Standard abrasive discs often create frustration. They can shatter, wear down fast, or ruin expensive materials. Professionals choose diamond cut off wheels to overcome these challenges. These advanced tools offer superior precision for any cutting task. They ensure clean results and perfect precision on every project. The industry’s shift toward these durable tools is clear, reflecting their growing value.

Key Takeaways

- Diamond cut off wheels offer great precision. They make clean cuts on hard materials like tile and glass.

- These wheels last much longer than regular abrasive discs. This saves money over time.

- Diamond wheels help you work faster. They cut hard materials quickly and reduce work stoppages.

- They are safer to use. Diamond wheels have a solid core and create less dust and sparks.

- Choose the right diamond wheel for your material. Diamond wheels work best on non-metals, while CBN wheels are for metals.

Superior Precision and Clean Cutting

Diamond cut off wheels deliver a level of precision that standard abrasive discs cannot match. The industrial diamonds fixed on the wheel’s edge grind material away smoothly. This action is very different from abrasive wheels, which often tear through material. The result is superior control and a higher quality of work.

The Advantage of a Fixed Diameter

A key benefit of diamond wheels is their fixed diameter. Abrasive wheels shrink as they are used, which reduces their cutting depth and control. In contrast, diamond wheels are built with a solid steel body and a diamond edge. This construction ensures the wheel maintains its original diameter from the first cut to the last. Consistent diameter provides predictable control, reach, and precision throughout the wheel’s entire life. This stability is crucial for jobs that demand exact measurements and flawless execution. The constant edge speed also guarantees consistent cutting performance.

Achieving a Perfect Finish

The smooth grinding action of a diamond wheel leads to a perfect finish. This is essential for aesthetic materials where chips and cracks are unacceptable. The clean cuts preserve the integrity and appearance of the workpiece.

- Ceramic Tile & Stone: Users achieve clean edges with no chipping, ensuring a professional look.

- Glass: The tool allows for smooth cutting without causing fractures.

- Metal: It produces clean cuts with fewer burrs, reducing cleanup time.

Thin-profile wheels, like those offered by Aimgrind, take this precision even further. Their slender design minimizes material waste and improves dimensional accuracy. For any project requiring high precision, from intricate precision grinding to simple cuts, these wheels provide unmatched results.

Enhanced Durability and Long-Term Value

Investing in the right tools directly impacts a project’s budget and timeline. While standard abrasive wheels seem cheaper upfront, their short lifespan leads to frequent replacements and higher long-term costs. Diamond cut off wheels, in contrast, provide exceptional durability that translates into significant value.

Why Diamond Wheels Last Longer

The secret to a diamond wheel’s longevity lies in its material composition. Industrial diamonds are made of carbon atoms arranged in a strong cubic crystal lattice. This structure makes diamond the hardest known material, giving it excellent wear resistance. Unlike abrasive wheels that quickly wear away, the diamond edge grinds tough materials without losing its sharpness. This superior grit retention ensures consistent cutting performance for much longer.

The unique carbon bond structure in diamonds allows them to maintain their cutting ability even under the high pressure of grinding. This results in a durable tool that delivers a precise finish cut after cut.

This robust construction means a single diamond wheel can do the work of many abrasive discs. Professionals spend less time changing wheels and more time getting the job done.

Calculating Your Cost Savings

A higher initial price for a diamond wheel can be misleading. A true cost analysis reveals its long-term financial benefits. Professionals often use a Total Cost of Ownership (TCO) approach. This method looks beyond the purchase price to include operational life and replacement frequency. A diamond wheel’s extended lifespan dramatically lowers its cost per hour of use.

While a diamond wheel may have a higher initial investment, its superior performance and durability lead to substantial savings. Studies show that diamond wheels can last 8 to 12 times longer than conventional wheels, reducing overall tooling costs by 40-60%.

Consider this simplified cost-per-hour comparison:

| Cost Factor | Diamond Wheels | Silicon Carbide Wheels |

|---|---|---|

| Initial Cost | $150-250 | $35-60 |

| Operating Life (hours) | 300-500 | 50-100 |

| Cost per Hour | $0.30-0.83 | $0.35-1.20 |

This data shows that the cost-effective choice becomes clear over the tool’s life. Choosing a durable wheel is a smart, data-driven decision that boosts productivity and saves money.

Increased Speed and Job Site Efficiency

Time is a critical resource on any job site. Diamond cut off wheels boost project efficiency by combining speed with precision. Their superior design allows professionals to complete tasks faster without sacrificing quality. This improvement in performance directly translates to greater productivity and profitability. The overall efficiency of the workflow sees a significant upgrade.

Faster Cutting Through Hard Materials

Diamond wheels excel at cutting through dense materials quickly. Their unique construction allows for high material removal rates, which shortens the time needed for each cut. This speed is a major advantage over traditional abrasives. However, increased cutting speed can generate significant heat, potentially damaging the workpiece. Diamond wheels manage this challenge effectively.

The grinding action of a diamond wheel is more controlled than the tearing action of an abrasive disc. This helps maintain excellent precision and reduces the risk of thermal damage, ensuring a clean finish even at high speeds.

This balance of speed and control delivers exceptional performance. Users achieve high material removal rates while protecting the integrity of their work, a key factor for maintaining project quality and efficiency.

Less Downtime, More Productivity

Productivity depends on continuous work. Frequent tool changes create costly downtime. Abrasive discs wear out quickly, forcing operators to stop and replace them often. Diamond wheels, with their incredible durability, solve this problem. A single diamond wheel lasts much longer, minimizing interruptions and maximizing active work time. This sustained performance keeps projects on schedule. Operators can focus on the task at hand, confident in their tool’s reliability. This boost in operational efficiency and consistent precision makes diamond wheels an invaluable asset for any professional seeking top-tier results.

The Safety of Diamond Cut Off Wheels

Safety is a top priority on any job site. Tools must perform well and protect the operator. Diamond cut off wheels offer significant safety advantages over traditional abrasive discs. Their design minimizes common workplace hazards, creating a more secure environment for everyone. Professionals can work with greater confidence, knowing their equipment is built for safety.

Reduced Risk of Wheel Failure

A primary safety concern with abrasive wheels is the risk of shattering. Bonded abrasive wheels can break apart at high speeds, sending dangerous fragments flying. Diamond wheels have a solid steel core that virtually eliminates this risk. This sturdy construction ensures the wheel remains intact even under intense pressure. Safety standards often recognize this structural difference.

- An abrasive wheel is defined by ANSI as abrasive grains held together by a bond.

- Diamond wheels use a solid steel disc with diamond segments attached to the edge.

- This construction is not considered a traditional abrasive wheel.

- Therefore, it has a much lower risk of catastrophic failure during operation.

This inherent strength means operators face a significantly reduced chance of injury from wheel breakage.

Less Dust and Debris

A clean workspace is a safe workspace. The grinding action of a diamond wheel produces less airborne dust than the tearing action of an abrasive disc. This reduction in particulate matter improves air quality and visibility for the operator. It also means less cleanup is required after the job is complete. Furthermore, these wheels generate fewer sparks. This feature is critical in environments with flammable materials.

The combination of less dust and fewer sparks makes the work area safer and more efficient.

Choosing Aimgrind for Your Cutting Needs

Selecting the right wheel is crucial for achieving professional results. Aimgrind is a specialized brand with nearly two decades of experience in customized abrasive tools. The company offers a wide range of high-quality cutting wheels, including diamond and CBN options. These tools are designed for various materials, from hard metals to delicate ceramics, ensuring you have the perfect wheel for any job.

Matching the Wheel to the Material

The material you are cutting determines the best type of wheel to use. Diamond and CBN (Cubic Boron Nitride) are two superabrasives with different strengths. Choosing the correct one prevents wheel damage and ensures a clean cut. These two materials have distinct applications.

- Diamond grinding wheels work best on non-ferrous materials. They excel at cutting carbide, glass, and ceramics. However, they react poorly with iron at high heat, making them unsuitable for steel.

- CBN grinding wheels are the top choice for ferrous (iron-based) materials. They handle high heat well, making them perfect for grinding hardened metals like steel and cast iron without degrading.

