The high initial purchase price of cbn wheels often causes hesitation. This upfront cost, however, masks a crucial advantage: a drastic reduction in the total cost per part.

Superior efficiency and process optimization turn a higher investment into significant long-term savings. These gains provide a powerful competitive edge for any operation. This shift in perspective reveals how a strategic equipment choice leads to greater profitability and improved manufacturing outcomes.

Key Takeaways

- CBN wheels last much longer than regular wheels, which means less stopping and more grinding.

- CBN wheels help keep parts from getting too hot, preventing damage and making them stronger.

- CBN wheels are very precise, helping factories make parts that are exactly the right size and shape.

- Using CBN wheels saves money over time because they work faster and need less maintenance.

- CBN wheels help factories use less energy and create less waste, which is good for the environment.

BOOSTING EFFICIENCY WITH CBN WHEELS

Operational efficiency is a direct result of optimized processes and minimized interruptions. The superior design of cbn wheels provides substantial gains in productivity. They transform the entire grinding workflow, delivering measurable improvements from start to finish.

MINIMIZING DOWNTIME

Conventional abrasives wear quickly, forcing frequent and costly production stops. CBN grinding wheels offer a powerful solution. They possess an exceptional lifespan, lasting 100 to 300 times longer than their traditional counterparts. This durability drastically reduces downtime associated with wheel changes, dressing, and conditioning. Operators spend more time on value-added grinding tasks and less time on machine maintenance. Key performance indicators improve across the board:

- Increased productivity from fewer interruptions.

- Reduced time for gauging and spark-out.

- Longer wheel life at high material removal rates.

ENABLING GRINDING AUTOMATION

The predictable wear of cbn wheels makes them ideal for automated manufacturing. Their consistent grinding performance is critical for “lights-out” operations where manual oversight is minimal. Vitrified CBN wheels feature dressable structures. This allows automated systems to refresh the grinding layer with rotary dressers, maintaining precision without operator intervention. This capability is essential for the automatic regeneration of complex profiles, ensuring tight tolerances over long production runs. The result is a stable and highly repeatable grinding process perfect for modern automation.

ACCELERATING CYCLE TIMES

Pro Tip: The high thermal conductivity of CBN allows for a more aggressive grinding approach, directly shortening production cycles.

The unique properties of CBN enable faster, more efficient grinding. Its thermal stability allows for higher feed rates without risking heat damage to the workpiece. This capability can reduce manufacturing times for hard-to-cut materials by as much as 80%. Faster material removal directly shortens the grinding cycle. Aimgrind leverages its expertise to create customized grinding solutions. These solutions match the wheel formula to specific equipment and processes, helping customers fully optimize their grinding performance and achieve the fastest possible cycle times.

ENHANCING PART QUALITY VIA THERMAL CONTROL

Controlling heat is fundamental to any precision grinding operation. The exceptional thermal properties of CBN grinding wheels give manufacturers a distinct advantage, directly translating to superior component quality and integrity.

PREVENTING HEAT DAMAGE

Excessive heat is the primary cause of workpiece rejection in grinding. Cubic Boron Nitride (CBN) has superior thermal conductivity. It pulls heat away from the cutting zone much faster than conventional abrasives. This efficient heat dissipation is critical when grinding hard or heat-sensitive alloys. The cooler grinding process prevents a range of thermal defects.

Using cbn wheels helps suppress common grinding thermal damages, including:

- Metallurgical burn and oxidation discoloration

- Microcracks and broken pits

- Reduction in surface hardness

- Unfavorable residual tensile stress

This level of thermal control ensures the grinding operation enhances the part, rather than damaging it.

MAINTAINING MATERIAL INTEGRITY

Heat generated during grinding can alter a material’s fundamental properties. Conventional grinding often introduces significant tensile residual stress into a workpiece’s surface, which can lead to premature part failure. In contrast, scientific studies show that CBN grinding produces burn-free parts with beneficial compressive residual stress. This compressive state strengthens the surface and extends the component’s service life. Maintaining the material’s intended microstructure and hardness is crucial. A stable, low-heat grinding process preserves these characteristics, ensuring every finished part meets strict engineering specifications.

IMPROVING COOLANT EFFICIENCY

Effective cooling is essential for high-performance grinding. The design of vitrified cbn wheels plays a key role in coolant delivery. Their porous structure acts like a sponge, ensuring coolant reaches the precise point of contact between the wheel and the workpiece. This targeted delivery provides several benefits:

- The open structure promotes rapid coolant access.

