A hybrid bond grinding wheel is an advanced abrasive tool. It merges the high material removal of a metal bond with the free-cutting action of a resin bond. This special grinding wheel achieves both aggressive stock removal and excellent surface finishes. It often completes the grinding process in a single operation.

The primary purpose of this hybrid tool is to provide high-efficiency grinding for hard and brittle materials. These include tungsten carbide, HSS, and ceramics.

Key Takeaways

- A hybrid bond grinding wheel combines metal and resin. This tool grinds hard materials well. It removes material fast and leaves a smooth finish.

- Hybrid wheels offer many benefits. They remove material quickly. They last longer than other wheels. They also use less force during grinding.

- These wheels are good for many jobs. They are used to make cutting tools. They grind ceramics and medical parts. They also work for car and airplane parts.

- Hybrid wheels save time and money. They can do many tasks. This means fewer tool changes. They make manufacturing more efficient.

What Is a Hybrid Bond Grinding Wheel?

A hybrid bond grinding wheel is a sophisticated tool. It combines two different types of bonding materials. This unique blend creates a powerful and versatile grinding wheel. The wheel excels at difficult grinding tasks.

Metal and Resin Synergy

The core of a hybrid bond is its special mixture of metallic and resinoid agents. This combination creates a synergy that outperforms traditional bonds.

- Resinoid Agents: These are typically synthetic resins. Common examples include phenolic or polyimide resins. The resin holds the superabrasive grains in place.

- Metallic Agents: These are metals like bronze or iron. The metal provides strength and durability.

The metal component gives the hybrid bond incredible strength and heat resistance. This is similar to the robust design of Aimgrind‘s durable metal bond wheels. The metal part efficiently pulls heat away from the grinding zone. Research shows that certain hybrid filler systems can increase thermal conductivity by up to 50%. This action protects the workpiece from heat damage.

The resin component allows for a self-sharpening, free-cutting action. During grinding, the resin wears away at a controlled rate. This process exposes fresh, sharp superabrasive grains. Scientific studies show this creates tiny pores on the wheel’s active surface. These pores improve the self-sharpening effect and reduce grinding forces. This synergy makes the hybrid bond grinding wheel a truly advanced tool.

The Grinding Mechanism

The dual-nature bond creates a highly efficient grinding mechanism. A hybrid wheel can perform both aggressive stock removal and fine surface finishing. This often happens in a single pass, which greatly reduces cycle times.

