You need an effective solution for concrete grinding. Old methods are slow and frustrating. A cup diamond wheel makes your grinding work fast and efficient. This tool is a game-changer. The industry is growing, with the market for these tools projected to reach $2.39 billion by 2033. This shows a big shift towards better equipment.

Using the right diamond cup wheel can boost your productivity by over 30%. This diamond cup grinding wheel gives you professional results. It saves you time and money on every project. A quality grinding wheel is a smart choice.

Key Takeaways

- A cup diamond wheel makes concrete grinding fast and efficient.

- This tool helps you get a smooth and professional surface finish.

- Investing in a good diamond wheel saves money and lasts a long time.

- You can choose different diamond wheels for different tasks, like removing coatings or smoothing floors.

Boost Speed with a Cup Diamond Wheel

You can finish your projects much faster with a cup diamond wheel. This tool is designed for speed and power. It removes material quickly, turning a long job into a short one. Your grinding work becomes more productive.

Aggressive Material Removal

The secret to fast grinding is aggressive material removal. A diamond cup grinding wheel uses special segments to tear through concrete. These segments are not flat. They have gaps between them that help in a few ways.

- Better Airflow: The spaces between segments improve airflow. This keeps the grinding wheel cool and prevents it from getting clogged with dust.

- Powerful Cutting: Segmented designs attack the concrete surface aggressively. This leads to faster grinding speeds and removes a lot of material at once.

- Specialized Designs: You can choose different segment patterns for your job. A Double Row design offers stable, heavy grinding. A Turbo design uses a fan-like pattern for even faster grinding and less heat.

Using a coarse grit size (#16–#30) with these segments makes the grinding even more powerful for tough jobs.

Faster Concrete Grinding

Choosing the right tool makes your concrete grinding fast and efficient. The design of the diamond segments plays a big role. Features like bond hardness and diamond concentration determine how the tool performs. A high concentration of diamonds ensures a long tool life and powerful grinding. For hard concrete, a softer bond allows new, sharp diamonds to be exposed as you work.

This table shows how different segment types are built for aggressive grinding.

| Segment Type | Bond Hardness Options | Diamond Concentration |

|---|---|---|

| Double Arrow | Soft, Medium | High |

| Double Bar | Extra-Soft to Extra-Hard | High |

| Twin Ellipse | Extra-Soft to Extra-Hard | High |

A quality diamond cup grinding wheel with the correct segments provides a more robust cut. This makes your grinding process quicker and more efficient.

Achieve a Superior Surface Finish

A fast job is great, but a beautiful finish is what makes your work stand out. A cup diamond wheel gives you both speed and precision. You can prepare a surface for coatings or smooth it to perfection. This tool gives you complete control over the final look of your concrete.

Profiling with a Diamond Cup Grinding Wheel

Surface profiling is the process of creating a specific texture on the concrete. This step is essential before applying coatings like epoxy. A proper profile helps the coating stick correctly.

You control the profile by choosing the right grit size for your diamond cup grinding wheel. Different grits produce different results for your grinding project.

| Grit Size | Surface Profile Effect |

|---|---|

| 20-40 (Coarse) | Fast cutting, rough finish for heavy prep |

| 50-80 (Medium) | Good balance of speed and smoothness |

| 100-200+ (Fine) | Slower cutting, ultra-smooth finish |

Industry standards, like the Concrete Surface Profile (CSP) guidelines, define these textures. Grinding typically achieves a CSP 1–3, which is ideal for many sealers and thin coatings.

Smoothing and Leveling Surfaces

You can easily fix surface imperfections with the right grinding technique. A diamond cup grinding wheel excels at removing high spots, trowel marks, and form marks. For leveling high spots, an aggressive grinding wheel with coarse, double-row segments works best.

To get a smooth, swirl-free finish, pay attention to your tool and technique.

- Segment Choice: Turbo or continuous rim segments create a smoother finish with fewer scratches.

- Grit Size: Use a finer grit (80+) for the final passes to polish the surface.

- Proper Technique: Let the tool do the work. Forcing the grinder can reduce its life and create an uneven surface.

This control over the grinding process ensures you leave behind a flat, professional-looking surface every time.

Durability and Long-Term Value

Investing in a quality diamond cup grinding wheel pays off in the long run. While cheaper options might seem tempting, a durable tool saves you significant money and frustration. Its long life and consistent performance make it a smart financial choice for any serious grinding project.

Long-Lasting Diamond Segments

The secret to a long-lasting tool lies in its diamond segments. A durable grinding wheel is engineered for endurance.

- Diamond Concentration: Wheels with a high concentration of diamonds are more durable. More diamonds share the workload, which reduces wear on each individual crystal.

- Controlled Wear: The metal bond holding the diamonds is designed to wear away at a controlled rate. This process constantly exposes new, sharp diamonds, ensuring the tool keeps cutting effectively throughout its life.

- Advanced Manufacturing: The way a wheel is made matters. Processes like sintering and brazing create a powerful bond between the diamonds and the metal matrix, making the segments incredibly durable and resistant to breaking.

This smart design means your tool remains a tough and reliable partner for many jobs.

Lower Overall Project Costs

A durable tool directly lowers your project expenses. You spend less on replacements and save big on labor. One high-quality wheel can handle tough jobs, like grinding over 350 square feet of thin set, which means a lower cost per square foot.

The biggest saving comes from time. A fast and efficient grinding process reduces labor hours, which often make up the largest part of your budget. Finishing a job faster means you save money and can move on to the next project sooner.

This is why choosing the right tool is so important. At Aimgrind, our focus is on creating high-quality, customized diamond grinding wheels. We are committed to customer satisfaction and efficiency. Our durable diamond cup grinding wheel ensures you get exceptional performance, reflecting our passion for helping you achieve your goals.

The Right Wheel for Any Task

Choosing the right tool is key to a successful project. A cup diamond wheel is versatile, but its design determines its best use. Wheels with large segments are perfect for heavy-duty grinding on stone and concrete. You can use wheels with smaller segments to remove paint, glue, and other coatings. This ensures you have the perfect tool for any surface preparation task.

Choosing Your Segment Type

The segment design on your grinding wheel affects its speed and finish. You have several options to match your job’s needs.

- Double-Row: This segmented diamond cup grinding wheel is a great all-purpose choice. It offers a good balance of aggressive grinding and speed for leveling high spots.

- Turbo: A turbo diamond cup grinding wheel gives you a faster cut and a smoother finish. Its design helps cool the wheel, making it great for both heavy work and detailing.

Pro Tip: Match the wheel’s bond to the concrete’s hardness. Using the wrong bond can slow you down or wear out your tool too quickly.

This table helps you pick the right bond for your grinding project.

| Concrete Hardness | Diamond Segment Bond Type |

|---|---|

| Soft Concrete (Under 3,500 PSI) | Hard Bond |

| Medium Concrete (3,500 – 5,500 PSI) | Medium Bond |

| Hard Concrete (Over 5,000 PSI) | Soft or Extra-Soft Bond |

Diamond vs. Silicon Carbide Cup Grinding Wheel

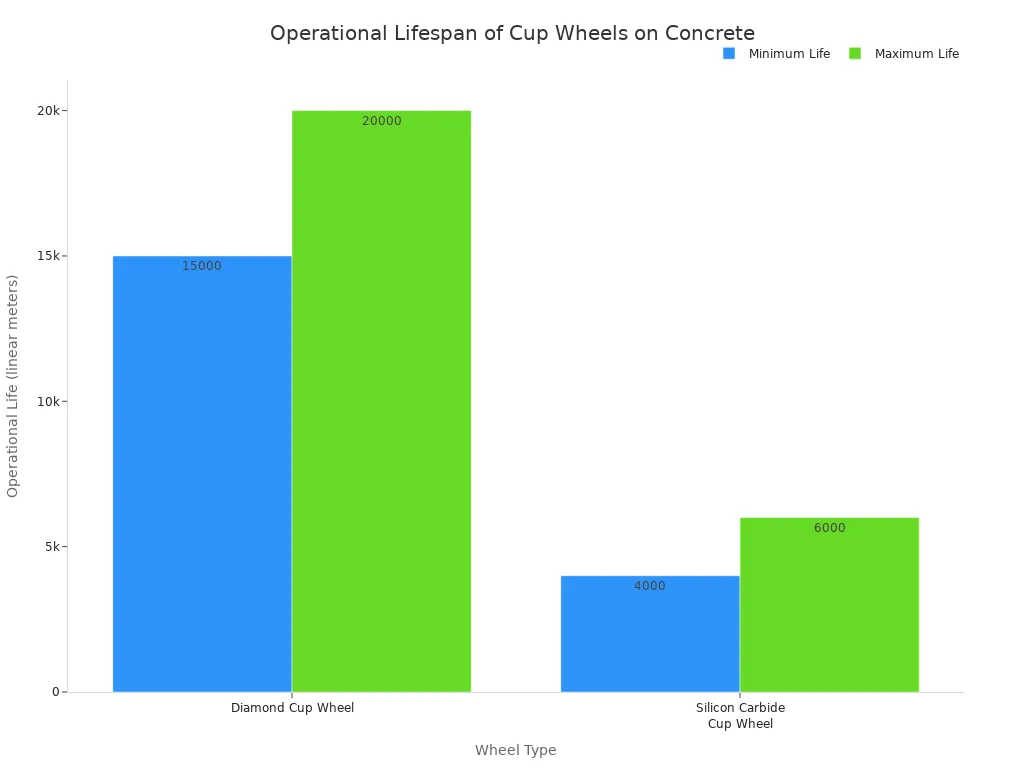

You will often choose between a diamond cup grinding wheel and a silicon carbide cup grinding wheel. For concrete, a diamond cup grinding wheel is almost always the better choice. A silicon carbide cup grinding wheel wears out much faster on hard materials. While a silicon carbide cup grinding wheel has good thermal shock resistance, its short lifespan makes it less cost-effective for big jobs. A silicon carbide cup grinding wheel is better suited for softer materials like limestone.

This comparison shows the clear advantages of diamond.

| Feature | Diamond Cup Wheel | Silicon Carbide Cup Grinding Wheel |

|---|---|---|

| Operational Life | 15,000-20,000 meters | 4,000-6,000 meters |

| Performance | Consistent over time | Less consistent |

| Best For | Hard materials like concrete | Softer materials |

The difference in lifespan is significant.

From Coating Removal to Prep

Your diamond cup grinding wheel is essential for surface preparation. You can use it to smooth concrete slabs and level uneven floors before adding new finishes. For removing thick coatings like epoxy, glue, or mastic, a PCD (polycrystalline diamond) wheel is the gold standard. These wheels make quick work of coatings thicker than 3mm. For a smooth finish with fewer scratches, you can use a continuous diamond cup grinding wheel on the final passes.

You have seen how a cup diamond wheel delivers incredible speed, a superior finish, and long-term value. This versatile tool is essential for any serious concrete work. A quality grinding wheel transforms your projects from difficult tasks into professional achievements.

Ready to work faster and smarter? Explore high-performance options from Aimgrind to get professional results on your next project. Grind with Passion, Achieve with Aim! 🚀

FAQ

What is a cup diamond wheel used for?

You use a cup diamond wheel for grinding concrete and stone surfaces. It is perfect for leveling high spots, removing coatings, and preparing a floor for a new finish. This tool gives you a fast and professional result.

Can I use a cup diamond wheel for wet and dry grinding?

Yes, you can use a diamond cup wheel for both wet and dry grinding. Wet grinding helps reduce dust and keeps the wheel cool. This can extend the tool’s life and give you a smoother finish on your project.

How do I choose the right grit size?

You choose the grit size based on your goal.

- Coarse grits (#16–#40) remove material quickly.

- Medium grits (#50–#80) offer a balance of speed and smoothness.

- Fine grits (#100+) create a polished, smooth surface.

Why is a diamond wheel better than silicon carbide for concrete?

A diamond wheel lasts much longer on hard materials like concrete. It provides consistent performance and a lower cost per square foot. A silicon carbide wheel wears out quickly, making it less efficient for large concrete jobs.

See Also

Selecting the Optimal Grinding Wheel for Your Carbide Tool Sharpening

Understanding CBN Grinding Wheels: Their Functionality and Applications Explained

Finding Your Ideal Grinding Wheel Dresser for Optimal Performance

Selecting the Perfect Bench Grinding Wheel Material for Specific Tasks

Picking the Ideal Metal Grinding Wheel for Your Specific Project

Contact Us

For More Grinding Solution or Customized Abrasive Tools