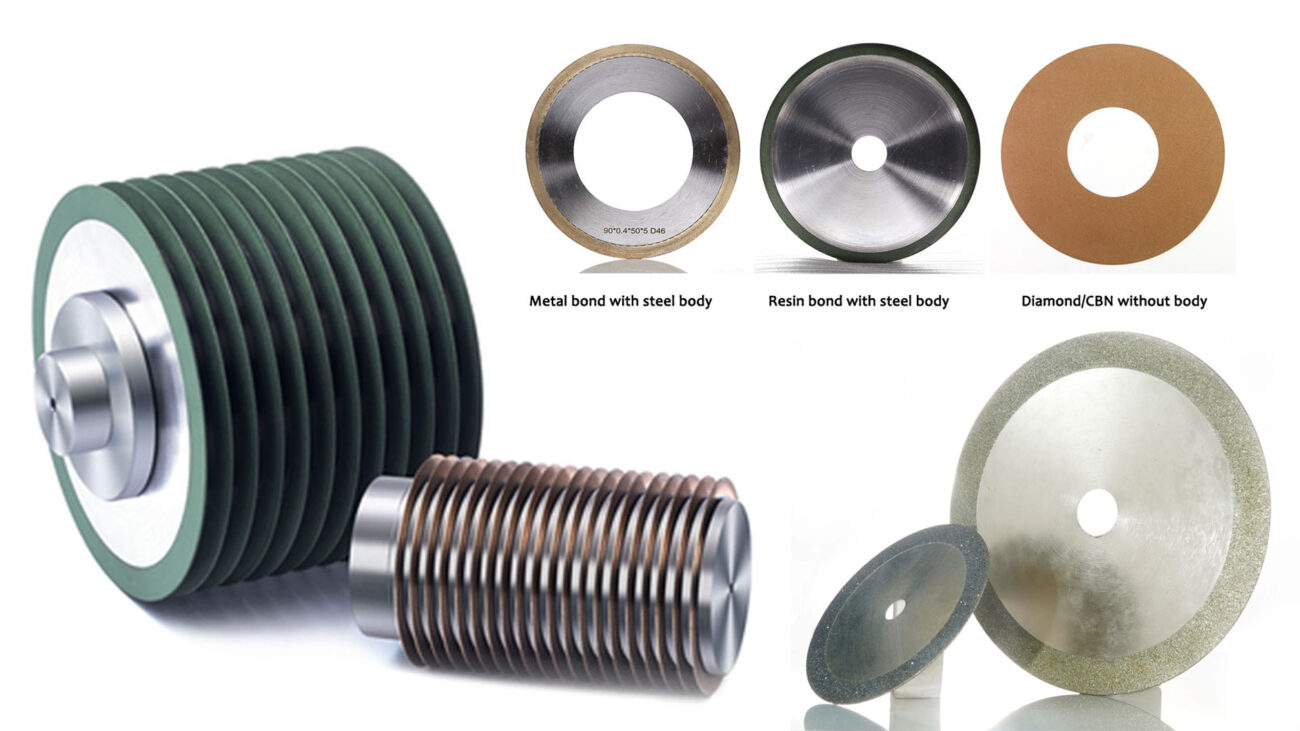

Types of Diamond Grinding Wheels

The way diamonds are bonded to the wheel also affects performance. Different bonding methods are suited for specific applications. The main types include sintered, vacuum brazed, and electroplated wheels.

| Feature | Sintered Diamond Wheels | Vacuum Brazed Diamond Wheels | Electroplated Diamond Wheels |

|---|---|---|---|

| Primary Use | Granite, marble, glass, ceramic | Concrete, soft stones, heavy-duty tasks | Precision machining, delicate work |

| Sharpness | Good | Good | Excellent (diamond is exposed) |

| Lifespan | Longer | Durable | Shorter (single diamond layer) |

| Advantages | Wide range of use, long life | Good wear resistance | High precision, sharp surface |

Wet vs. Dry Application

Wet Cutting: Using water is the preferred method for many materials. Water cools the blade, which prevents overheating and extends its life. It also washes away debris for a faster, cleaner cut and significantly reduces airborne dust.

Dry Cutting: This method is convenient when water is not available. However, it creates more dust and heat. To prevent the wheel from overheating, operators should allow it to cool for about 10 seconds after every 30 seconds of use.

Understanding these factors helps you select the ideal tool for your project. Explore the diverse options at Aimgrind to find the perfect wheel for your cutting needs.

Diamond cut off wheels provide unmatched precision, durability, and safety. Investing in a quality tool ensures superior cutting precision and delivers long-term value. This smart choice saves time and money while delivering professional precision on every project. Aimgrind provides the tools needed to achieve this high level of precision.

Upgrade your toolkit and achieve professional results. Grind with Passion, Achieve with Aim. Explore Aimgrind’s cutting solutions today.

FAQ

What materials can diamond wheels cut?

Diamond wheels are very versatile tools. They cut a wide range of hard, non-metallic materials effectively. Operators use them for precise cuts on many common job site materials.

- Ceramics and Porcelain Tile

- Stone, Granite, and Marble

- Glass

- Concrete and Masonry

- Carbide

What is the difference between diamond and CBN wheels?

Choosing the right abrasive is key. Diamond and CBN (Cubic Boron Nitride) wheels serve different purposes based on the material’s properties.

Diamond wheels excel at cutting non-ferrous materials like glass and stone. CBN wheels are the best choice for ferrous metals, such as hardened steel and cast iron, because they handle high heat well.

How do I choose the right cutting wheel?

Selecting the correct wheel ensures safety and performance. An operator should consider three main factors for the best results.

- Identify the material you need to cut.

- Choose between wet or dry cutting applications.

- Match the wheel’s specifications to your grinder or saw.

Can I use a diamond wheel on a standard angle grinder?

Yes, operators can use diamond wheels on standard angle grinders. They must ensure the wheel’s diameter and arbor size match the grinder’s specifications. Always check that the grinder’s maximum RPM (Revolutions Per Minute) does not exceed the RPM rating marked on the diamond wheel.

See Also

Selecting the Optimal Abrasive Wheel for Your Carbide Tool Sharpening

Picking the Ideal Bench Grinder Wheel Material for Specific Applications

Selecting the Perfect Metal Grinding Disc for Your Fabrication Endeavor

Identifying the Appropriate Grinding Disc for Your Circular Saw Blade

Discovering the Most Effective Grinding Wheel Dresser for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools