You need the best tool for the job. Here are the top-rated Abrasive Sticks you can buy today:

- Gesswein Ultramax Ceramic: Best Overall

- Boride Polishing Stones: Best for Mold Polishing

- Norton Abrasives Sticks: Best for Deburring

- Aimgrind Super Hard Abrasives: Best for Custom Solutions

The industrial abrasives market is projected to exceed USD 70 billion by 2032. This guide details why these Abrasive Sticks are top-rated and their ideal applications. You can find the perfect match for your project.

Key Takeaways

- Different abrasive sticks work best for different jobs, like polishing, deburring, or sharpening.

- Gesswein Ultramax Ceramic sticks are great for detailed finishing work on molds and small parts.

- Boride Polishing Stones are best for making molds very smooth, especially for specific types of steel.

- Norton Abrasives Sticks are good for general tasks like removing rough edges from metal.

- DMT Diamond Sharpening Sticks are needed for sharpening very hard materials that other tools cannot handle.

Our Top Abrasive Stick Picks

This section breaks down our top choices. You will learn what makes each stick a leader in its category. We will explore their features and best uses to help you make an informed decision.

Best Overall: Gesswein Ultramax Ceramic

Gesswein Ultramax Ceramic stones are the top choice for all-around performance. These sticks use ceramic fibers. This material gives you incredible strength and precision. You can use them for delicate finishing work on molds, dies, and other intricate parts. The fibers cut in all directions. This allows you to polish tight corners and complex surfaces with ease. Their structure prevents clogging and ensures a consistent finish from start to finish.

Best for Mold Polishing: Boride Polishing Stones

Boride is the professional’s choice for mold polishing. You need the right grit to achieve a perfect finish on tool steels like P20 and H13. Boride offers a wide range of stones designed for specific materials. This ensures you get optimal results every time.

💡 Pro Tip: Matching the stone to the steel is critical. Using the wrong grit can damage your mold and create more work.

Here is a guide to help you select the right Boride stone for common tool steels:

| Polishing Stone | Materials | Recommended Grit Ranges for P20/H13 |

|---|---|---|

| AM-K | All mold steels, including P20 | 400 and 600 grit for finishing |

| CS-M | Pre-hardened tool steels, like H-13 | 120-1200 grit |

| CS-HD | All mold and die steels, including H-13 | 120-1200 grit |

| AO | P20 | 120-1200 grit |

| 900-F | P20 | 900 grit |

| T2 | P20, H-13 | 150-1200 grit |

Best for Deburring: Norton Abrasives Sticks

Norton Abrasives Sticks are workhorses for deburring and general-purpose tasks. You can use them to remove sharp edges, clean threads, and dress grinding wheels. These sticks are made from durable aluminum oxide or silicon carbide. They offer excellent cutting action and a long lifespan. Their simple, effective design makes them a must-have in any workshop for quick cleanup and maintenance jobs.

Best for Sharpening: DMT Diamond Sharpening Stick

When you need to sharpen the hardest materials, you need a DMT Diamond Sharpening Stick. DMT uses a unique monocrystalline diamond surface. This gives you remarkable sharpening speed and durability.

What makes monocrystalline diamonds special?

- Strong Structure: Each diamond is a single, complete crystal. It does not break apart easily.

- Slow Wear: The surface wears very slowly, giving the tool a long life.

- Uniform Surface: The diamonds are precisely sized and bonded in nickel, ensuring a consistent sharpening experience.

In contrast, many competitors use polycrystalline diamonds. These are fragmented compounds that can fracture and wear away quickly. DMT’s superior construction means you get a reliable sharpener that performs for years.

Best for Belt Cleaning: POWERTEC Natural Rubber Stick

You can extend the life of your sanding belts and discs with a POWERTEC Natural Rubber Stick. Over time, sanding belts get clogged with wood dust and resin. This buildup reduces their cutting ability and can burn your workpiece.

The cleaning process is simple. You just hold the stick against the moving sanding belt. The friction and heat cause the rubber to melt slightly, pulling the clogged particles away. This action instantly restores the belt’s cutting surface.

Using this stick saves you money. You will buy fewer sanding belts and get more consistent results from your sander.

Best for Custom Solutions: Aimgrind Super Hard Abrasives

Sometimes, an off-the-shelf product is not enough. You may have a unique material or a high-precision application. Aimgrind specializes in creating custom grinding solutions. They do not just sell Abrasive Sticks; they engineer them for your specific needs. Using super hard materials like diamond and cubic boron nitride (CBN), Aimgrind develops tools for the most demanding industries, such as aerospace and precision tool manufacturing. Their process involves diagnosing your problem and designing a tool with the perfect material, bond, and grit to optimize your work.

Top Abrasive Stick Reviews

This section gives you a closer look at our top picks. You will discover the key features that make each stick a standout choice. We will explore their ideal uses to help you select the right tool for your specific project.

Gesswein Ultramax: Precision and Finesse

You need Gesswein Ultramax stones for tasks that demand ultimate precision. These tools are not ordinary Abrasive Sticks; they are engineered for detailed finishing work.

- Ceramic Fiber Structure: The sticks use strong ceramic fibers. This unique construction allows you to apply pressure without the stick breaking. The fibers cut cleanly on both forward and backward strokes.

- Multi-Directional Cutting: You can polish complex shapes, tight corners, and narrow slots with ease. The stick’s end and sides are equally effective, giving you complete control.

- Ideal Applications: Use these for finishing molds, dies, and other intricate metal parts. They excel at removing machine marks and achieving a uniform surface.

Note: The structure of Gesswein stones resists loading. This means they do not clog with material, ensuring a consistent finish from start to finish.

Boride Polishing Stones: The Professional’s Choice

You can trust Boride Polishing Stones for professional-grade mold and die polishing. Boride offers a wide variety of stones, so you can perfectly match the abrasive to the tool steel you are working on. This precision is key to achieving a flawless, mirror-like finish.

| Stone Series | Application/Grit Performance | Hardness/Wear Characteristics | Finish Produced |

|---|---|---|---|

| AS-9 | Great for 120, 320, 600, and 1000 grit work. | Wears slowly and is harder than many other stones. | Creates a bright, semi-polished finish. |

| T2 | A top performer at 400 grit and very popular for 800 grit. | N/A | N/A |

Choosing the right series and grit helps you work more efficiently. You will remove material effectively without damaging the workpiece.

Norton Dressing Sticks: Durable and Versatile

You will find Norton Dressing Sticks to be essential tools for workshop maintenance. These sticks are built for durability and versatility. Their primary job is to “dress” or clean the surface of grinding wheels. Dressing removes clogged material and exposes fresh abrasive grains, restoring the wheel’s cutting ability.

Norton makes these sticks from tough Aluminum Oxide. This material provides excellent cutting action for a variety of tasks.

- Cleaning and shaping grinding wheels.

- Deburring sharp edges on metal parts.

- General-purpose sharpening and honing.

Their simple, rugged design makes them a reliable and cost-effective solution for keeping your other abrasive tools in top condition.

DMT Diamond Sharpeners: For the Hardest Materials

When you face the toughest materials, you need the superior power of a DMT Diamond Sharpener. These sharpeners use a surface of monocrystalline diamonds. This gives you incredible sharpening speed and a tool that lasts for years.

DMT sharpeners are effective on an extremely wide range of hard materials. You can easily sharpen items that other tools cannot handle. This includes:

- Tungsten carbide tools

- Hardened tool steels

- Tough composites

- Various ceramics

- Even polycrystalline diamond inserts

The single-crystal structure of the diamonds ensures they do not fracture or wear down quickly. You get a consistent, flat sharpening surface every time, making them a smart investment for any serious craftsperson or fabricator.

POWERTEC Cleaning Stick: Extend Sanding Belt Life

You can save money and improve your results with the POWERTEC Cleaning Stick. Sanding belts and discs quickly clog with wood dust, resin, and other debris. This buildup reduces cutting efficiency and can cause burn marks on your project.

Using this stick is simple. Just press it gently against your moving sanding belt or disc. The friction generates heat, which melts the rubber just enough to pull the embedded particles out of the abrasive.

This action instantly restores the cutting surface of your sanding belts. You will buy fewer replacements and achieve a more consistent finish on your work. It is a simple tool that provides significant value.

Specialty Spotlight: Aimgrind Super Hard Abrasives

Sometimes, a standard abrasive stick does not meet your project’s demands. You might work with unique materials or require extreme precision. This is where a specialist provides the perfect solution.

The Aimgrind Advantage: Customization and Quality

Aimgrind delivers custom grinding solutions engineered for your specific needs. The company does not just sell products; it partners with you. Their process starts with diagnosing your grinding challenge. Then, they design a tool with the ideal material, bond, and grit to optimize your work. This comprehensive service ensures you get an abrasive stick that is perfectly matched to your equipment and process.

Aimgrind’s slogan, “Grind with Passion, Achieve with Aim,” reflects their commitment. They focus on creating high-quality, customized tools that boost your productivity and efficiency.

Diamond and CBN: The Ultimate in Hardness

Aimgrind’s custom solutions often use super hard abrasives. These tools feature diamond or cubic boron nitride (CBN) grains. These are two of the hardest materials known. You can choose the right one based on the material you are grinding.

| Feature | CBN Grinding Wheel | Diamond Grinding Wheel |

|---|---|---|

| Primary Use (Ferrous) | Hard ferrous materials (e.g., steel, cast iron) | Not feasible for low carbon steel |

| Primary Use (Non-Ferrous) | Less common for non-ferrous | Hard and brittle materials (e.g., ceramics, glass) |

| Surface Finish | Good, but less fine than diamond | Excellent, ideal for fine finishes |

| Grinding Speed | Can perform well at high speeds | Can handle higher speeds |

Applications in High-Precision Industries

Industries like aerospace and precision tool manufacturing rely on these super hard abrasives. The tools offer incredible longevity and create a superior surface finish. This efficiency is critical for high-stakes applications. The bond holding the abrasive grains together also plays a key role.

| Abrasive Stick Type | Bonding Agent/Material | Manufacturing Process | Key Characteristics |

|---|---|---|---|

| Vitrified-bonded | Clay and other ceramic materials | Fused at very high temperatures | Strong, rigid, porous, glass-like material |

| Resin-bonded (Resinoid) | Synthetic resins (e.g., phenolic) | Resins mixed with grains, then heat-cured | Tough, slightly flexible plastic |

By customizing both the abrasive and the bond, Aimgrind creates tools that solve the toughest grinding challenges. You get a solution built for performance and durability.

Choosing the Right Abrasive Sticks

You need to select the right tool to get the best results. This guide will help you understand the key factors in choosing the perfect abrasive sticks for your project.

Abrasive Material Guide

The material of your abrasive stick determines what it can grind. Silicon Carbide is a popular and versatile choice. It is extremely hard and resists heat well. This makes it great for tough jobs.

💡 Did You Know? Silicon Carbide has a Mohs hardness of 9.5, making it almost as hard as diamond.

You can use Silicon Carbide for many materials:

- Hard materials like glass, stone, and ceramics

- Metals with low tensile strength, such as cast iron

- Precision polishing of tough alloys like titanium

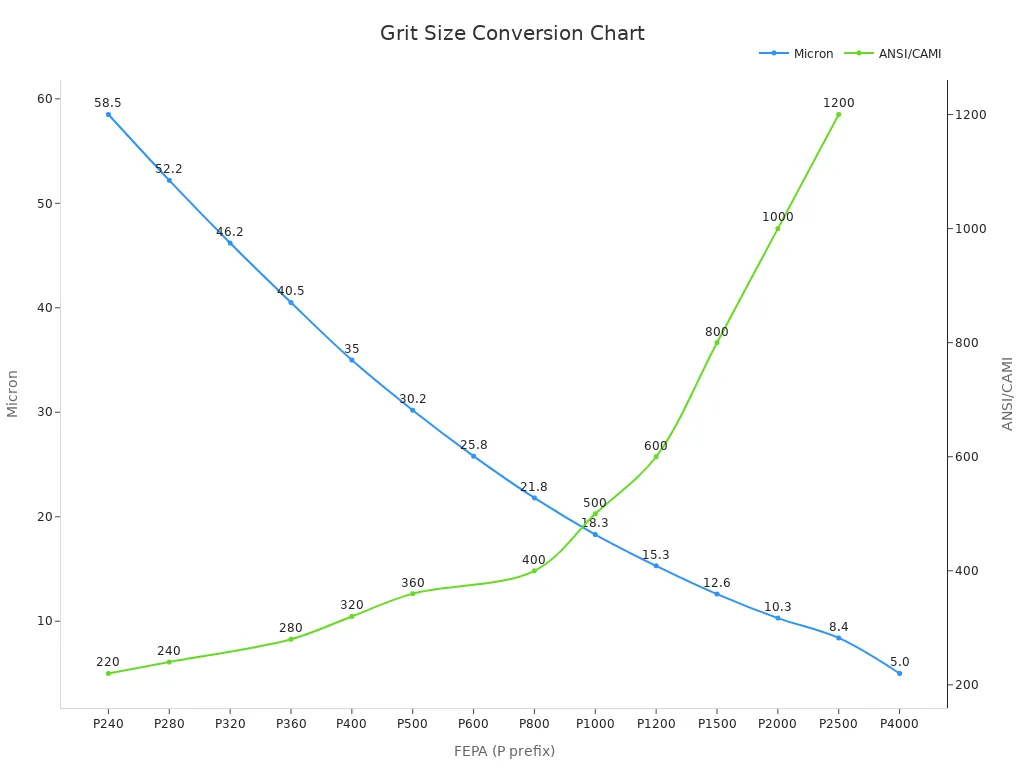

Understanding Grit Size

Grit size tells you how coarse or fine an abrasive is. A lower number means a coarser grit, which removes material quickly. A higher number means a finer grit, which creates a smoother finish. Different rating systems exist, so you can use a chart to compare them.

| FEPA (P prefix) | Micron | ANSI/CAMI |

|---|---|---|

| P400 | 35 | 320 |

| P800 | 21.8 | 400 |

| P1200 | 15.3 | 600 |

| P2500 | 8.4 | 1200 |

Matching Stick to Application

The bond holds the abrasive grains together. The bond’s hardness affects how the stick performs. You must match the bond to your task for optimal results.

| Bond Hardness | Performance Effect |

|---|---|

| Too Soft | Wears down too fast and has a short tool life. |

| Too Hard | Becomes dull quickly and requires frequent cleaning. |

| Optimal | Wears at the right pace to expose fresh, sharp grains. |

An optimal bond ensures the stick cuts efficiently and lasts longer.

Shape and Size Considerations

The shape of your stick helps you work on different surfaces. Each shape has a specific purpose.

| Shape | Primary Use |

|---|---|

| Square | General sharpening and flat surfaces. |

| Triangular | Getting into sharp corners and V-grooves. |

| Round | Polishing curved surfaces and holes. |

Choosing the right shape allows you to work more effectively in tight or complex areas.

You now have the knowledge to choose the best tool. For precision work, you can select Gesswein. For professional polishing, you can rely on Boride. For unique, high-performance needs, you can turn to Aimgrind.

The key to success is simple. You must match the right material and grit to your specific job.

These expert insights will help you select the perfect Abrasive Sticks. You can now confidently tackle any project and achieve outstanding results.

FAQ

What is the best abrasive stick for beginners?

You should start with a versatile option. A Norton Abrasives Stick made from aluminum oxide is a great choice. It works well for general deburring and cleanup tasks. This stick helps you learn basic techniques without a large investment.

What is the main difference between ceramic and diamond sticks?

You choose the stick based on your material.

- Ceramic sticks, like Gesswein, are excellent for detailed finishing on molds and dies.

- Diamond sticks, like DMT, sharpen the hardest materials, including carbide and hardened steel.

Why do I need a dressing stick for my grinding wheel?

You use a dressing stick to clean your grinding wheels. Over time, wheels get clogged with metal and old abrasive. A dressing stick removes this buildup. This action exposes fresh, sharp grains and restores the wheel’s cutting performance.

When should I consider a custom abrasive solution?

You need a custom solution for unique challenges. If standard sticks fail on your material or you require extreme precision, contact a specialist. Aimgrind creates custom tools with diamond or CBN for industries like aerospace and tool manufacturing.

See Also

Selecting the Optimal Crankshaft Grinding Wheel for Your Budgetary Needs

Finding the Ideal Grinding Wheel Dresser for Your Specific Requirements

Expert Guide: Selecting the Premier Grinding Wheel for Carbide Tooling

Picking the Perfect Bench Grinding Wheel Material for Your Workshop

Exploring Diverse Grinding Wheel Types and Their Real-World Applications

Contact Us

For More Grinding Solution or Customized Abrasive Tools