- Efficient coolant penetration keeps grinding temperatures low.

- Enhanced cooling contributes to a more efficient grinding process.

This improved efficiency can even enable advanced lubrication techniques like Minimum Quantity Lubrication (MQL), reducing overall coolant consumption and supporting cleaner production goals.

ACHIEVING SUPERIOR PRECISION

Precision is the benchmark of quality in manufacturing. The physical properties of cbn grinding wheels provide an unmatched level of accuracy, enabling manufacturers to meet the most demanding specifications with confidence. This capability transforms grinding from a simple finishing step into a high-value precision machining process.

HOLDING TIGHTER TOLERANCES

Maintaining dimensional accuracy over long production runs is a significant challenge. The exceptional hardness and low wear rate of CBN abrasives ensure the wheel holds its form. This stability allows for consistent material removal and predictable results. The result is superior surface finishes that meet strict quality standards.

Scientific studies confirm the high level of precision achievable. Depending on the process parameters, surface roughness values can range from Ra 2.8 µm down to an impressive 0.32 µm. A finish of less than Ra 0.5 µm is consistently attainable, demonstrating exceptional control over the grinding operation.

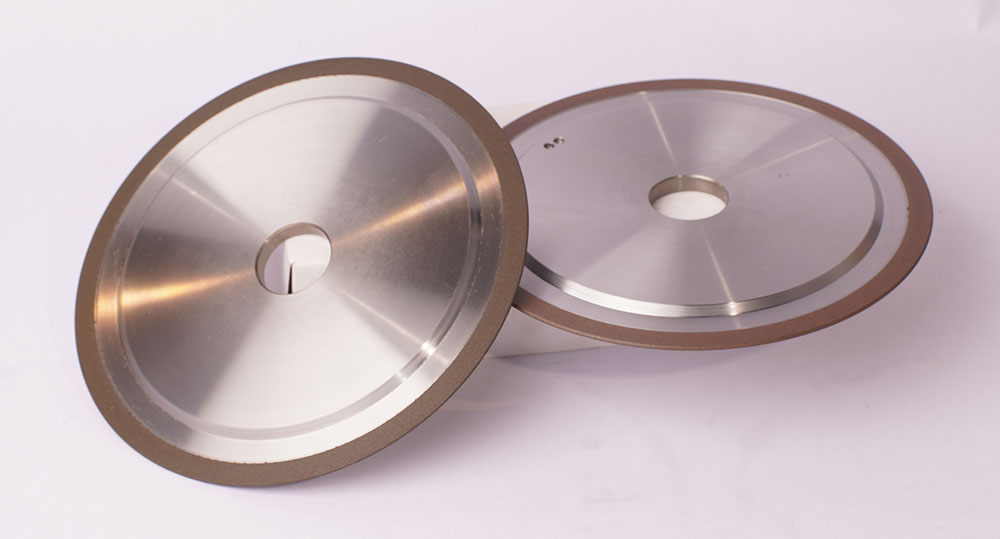

PRECISION WITH VITRIFIED CBN GRINDING WHEELS

The bond system is critical for achieving ultimate precision. Vitrified cbn grinding wheels use a ceramic matrix that creates a rigid, porous structure. This design offers several key advantages for precision grinding:

- Exceptional Rigidity: The strong bond minimizes wheel deflection, ensuring the wheel maintains its profile for accurate grinding.

- High Porosity: The open structure allows for excellent coolant flow, preventing thermal damage and maintaining workpiece stability.

- Dressable Structure: Vitrified cbn grinding wheels can be dressed to create and regenerate complex profiles, essential for intricate parts.

This makes vitrified cbn grinding wheels ideal for demanding applications in precision machining. Industries rely on these wheels for grinding engine components like camshafts and crankshafts, as well as aerospace turbine blades. Aimgrind’s expertise in formula design ensures that each of our vitrified cbn grinding wheels is optimized for specific materials like hardened steels. We engineer our vitrified cbn grinding wheels to deliver superior accuracy and surface finish. The right vitrified cbn grinding wheels make all the difference in high-stakes grinding.

