To maximize the operational life of your electroplated grinding wheels, you need a strategy that reduces costs and improves grinding efficiency. The key to a longer lifespan involves a three-part approach: optimizing operational parameters, performing consistent maintenance, and ensuring proper handling. Starting with a high-quality, customized electroplated wheel provides a strong foundation. A superior tool leverages the competitive edge of electroplated grinding technology for peak performance from the very first use.

Key Takeaways

- Adjust grinding speed, feed rate, and cut depth. This helps your electroplated wheels work their best.

- Clean your wheel after each use. Also, inspect it for damage. You can recondition worn wheels.

- Handle wheels carefully to avoid damage. Store them in a cool, dry place. Mount them correctly on the machine.

Optimize Parameters for Electroplated Grinding Wheels

You can unlock the full potential of your electroplated grinding wheels by optimizing your operational settings. The right speed, feed, and pressure are essential for top performance. High-quality wheels perform best when you match them with the correct settings. At Aimgrind, our service includes problem diagnosis and parameter matching. We ensure our wheels perfectly suit your process, which enhances the tool’s lifespan from the start.

Select the Correct Wheel Speed

You must operate your wheel at the correct speed. Running a wheel above its maximum rated RPM is dangerous. It creates immense centrifugal force, which pulls the wheel’s mass outward.

- This force increases as the square of the speed. Doubling the speed quadruples the stress on the wheel.

- Exceeding the RPM rating can cause cracks and lead to breakage.

Proper speed ensures both safety and effective grinding.

Control Feed Rate and Cut Depth

You should control the feed rate and depth of cut carefully. Aggressive cuts can overload the single electroplated layer of abrasive. This causes premature grit pull-out and shortens the wheel’s life. A steady, controlled approach allows the diamond or CBN particles to work efficiently. This improves your grinding performance and efficiency without sacrificing the tool’s durability.

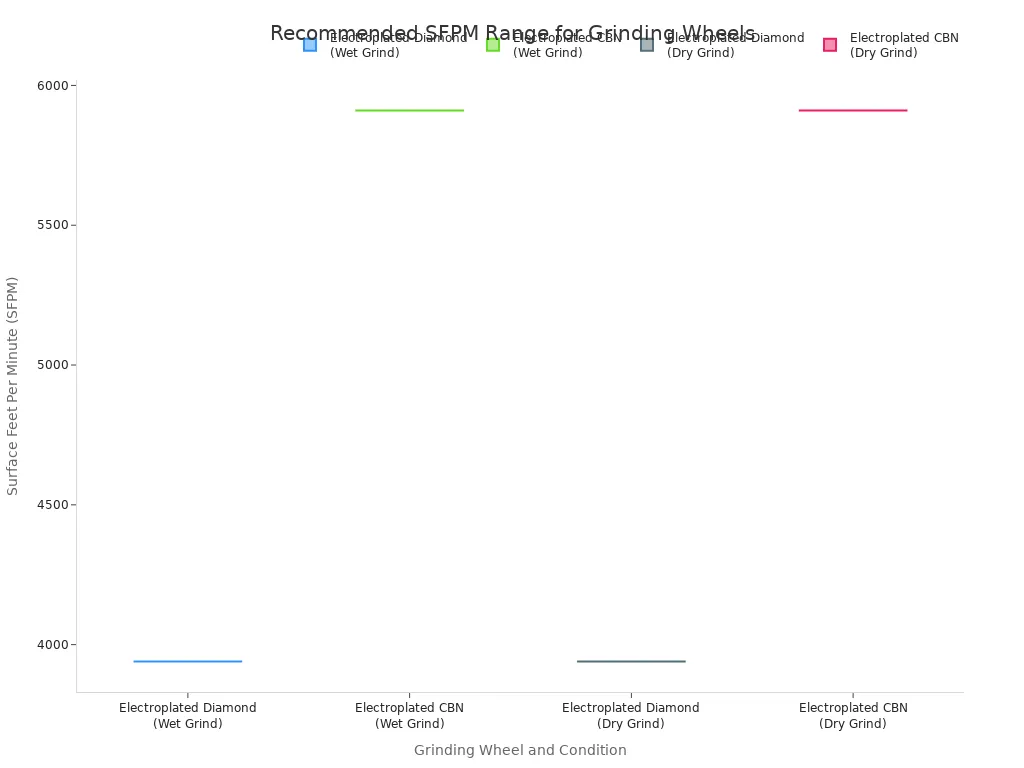

Calibrate Settings for Electroplated Diamond Grinding Wheels

You need to calibrate settings specifically for your wheel type. Electroplated diamond grinding wheels and CBN wheels operate at different optimal speeds. The recommended surface feet per minute (SFPM) varies, as shown below.

| Grinding Condition | Wheel Type | SFPM Range |

|---|---|---|

| Wet Grind | Electroplated Diamond | 3940-6895 |

| Wet Grind | Electroplated CBN | 5910-9850 |

| Dry Grind | Electroplated Diamond | 3940-6895 |

| Dry Grind | Electroplated CBN | 5910-9850 |

Matching the speed to the abrasive type is key for optimal grinding.

Ensure Proper Coolant Application

Pro Tip: Proper coolant use is non-negotiable for extending wheel life. Effective cooling prevents thermal damage to both the workpiece and the wheel.

Coolant also flushes away swarf from the grinding zone. This action prevents the wheel from loading. It protects the strong bond between abrasive and substrate that defines a quality electroplated tool. For grinding hardened steel, a flow rate of 2 to 3 gallons per minute per inch of wheel width keeps the electroplated surface clean and sharp.

