Vitrified bond grinding wheels are indispensable tools in high precision manufacturing. The automotive and aerospace sectors rely on these wheels for critical applications. A unique vitrified structure provides rigidity and porosity, enabling the high precision needed for tight tolerances. This vitrified bond grinding wheel delivers superior accuracy and surface finishes. The global market reflects this importance, with projections showing growth to USD 2.6 billion by 2032. The vitrified wheel’s properties make it the standard for any industry demanding ultimate precision.

Key Takeaways

- Vitrified bond grinding wheels are important tools in making things very exact.

- These wheels help make car parts like engines and gears work well and last a long time.

- They are also used to make strong airplane parts that must be very safe.

- Vitrified wheels help make smooth parts for bearings and medical tools.

- They are good for grinding hard materials like steel and special metals without breaking them.

Automotive Manufacturing Applications

The automotive industry demands extreme precision and efficiency in its manufacturing operations. Vitrified grinding wheels are central to this process, enabling the high-volume automotive production of critical components. These applications require superior accuracy to ensure engine performance, safety, and fuel economy. The unique properties of a vitrified wheel make it the go-to technology for these demanding tasks.

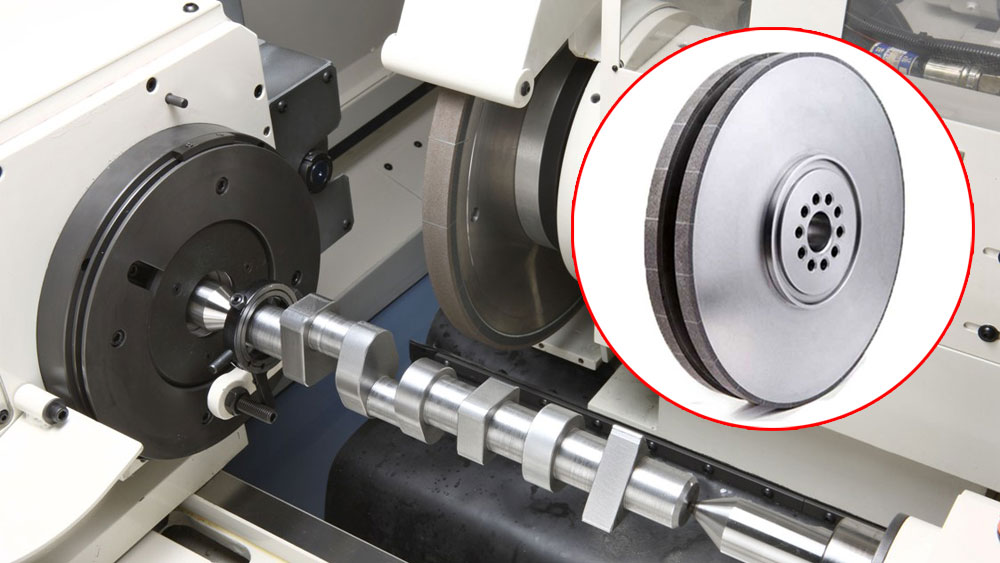

Crankshaft and Camshaft Grinding

Crankshafts and camshafts are the heart of an internal combustion engine. Their flawless operation depends on incredible precision. The grinding process must achieve extremely tight tolerances to ensure perfect balance and timing. For high-quality production, manufacturers rely on a vitrified wheel to meet these standards.

Key Grinding Tolerances:

- Surface finish (Ra) must be less than or equal to 0.4 μm.

- Dimensional tolerances must stay within ±0.005 mm.

- Some advanced grinding can even achieve a surface finish of 0.1 μm on camshafts.

Transmission and Gear Finishing

Gears and other transmission parts must be perfectly smooth to reduce noise, vibration, and wear. The porous structure of a vitrified wheel is a major advantage here. These pores act as channels, allowing coolant to flood the grinding zone. This action prevents thermal damage to the heat-sensitive gear material. The open structure also clears away metal chips, keeping the wheel cutting efficiently throughout the production run.

Engine Valve and Piston Grinding

Grinding engine components made from hard materials is another key task. Engine valves often use tough alloys like Stellite to withstand intense heat and pressure. Pistons must also meet strict dimensional standards. A vitrified wheel has the necessary hardness and thermal stability to shape these durable materials accurately, ensuring a perfect seal and optimal engine compression. This capability is vital for modern automotive manufacturing.

Fuel Injector Component Grinding

Modern fuel injectors operate with microscopic precision to deliver fuel efficiently. The small, intricate parts inside them require exceptionally smooth surfaces and exact dimensions. The vitrified bond grinding wheel provides the control needed for this delicate work. This ensures every injector performs reliably, contributing to better fuel economy and lower emissions across the automotive sector.

Aerospace: High Performance Grinding for Critical Parts

The aerospace industry operates under the most stringent standards, where component failure is not an option. This sector relies on high-strength superalloys and hardened steels that are notoriously difficult to machine. High performance grinding is essential to shape these materials into critical parts with flawless precision and surface integrity. The unique properties of vitrified bond grinding wheels make them a cornerstone technology for these high-stakes aerospace applications.

Turbine Blade, Vane, and Seal Grinding

Grinding turbine blades, especially their complex fir-tree root forms, is a demanding process. The geometry must be perfect to ensure a secure fit and withstand extreme operational stresses. This requires a grinding process that delivers exceptional accuracy and avoids thermal damage. Manufacturers often use advanced techniques like creep feed grinding. The porous, rigid structure of a vitrified wheel is ideal for this task. Aimgrind‘s custom grinding wheels are specifically designed with the thermal stability needed for grinding turbine blades and other critical aerospace components, ensuring superior performance.

Landing Gear Component Finishing

Aircraft landing gear must endure immense forces during takeoff and landing. These components are often made from high-strength steels like 300M, which offers incredible tensile strength but requires careful machining.

| Element | Percentage Range (%) |

|---|---|

| Carbon (C) | 0.41-0.46 |

| Manganese (Mn) | 0.65-0.90 |

| Silicon (Si) | 1.45-1.80 |

| Chromium (Cr) | 0.65-0.95 |

| Nickel (Ni) | 1.6-2.0 |

| Molybdenum (Mo) | 0.30-0.40 |

| Vanadium (V) | ≥0.05 |

Any surface defect, such as microscopic cracks or rough finishes, can lead to fatigue failure. A vitrified bond grinding wheel provides the high precision needed to create a smooth, defect-free surface, ensuring the structural integrity and safety of the landing gear.

Ball Screw and Actuator Grinding

Flight control surfaces depend on the flawless performance of ball screws and actuators. These components require exceptionally smooth and precise surfaces to operate without friction or wear. The vitrified grinding process delivers the fine surface finishes and tight dimensional tolerances necessary for their reliable performance. This level of quality is vital for the safe and efficient operation of an aircraft.

Grinding High-Strength Superalloys

Superalloys like Inconel and titanium alloys are essential in aerospace for their strength at high temperatures. However, these materials present significant grinding challenges:

- Work Hardening: The material hardens during the grinding process.

- High Heat Generation: Grinding produces intense heat that can damage the part.

- Rapid Tool Wear: The material’s toughness wears down grinding wheels quickly.

High-performance grinding wheels, including vitrified CBN and diamond grinding wheels, are engineered to overcome these issues. The vitrified bond provides the durability and heat resistance needed to machine these tough materials effectively, making complex applications possible.

Bearing Manufacturing and Machinery

The bearing manufacturing industry is a cornerstone of modern machinery, demanding exceptional component quality and consistency. Vitrified bond grinding wheels are essential to this sector, providing the high precision needed for mass production. The performance of everything from tiny motors to massive industrial equipment depends on the accuracy of its bearings. This makes the grinding process a critical step in ensuring reliability and efficiency.

Inner and Outer Ring Raceway Grinding

The raceway is the path where balls or rollers travel inside a bearing. Its geometry and surface finish directly influence the bearing’s performance and lifespan. A vitrified wheel provides the rigidity and sharp cutting action needed to create perfectly round and smooth raceways. This precision minimizes friction and vibration, allowing machinery to run quietly and efficiently. The production of these parts requires a technology that delivers consistent results.

Roller and Ball Bearing Finishing

Finishing rollers and balls requires a highly efficient production method. Manufacturers often use a centerless grinding process. In this setup, the workpiece rests between a vitrified grinding wheel and a regulating wheel. The regulating wheel drives the part while the grinding wheel removes material to achieve the final dimension. This automated process is ideal for the high-volume production of bearing components, ensuring uniform size and shape.

Precision Machine Tool Spindles

The heart of any machine tool is its spindle, which holds the cutting tool or workpiece. The spindle’s accuracy determines the final quality of any part the machine makes. These spindles rely on high precision bearings to rotate smoothly at high speeds without any runout. The use of a vitrified grinding wheel in bearing manufacturing enables the creation of components that meet these strict requirements, directly contributing to the machine’s overall performance.

Grinding Hydraulic Components

Hydraulic systems require extremely smooth internal surfaces to prevent fluid leakage and ensure proper function. A vitrified wheel delivers the fine surface finish needed for components like valve bodies and spools. A rough surface can cause serious issues.

Key reasons for a smooth finish:

- Prevents spool jamming and uncontrolled movement.

- Ensures a proper seal to stop leaks.

- Reduces wear on moving parts.

- Lowers friction for better system efficiency.

Achieving a surface finish of 1.5 – 3.2 μm Ra is critical. A vitrified grinding process helps manufacturers avoid the problems associated with poor-quality casting, ensuring reliable system performance.

Tool and Die: Using a Vitrified Bond Grinding Wheel

The tool and die industry demands absolute precision to create the molds and cutting implements that drive modern manufacturing. Aimgrind’s expertise in the cutting tool sector highlights the critical role of advanced abrasive technology. A vitrified bond grinding wheel provides the necessary hardness and stability for this work. Its unique structure ensures that every tool and die meets exact specifications for superior performance and longevity. This makes the vitrified wheel an essential tool for high-quality production.

Sharpening Cutting Tools

Sharpening cutting tools made from high-speed steel (HSS) or carbide requires a delicate balance. The grinding process must restore a sharp edge without overheating and ruining the tool’s temper. The porous, vitrified structure of the wheel is key to achieving this. It allows for better coolant flow and chip removal, leading to a cooler, more efficient sharpening process.

Key Advantages of Vitrified Wheels in Sharpening:

- They offer superior grinding power while maintaining lower temperatures.

- The rigid bond provides excellent shape retention for a precise edge.

- Good self-sharpening properties expose fresh abrasive grains, enhancing performance.

- The open structure prevents wheel clogging and workpiece burning.

Form Grinding for Dies and Molds

Form grinding creates complex, non-flat surfaces on dies and molds. This process is vital for producing parts with intricate shapes, such as non-circular punches or the detailed geometries on nameplate blanking dies. Achieving high tolerance form accuracy depends on a wheel that holds its shape perfectly. The rigid vitrified bond ensures the wheel’s profile remains consistent, transferring the exact geometry to the workpiece for reliable production and quality.

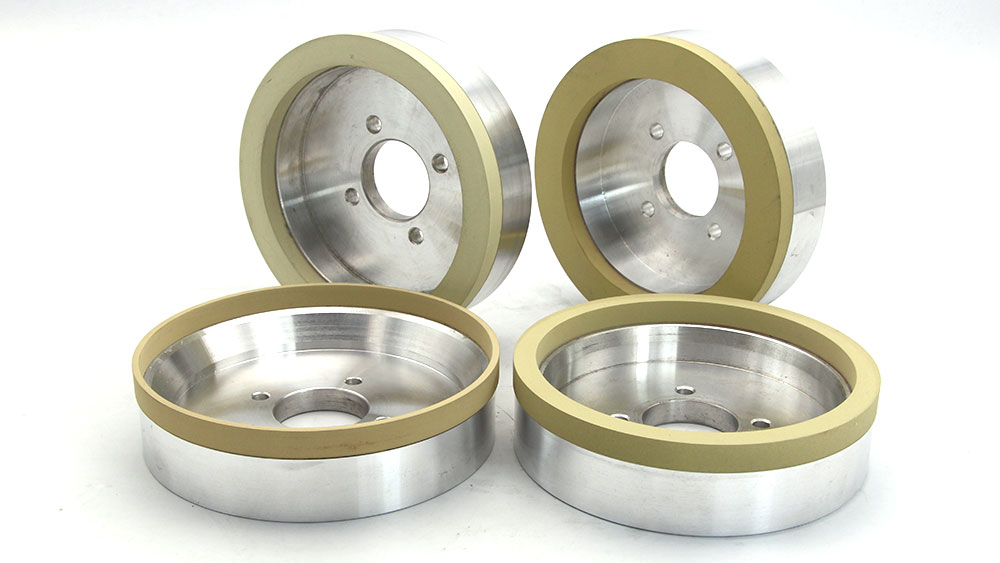

Grinding Tungsten Carbide Tools

Tungsten carbide is an extremely hard and wear-resistant material used for high-performance cutting tools. Grinding it effectively requires specialized high-performance grinding wheels. Vitrified diamond grinding wheels and vitrified CBN grinding wheels are the ideal technology for this task. The vitrified bond securely holds the superabrasive diamond or CBN particles, allowing them to cut the hard material efficiently. This combination delivers exceptional performance, making the manufacturing of durable, long-lasting carbide tools possible. Aimgrind’s vitrified diamond grinding wheels and CBN grinding wheels provide the value needed for this demanding application.

