Precision grinding is a cornerstone of modern industrial manufacturing. The market for precision grinding wheels continues to expand, reflecting its importance.

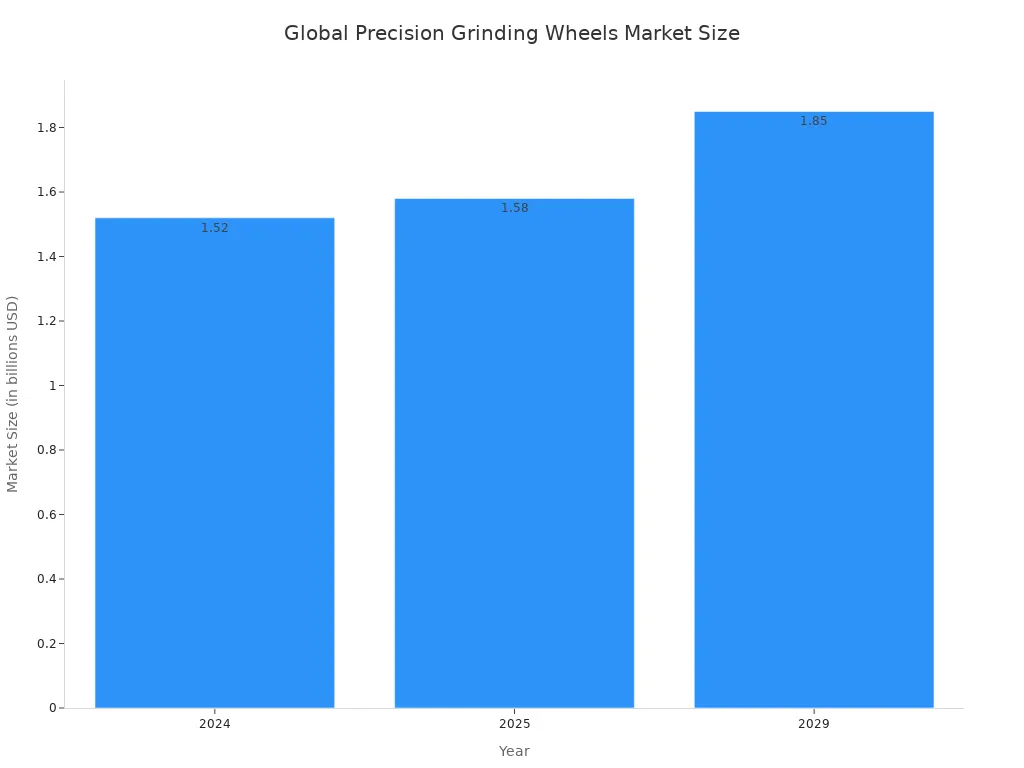

| Metric | 2024 | 2025 | 2029 |

|---|---|---|---|

| Market Size (Precision Grinding Wheels) | $1.52 billion | $1.58 billion | $1.85 billion |

Electroplated grinding wheels excel in many demanding applications, including:

- Aerospace Component Grinding

- Medical Device Manufacturing

- Automotive Powertrain Production

- Precision Tool Grinding

- Electronics and Semiconductor Processing

- Shaping Glass and Ceramics

- Mold and Die Making

As experts in customized solutions, Aimgrind understands these applications and the specific grinding challenges of electroplated grinding wheels intimately.

Key Takeaways

- Electroplated grinding wheels are important in many industries. They help make parts for aerospace, medical, and automotive uses.

- These wheels are very precise. They can shape hard materials like superalloys and ceramics without causing damage.

- Electroplated wheels cut fast and stay sharp. This helps factories make things quicker and with less waste.

- These wheels do not need dressing. This saves time and makes the grinding process easier for workers.

- Aimgrind offers special electroplated wheels. These wheels help improve how well factories make their products.

Aerospace Component Grinding

The aerospace industry demands extreme precision and reliability for every component. Manufacturers use electroplated grinding wheels to shape parts from some of the toughest materials on earth. This advanced grinding technology ensures that components meet strict safety and performance standards.

Application Focus: Turbine Components

Jet engine turbines operate under intense heat and stress. They require components made from high-performance superalloys. The grinding process shapes critical parts like turbine blades and vanes from these durable materials. Common superalloys used include:

- Inconel 188: Used in commercial gas turbine and aerospace applications.

- Inconel 625: Applied in aeronautic and aerospace industries.

- Inconel X-750: Commonly used for gas turbine components, including blades and rotors.

- Inconel 792: Specifically used in gas turbines for its corrosion resistance.

Beyond engines, these wheels also shape composite materials like fiberglass for airframes. Grinding composites is challenging due to their abrasive nature, which can cause rapid tool wear and generate harmful dust. Effective grinding is essential to avoid material damage.

