The tools used for each process are designed for different tasks. Truing tools must be rigid and hard enough to reshape the wheel, while dressing tools are made to fracture abrasive grains.

Tools for truing are chosen for their ability to correct wheel profile and form errors. A single-point diamond tool mounted rigidly in a CNC machine is a common example. These tools precisely shave material away to create a perfectly concentric and profiled wheel.

Tools for dressing are designed to remove swarf and dull grains from the wheel’s surface.

- Dressing Sticks: These are simple abrasive blocks that scour the wheel face.

- Star Dressers: These have spinning cutters that aggressively break up a loaded wheel surface.

- Diamond Dressers: These versatile tools use diamond points to precisely fracture dull grains and expose sharp new ones, conditioning the wheel for a specific finish.

Ultimately, the tool choice depends on the goal: correcting form requires a shaping tool, while exposing grain requires a sharpening tool.

Choosing the Right Tools: Aimgrind Diamond Tools

Selecting the right tool for truing and dressing is just as important as understanding the processes themselves. As a specialized provider with nearly two decades of experience, Aimgrind offers customized grinding wheels and abrasive tools built on deep expertise. The quality of your dressing tool directly impacts the efficiency and precision of your work.

Why Quality Tools Matter for Grinding

High-quality tools are an investment in performance and cost-efficiency. Using durable, high-performance tools can increase machine efficiency by 15% and significantly reduce cycle times. Operators experience fewer dressing intervals, which minimizes machine idle time and improves process security for large production batches.

A quality diamond tool is essential for achieving a superior surface finish. It impacts the workpiece in several key ways:

- Restores Wheel Geometry: It helps restore the grinding wheel’s original shape for uniform contact.

- Exposes Fresh Abrasives: Proper grinding wheel dressing removes dull grains, leading to a smoother finish and better dimensional accuracy.

- Reduces Heat Generation: An efficient tool reduces friction, preventing surface burns and material damage.

Selecting a Dresser for Your Application

The choice of dresser depends on the job’s requirements. For general grinding, a basic dresser may be enough. However, for a smooth surface finish or intricate detailing, an accurate dresser is necessary.

Note: For fine-grit or precision grinding wheels, diamond dressing tools are highly recommended to maintain accuracy and provide a clean finish.

If your product requires a true mirror finish or a specific surface roughness (Ra) below 0.05 µm, a high-quality diamond tool is often the only option. The right tool for grinding wheel dressing ensures the wheel is conditioned perfectly for the task.

The Aimgrind Advantage in Precision

Aimgrind provides durable and high-performing Diamond Tools designed for precision in both truing and dressing. These tools offer superior cutting performance and longevity, making them a cost-effective choice for professionals. Aimgrind excels at providing custom solutions, ensuring your tools are perfectly matched with your equipment and processes. This commitment to customer satisfaction reinforces the brand’s mission to enhance productivity. For any grinding wheel dressing task that demands accuracy, Aimgrind delivers the tools you need to achieve professional results.

The Relationship Between the Two Processes

Truing and dressing are distinct but closely related maintenance tasks. An operator cannot achieve optimal results by performing only one. Understanding their connection is essential for any precision grinding operation.

Why You Must Dress a Wheel After Truing

Operators must perform dressing on a grinding wheel immediately after truing. The truing process creates a geometrically perfect shape. It leaves a fresh surface with sharp cutting edges and open pores for chip clearance. This fresh surface also generates less heat during grinding.

However, a trued-only surface is not ideal for efficient cutting. The truing process can sometimes glaze the wheel, which prevents it from cutting well. It may also fail to expose enough abrasive particles to the necessary height. These ineffective particles cannot engage the workpiece, which reduces the material removal rate. A final light dressing pass exposes the abrasive grit, conditioning the wheel for effective cutting.

Can Dressing Also True a Wheel?

Many operators wonder if dressing can also true a wheel. The answer is complex. Dressing can make very minor corrections to a wheel’s shape. However, it is not a substitute for proper truing.

Caution: Attempting to correct significant runout with only a dressing tool is ineffective and unsafe. ⚠️

Dressing cannot fix fundamental problems. For example, it cannot correct an imbalance caused by a bent machine shaft or dense spots within the wheel’s material. A dressing tool only scours the surface. It does not have the rigidity or purpose to reshape a wheel with significant geometric flaws. For major shape correction, truing is the only correct procedure.

Truing corrects a grinding wheel’s geometric shape. Dressing restores its cutting function. Properly maintaining grinding wheels through both of these steps is essential for safe and efficient work.

Mastering this wheel maintenance for performance and precision is fundamental for any operator. Using quality tools from specialists like Aimgrind helps achieve professional, high-quality results every time. 🏆

FAQ

What is the main difference between truing and dressing?

Truing corrects a grinding wheel’s physical shape, making it perfectly round. Dressing, however, sharpens the wheel’s cutting surface. Truing is about geometry, while dressing is about cutting performance.

How often should an operator dress a grinding wheel?

An operator should dress a wheel whenever it stops cutting well. Signs include a glazed surface, burn marks on the workpiece, or a loud screeching sound. The frequency depends on the grinding task and materials.

Why are diamond tools good for truing and dressing?

Diamond is the hardest material available. This hardness allows diamond tools to precisely shape and sharpen any type of grinding wheel. Quality tools from specialists like Aimgrind ensure accuracy and a long service life.

Can you true a wheel without dressing it afterward?

No, an operator must always dress a wheel after truing it. ⚙️

Truing creates a perfect shape but can leave the surface too smooth to cut effectively. A final dressing pass exposes the sharp abrasive grains needed for efficient grinding.

See Also

Selecting the Optimal Grinding Wheel Dresser for Your Specific Needs

Identifying the Ideal Grinding Wheel for Your Carbide Tooling

Exploring Various Grinding Wheel Types and Their Real-World Uses

Understanding the Key Differences Between Dry and Wet Grinding Methods

Mastering Safe and Effective Techniques for Dremel Grinding Wheel Use

Contact Us

For More Grinding Solution or Customized Abrasive Tools