Understanding buffing vs polishing is simple. Polishing is an abrasive, corrective process to remove surface flaws, while buffing is a fine finishing process that creates a brilliant shine. The process of buffing and polishing is like using two types of sandpaper. Polishing is your coarse grit, and buffing is your fine grit. You use a polishing wheel for correction before using buffing wheels for the final shine. This two-step approach to buffing and polishing is key in the global metal finishing market, an industry valued at over USD 100 billion in 2024 and projected to grow.

Key Takeaways

- Polishing removes surface flaws like scratches. It uses abrasive compounds to smooth the material.

- Buffing creates a shiny finish. It uses softer wheels and fine compounds after polishing.

- Always polish before you buff. Polishing fixes problems, and buffing makes it shine.

- Choose the right tools for your project. Match the wheel and compound to your material and its condition.

What Is a Polishing Wheel?

Think of a polishing wheel as the first and more aggressive tool in your surface finishing toolkit. You use it to correct imperfections and prepare a surface for its final shine. This initial step of polishing is crucial for achieving a truly flawless result.

The Goal of Polishing

The main goal of polishing is to create a smooth, uniform surface. This process removes minor flaws like light scratches, oxidation, and orange peel from your workpiece. Polishing works by using an abrasive to level the surface, effectively erasing these small blemishes. It sets the stage for the next step, buffing, by providing a clean and consistent foundation.

Wheel Characteristics

Polishing wheels are designed for durability and versatility. They are often made from materials that can hold an abrasive compound and withstand the friction of surface correction. Expert suppliers like Aimgrind offer a wide range of durable polishing wheels, including types like BD, BK, and wool felt wheels, designed for high-quality results. The abrasives used with these wheels vary depending on the job:

- Aluminum Oxide: You can use this for creating satin finishes on non-ferrous metals and steel.

- Silicon Carbide: This tougher abrasive is great for smoothing non-metallic materials like glass.

- Walnut Shells: This soft, natural abrasive is perfect for polishing delicate surfaces.

- Corn Cobs: You can use this gentle abrasive for cleaning and burnishing various parts.

When to Use Polishing

You should turn to polishing when your workpiece has visible but shallow surface defects. It is the right choice for removing the initial roughness left over from sanding or manufacturing. This process prepares the surface for a higher level of refinement.

Important Tip: Polishing is excellent for fine-tuning a surface. However, it is not designed to fix major damage. It is less effective for removing deep scratches, gouges, or dents.

Choosing the right polishing wheel and abrasive is the first step toward a professional-grade finish.

What Is a Buffing Wheel?

After you have corrected the surface with polishing, you will use a buffing wheel for the final finishing touch. Buffing is the less aggressive process that transforms a dull, corrected surface into one with a brilliant, high-quality shine. This step is all about aesthetics and achieving a flawless appearance.

The Goal of Buffing

The primary goal of buffing is to create a smooth, reflective finish. You use buffing wheels with a fine compound to eliminate the tiniest scratches left from polishing. This process smooths microscopic peaks and valleys on the surface. The result is a beautiful, high-gloss finish that enhances the workpiece’s overall appearance. Your ultimate objective with buffing is to achieve a clean, professional look, which can range from a soft satin sheen to a perfect mirror-like finish.

Wheel Characteristics

Buffing wheels are much softer and more flexible than polishing wheels. This allows them to glide over a surface to create a shiny appearance without removing much material. They are typically made from soft, pliable fabrics. Common materials include:

- Cotton: A versatile and widely used material for general-purpose buffing.

- Flannel: An even softer fabric used for achieving a very high shine on delicate surfaces.

- Sisal: A stiffer natural fiber often used for an initial buffing step before moving to softer cotton wheels.

These wheels come in various constructions, from simple sewn wheels to densely packed compress wheels, giving you options for different contours and materials.

When to Use Buffing

You should use buffing as the final step in your finishing process, right after you have completed polishing. This is the stage where you bring out the ultimate shine. Use buffing to remove any lingering compound from the polishing stage and create exceptionally smooth surfaces. This final buffing step ensures your workpiece has a professional appearance and is ready for a protective coating or simply to be admired.

Buffing vs Polishing: A Direct Comparison

While both buffing and polishing contribute to a beautiful final product, they play very different roles. Understanding the core distinctions in the buffing vs polishing debate helps you choose the right process at the right time. This ensures you achieve a professional appearance efficiently.

Aggressiveness and Abrasives

The biggest difference between the two processes is their level of aggression. Polishing is the more aggressive step. You use it to remove material and correct surface flaws. A polishing wheel works with coarse abrasive compounds to cut away imperfections.

Buffing, on the other hand, is a much gentler process. You use it to enhance the surface, not correct it. Buffing involves very fine abrasives that smooth the surface with minimal material removal, creating a brilliant shine.

The compounds used for buffing and polishing reflect this difference. Polishing compounds are more abrasive, designed for cutting. Buffing compounds are finer, designed for coloring or bringing out luster.

- Coarse Abrasives (for polishing): You use compounds like Black Emery or Brown Tripoli to remove scratches and level a surface.

- Fine Abrasives (for buffing): You use compounds like White, Green, or Blue Rouge to create a high-gloss finish on various metals.

Because of these differences, polishing has a medium-to-high material removal rate, while buffing has a very low one.

Order of Operations

The sequence of buffing and polishing is not interchangeable. You must always perform polishing before buffing. Think of it as building a foundation. Polishing creates the uniform, smooth surface that buffing needs to work effectively.

You cannot achieve a true mirror shine with buffing if the underlying surface still has scratches and flaws. Polishing removes those defects first, paving the way for a perfect final appearance.

Attempting to use a buffing wheel on an unpolished, flawed surface will only highlight the imperfections. The correct order is essential for a professional result.

Resulting Surface Finish

Each process leaves a distinct surface appearance.

- Polishing: After polishing, your workpiece will feel smooth to the touch. However, its appearance will likely be bright but hazy or cloudy. You may see very fine abrasive lines. This is a uniform, prepped surface, not a final finish.

- Buffing: Buffing transforms that prepped surface. It removes the haze and fine lines, creating a highly reflective, clear appearance. The ultimate goal of buffing is often a #8 Buffed Finish, which is a true mirror-like surface with exceptional clarity and no visible grain. It reflects light and images with sharp precision.

Key Differences Summarized

Here is a simple table to help you remember the key differences between these two essential finishing steps.

| Feature | Polishing | Buffing |

|---|---|---|

| Primary Goal | Remove surface defects (scratches, oxidation) | Create a high-gloss, reflective shine |

| Aggressiveness | More aggressive; cuts the surface | Less aggressive; glides over the surface |

| Material Removal | Medium to high | Very low to none |

| Abrasives Used | Coarser compounds (e.g., Black Emery) | Finer compounds (e.g., White Rouge) |

| Order | First step (after sanding/grinding) | Final step |

| Final Appearance | Smooth but often dull or hazy | Clear, shiny, and reflective |

Understanding these points is crucial for mastering the art of buffing and polishing.

How to Choose the Right Polishing Wheels

Selecting the right tools is the key to a flawless finish. Your choice of polishing wheels and compounds depends entirely on your workpiece and your final goal.

Assessing Your Surface

First, you need to examine your workpiece closely. Does it have deep gouges or just light surface haze? This assessment tells you if you need aggressive polishing, light buffing, or both.

You can classify surface flaws to guide your decision:

- Minor (Type I): These are light marks that do not go past the surface layer. A simple buffing step might be enough.

- Moderate (Type II): These scratches reach the material underneath. You will need polishing to remove them before buffing.

- Severe (Type III): These are deep gouges that may require grinding before you even begin polishing.

A careful look helps you create a clear plan. You can avoid wasting time or damaging your workpiece.

Matching Wheels to Materials

Different materials require different tools. You must match your wheel to the surface you are working on. For example, polishing hard metals like stainless steel often involves using a firm wheel with a cutting compound. Softer metals like aluminum or brass need a gentler approach, perhaps starting with a sisal wheel and a Tripoli compound.

Non-metals have their own unique needs.

For materials like glass and ceramics, you might use felt wheels or even specialized diamond wheels for effective results. Expert providers like Aimgrind offer solutions for a wide range of industries, from metalworking to glass processing, ensuring you have the right tool for any job.

The Role of Compounds

A polishing wheel does not work alone. The compound you choose is just as important. The compound contains abrasives that do the actual work of removing material.

- Cutting Compound: A coarse compound, like Black Emery, is designed for aggressive material removal. You use this compound to erase scratches during the initial polishing stage.

- Finishing Compound: A finer compound prepares the surface for the final buffing step.

The compound also acts as a lubricant. It helps reduce heat buildup, which protects both your workpiece and your polishing wheels from damage. Using the right compound ensures an efficient and safe polishing process.

Mastering buffing and polishing is simple when you remember their distinct roles. You use a polishing wheel for correcting flaws and then use buffing for creating a brilliant shine. The correct sequence of polishing before buffing is the essential path to a flawless result. This two-step process of buffing and polishing is vital in many industries.

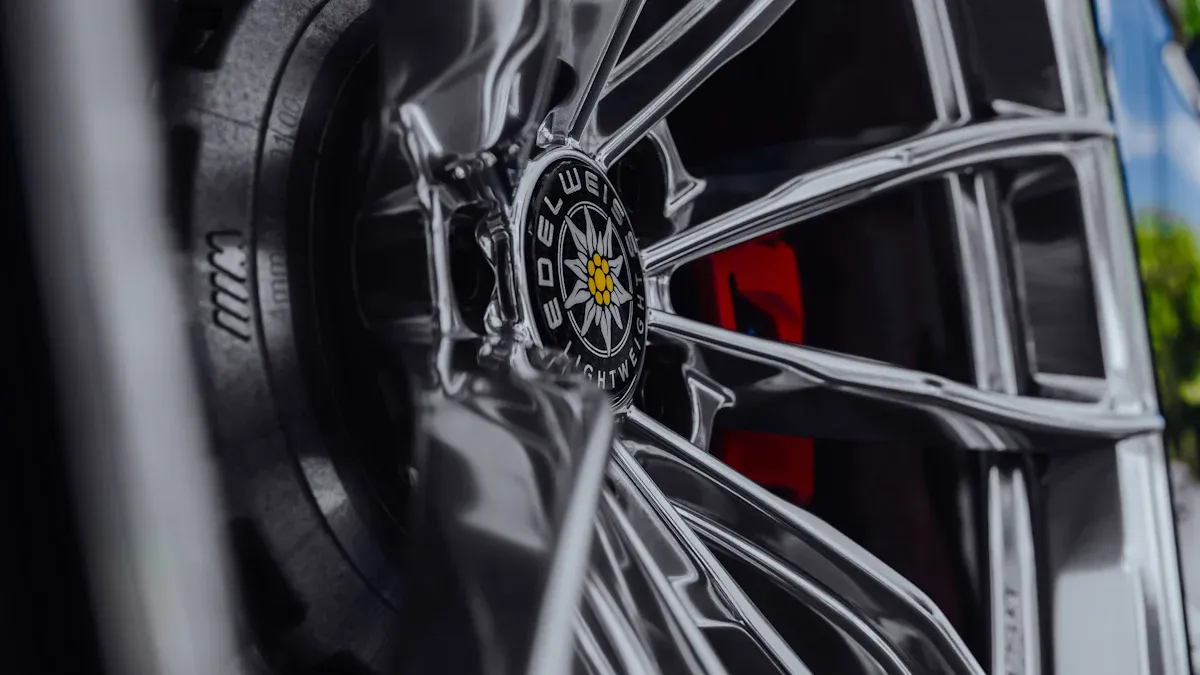

For example, professionals rely on this exact sequence for quality control in:

- Aerospace: For smoothing turbine blades and aircraft panels.

- Automotive: For creating a mirror shine on alloy wheels and trim.

- Rail: For reducing friction on train wheel sets and bearings.

Ultimately, selecting the right tools makes all the difference in your buffing and polishing projects.

FAQ

Can I skip polishing and go straight to buffing?

You should not skip polishing if your surface has visible flaws. Buffing a scratched surface only makes imperfections more noticeable. You must polish first to create a smooth, uniform base. This step is essential for achieving a true mirror shine.

What materials can polishing wheels be used on?

You can use polishing wheels on a wide variety of materials. They work effectively on metals like steel and aluminum. Specialized wheels, like the BD, BK, and wool felt wheels offered by Aimgrind, are also perfect for glass, ceramics, and gemstones.

How do I choose the right polishing wheel for my project?

To choose the right wheel, you must first assess your material and its condition. Harder materials require tougher wheels and compounds. Matching the wheel to your specific job ensures you get the best possible results safely and efficiently.

How long do polishing wheels last?

A wheel’s lifespan depends on several things. The material you are working on, your machine’s speed, and the pressure you apply all affect durability. Quality wheels are built to last, but their exact life will vary from one project to another.

See Also

Selecting the Optimal Bench Grinding Wheel Material for Specific Applications

Discovering the Ideal Grinding Wheel Dresser for Your Workshop

Exploring Various Grinding Wheel Types and Their Real-World Uses

Understanding Dry Versus Wet Grinding: Essential Information for Users

Unveiling the CBN Grinding Wheel: Its Functionality and Benefits

Contact Us

For More Grinding Solution or Customized Abrasive Tools