Other Key Industrial Applications

Beyond the major manufacturing sectors, vitrified bond grinding wheels serve a variety of other critical industrial applications. Their unique properties make them the ideal technology for processing difficult materials where precision and performance are paramount. From primary metals to advanced electronics, the vitrified bond provides solutions for complex challenges.

Steel and Primary Metals: Mill Roll Grinding

In steel production, massive mill rolls shape hot metal into finished products. The performance of these rolls is crucial, but they face constant challenges that affect their service life and the quality of the steel.

Key challenges in maintaining mill rolls include:

- Excessive wear and surface defects.

- Thermal distortions from high temperatures.

- Vibration and chatter during operation.

Regrinding these rolls requires a wheel that can restore a perfect profile with extreme accuracy. A hard, durable vitrified wheel provides the stability needed to remove material consistently, correcting defects and ensuring the rolls meet tight tolerances for continued production.

Medical: Surgical Tool and Implant Grinding

The medical industry has zero tolerance for error. Surgical tools and implants demand exceptionally smooth surfaces to ensure biocompatibility and prevent issues like pathogen spread or implant rejection. Medical devices often use hard materials like cobalt-chromium and titanium alloys. Grinding these materials to a flawless finish is essential for patient safety.

Vitrified diamond grinding wheels deliver the precision needed for these sensitive medical applications. The rigid vitrified bond holds the abrasive particles securely, creating ultra-smooth surfaces that meet strict sanitation and quality standards. This high-performance grinding is fundamental to modern medical device manufacturing.

Electronics: Grinding Ceramic and Silicon

Manufacturers of electronic components work with hard, brittle materials like silicon wafers and ceramic substrates. These materials can easily chip or crack during the manufacturing process. Grinding them requires a specialized approach to achieve the necessary precision without causing damage.

Vitrified diamond grinding wheels offer the perfect solution. The strong vitrified bond provides the rigidity needed to make clean, precise cuts on these delicate materials. This advanced technology enables the production of high-quality electronic components with the tight tolerances required for today’s advanced devices.

Vitrified bond grinding wheels are the standard for precision grinding across critical manufacturing sectors. The automotive and aerospace industries rely on these high-performance grinding wheels for demanding applications. The unique vitrified bond provides the hardness, porosity, and chemical inertness needed for superior performance. This vitrified structure ensures the accuracy and productivity required for modern production. As one expert notes:

This focus on performance and precision makes the vitrified bond grinding wheel essential for any industry seeking reliable grinding solutions and efficient production.

FAQ

What makes a vitrified wheel different from other grinding wheels?

A vitrified wheel uses a glass-like bond to hold abrasive grains together. This bond creates a rigid, strong, and porous structure. It provides excellent shape retention and thermal stability, making it ideal for high-precision grinding applications where accuracy is critical.

What materials can a vitrified grinding wheel handle?

These wheels excel at grinding very hard materials. Common applications include hardened steels, superalloys like Inconel, and ceramics. The strong vitrified bond ensures the wheel can effectively cut these tough materials without rapid wear, delivering consistent performance and high-quality surface finishes.

Are vitrified wheels suitable for high-speed grinding?

Yes, they are designed for high-speed operations. The inherent strength and thermal stability of the vitrified bond allow the wheel to perform reliably at high rotational speeds. This capability increases productivity while maintaining tight dimensional tolerances on the workpiece.

Why is the porous structure of a vitrified wheel important?

The porous vitrified structure creates open pockets within the wheel. These pockets serve two key functions:

- They allow coolant to reach the grinding zone, preventing heat damage.

- They provide space for chip clearance, which stops the vitrified wheel from clogging.

See Also

Exploring Grinding Wheel Varieties and Their Real-World Uses

Selecting Optimal Bench Grinding Wheel Materials for Specific Requirements

Identifying the Ideal Grinding Wheel for Your Carbide Tooling

Finding the Most Effective Grinding Wheel Dresser for Your Workshop

Understanding CBN Grinding Wheels: Functionality and Operational Principles

Contact Us

For More Grinding Solution or Customized Abrasive Tools