A deburring wheel is a specialized abrasive tool. It removes small, sharp imperfections called burrs from a workpiece. These burrs appear after cutting or machining. The primary purpose of a deburring wheel is effective edge deburring. This process creates smooth, safe edges and improves the final finish. Proper edge deburring ensures that components fit together correctly.

In fact, burrs are responsible for 15-20% of assembly failures in parts needing tight tolerances. This highlights the tool’s importance in a global abrasive wheel market projected to reach $42.85 billion by 2025.

Key Takeaways

- A deburring wheel removes sharp edges from metal parts. This makes parts safe and helps them fit together well.

- Burrs are small, sharp pieces of metal left after cutting. They can cause problems if not removed.

- Always wear safety glasses and gloves when using a deburring wheel. Secure your part and use light pressure.

- Different jobs need different wheels. Choose a wheel based on the material, the size of the burr, and how smooth you want the finish to be.

Understanding the Deburring Wheel

What are Burrs?

Burrs are small, sharp pieces of material left on a workpiece after machining. These undesirable projections form from plastic deformation when a tool cuts, drills, or grinds a part. The creation of burrs is a complex process. Several factors influence their size and shape.

- Workpiece Material: Softer, more ductile materials tend to form larger burrs.

- Tool Geometry: The shape and angle of the cutting tool play a significant role.

- Cutting Conditions: Higher speeds and feed rates often increase burr size.

For example, in drilling, burrs at the entrance of a hole are caused by material being pushed sideways. Exit burrs form as the drill pushes through the other side. These exit burrs are often larger and a primary concern in manufacturing. Understanding these factors helps operators predict and manage burr formation.

Primary Functions and Benefits

The main function of a deburring wheel is to remove burrs and create a smooth, clean edge. This process of edge deburring is critical for several reasons. First, it improves the safety of a part by eliminating sharp edges that can cause injuries. Second, it ensures that components fit together correctly in an assembly.

A clean, burr-free finish also improves the aesthetic quality of the final product. This makes the part not only safer and more reliable but also more professional in appearance.

How to Use a Deburring Wheel Safely

Using a deburring wheel on a tool like a bench grinder requires skill and attention to safety. Following a correct procedure ensures a quality finish and protects the operator from injury. Common injuries from improper use include cuts, burns, and serious eye damage.

The Basic Deburring Process

A systematic approach to edge deburring yields the best results. Operators should follow these fundamental steps for a clean and safe outcome.

- Secure the Workpiece: An operator must firmly clamp the workpiece. This prevents it from moving unexpectedly during the process.

- Mount the Wheel: The correct deburring wheel must be mounted securely on the bench grinder.

- Apply Light Pressure: The user holds the tool at a 15 to 30-degree angle to the burr. They apply gentle, consistent pressure to remove the imperfection without damaging the part.

- Move Along the Edge: Smooth, controlled movements along the burr’s edge create a cleaner finish. The operator should avoid pushing too hard.

- Inspect the Work: After a pass, the operator inspects the edge. They repeat the process if any burrs remain.

Essential Safety Practices

Safety is the top priority when operating a bench grinder. Neglecting safety measures can lead to wheel breakage, flying debris, or tool kickback.

Always wear proper Personal Protective Equipment (PPE). OSHA standard 1915.134(j) mandates eye protection. Safety glasses and gloves protect against flying particles and sharp edges.

Key safety rules include:

- Ensure the wheel’s maximum RPM rating is higher than the speed of the bench grinder.

- Use the machine’s safety guards. OSHA requires guards that can contain fragments if a wheel breaks.

- Keep the work area clean and free of flammable materials to prevent trips and fires.

- Never wear loose clothing or jewelry that could get entangled in the bench grinder.

Mounting Wheels Correctly

Proper mounting is critical for safe operation. An improperly mounted wheel can cause severe vibration, leading to poor results and equipment failure. Before mounting, operators should inspect and ring-test wheels for hidden cracks, as required by OSHA.

A wheel must fit freely on the spindle of the bench grinder. It should never be forced. The spindle nut should be tightened just enough to hold the wheel securely. Signs of an improperly mounted wheel include visible misalignment or excessive wobble. Using a wheel that is damaged or the wrong size for the grinder is a primary cause of accidents.

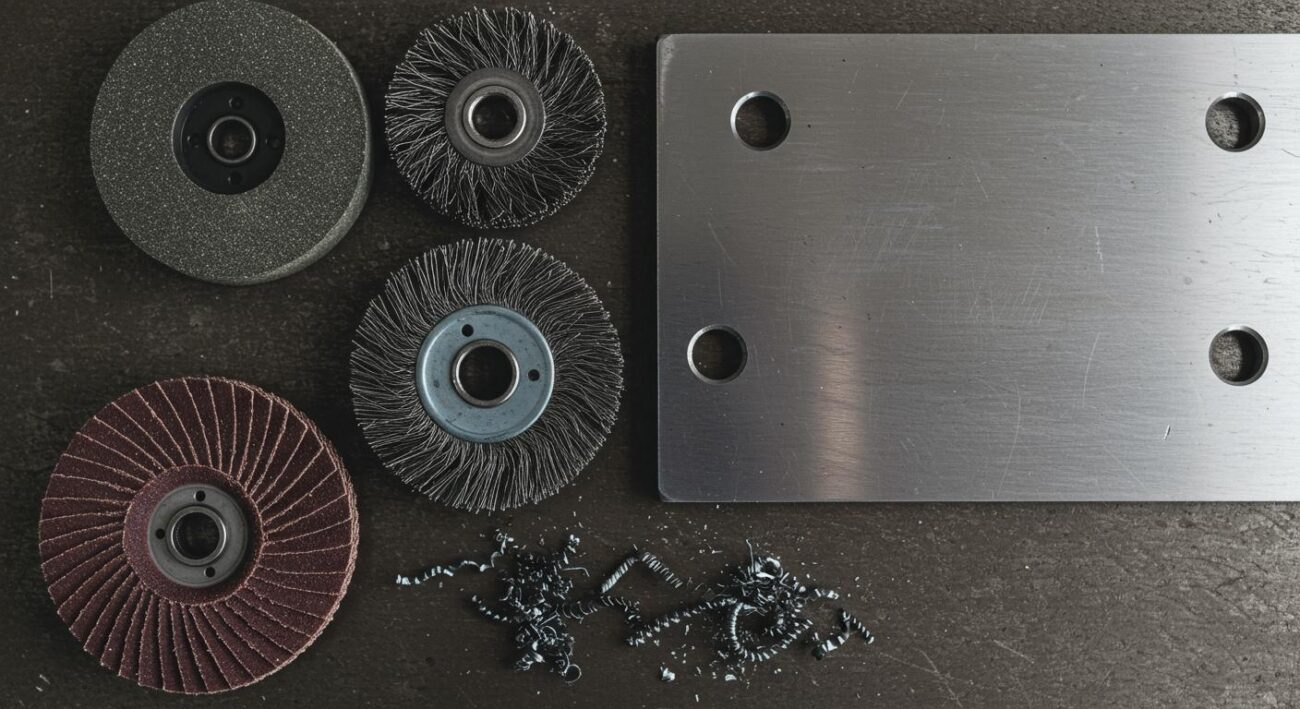

Common Types of Deburring Wheels

Choosing the right tool is essential for effective deburring. Different materials and desired finishes require specific types of wheels. Each wheel has a unique construction and abrasive material designed for particular tasks, from aggressive material removal to fine polishing.

Wire Wheels for Heavy-Duty Jobs

Wire wheels are aggressive tools used for heavy-duty cleaning and deburring. They consist of metal wire bristles attached to a central hub. These wheels excel at removing rust, paint, and heavy scale from metal surfaces. Operators often use them for weld cleaning and preparing surfaces for painting or coating. Carbon steel wire wheels are effective for these general-purpose tasks but should not be used on stainless steel, as they can cause contamination.

Wire wheels come in two main styles: knotted and crimped. Each offers a different level of aggressiveness and produces a different finish.

| Feature | Knotted Wire Wheels | Crimped Wire Wheels |

|---|---|---|

| Aggressiveness | Very aggressive | Mild to moderate |

| Surface Finish | Rough, uneven finish | Smoother, more uniform finish |

| Best For | Heavy rust, weld scale | Light deburring, surface prep |

| Typical Use Cases | Industrial descaling, pipelines | Finishing, metal polishing |

The Scotch Brite Wheel for Finishing

The scotch brite wheel is a popular name for a non-woven abrasive wheel. These wheels are excellent for finishing, blending, and light deburring. Their unique structure sets them apart. They are made of a non-woven web of nylon fibers combined with abrasive grains, such as aluminum oxide.

This open-web construction is a key feature. It resists loading up with debris and helps the wheel run cool. This prevents damage to the workpiece and ensures the wheel cuts consistently for a longer time.

These wheels are widely used in the aerospace and automotive industries for detailed work. Common applications include:

- Deburring and finishing rotors, shrouds, and turbine buckets.

- Blending surfaces on gears and engine components.

- Cleaning up machined and stamped parts.

Flap Wheels for Blending

Flap wheels are versatile tools for blending, finishing, and deburring. They are constructed from hundreds of overlapping abrasive cloth flaps, or “pages,” arranged around a central hub. This flexible design allows the wheel to conform to contours and irregular surfaces without gouging the material. As the flaps wear down, they expose fresh abrasive grains, providing a consistent cutting rate throughout the wheel’s life.

Flap wheels offer several advantages over solid grinding wheels for blending tasks.

- They operate at a cooler temperature, reducing the risk of burn marks.

- They produce less vibration, leading to reduced operator fatigue.

- They create a superior surface finish with less gouging.

- Operators have better control, which makes them easier to use for less-skilled workers.

Aimgrind’s Diamond Grinding Wheels

For the hardest materials, standard abrasives are not enough. Diamond grinding wheels are necessary for precision work on materials like ceramics, hard alloys, and composites. These wheels use diamond particles as the abrasive, offering exceptional durability and cutting power. Brands like Aimgrind specialize in high-performance diamond grinding wheels designed for these demanding applications.

A high-quality diamond deburring wheel provides unmatched precision. Its robust construction ensures a long service life and efficient material removal, which is critical in industries like aerospace and electronics. When an operator needs to create a perfect, burr-free edge on a ceramic component or a superhard metal part, these are the good wheels for the job. Using the right diamond deburring wheels ensures a flawless finish where other tools would quickly wear out or fail.

How to Choose the Right Deburring Wheel

Selecting the correct deburring wheel is crucial for achieving a quality finish. An operator must consider the workpiece material, the size of the burrs, and the desired final appearance. The right choice ensures efficient work and protects the part from damage.

Material Compatibility

Different materials require different types of deburring wheels. Matching the wheel to the workpiece prevents issues like loading, where the wheel clogs with material. For non-ferrous metals like aluminum or brass, a silicon carbide wheel is an excellent choice. These good wheels are engineered to prevent clogging and minimize heat.

- Cool, Clean Cuts: They reduce heat buildup, which protects softer metals from warping.

- Non-Loading Performance: The wheel’s bond resists clogging, ensuring it cuts freely on materials like aluminum and bronze.

- Sharp Abrasive Grain: Premium silicon carbide provides sharp, fast cutting action for efficient edge deburring.

Using the wrong wheel, such as a standard carbon steel wire wheel on stainless steel, can cause contamination and rust. An operator must always select a wheel compatible with the metal to achieve the best results.

Burr Size and Aggressiveness

The size of the burr dictates the aggressiveness of the wheel needed. Larger burrs require a more aggressive wheel with a larger grit size for effective material removal. Finer grits are less aggressive and produce a smoother finish. Using a fine grit on a large burr will take too long and wear out the wheel. Using a coarse grit for a small burr can damage the part.

The type of wheel also determines its aggressiveness.

| Brush Type | Aggressiveness | Burr Classes Removed |

|---|---|---|

| Nylon Abrasive Filament | Least Aggressive | Class 1, 2 (sometimes 3) |

| Crimped Wire | More Aggressive | Class 3, some 4 |

| Knot Wire | Most Aggressive | Class 3, 4 |

Choosing the right level of aggression saves time and ensures the workpiece meets its required specifications.

Using a Light Deburring Wheel

For delicate parts or applications requiring tight tolerances, a light deburring wheel is the ideal tool. Overly aggressive material removal can ruin sensitive components. A light deburring wheel offers control and precision, preventing damage. Its unique construction provides several key benefits.

- Soft Construction: A light deburring wheel requires less operator effort, reducing the chance of applying too much pressure.

- Conformability: It adapts to the part’s shape, ensuring a consistent finish while maintaining critical dimensions.

- Cool Operation: The non-woven web design resists loading and minimizes heat, which prevents part discoloration and warping.

- Fine Abrasive: It often uses a fine-grade silicon carbide abrasive, perfect for low-pressure work that results in a superior finish.

These features make a light deburring wheel one of the good wheels for finishing aerospace components or other high-precision parts.

Desired Final Finish

The final goal for the workpiece edge determines the wheel selection. Some jobs only require removing sharp points to make a part safe to handle. Other applications demand a specific chamfer or a perfectly rounded edge to meet engineering standards. For example, industry guidelines often specify a maximum edge break of 0.015 inches for steel parts. Advanced ceramic components may require a minimum chamfer of 0.020 inches to improve durability.

The Society of Manufacturing Engineers (SME) outlines several levels of edge finishing:

- Deburring not required: The edge is left as is.

- Break sharp edges: The edge is smooth enough not to cut hands.

- Remove all visible burrs: No projections are visible to the unaided eye.

- Remove burrs visible at magnification: No burrs are visible under a specified magnification.

- Break edges to a minimum dimension: The edge must have a specific minimum chamfer.

An operator must understand these requirements to select the right tools. A coarse wire wheel might be fine for breaking sharp edges, but achieving a specific radius requires a more precise tool like a flap wheel or a specialized diamond wheel.

A deburring wheel is an essential tool for removing sharp, unwanted edges after manufacturing. Successful deburring depends on a structured approach. An operator must choose the correct wheel for the material, use a step-by-step process with light pressure, and always prioritize safety with proper PPE. Implementing a better process yields significant results. For example, one aerospace manufacturer improved its deburring method and saw great benefits.

- Cycle time fell by 30%.

- Scrap rates dropped by 18%.

- The final surface finish improved.

This shows how the right tools and techniques enhance both quality and efficiency.

FAQ

What is the main difference between a wire wheel and a scotch brite wheel?

A wire wheel is for aggressive jobs like removing heavy rust. A scotch brite wheel is less aggressive. It is used for finishing, blending, and light edge deburring. The choice depends on the required finish.

Can I use any deburring wheel on my bench grinder?

No. An operator must match the wheel’s RPM rating to the bench grinder’s speed. Using a wheel with a lower RPM rating is dangerous. It can cause the wheel to break during use.

When should I use a light deburring wheel?

A light deburring wheel is for delicate parts. It offers precision for jobs needing tight tolerances. These good wheels prevent damage and ensure a high-quality finish on sensitive components without removing too much material.

How do I know which deburring wheels to choose?

An operator chooses deburring wheels based on the material, burr size, and desired finish. For example, a coarse wheel removes large burrs. A fine wheel creates a smooth surface. The right deburring wheel ensures quality work.

See Also

Selecting the Ideal Grinding Wheel Dresser for Your Specific Needs

Mastering Safe and Effective Dremel Grinding Wheel Operation

Understanding CBN Grinding Wheels: Functionality and Core Principles

Exploring Diverse Grinding Wheel Types and Their Real-World Uses

Contact Us

For More Grinding Solution or Customized Abrasive Tools