You should pick a low speed grinding wheel when sharpening tools that can get soft from heat. Many experts use a low-speed grinder for knives and chisels. The slow wheel speed keeps tool edges cool. Using a bench grinder with slow speed helps you stop overheating. Overheating can hurt high-speed steel. Sharpening is easier and safer at lower speeds. If you use heat-sensitive tools or want more control, a low speed grinding wheel is a good choice. Diamond is often used for cutting and grinding, but a low speed grinding wheel does not use diamond. Diamond wheels are not good for sharpening steel tools. Diamond is best for carbide tools. You might see diamond in special wheels, but slow speed grinders focus on safety and control, not diamond. Diamond is very hard and strong, but it is not always the best for sharpening. Diamond works well for some materials, but not for every sharpening job.

Key Takeaways

Use a low speed grinding wheel to keep tools cool. This helps stop heat damage when you sharpen tools. Low speed grinding wheels help keep steel tools hard and sharp. They do this by stopping the tools from getting too hot. You can control the grinder better at low speed. It is also safer to sharpen tools this way. This is very helpful for chisels, knives, and carving tools. Diamond grinding wheels are best for carbide tools. But they can get steel tools too hot and cause damage. So, do not use diamond wheels on steel tools. Take care of your slow-speed grinder by dressing the wheels. Cool your tools often. Always follow safety tips to get the best sharpening results.

Benefits of a Low Speed Grinding Wheel

Less Heat

When you use a low speed grinding wheel, you keep the temperature at the tool edge much lower than with a high-speed grinder. High speed wheels create more friction, which makes the edge heat up fast. This heat can damage your tools by making the steel soft or changing its hardness. You want to avoid this because a soft edge will not stay sharp for long. A low speed grinding wheel helps you control the grinding process and keeps the edge cool. If you use a bench grinder with slow speed, you can sharpen tools like chisels and carving knives without worrying about overheating. Many woodworkers choose a low-speed grinder for this reason. You can also use water cooling or CBN wheels to keep the temperature even lower. Remember, temperature is the enemy during sharpening work.

Tip: Always check the edge temperature with your fingers. If it feels hot, dip it in water to cool it down.

Preserves Temper

You need to keep the temper of your tools when sharpening. Temper is the hardness that makes your tool strong and sharp. If you lose temper, your tool edge becomes weak and dulls quickly. A low speed grinding wheel helps you avoid this problem. High speed grinding wheels often make the edge so hot that it loses temper. The small edge heats up fast and can go past the safe temperature. With a low speed grinding wheel, you keep the edge cool and safe. This is very important for high-speed steel tools and heat-sensitive blades. You get a longer-lasting edge and better performance from your tools.

More Control

A low speed grinding wheel gives you more control over the sharpening process. You can move the tool slowly and carefully. This helps you shape the edge exactly how you want. You also lower the risk of accidents because the wheel turns slower. Many experts recommend a slow-speed grinder for woodworking tools. Chisels, plane irons, turning tools, and carving knives all benefit from this extra control. You can use a bench grinder with a low speed grinding wheel to sharpen these tools safely. If you use diamond grinding wheels, you get a very hard surface, but diamond is not always the best for sharpening steel tools. Diamond works well for carbide tools, but for steel, a low speed grinding wheel is better. Diamond grinding wheels can grind fast, but they may overheat steel edges. You should use diamond grinding wheels for carbide, not for high-speed steel or woodworking tools.

Note: Diamond is very hard and strong. You see diamond in many grinding wheels, but diamond grinding wheels are not the best choice for sharpening steel. Use them for carbide tools instead.

Common Mistakes and How to Avoid Them

Do not grind all the way to the edge. The sharp edge heats up quickly and can burn.

Keep the tool rest slightly above the wheel center. This helps push the tool away from the wheel and keeps you safe.

Do not grind too long without cooling the tool. Dip it in water often.

Use coarse grit wheels for fast material removal.

Dress your wheel with a diamond dresser to keep it sharp and flat.

If you follow these tips, you make your sharpening work safer and more effective. Slow speed grinders help, but you still need good technique.

Remember: The right wheel and careful grinding process protect your tools and keep them sharp longer.

Low-Speed Grinder vs High-Speed Grinder

Key Differences

You will notice several differences between a low-speed grinder and a high-speed grinder. The most obvious difference is the speed. A low-speed grinder usually runs at about 1440 RPM. A high-speed grinder often spins at 2850 RPM or even 3450 RPM. This speed affects how much heat builds up during sharpening. Less speed means less heat, which helps you avoid damaging your tools.

Here is a table to help you compare:

Feature | Low-Speed Grinder (~1440 RPM) | High-Speed Grinder (~2850-3450 RPM) |

|---|---|---|

Heat Generation | Low | High |

Control | High | Moderate |

Material Removal | Slower | Faster |

Risk of Overheating | Low | High |

Best For | Precision Sharpening | Heavy Grinding |

You get better control with a low-speed grinder. This helps you shape edges with care. High-speed grinders remove material quickly but can overheat the edge. You need to use water or take breaks to keep the tool cool. The choice of wheel also matters. Many people use diamond grinding wheels for hard materials. Diamond grinding wheels cut fast, but they can make steel tools too hot. You should use diamond grinding wheels for carbide tools, not for steel. Diamond is very hard, but diamond grinding wheels are not always the best for every sharpening job. Diamond works best for carbide, not for high-speed steel or woodworking tools. If you use a bench grinder, you may see diamond wheels, but always check if diamond is right for your tool.

Tip: Always match the wheel type to your tool material. Diamond grinding wheels are great for carbide, but not for steel.

When to Use Each

You should choose a low-speed grinder when you want to sharpen tools like chisels, knives, or carving tools. These tools need a cool edge and careful shaping. A low-speed grinder helps you avoid overheating and keeps the temper of your tools. Many woodworkers and hobbyists use a low-speed grinder for sharpening because it gives them more control.

Use a high-speed grinder when you need to remove a lot of material fast. If you want to reshape a lawn mower blade or fix a damaged edge, a high-speed grinder works well. You must watch for heat and use cooling methods. High-speed grinders work best for heavy-duty jobs and production work.

Some users prefer diamond grinding wheels for tough jobs. Diamond grinding wheels last a long time and cut hard materials quickly. You should use diamond grinding wheels for carbide tools. Diamond is not the best for sharpening steel tools. If you use diamond grinding wheels on steel, you risk overheating and losing the edge. Diamond is strong, but diamond grinding wheels are not always the answer for every sharpening task.

Note: Many users say that a low-speed grinder is perfect for light sharpening. High-speed grinders work better for heavy grinding and reshaping. Always consider your needs before choosing a grinder or wheel. Diamond grinding wheels are best for carbide, not for steel.

Using a Slow-Speed Bench Grinder

Wheel Selection

Choosing the right wheel for your slow-speed bench grinder makes a big difference in sharpening results. You will find many types of abrasive wheels, but not all work well for tool steels. The table below shows how different wheels perform:

Abrasive Wheel | Abrasive Type and Composition | Bond Hardness | Friability | Sharpening Performance on Tool Steels | Heat Generation and Burning Risk | Additional Notes |

|---|---|---|---|---|---|---|

Norton 3X | 30% SG aluminum oxide + white aluminum oxide | Soft (I) | Friable | Effective sharpening without burning | Low heat, cool grinding | Sheds fewer particles, less dressing needed |

Norton White 9A | White aluminum oxide | Hard (J) | Very friable | Loads quickly, causes burning | High heat, risk of overheating | Surface dulls quickly, poor for tool steels |

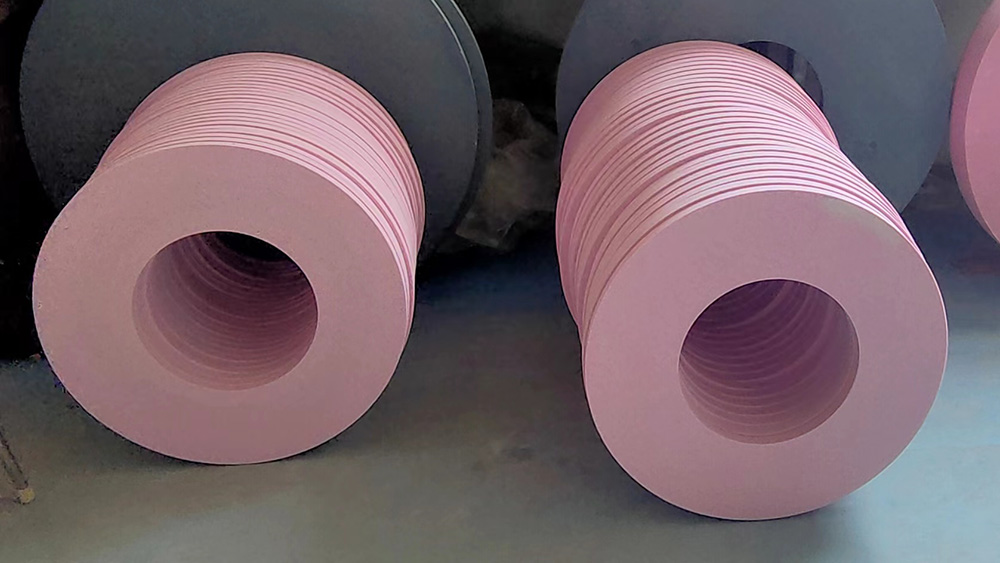

Radiac RAA | Pink chromium-based abrasive | Soft (H) | Very friable | Effective sharpening without burning | Low heat, cool grinding | Cuts faster, sheds many particles, requires cleanup |