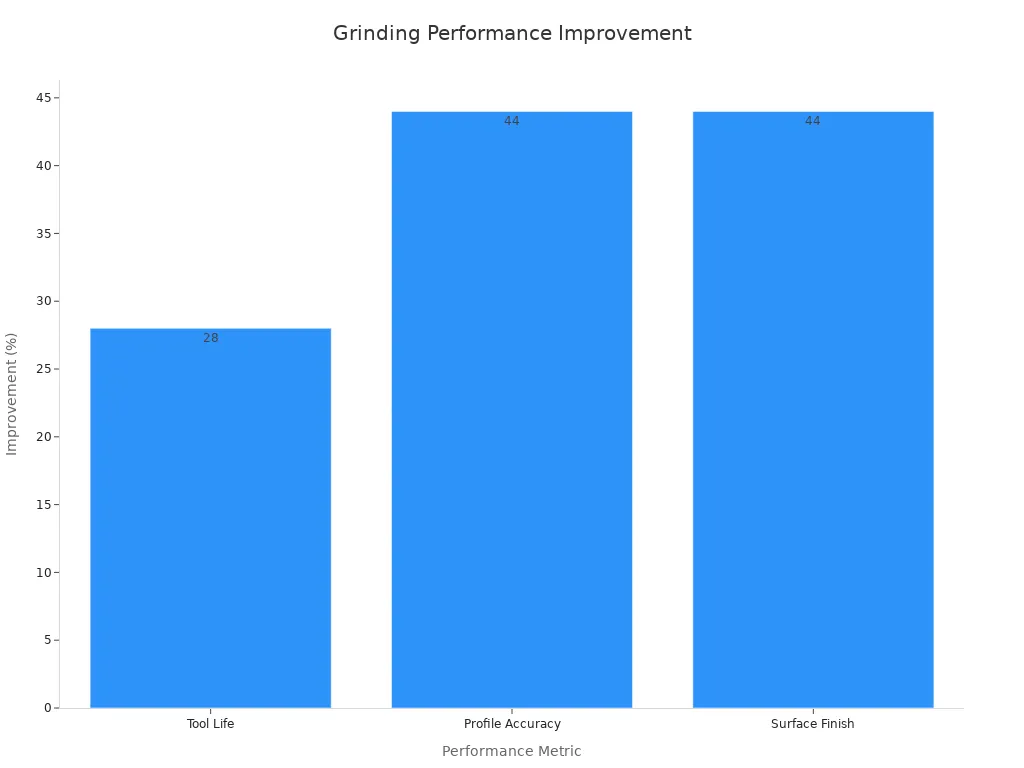

The ratio of metal to resin in the hybrid bond directly affects grinding performance. Increasing the metal content enhances the wheel’s durability and precision. This leads to significant improvements across key metrics.

| Performance Metric | Improvement |

|---|---|

| Tool Life | Up to 28% |

| Profile Accuracy | Up to 44% |

| Surface Finish | Up to 44% |

This powerful combination allows the hybrid grinding wheel to behave like a porous bond. It carries coolant effectively and uses low cutting force. Yet, it maintains the toughness of a metal bond. This makes the hybrid tool ideal for demanding applications on hard materials. The result is faster, more efficient grinding with superior outcomes.

Key Advantages of Hybrid Bonds

Hybrid bond grinding wheels offer significant benefits for modern manufacturing. Their unique composition delivers superior grinding performance, efficiency, and quality. These advantages make them a go-to solution for difficult materials.

Superior Material Removal Rates

Productivity sees a massive boost with hybrid wheels. They can remove material up to 10 times faster than traditional resin bonds. This aggressive cutting action shortens cycle times for any grinding operation. Manufacturers can produce more parts in less time. This efficiency gain directly translates to higher output and profitability. The hybrid design combines speed with precision for optimal results.

Extended Wheel Life

The durable hybrid bond extends the life of the grinding wheel. It draws on the robust principles of high-wear metal bonds, like those perfected by Aimgrind. This strong bond securely holds the superabrasive grains, reducing wear and maintaining the wheel’s shape. The result is excellent profile retention and fewer dressing cycles.

A case study shows the clear advantage of a hybrid wheel over a standard resin-bond wheel in a grinding application:

| Wheel Type | Dress Depth (inches) | Truing/Dressing Cycle Time (minutes) | Grinding Cycle Time (seconds) | Abrasive Cost per Part |

|---|---|---|---|---|

| Resin-bond | 0.010 | 15 | 42 | $0.20 |

| Hybrid | 0.0005 | 3 | 29 | $0.02 |

This data highlights a dramatic reduction in wheel wear and cost per part.

Reduced Grinding Forces

The free-cutting nature of hybrid bond grinding wheels minimizes pressure and heat. The resin part of the bond wears away to expose fresh superabrasive grains. This self-sharpening action lowers grinding forces.

- It prevents thermal damage to the workpiece.

- It reduces the risk of micro-cracks on the material surface.

- It ensures higher part quality and integrity.

This gentle yet effective grinding is crucial for heat-sensitive materials.

Application Versatility

A single hybrid wheel can often replace multiple conventional wheels. Its versatile nature allows it to perform different grinding tasks, from aggressive fluting to fine finishing. For example, one wheel can handle:

- Fluting from solid

- Regrinding

- Gashing and end work

- Relief grinding

This ability to consolidate operations simplifies the manufacturing process. It reduces tool changes and streamlines production, making the entire workflow more efficient.