ENSURING PART CONSISTENCY

Repeatability is the foundation of modern manufacturing. The stability of vitrified cbn grinding wheels translates directly to part-to-part consistency. Because the wheel wears so slowly and predictably, every component in a batch receives the same precise grinding action. This reliability reduces the need for constant measurement and adjustment, streamlining production. Manufacturers can trust that the first part and the last part will be dimensionally identical, securing process control and delivering unparalleled quality. This consistency is a hallmark of advanced grinding with vitrified cbn grinding wheels.

LOWERING TOTAL OPERATIONAL COSTS

The initial investment in advanced grinding technology often overshadows the substantial long-term financial benefits. High-performance cbn wheels deliver savings that extend far beyond the purchase price, impacting everything from energy bills to inventory management. These efficiencies combine to lower the total cost of production and strengthen a company’s bottom line.

CALCULATING LONG-TERM SAVINGS

A simple cost-per-part analysis reveals the true value of CBN grinding. While conventional wheels seem cheaper upfront, their operational costs quickly add up. Faster cycle times and reduced dressing needs create dramatic savings. A direct comparison shows the financial impact:

| Metric | Ceramic Wheel | CBN Wheel |

|---|---|---|

| Cycle Time (min) | 150 | 10 |

| Grind time cost/part | $137 | $9 |

| Dress cycle cost/part | $24 | $0.11 |

| Total cost per part | $202 | $11 |

This data illustrates a cost reduction of over 90% per part. Furthermore, CBN grinding requires lower Specific Grinding Energy, meaning less power is consumed to remove the same volume of material. This energy efficiency translates directly into lower utility costs for every component produced.

REDUCING ENVIRONMENTAL IMPACT

Modern manufacturing prioritizes sustainable practices. The extended lifespan of cbn wheels directly supports these goals. For example, one aerospace client achieved a 40% longer wheel life after switching, significantly reducing abrasive waste sent to landfills. Fewer wheel changeovers also mean less consumption of resources. This commitment to efficiency helps companies minimize their environmental footprint while improving operational performance. A cleaner, more sustainable process becomes an achievable standard.

SHRINKING YOUR OPERATIONAL FOOTPRINT

Efficient use of factory space is critical for lean manufacturing. The durability of CBN grinding wheels eliminates the need for large inventories of replacements. Since these wheels maintain their diameter and rarely require dressing, facilities can drastically reduce the storage space dedicated to abrasives. This operational advantage provides several key benefits:

- A long lifespan means fewer wheels are needed on hand.

- Minimal downtime for wheel changes increases productivity.

- Reduced maintenance frees up operator time and resources.

This streamlined approach allows for a more organized and efficient production floor, optimizing the entire operational footprint.

The true value of CBN wheels lies in the cumulative financial and operational gains they unlock, not their initial price. “Unseen” advantages—automation, precision, thermal stability, and lower waste—deliver a powerful return on investment, making them a superior choice for grinding. A thorough analysis of your current grinding process can reveal significant opportunities for improvement.

Ready to unlock these savings? Contact an Aimgrind expert at brian@aimgrind.com or visit aimgrind.com for a customized application review.

FAQ

Are CBN wheels worth the higher initial cost?

Yes. The higher initial price is offset by a dramatic reduction in the total cost per part. CBN wheels offer a longer lifespan, faster cycle times, and less downtime. These efficiencies create significant long-term savings and a strong return on investment.

What materials are best for CBN grinding wheels?

CBN grinding wheels excel on ferrous materials with a hardness above 45 HRC. They are the ideal choice for grinding hardened steels, tool steels, and superalloys. Their unique properties ensure efficient and precise results on these difficult-to-machine metals.

How do CBN wheels support automated grinding?

CBN wheels have highly predictable wear rates. This consistency is critical for unattended “lights-out” manufacturing. Their dressable structures also allow automated systems to maintain the wheel’s profile, ensuring continuous precision without any manual intervention from an operator.

Can CBN wheels achieve a high-quality surface finish?

Absolutely. The exceptional hardness and stability of CBN wheels allow them to hold their form. This results in superior surface finishes, consistently achieving roughness values below Ra 0.5 µm. This precision is essential for high-quality component manufacturing.

See Also

Understanding CBN Grinding Wheels: Their Functionality and Operational Principles

Selecting the Optimal Grinding Wheel for Your Carbide Tooling Needs

Exploring Diverse Grinding Wheel Varieties and Their Real-World Uses

Selecting the Ideal Bench Grinding Wheel Material for Specific Requirements

Finding the Most Effective Grinding Wheel Dresser for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools