A diamond grinding wheel delivers exceptional precision and efficiency. It leverages diamond’s unparalleled hardness and advanced bonding systems for superior grinding performance.

The global market for approximately USD 1.2 billion in 2023, reflecting their critical role in modern manufacturing.

This post explores the science behind these powerful tools. It draws on insights from industry experts like Aimgrind to explain how they master the toughest materials.

Key Takeaways

- Diamond grinding wheels use the hardest material on Earth, diamond, to cut very tough materials like ceramics and tungsten carbide.

- The wheel’s design, including the size and shape of diamond grains and how they are held together, helps it cut well and last a long time.

- New technologies, like porous diamonds and special coatings, make these wheels even better at cutting precisely and quickly.

- The wheel’s core, called the hub, helps stop shaking during grinding, which makes the finished product smoother and more accurate.

- Managing heat and clearing away tiny bits of material are important for the wheel to work best and create a high-quality surface.

The Science of Diamond Grinding Wheels

The performance of diamond grinding wheels comes from a deep understanding of material science. The diamond itself, its specific characteristics, and new technologies all play a role in creating a superior tool for high-speed grinding.

The Unmatched Hardness of Diamond

Diamond is the hardest known natural material. This incredible strength comes from its molecular structure. Each carbon atom shares strong covalent bonds with four other carbon atoms. These atoms form a rigid tetrahedral unit. This interconnected lattice creates an incredibly strong and stable molecule, giving diamond a perfect 10 on the Mohs hardness scale.

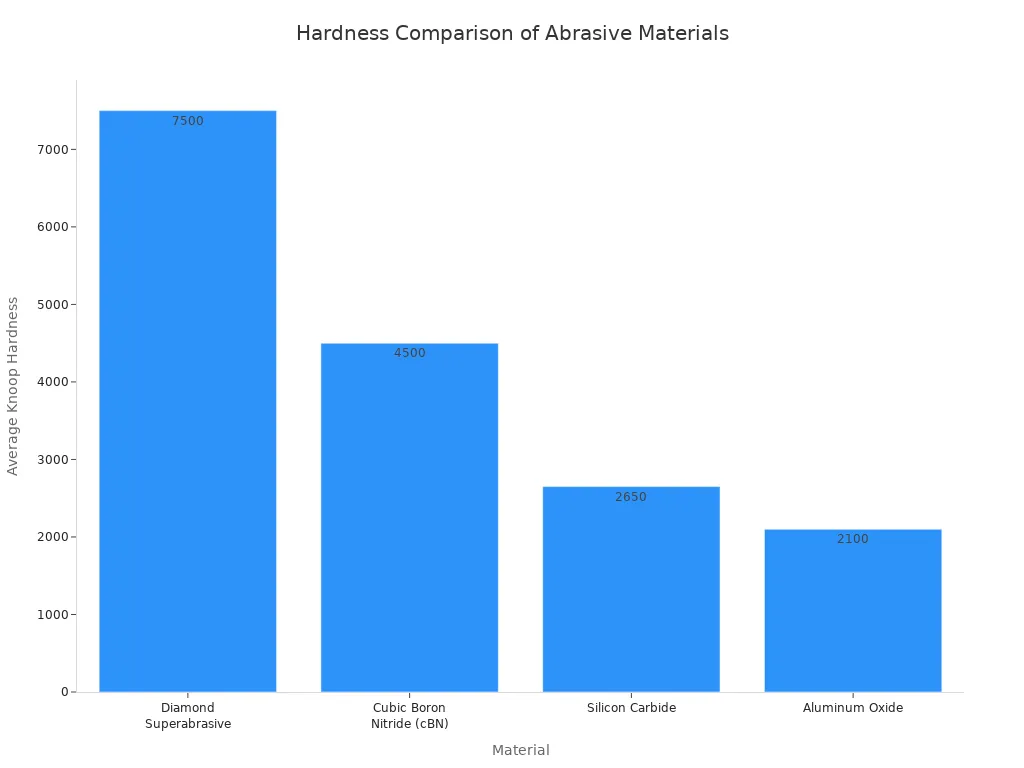

Conventional abrasive materials cannot match this hardness. A comparison shows the significant difference in cutting power.

| Material | Knoop Hardness |

|---|---|

| Diamond Superabrasive | 7000-8000 |

| Cubic Boron Nitride (cBN) | 4000-5000 |

| Silicon Carbide | 2500-2800 |

| Aluminum Oxide | 2000-2200 |

This unmatched hardness is essential for precision grinding of ultra-hard materials. Materials like tungsten carbide, ceramics, and sapphire substrates require an abrasive that is significantly harder to achieve efficient material removal. Diamond’s cutting capability makes it the primary choice for these demanding jobs.

Grain Size, Shape, and Concentration

Scientists and engineers carefully select the properties of the diamond grains to control grinding performance. Three key factors are size, shape, and concentration.

- Grain Size: The size of the diamond grains, measured in mesh or microns, directly controls the material removal rate. Larger, coarser grains create more space for chip removal and cut more aggressively. This leads to faster material removal. Smaller, finer grains produce a smoother surface finish.

- Grain Shape: The shape of the abrasive grains affects the cutting action. Friable grains have an irregular shape and are designed to fracture during use. This process constantly exposes new, sharp cutting edges, which is ideal for achieving a fine polish. Blocky grains are more durable and last longer but can become dull over time.

- Grain Concentration: This measures the amount of diamond grains in a given volume of the abrasive layer. A higher concentration provides more cutting points. This increases the tool’s lifespan and makes the wheel act harder.

💡 Expert Tip: The ideal combination of these three factors depends entirely on the material and the desired outcome. Specialists like Aimgrind provide personalized selection services. They help customers match the right diamond grains to their specific equipment and processes for optimal results.

Innovations in Abrasive Technology

The field of abrasive technology is always advancing. New innovations are pushing the boundaries of what diamond grinding wheels can achieve in high-speed grinding applications. These advancements focus on improving efficiency, precision, and tool life.

One key innovation is the use of porous diamond grains. These engineered grains create microscopic pores within the abrasive structure. This design offers several benefits:

- It improves coolant flow to the cutting zone, reducing heat.

- It prevents the wheel from clogging with material, ensuring consistent removal.

- It lowers grinding forces, which increases energy efficiency.

Another major advancement is Chemical Vapor Deposition (CVD). This process grows a pure, binder-free diamond film directly onto the tool’s surface, atom by atom. CVD diamond grinding wheels offer super high grain density and uniform abrasive dispersion. This technology is crucial for ultra-precision grinding and ultra-precision machining. The pure diamond coating provides exceptional wear resistance and allows for the creation of extremely sharp cutting edges, leading to nanometer-level surface finishes. These CVD diamond grinding wheels are vital in aerospace and electronics manufacturing.

Finally, new micro-structured diamond abrasives are changing high-speed grinding. These include agglomerated diamond (AD) grains that offer excellent micro-cutting and self-sharpening abilities. This ensures a high material removal rate over long periods. Such innovations in abrasive design make precision grinding more efficient and stable, especially for the toughest materials.

The Structure: Bonds, Hubs, and Stability

The structure of diamond grinding wheels is just as important as the abrasive grains. The bond system, which holds the abrasive grains, and the hub, which provides stability, are engineered to maximize grinding performance, especially in high-speed grinding.

Bond Systems and Grinding Performance

The bond system is the matrix that holds the abrasive grains in place. Its wear rate is scientifically engineered to achieve a “self-sharpening” effect. As the wheel works, the bond slowly erodes, allowing dull abrasive grains to fall away and expose new, sharp grains. This process is crucial for maintaining consistent grinding performance. If the bond is too strong, worn abrasive grains and debris clog the wheel, reducing its cutting ability.

Did You Know? When a wheel becomes clogged, a process called “dressing” is used. Dressing removes the loaded material and dull grains from the wheel’s surface, restoring its porosity and cutting efficiency for high-speed grinding.

Aimgrind’s Customized Bond Solutions

Choosing the right bond is critical for optimizing grinding wheel performance. Different bonds offer unique properties for specific tasks. Experts at Aimgrind help customers select the ideal formula for their material and high-speed grinding needs. The primary bond types include resin, metal, vitrified, and electroplated.

| Bond Type | Wear Resistance | Thermal Stability | Best For |

|---|---|---|---|

| Resin | Good | Lower | Carbide, ceramics, glass |

| Metal | High | High | Stone, construction materials |

| Vitrified | Moderate | Excellent | Precision grinding of brittle materials |

For example, resin bonds are excellent for high-speed grinding of tough materials like tungsten carbide. Vitrified bonds, with their high porosity, are perfect for the precision grinding of ceramics because they allow coolant to flow freely.

Hub Materials and Vibration Damping

The hub is the core of the grinding wheel and provides structural support. In high-speed grinding, vibrations known as “chatter” can occur. These vibrations create a poor surface finish and can damage the workpiece or the tool, limiting productivity in high-speed applications.

To solve this, manufacturers use advanced hub materials. Carbon Fiber Reinforced Polymer (CFRP) is a modern choice that significantly dampens vibrations compared to traditional steel hubs. By reducing chatter, these advanced hubs improve surface quality, increase grinding wheel life, and ensure stable, effective high-speed grinding. This stability is essential for achieving the highest levels of precision grinding.

Engineering the Cut for Peak Efficiency

Engineering the cut is about controlling the interaction between the grinding wheel and the workpiece. This control maximizes efficiency and ensures a high-quality finish. The mechanics of material removal, the pursuit of accuracy, and effective chip evacuation are all critical for peak performance in high-speed grinding.

The Mechanics of Material Removal

Material removal in grinding is a complex process. It involves a shearing action where the diamond grains interact with the workpiece surface. This interaction happens in three main ways:

- Cutting: The sharp edges of the diamond grains shear the material, creating chips. This is the most effective mode for material removal.

- Plowing: The grains push material aside without forming a chip. This deforms the surface plastically.

- Rubbing: The grains slide against the surface, creating friction and heat but very little material removal.

The dominant cutting mechanism depends on the depth of the cut. A shallow cut might only cause rubbing. As the depth increases, the process transitions from plowing to cutting. The size of the diamond grains also affects this transition. Larger grains can shift to the cutting phase at a shallower depth, which improves the material removal rate and overall efficiency. Understanding this relationship is key to optimizing high-speed grinding operations.

Achieving Precision Grinding

Achieving precision grinding requires extreme stability and control. Two essential maintenance procedures are truing and balancing. Truing shapes the wheel so its cutting surface runs perfectly round and true to the machine’s spindle. Balancing ensures the wheel’s weight is evenly distributed. An unbalanced or out-of-true wheel causes vibrations, or chatter, during high-speed grinding. This leads to poor surface finishes and can damage the workpiece.

🌡️ Heat Management is Critical: High-speed grinding generates intense heat. If not managed, this heat can cause thermal damage, such as softening or cracking the workpiece surface. This is a major concern in precision manufacturing. Proper coolant application is vital for controlling temperature and ensuring high workpiece processing quality. This control is essential for both high precision grinding and ultra-precision machining.

These steps are fundamental to achieving the tight tolerances required in ultra-precision grinding. They ensure the diamond grains make consistent, predictable contact for flawless removal of material.

Enhancing Chip Evacuation

Effective chip removal is crucial for maintaining grinding efficiency. If chips and abrasive debris are not cleared from the cutting zone, they can clog the wheel. This clogging reduces cutting performance, increases heat, and can scratch the workpiece, lowering the quality of the final product. The goal is to ensure a clean path for the diamond grains.

Coolant plays a double role here. It dissipates heat and also flushes away chips. Advanced coolant systems use high-pressure nozzles to deliver a powerful, coherent jet of fluid directly into the grinding zone. This enhances the removal of debris. Some modern wheels even feature special designs to improve this process.

- Slotted Wheels: These wheels have grooves or segments that act as channels. They carry more coolant to the cutting area and provide extra space for chip removal.

- Porous Grains: Wheels made with porous grains allow coolant to flow through the abrasive structure, improving cooling and chip removal from within.

These innovations in wheel design and coolant delivery are vital for sustained high-speed grinding, boosting efficiency and extending the life of the tool. They ensure a clean, effective cutting mechanism for superior micro-structured surfaces.

Three scientific pillars support superior grinding performance. Diamond’s hardness provides the cutting force. An engineered bond system maintains sharpness. The wheel’s structure ensures stability and precision. The efficiency of modern diamond grinding wheels shows the power of this science. For businesses seeking better efficiency and grinding performance, partnering with a specialist like Aimgrind applies these principles directly to their challenges. This partnership optimizes grinding performance.

Grind with Passion, Achieve with Aim.

FAQ

What materials can diamond wheels grind?

Diamond grinding wheels are ideal for very hard materials. They effectively grind tungsten carbide, technical ceramics, sapphire substrates, and hard composite materials. Their unmatched hardness allows them to cut materials that conventional abrasives cannot handle efficiently.

Why are there different bond types?

Different bond types hold the diamond grains and control the wheel’s performance. Resin bonds offer good finishes on carbide. Metal bonds provide high durability for stone. Vitrified bonds ensure precision on brittle materials. Experts like Aimgrind help select the best bond for each job.

Can diamond wheels be used without coolant?

Diamond wheels can perform both wet and dry grinding. However, using a coolant is highly recommended. Coolant manages heat, flushes away debris, and prevents damage to the workpiece. This extends the wheel’s life and improves the surface finish, especially in high-speed grinding.

How do diamond wheels improve efficiency?

Diamond wheels offer faster material removal rates than conventional abrasives. Their exceptional durability means fewer wheel changes and less machine downtime. This combination of speed and longevity leads to significant gains in manufacturing productivity and overall cost-effectiveness.

See Also

Selecting the Optimal Grinding Wheel for Your Carbide Tool Sharpening

Picking the Perfect Bench Grinding Wheel Material for Specific Tasks

Mastering Safe and Effective Techniques for Dremel Grinding Wheel Usage

Exploring Various Grinding Wheel Types and Their Real-World Uses

Selecting the Ideal Metal Grinding Wheel for Your Specific Project

Contact Us

For More Grinding Solution or Customized Abrasive Tools