Key Applications for Hybrid Bond Grinding Wheels

The unique properties of hybrid bond grinding wheels make them ideal for a wide range of demanding applications. They excel in industries where precision, efficiency, and superior surface quality are critical. These wheels provide solutions for grinding some of the toughest materials used in modern manufacturing.

Cutting Tool Manufacturing

The cutting tool industry relies heavily on precision grinding to create sharp, durable tools. A hybrid bond grinding wheel is perfect for tasks like fluting, gashing, and clearance grinding on solid carbide and High-Speed Steel (HSS) tools. Manufacturers of end mills and drills use these wheels to achieve aggressive material removal while maintaining tight geometric tolerances. With extensive experience in the cutting tool industry, brands like Aimgrind understand the need for a cool cutting action and long-lasting superabrasive performance.

Grinding Technical Ceramics

Technical ceramics like silicon carbide and zirconia are extremely hard and brittle. Grinding these materials presents a significant challenge. Hybrid bond grinding wheels solve this problem by combining high stock removal with low grinding forces. This prevents thermal damage and micro-cracks, ensuring the integrity of the ceramic part.

Performance data shows remarkable improvements when grinding technical ceramics:

- Grinding forces reduce by up to 30%.

- Cycle times are cut in half.

- Tool life increases by up to 20 times.

Medical Component Manufacturing

The medical industry demands flawless precision and biocompatible finishes. CBN hybrid wheels are essential for grinding orthopedic components like bone drills and reamers from hardened materials. The controlled grinding action creates ultra-smooth surfaces that meet strict medical standards. These advanced superabrasive wheels are effective on a variety of materials used for medical instruments and implants.

Common materials and applications include:

- Stainless steel, cobalt chrome, and titanium for surgical tools.

- Hardened steels and tungsten carbide for bone drills.

- Ceramic and metal components for knee and hip joints.

Automotive and Aerospace

Automotive and aerospace industries require components that withstand extreme stress and high temperatures. Hybrid bond grinding wheels are used for high-performance grinding applications involving hard-coated powertrain parts, turbine blades, and landing gear components. The wheels deliver the necessary precision for these critical parts. Their ability to hold a sharp profile ensures consistent quality, making them a trusted choice for these high-stakes grinding applications.

A hybrid bond grinding wheel merges the strengths of metal and resin bonds. This creates a powerful tool for high-efficiency grinding on hard materials. The hybrid design delivers faster material removal, longer grinding wheel life, and superior workpiece quality.

As manufacturing evolves, these hybrid innovations are becoming indispensable. They offer an advanced solution for precision industries, reflecting the forward-thinking spirit of brands like Aimgrind. The unique hybrid bond ensures both toughness and flexibility for demanding applications.

FAQ

What makes a hybrid wheel different?

A hybrid bond grinding wheel combines metal and resin bonding agents. This mixture provides the strength and heat resistance of a metal bond. It also offers the free-cutting, self-sharpening action of a resin bond.

What materials are best for hybrid wheels?

These wheels work best on very hard and brittle materials. They are ideal for tungsten carbide, High-Speed Steel (HSS), and technical ceramics. The wheel’s design prevents damage to these sensitive materials.

Can one hybrid wheel perform multiple tasks?

Yes. A single hybrid wheel often handles both aggressive stock removal and fine finishing. This versatility reduces the need for tool changes. It helps streamline the entire manufacturing workflow and improves efficiency.

Are hybrid wheels more cost-effective?

The initial purchase price may be higher than traditional wheels. However, their extended life and faster cycle times often result in a lower cost per part. This makes them a valuable investment for high-volume production.

See Also

Exploring Various Grinding Wheel Types and Their Real-World Uses

Understanding CBN Grinding Wheels: Functionality and Operational Principles Explained

Selecting the Optimal Grinding Wheel for Your Carbide Tooling Needs

Picking the Ideal Bench Grinding Wheel Material for Specific Requirements

Finding the Most Cost-Effective Crankshaft Grinding Wheel for Your Project

Contact Us

For More Grinding Solution or Customized Abrasive Tools