You should avoid hard-bond wheels like Norton White 9A for sharpening. Softer bonds, like Norton 3X and Radiac RAA, keep the grinding process cool and safe. Many people ask about diamond and diamond grinding wheels. Diamond is very hard, but diamond grinding wheels are not the best for sharpening steel tools. You should use diamond grinding wheels for carbide, not for tool steels. Diamond wheels can overheat steel and damage the edge.

Sharpening Tips

When you use a slow-speed bench grinder, you want to keep your tools cool and sharp. Always use light pressure during sharpening. Heavy pressure can heat up the edge and ruin the temper. If your grinder has a water-cooling system, use it to cool the tool. Water-cooled grinding keeps blades cool and protects the edge. This method works well for knives, chisels, and other fine tools. You get better results and longer tool life.

Diamond grinding wheels cut fast, but they can make steel tools too hot. You should use diamond for carbide tools, not for sharpening steel. If you use diamond grinding wheels, check the tool often and cool the tool in water. Diamond is strong, but it is not always the best for every sharpening job. For most woodworking tools, a regular abrasive wheel on a slow-speed bench grinder gives you more control and less risk of burning.

Tip: Move the tool slowly and check the edge often. If it feels warm, dip it in water to cool the tool and keep the edge safe.

Maintenance

You need to keep your bench grinder in good shape for safe and effective sharpening. Follow these steps:

Inspect the grinding wheels for cracks or damage before each use.

Dress the wheels with a diamond dresser to keep them sharp and flat.

Clean the grinder after each use to remove dust and debris.

Adjust the tool rest close to the wheel, but do not let it touch.

Replace any wheel that is damaged or worn down to 70% of its original size.

Always wear safety goggles and stand to the side when starting the grinder.

Secure the wheels properly, but do not overtighten.

Frequent dressing is important, especially when using diamond grinding wheels or sharpening hard materials. A well-maintained slow-speed bench grinder runs quietly and smoothly. You get better sharpening results and a safer workspace.

You get the best results from a low speed grinding wheel when you want to sharpen tools without risking heat damage. You protect the temper of your blades and gain more control over the sharpening process. Many woodworkers use slow-speed grinders for chisels, knives, and carving tools. Before you choose a grinder, think about the material type, bond, grit size, speed, coolant, work environment, wheel shape, and wheel size. If you work with steel, a low speed grinding wheel works better than a diamond wheel. Diamond wheels suit carbide, but diamond can overheat steel. Diamond is strong, but diamond does not always give the best finish for steel. Diamond wheels cut fast, but diamond can burn tool edges. Diamond is not ideal for heat-sensitive blades. Diamond wheels last long, but diamond may not fit every sharpening job. Diamond works for hard materials, but diamond is not the answer for every tool. Diamond wheels shine with carbide, but diamond falls short with steel. Diamond is popular, but diamond is not always the right choice.

Tip: Always match your grinding wheel to your tool material and sharpening needs. You get safer, sharper results when you choose wisely.

FAQ

What tools work best with a low speed grinding wheel?

You get the best results when you sharpen chisels, plane irons, and carving knives. These tools need a cool edge. You should not use a diamond wheel for these steel tools. Diamond works better for carbide tools.

Can you use a diamond wheel on a slow-speed grinder?

You can use a diamond wheel, but it is not the best for sharpening steel. Diamond wheels cut fast, but they can overheat steel edges. You should use diamond wheels for carbide tools, not for woodworking tools.

Why does diamond not work well for sharpening steel?

Diamond is very hard and strong. When you use diamond on steel, it can cause overheating. This heat can damage the tool’s edge. You should save diamond wheels for carbide tools, not for high-speed steel.

How do you keep tools cool while sharpening?

You should use light pressure and dip the tool in water often. Avoid using a diamond wheel for steel tools, as diamond can make the edge too hot. Water cooling and slow speed help protect the tool’s temper.

Contact Us

For More Grinding Solution or Customized Abrasive Tools