Proper Maintenance and Reconditioning

Proper maintenance and reconditioning are vital for getting the most out of your tools. For single-layer electroplated wheels, this process focuses on cleaning and restoring the original cutting surface, not exposing new abrasive. This routine care maximizes the tool’s intended lifespan and ensures consistent grinding results. While Aimgrind’s superior electroplated bond offers excellent grit retention, routine maintenance is still key to peak performance.

Clean the Wheel After Use

You should clean your wheel after every grinding session. Cleaning removes swarf and other debris that can clog the wheel’s surface, a problem known as loading.

Cleaning Tip: You can use a heavy-duty detergent safe for nickel alloys to wash away residue. For hardened steel loading on CBN wheels, some operators use a dressing stick. If you try this, you must be very careful. Secure the stick in a vise and reduce the wheel speed to avoid damaging the electroplated layer.

Regular cleaning keeps the diamond particles exposed and ready to cut efficiently.

The Role of Reconditioning

You can give your wheel a second life through reconditioning. This process is not the same as dressing. Reconditioning involves sending your used wheel back to the manufacturer. There, they will chemically remove the worn diamond layer and old nickel bond. This is the first step in a strip and replate program. After stripping, a fresh layer of diamond grit is applied to the original steel core. This reconditioning returns the tool to a like-new condition. A strip and replate program is a cost-effective choice that reuses the wheel’s body.

Inspect for Damage and Wear

You need to inspect your electroplated grinding wheels regularly. Look for signs of uneven wear, missing diamond grit, or damage to the wheel’s edge. A simple visual check can spot major issues. For a closer look, you can use a microscope to examine the diamond surface for microscopic damage or wear patterns. This simple maintenance step helps you catch problems early. It ensures the tool’s durability and protects the quality of your grinding work.

Ensure Proper Handling and Storage

You can significantly extend the life of your grinding wheels by handling and storing them correctly. Proper care prevents hidden damage that can lead to poor performance and premature failure. Following these practices protects your investment and ensures consistent grinding results.

Handle with Care to Avoid Impact

You must treat your grinding wheels as fragile instruments. A single drop or bump can create hidden cracks that compromise the wheel’s integrity. To prevent this, always handle your diamond wheels with care.

Safety First! 🛡️ Always wear proper Personal Protective Equipment (PPE) when handling wheels. This includes:

- Safety glasses or a face shield

- Durable gloves to protect your hands

This protects you from injury and helps you maintain a secure grip on the wheel.

Never roll a wheel on its edge or pile tools on top of it. Careful handling is the first step toward a longer lifespan for your diamond tools.

Store in a Controlled Environment

You should store your wheels in a stable, controlled environment to maintain their condition. The ideal storage conditions help preserve the wheel’s structural integrity and the bond holding the diamond abrasive.

For optimal durability, store your electroplated wheels in an area with:

- Temperature: 18°C to 22°C (64°F to 72°F)

- Relative Humidity: 45% to 65%

Use racks or shelves to store your wheels. Avoid stacking them directly on top of each other or on concrete floors where they can absorb moisture. Keeping your grinding tools away from direct sunlight, water, and extreme temperatures prevents corrosion and damage.

Mount the Wheel Correctly

You need to mount your electroplated diamond wheel correctly to ensure it runs true and performs well. An improperly mounted wheel can cause vibrations, leading to poor grinding quality and potential damage.

Follow these key steps for proper mounting:

- Inspect Everything: Before you begin, check the diamond wheel for any visible damage. Ensure the machine’s spindle and flanges are clean and free of burrs.

- Use Correct Flanges: Always use clean, matching flanges of the correct size. This ensures even pressure is applied to the wheel.

- Secure Properly: Slide the wheel onto the spindle carefully. Tighten the nut just enough to hold it snug, but do not overtighten. Follow the manufacturer’s torque specifications.

- Test Run: After mounting, stand to the side and let the wheel run for a full minute to ensure it is balanced and running smoothly.

You can extend the lifespan of your electroplated grinding wheels by following three key strategies.

- Optimize your grinding settings.

- Perform consistent maintenance.

- Handle your diamond tools correctly.

You get the best results when you apply these practices to a high-performance tool. An Aimgrind electroplated diamond wheel offers superior durability and grinding performance. This combination ensures your diamond grinding work has maximum diamond grinding efficiency.

Grind with Passion, Achieve with Aim.

FAQ

What is the difference between cleaning and dressing an electroplated wheel?

You clean a wheel to remove debris from its surface. Dressing is an aggressive action that removes bond material. You should only clean single-layer electroplated wheels. This careful cleaning avoids damage and preserves the wheel’s life, unlike dressing which would strip the abrasive.

Can you reuse an old electroplated grinding wheel?

Yes, you can give your wheel a second life. Aimgrind’s strip and replate program reconditions your used tool. We remove the worn abrasive and apply a new layer to the original core. This service restores your wheel to like-new condition cost-effectively.

Why is coolant so important for electroplated wheels?

Coolant is essential for two main reasons:

- It prevents heat damage to your wheel and workpiece.

- It flushes away grinding debris, which stops the wheel from loading.

Proper coolant use keeps the abrasive particles sharp and extends the tool’s operational lifespan.

What should you do if your wheel stops cutting well?

First, you should inspect the wheel for loading or visible damage. A thorough cleaning often restores its cutting performance. If the abrasive layer is completely worn, consider using a reconditioning service to return the tool to its original specifications.

See Also

Selecting the Optimal Metal Grinding Wheel for Your Specific Project

Picking the Perfect Grinding Wheel for Your Stainless Steel Work

Identifying the Ideal Bench Grinding Wheel Material for Your Requirements

Mastering Safe and Effective Usage of Your Dremel Grinding Wheel

Discovering the Premier Grinding Wheel for Your Carbide Tool Sharpening

Contact Us

For More Grinding Solution or Customized Abrasive Tools