Your concrete projects demand efficiency, a superior finish, and long-term value.

Forget slow, messy, and labor-intensive grinding. Modern diamond abrasive technology offers incredible speed and precision.

Using the right diamond grinding cup wheels is essential for modern construction. These powerful concrete grinding cup wheels are a critical investment. They help you deliver consistent, professional results every time. This guide explains why this tool is vital for your success.

Key Takeaways

- Diamond grinding wheels make concrete projects faster and more efficient. They remove material quickly and precisely.

- These tools help create a superior finish. They prepare concrete surfaces for coatings and smooth out uneven spots.

- Using diamond grinding wheels saves money over time. They last longer and prevent costly rework.

- Diamond grinding wheels help keep your workspace clean and safe. They minimize dust when used with proper equipment.

- Choosing the right diamond wheel is important. Match the wheel’s type, grit, and bond to your specific concrete project.

The Power of Diamond Grinding Cup Wheels

Diamond grinding cup wheels are powerful surface preparation tools that transform how you work with concrete. They offer an aggressive grinding action that drastically reduces labor hours compared to older, less effective methods. You can power through tough materials and surface imperfections with unmatched speed.

Boost Job Site Speed and Efficiency

You can significantly increase your job site productivity with the right tools. Concrete grinding cup wheels allow you to remove material quickly and precisely. For many projects, you can remove between 0.01 and 0.1 inches of concrete in a single pass. This efficiency is crucial for heavy duty applications where time is money. Using diamond cup wheels means you finish jobs faster, reduce worker fatigue, and move on to the next project sooner.

Erase Bumps, Glues, and Mastics

Old coatings and uneven spots can ruin a new floor finish. A diamond cup wheel makes removing these stubborn materials simple. You can easily grind away a variety of tough substances.

- Mastic and Glue Residues

- Old Paint and Epoxy Coatings

- Uneven Concrete Bumps

For especially difficult coatings, a PCD (Polycrystalline Diamond) cup wheel is an excellent choice. It is widely used on angle grinders to remove paint, epoxy, glue, mastic, acrylic, and other residues with ease.

Minimize Dust for a Cleaner Workspace

Concrete grinding creates fine dust containing respirable crystalline silica. This dust is a serious health hazard. OSHA regulations limit worker exposure to just 50 micrograms per cubic meter of air (50 μg/m³). Using diamond grinding cup wheels with a proper dust shroud and a HEPA vacuum system is the best way to control this risk. This setup captures up to 95% of airborne dust, creating a cleaner, safer workspace for everyone. These concrete grinding cup wheels help you comply with safety standards and protect your team’s health.

Deliver a Superior Finish

A high-quality finish is the hallmark of a professional concrete project. Diamond grinding wheels give you the control needed for exceptional surface prep and finishing. You can transform rough, imperfect concrete into a perfectly smooth and prepared canvas. This preparation is the key to a durable and beautiful final floor.

Prepare Flawless Concrete Surfaces

You need to create the right texture for coatings to stick properly. The International Concrete Repair Institute (ICRI) created the Concrete Surface Profile (CSP) standard to measure this. The scale runs from CSP 1 (very smooth) to CSP 10 (very rough). You can use physical CSP chips to visually and physically compare your work, ensuring your concrete surfaces match the required profile for the job. This step guarantees your surface preparation is accurate.

Achieve a Uniform Profile for Coatings

Diamond grinding wheels produce a perfectly even grind. This avoids the “zebra stripes” or “hot spots” that other methods like shot blasting can leave behind. A uniform profile ensures coatings apply evenly and bond correctly. Different coatings require specific profiles for the best adhesion.

| Coating Type | Required CSP Level |

|---|---|

| Epoxy | 3-5 |

| Thick Urethanes | 5-7 |

Achieving the correct CSP with a diamond grinder means you use less coating material and prevent costly failures. The planetary grinding action creates a flat, monolithic surface, removing imperfections for a flawless result.

Smooth and Level Uneven Spots

Uneven concrete surfaces are a common problem. Diamond grinding easily corrects these issues, creating a flat and safe floor. Common causes of unevenness include:

- Slab curling from uneven drying

- Over-poured areas or screed build-up

- Heaving or slab movement over time

- Poorly set formwork or old repairs

Pro Tip 💡: When using a handheld grinder to level a joint, avoid removing more than two inches of material. Removing too much can weaken the concrete slab.

By smoothing these spots, you eliminate trip hazards and create a professional look for all your concrete surfaces.

Maximize Long-Term Value

Investing in the right tools is about more than just the initial price. High-quality concrete grinding cup wheels deliver significant long-term value. You save money, avoid project setbacks, and ensure your work lasts for years. This smart investment pays for itself through superior performance and durability.

Why Concrete Grinding Cup Wheels Save Money

You can lower your operational costs by choosing durable tools. Diamond abrasives are incredibly tough and last much longer than conventional options. This means you spend less time and money replacing worn-out wheels. The extended lifespan of diamond tools keeps your projects on budget.

| Wheel Type | Lifespan (hours) |

|---|---|

| Conventional Wheel | 8 – 16 |

| Diamond Wheel | 800 – 1,200 |

This durability means a single diamond grinding cup wheels can handle the work of dozens of conventional wheels, offering a clear financial advantage.

Reduce Costly Rework and Delays

Mistakes in surface preparation lead to expensive problems. When a floor coating fails because of poor adhesion, the repair costs can be huge. Getting the surface right the first time with concrete grinding cup wheels prevents these costly failures and project delays. Proper preparation is your best insurance against rework.

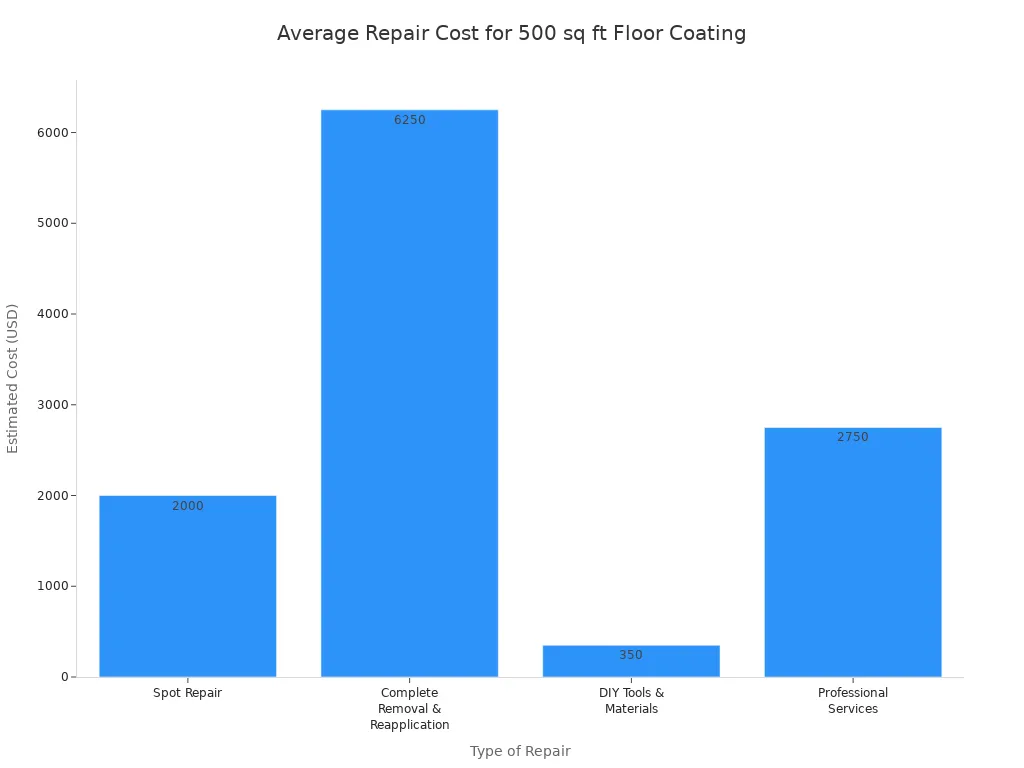

The chart below shows the average costs to fix a failed 500 sq. ft. floor coating. A complete removal and reapplication can cost thousands of dollars, all because the initial surface was not prepared correctly.

Extend the Life of Floor Coatings

A perfectly prepared surface is the foundation for a long-lasting floor coating. Diamond grinding creates the ideal texture for epoxies and sealers to bond securely. This strong bond prevents peeling, chipping, and premature wear. Your finished floors will look better and last much longer.

Proper grinding can extend the life of an epoxy coating by more than 50 percent. This is due to improved adhesion and a significant reduction in surface failure.

By using the right tools for your surface preparation, you directly increase the value and durability of the final product for your clients.

Choosing the Right Aimgrind Diamond Cup Wheels

Selecting the right tool is crucial for your project’s success. Aimgrind is a specialized brand offering customized grinding solutions. With deep expertise in formula design, Aimgrind ensures your tool is perfectly matched to your equipment and material. Their comprehensive service helps you find the ideal diamond cup wheels for all your concrete flooring needs.

Double Row Wheels for Stability

You should choose a double row diamond cup wheel for aggressive grinding and fast material removal. These wheels provide excellent stability for heavy duty applications. Use them for tasks like:

- Grinding down high spots on floors and sidewalks

- Removing old paint and coatings

- Preparing concrete, stone, and brick surfaces

Turbo Row Wheels for a Smooth Finish

You can achieve a smoother finish with turbo row wheels. These wheels feature slanted segments that improve airflow and reduce heat, making them great for both wet and dry grinding. While still aggressive, they offer a better finish than double row wheels. For an even smoother profile, a 24-segment wheel works better than a 12-segment version.