Key Advantages: Form and Durability

Electroplated wheels offer two primary advantages in aerospace: form holding and durability. Their ability to maintain a precise shape is essential for grinding complex aerodynamic profiles, such as the intricate ‘fir-tree’ roots of turbine blades. This ensures every part fits perfectly for maximum efficiency and operational reliability.

These wheels also provide aggressive cutting action. When grinding aerospace alloys, an electroplated CBN grinding wheel can achieve a stock removal rate at least double that of milling. This performance can reduce cycle times by approximately 50%, boosting production efficiency without sacrificing quality. The single, exposed abrasive layer cuts freely, making these wheels highly durable for aggressive grinding on hard materials.

Medical Device Manufacturing

The medical field requires absolute perfection in its tools and implants. Patient safety depends on components that meet the highest standards of precision and material integrity. Electroplated grinding wheels play a vital role in achieving these exacting requirements.

Application Focus: Implants and Surgical Tools

Manufacturers produce life-changing medical devices from biocompatible metals like titanium and stainless steel. The grinding process is essential for shaping orthopedic implants, including hip joints and bone screws, to exact anatomical specifications. It is also a key step in creating sharp surgical instruments. Processes like grinding create the initial sharp edges needed for scalpels and other tools to make precise incisions. These parts then undergo further treatment to ensure they are sterile and have the perfect finish.

Key Advantages: Precision and Finish

Medical device manufacturing demands high precision and an excellent surface finish. The integrity of the material is paramount. Excessive heat during grinding can damage medical-grade metals. It can create a thin, brittle “white layer” on the material’s surface, altering its properties and compromising biocompatibility.

Note: This heat-induced damage can lead to component failure, making temperature control a critical factor in medical grinding operations.

Electroplated wheels excel in this environment. Their single, exposed layer of abrasive cuts freely and efficiently. This action minimizes heat generation, protecting the material from thermal damage. A specialized grinding wheel ensures that each part achieves the desired surface finish without introducing harmful stresses. These wheels provide the control needed to produce safe, reliable, and effective medical devices.

Automotive Powertrain Production

The performance of a vehicle’s engine depends heavily on the precision of its powertrain components. In high-volume automotive manufacturing, efficiency and accuracy are essential. Electroplated grinding wheels provide the speed and control needed to produce reliable engine parts.

Application Focus: Camshafts and Crankshafts

Automakers build engine components like camshafts and crankshafts from durable materials. These parts must withstand constant stress and friction. The manufacturing process often involves form grinding on hardened steel and cast iron to create the final, precise shapes. This grinding step is critical for achieving the exact profiles required for optimal engine timing and power delivery.

Key materials and techniques in this process include:

- Materials: Hardened steel, alloy steel, and cast iron.

- Grinding Techniques: CNC cylindrical grinding and cam grinding for precise shaping.

- Abrasives: CBN superabrasives are often used for their effectiveness on these hard metals.

This specialized grinding ensures each component meets strict engineering tolerances.

The Right Grinding Wheel for Powertrains

Electroplated wheels are the right choice for powertrain production lines. They offer high material removal rates, which speeds up the manufacturing cycle. Their excellent form-holding ability means the grinding wheel maintains its shape, delivering consistent results from the first part to the last. This consistency is vital for mass production.

Precision grinding restores the geometric integrity of crankshafts. It removes tiny imperfections and ensures the part is perfectly round and balanced. This process minimizes engine vibrations, reduces frictional losses, and maximizes power output. A well-ground crankshaft leads to a smoother, more efficient, and longer-lasting engine. These advanced wheels help manufacturers achieve this level of quality efficiently.

Precision Tool Grinding

The performance of cutting tools directly impacts manufacturing quality and efficiency. Precision tool grinding is the process that gives tools like drills and end mills their sharp, effective cutting edges. Manufacturers rely on electroplated grinding wheels to create the complex geometries required for modern, high-performance tooling.

Application Focus: Drills and End Mills

Creating a high-quality drill or end mill involves the precise grinding of its flutes—the helical grooves that evacuate chips and define the cutting edge. The geometry of these flutes determines how the tool performs in different materials. Electroplated wheels are essential for forming these intricate profiles on hard materials like tungsten carbide.

Common flute geometries created through grinding include:

- High Helix: Features a steep angle for fast chip removal in hard materials.

- Low Helix: Uses a shallower angle that reduces chatter in softer materials.

- Variable Helix: An advanced design that changes the helix angle to break up resonance and minimize vibration.

- Straight Flute: A simple design with no helix, used for specific applications.

This grinding process shapes the tool and ensures it meets exact specifications for optimal performance.

