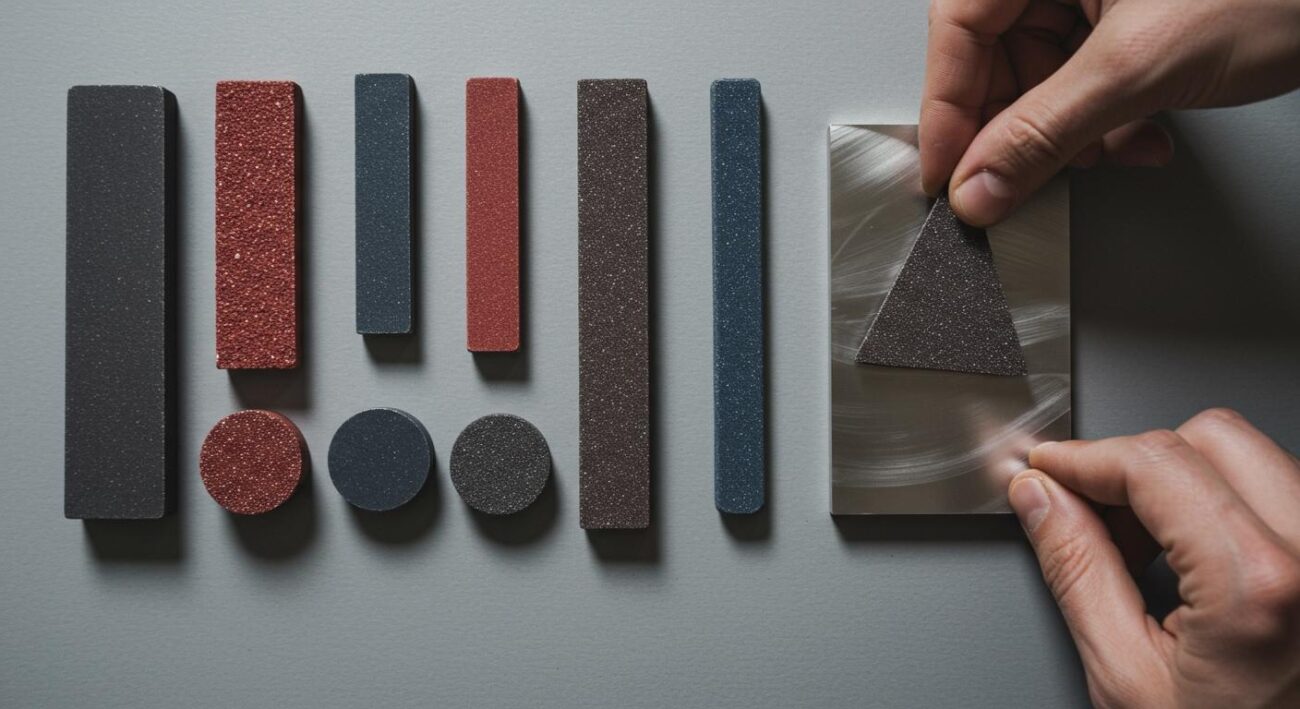

Proper maintenance for your Abrasive Sticks involves three key steps: cleaning, dressing, and storage. Mastering these practices will significantly extend the life of your tools. You can achieve consistent, peak performance from your Abrasive Sticks with a simple routine. This habit ensures top performance and saves you money over time by preventing common issues.

Key Takeaways

- Clean your abrasive sticks after each use to prevent clogging and keep them cutting well.

- Dress your abrasive sticks regularly to make them sharp again and improve how they cut.

- Store your abrasive sticks in a dry place with a steady temperature to protect them from damage.

Clean Your Abrasive Sticks

A clean tool is an effective tool. Regular cleaning is the first line of defense against poor performance, ensuring your abrasive sticks deliver excellent results every time you start a grinding job.

Prevent Clogging and Loading

During grinding, small particles of metal and debris can get stuck on your tool. This buildup is called “loading.” When a stick is loaded, the material gums up and attaches itself to the bond surface. This clogs the tool and covers the sharp abrasive particles. As a result, the stick can no longer cut effectively, which reduces its cutting performance and slows down material removal. This clogging also increases friction, hindering the smoothing process and leading to a rougher final surface.

Use Brushes and Compressed Air

You can easily remove this buildup with a couple of simple tools.

- Stiff-bristled Brush: Use a wire or firm nylon brush to scrub the surface of the stick. This action dislodges most of the caked-on debris.

- Compressed Air: After brushing, use compressed air to blow away any remaining loose particles. This leaves you with a clean, ready-to-use tool.

Safety Tip 💡: Always wear safety glasses when using compressed air to protect your eyes from flying debris.

Establish a Cleaning Routine

The best way to prevent loading is to clean your tools regularly. Make it a habit to clean your abrasive sticks after each grinding session. This simple step prevents severe buildup and ensures your tools are always ready for the next task. Consistent maintenance is crucial for getting the best performance out of high-quality tools, such as Aimgrind‘s durable conventional bonded abrasives made from aluminum oxide and silicon carbide. A clean tool maintains its cutting performance, extends its lifespan, and gives you the precision needed for quality grinding.

Dress and True for a Fresh Surface

Over time, even the best abrasive sticks wear down. Constant grinding can cause the tool’s surface to become smooth and shiny, a condition known as “glazing.” This happens when heat and pressure make the tool lose its cutting ability. To fix this, you need to perform dressing and truing.

The Goal of Dressing and Truing

People often use the terms dressing and truing interchangeably, but they are two distinct jobs for restoring your grinding wheels.

- Truing restores the tool’s geometric shape. It makes sure the profile is correct and concentric.

- Dressing is the process of exposing fresh, sharp abrasive grains. It removes clogged material and worn-down bond from the surface.

Both actions are vital. A glazed or out-of-shape tool will slide instead of cut, which ruins your grinding performance and leads to a poor surface finish. Regular dressing ensures your tool is always ready for effective grinding.

Tools for Restoring Shape

You can use several tools for dressing grinding wheels. The right tool depends on your needs and the type of grinding you do.

| Tool Type | Description | Best For |

|---|---|---|

| Star Dressers | These have free-spinning, star-shaped cutters. | Creating a rough, open surface for aggressive grinding. |

| Diamond Dressers | These use industrial diamonds. | Achieving a smooth, precise finish. They are very durable. |

For many applications, diamond dressing sticks offer an excellent balance of precision and durability, making them a valuable tool for maintaining your grinding wheels.

Restore Your Surface for Better Grinding

The main benefit of dressing is creating a fresh cutting surface. The process removes dull grains and clears away excess bond material. This exposes the sharp abrasive particles underneath, which dramatically improves cutting efficiency. A properly dressed surface allows your tool to cut aggressively and achieve a smoother finish. This control is essential for precision grinding. When your tool’s surface is perfectly prepared, you can maintain tight tolerances and produce high-quality work consistently.

How to Properly Store Abrasives

Your work doesn’t end when the grinding stops. How you store abrasives directly impacts their lifespan and performance. Proper storage protects your investment and ensures your tools are ready for the next job.

Maintain a Dry Environment

Moisture is the enemy of abrasive tools. High humidity can cause the bonding material to absorb water, which reduces its strength by up to 30%. This makes the tool less effective and more prone to accidents.

- High Humidity: When humidity is too high, the abrasive can soften and lose its shape. This leads to clogging and early grit loss.

- Low Humidity: When the air is too dry, the tool can become brittle and crack easily.

Pro Tip 💡: You should store abrasives in a space with a relative humidity between 45% and 65%. This humidity controlled storage environment prevents moisture damage and keeps your tools in optimal condition.

Control Storage Temperature

Extreme temperatures and rapid temperature changes can ruin your tools. Fluctuations cause the bonding material to expand and contract, creating tiny microcracks that weaken the entire structure. This damage reduces the tool’s cutting ability and overall strength. For best results, you should store abrasives in a room with a stable temperature between 60°F and 80°F (18°C and 22°C). Keep your abrasive sticks away from direct sunlight, heaters, and cold concrete floors.

Use Racks or Original Packaging

Proper physical storage prevents accidental damage. Keeping your tools in their original packaging is an excellent way to protect them. The packaging shields them from moisture and makes them easier to stack and handle.

If you remove the tools from their packaging, place them flat on a shelf or in a storage rack. Avoid hanging them on pegboards. Hanging exposes both sides to changes in temperature and humidity, which can compromise the tool’s integrity. A good storage habit ensures your tools remain flat, stable, and ready for precise work.

Maximizing your abrasive stick’s performance is straightforward. Your success boils down to three essential habits that protect your investment and guarantee quality work.

- Clean your sticks after each use.

- Perform dressing to restore the cutting surface.

- Store them in a proper environment.

This simple routine is the secret to consistent, high-quality results. You will unlock the best performance from your tools and extend their lifespan, ensuring you get greater value with every grind.

FAQ

How often should I dress my grinding wheels?

You should dress your grinding wheels when you notice glazing or a drop in performance. A good rule is to dress the tool when the grinding action feels slow. This simple step restores the surface for efficient grinding.

Can I use water to clean my abrasive sticks?

It is best to avoid water. Moisture can weaken the bond in many abrasive tools. You should use a stiff brush and compressed air for cleaning. This method safely removes debris without risking damage to your tools.

What is the difference between aluminum oxide and silicon carbide?

Aluminum oxide is great for grinding strong metals like steel. Silicon carbide works best on harder materials like cast iron. Your choice depends on the material you are grinding. Both are excellent abrasives for different types of grinding wheels.

Why is proper storage so important for grinding wheels?

Proper storage protects grinding wheels from damage. It prevents cracks from temperature changes and weakening from humidity. Good storage ensures your tools are safe and ready for your next job, maintaining their performance and integrity.

See Also

Selecting Optimal Grinding Wheels for Precision Carbide Tool Sharpening

Finding the Perfect Bench Grinding Wheel Material for Specific Applications

Mastering Safe and Effective Techniques for Dremel Grinding Wheel Operation

Identifying the Most Suitable Grinding Wheel Dresser for Your Workshop

Picking the Ideal Metal Grinding Wheel for Your Specific Project

Contact Us

For More Grinding Solution or Customized Abrasive Tools