Specialized Wheels for Coating Removal

Some coatings require a specialized tool. Polycrystalline Diamond (PCD) wheels are designed to remove tough materials without smearing. You can use them to strip away:

- Thick mastics

- Old, stubborn paints

- Carpet glues and VCT adhesives

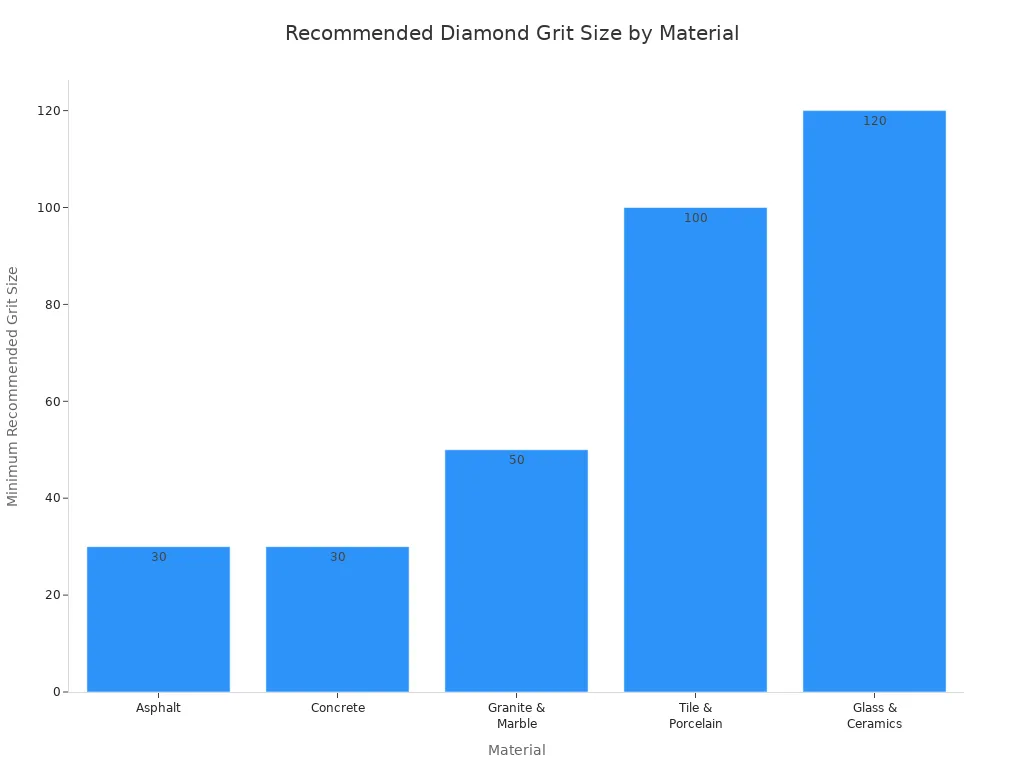

Understanding Grit and Bond Hardness

You need to match the wheel’s grit and bond to the concrete. The general rule is to use an opposite bond hardness.

| Concrete Hardness | Recommended Bond |

|---|---|

| Soft Concrete | Hard Bond |

| Medium Concrete | Medium Bond |

| Hard Concrete | Soft Bond |

Grit size determines the roughness of the finish. Lower grit numbers mean faster, more aggressive removal, while higher numbers create a smoother surface. For most concrete grinding cup wheels, a 30-50 grit is a great starting point.

Choosing the correct concrete grinding cup wheels ensures you get professional results efficiently and safely.

Your projects deserve the best results. You gain unmatched efficiency, a flawless surface, and great long-term value with the right tools. Using high-quality diamond grinding cup wheels from a specialized brand like Aimgrind means you work smarter, not harder. You deliver a higher standard of quality on every job.

Take the next step! 🚀 Invest in the right grinding technology. You will guarantee the success and durability of your concrete projects for years to come.

FAQ

What makes diamond grinding wheels better than regular ones?

You will find diamond wheels last much longer. Their industrial-grade diamonds remove concrete faster than conventional abrasives. This saves you significant time and money on replacements. They provide superior performance for tough jobs.

Can I use a diamond cup wheel on my standard angle grinder?

Yes, you can use diamond cup wheels on most standard angle grinders. You must match the wheel’s arbor size to your grinder’s spindle. Always check the tool’s maximum RPM rating to ensure it is compatible with the wheel for safe operation.

Do I need to use water when grinding concrete?

You can grind concrete wet or dry. Wet grinding cools the wheel and eliminates dust. Dry grinding is more common and requires a dust shroud connected to a HEPA vacuum.

Safety Tip 💡: Always use a dust collection system for dry grinding. This protects your health and keeps the job site clean.

How do I choose the right grit for my project?

You should choose a low grit number (like 30) for fast material removal. Use a high grit number (like 100+) for a smoother finish. A 30-50 grit is a great all-purpose choice for most concrete preparation tasks.

See Also

Selecting The Optimal Metal Grinding Wheel For Your Specific Project

Picking The Perfect Grinding Wheel For Your Carbide Tooling Needs

Identifying The Ideal Grinding Wheel For Your Circular Saw Blade

Selecting The Appropriate Bench Grinding Wheel Material For Your Requirements

Discovering The Most Effective Grinding Wheel Dresser For Your Usage

Contact Us

For More Grinding Solution or Customized Abrasive Tools