Key Advantages: Aggressive Profile Creation

Electroplated wheels excel at aggressive profile creation. Their single layer of superabrasive grit cuts freely and removes material quickly, making the grinding process highly efficient. This capability is crucial for shaping complex tool geometries. Modern end mills with exotic features require a full-fledged CNC tool grinder, as manual grinding can no longer produce these designs without destroying them.

The more intricate the features, the more challenging the grinding becomes. Electroplated wheels rise to this challenge.

The sharp, exposed abrasives on an electroplated grinding wheel allow for the creation of precise, clean profiles without generating excessive heat. This protects the integrity of the tool’s base material. The result is a sharper, more durable cutting edge that delivers superior performance and a longer service life. These wheels provide the aggressive yet controlled action needed for state-of-the-art tool manufacturing.

Electronics and Semiconductor Processing

The electronics industry operates on a microscopic scale where precision is everything. From smartphones to advanced computing systems, performance relies on flawlessly manufactured components. Electroplated grinding wheels provide the accuracy needed to produce these delicate parts.

Application Focus: Wafer Dicing and Ferrites

Semiconductor manufacturing involves a critical step called wafer dicing. This process separates a large silicon wafer into hundreds or thousands of individual chips, known as dies. A high-speed blade, often a specialized grinding wheel, cuts along pre-defined paths called “dicing streets” to create these dies. This grinding process is one of the final steps before the dies are packaged for use in electronic circuits.

Beyond silicon, these wheels also shape other essential electronic components.

- Ferrite Cores: These ceramic parts are vital in managing electrical energy and preventing electromagnetic interference (EMI) in devices for telecommunications, automotive systems, and medical equipment.

- Electrical Carbon Products: Precise grinding is necessary to form these components for various applications.

The precise shaping of these brittle materials is a demanding task that requires specialized grinding tools.

Key Advantages: Minimizing Chip Damage

In semiconductor processing, any damage can be catastrophic. The cut made by a dicing blade is called a kerf, and keeping it clean is essential. Electroplated wheels excel at this task, creating extremely thin and precise kerfs with minimal chipping.

For advanced semiconductor wafers, chip damage larger than 5–10 micrometers can cause the entire die to be rejected. This makes controlled, low-impact grinding a necessity.

The single layer of exposed abrasive on electroplated wheels cuts freely and efficiently. This action reduces heat and mechanical stress on the delicate material, preventing cracks and chips. The result is a higher yield of usable dies and reliable components. These wheels deliver the clean, precise cuts required for high-tech manufacturing, ensuring that even the smallest parts meet strict quality standards.

Shaping Glass and Ceramics

Glass and ceramics are essential materials in many high-tech industries. However, their brittle nature makes them difficult to shape without causing cracks or chips. Manufacturers use specialized grinding techniques to form these materials into precise components for technical and optical applications. This process demands control and accuracy to maintain the material’s integrity.

Application Focus: Technical and Optical Parts

Precision grinding is critical for creating a wide range of advanced parts from glass and ceramic materials. These components are vital in fields from telecommunications to scientific research. The grinding process shapes everything from durable industrial parts to delicate lenses.

Common materials shaped through grinding include:

- Optical components made from glasses like BK7, N-BK7, and fused silica.

- Technical ceramics such as Zirconia and glass-ceramics like Zerodur.

- Advanced single crystals, including Yttrium Aluminum Garnet (YAG).

Each of these materials requires careful handling to achieve the exact dimensions and surface quality needed for its final application.

Shaping with Specialized Grinding Wheels

Electroplated diamond wheels are the ideal solution for shaping brittle materials. Their single layer of exposed abrasive provides an aggressive yet controlled cutting action. This efficiency is crucial for achieving a high-quality finish without damaging the workpiece.

A key benefit is the reduction of thermal damage. Diamond’s excellent thermal conductivity pulls heat away from the grinding zone. This prevents the material from cracking and preserves its structural properties, ensuring a reliable final part.

The hardness of the diamond abrasive ensures the grinding wheel maintains its precise profile for a long time. This longevity makes the wheels highly cost-effective, as it reduces the need for frequent replacements and minimizes machine downtime. Using the right grinding wheel allows manufacturers to achieve tight tolerances and smooth surfaces, turning brittle blanks into high-performance components.

Mold and Die Making

Molds and dies are the foundation of mass production, shaping everything from plastic car parts to metal components. Creating these tools requires finishing intricate cavities and profiles in hardened steel. Electroplated grinding wheels provide the precision needed to produce high-quality injection molds and stamping dies that perform reliably.

Application Focus: Hardened Steel Molds

The performance of a stamping die depends heavily on its profile. Manufacturers must create precise shapes to ensure part quality and extend the tool’s lifespan. Key profile considerations include:

- Stamping Angle: A well-designed angle is essential, and sharp corners must be avoided to prevent premature wear.

- Die Clearance: The space between the punch and die is critical. Too little clearance causes rapid tool wear, while too much clearance results in poor part quality.

- Material Flow: The profile must allow for uniform material flow, preventing defects like wrinkling.

Finishing these complex features in hardened tool steel demands a grinding solution that can hold its form and cut efficiently. Electroplated wheels excel at this task, accurately shaping the critical surfaces of molds and dies.

Key Advantages: Custom and Internal Forms

Electroplated grinding wheels offer unique advantages for mold and die making. Manufacturers can custom-engineer these tools with specific profiles and grit sizes for internal grinding. This allows for the creation of intricate internal forms that would be difficult to achieve with standard tools.

A significant benefit of these wheels is that they do not require dressing. The robust bond holds the abrasive particles securely, maintaining sharpness without needing a dressing cycle.

This no-dressing feature is especially valuable on CNC mills. It eliminates the downtime associated with dressing, maximizing productivity. The absence of dressing also reduces material wastage and ensures consistent cutting performance from start to finish. This reliability makes the entire process more cost-effective. The lack of a dressing step simplifies operations and helps maintain tight tolerances throughout the production run.

Aimgrind’s Electroplated Grinding Wheels

For the demanding applications discussed, choosing the right tool is critical. Aimgrind offers its Electroplated bond grinding wheels as a premier solution, engineered to meet the highest standards of modern manufacturing. These tools provide the performance needed to tackle the toughest materials and most complex geometries.

Designed for Precision and Performance

Aimgrind’s electroplated grinding wheels deliver superior cutting action on hard alloys and ceramics. The design focuses on maximizing abrasive exposure for an aggressive, free-cutting performance. This efficiency comes from an advanced manufacturing process that ensures ultra-high grit retention.

- The electroplating process creates a firm bond between the abrasive particles and the core base.

- This strong bond significantly enhances the durability and grinding efficiency of the tool.

- Strict production controls prevent the plating from peeling, even under extreme grinding conditions.

This robust construction means each grinding wheel maintains its sharpness and form, delivering consistent results in high-stakes industries like aerospace and medical device manufacturing.

The Aimgrind Advantage

The right wheel selection directly impacts productivity and cost. Aimgrind’s grinding wheels provide a strong value proposition through a longer lifespan and minimal material wastage. The unparalleled precision of an electroplated diamond grinding wheel allows for exact material removal, creating a superior surface finish without unnecessary waste.

For manufacturers comparing options, understanding the differences is key. The following table highlights how electroplated wheels perform against other common bond types on hard alloys.

| Feature/Bond Type | Electroplated Wheels | Metal Bond Wheels | Vitrified Bond Wheels |

|---|---|---|---|

| Cutting Action | Aggressive, free-cutting | Robust, consistent | Superior dimensional accuracy |

| Form Holding | Excellent initially | Excellent | Maintains form and precision |

| Durability/Lifespan | Finite, single layer | Exceptional wear resistance | Excellent wear resistance |

| Dressing Requirement | Not applicable | Harder to dress | Requires proper dressing |

This combination of aggressive cutting, form holding, and cost-effectiveness makes Aimgrind’s tools a powerful asset for enhancing operational efficiency.

Electroplated grinding wheels are vital across many industrial manufacturing applications. These grinding wheels offer an excellent finish and hold their form in demanding applications. Their high removal rates ensure a quality finish on complex materials. Aimgrind provides customized electroplated grinding wheels to enhance precision and productivity. Partner with Aimgrind to improve your grinding wheels. Grind with Passion, Achieve with Aim.

FAQ

What are electroplated wheels best for?

They excel at grinding hard, brittle materials like ceramics, superalloys, and glass. Industries such as aerospace, medical, and electronics use them for precision shaping and finishing tasks. Their accuracy is critical for these demanding applications.

What are common mistakes when using grinding wheels?

Two common mistakes are selecting the wrong wheel for the material and ignoring wheel dressing. However, electroplated wheels do not require wheel dressing. This unique feature saves time and simplifies the grinding process for operators.

Are these wheels cost-effective?

Yes, they are. Their strong bond provides a long service life, which reduces replacement frequency. They also cut efficiently. This efficiency minimizes material waste and machine downtime, making them a valuable investment for production.

Can these wheels be used for both wet and dry grinding?

Yes, operators can use them in both wet and dry conditions. Wet grinding is often preferred because it helps control temperature and clear away debris. This versatility makes them suitable for many manufacturing environments.

See Also

Exploring Grinding Wheel Varieties and Their Real-World Uses

Selecting the Ideal Metal Grinding Wheel for Specific Projects

Picking the Perfect Bench Grinding Wheel Material for Every Task

Finding Your Best Grinding Wheel Dresser for Optimal Performance

Selecting the Top Grinding Wheel for Carbide Tool Sharpening

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Contact Us

For More Grinding Solution or Customized Abrasive Tools