For the best sharpening, pick a CBN or diamond chainsaw grinding wheel. These wheels take off metal fast and last longer than aluminum oxide wheels. Most grinders can use different wheel types and sizes, like vitrified or 5-3/4 inch wheels. This lets you match the wheel to your chain and grinder. Each type has its own strengths for home or professional use.

Key Takeaways

Pick CBN or diamond wheels if you want to sharpen faster and make your wheel last longer than aluminum oxide wheels. – Use aluminum oxide wheels if you only sharpen sometimes and want to save money, but you will need to fix them more and they cut slower. – CBN wheels are best for steel chains because they stay cool and give steady results, and you do not need to fix them often. – Diamond wheels are best for carbide-tipped chains because they cut very well, do not get hot, and last the longest. – Always use the right size and type of grinding wheel for your chain pitch, and take care of your wheels often to keep cutting safe and sharp.

Types of Abrasive Wheels

There are three main abrasive wheels for chainsaw sharpening. These are aluminum oxide wheels, CBN wheels, and diamond cut-off wheels. Each wheel is good for different jobs and materials.

Aluminum Oxide

Aluminum oxide wheels are the most popular for basic grinding. You use them for simple sharpening tasks. These wheels have medium hardness. They work well with regular steel chainsaw teeth. Aluminum oxide wheels wear out faster than other wheels. They get hot quickly, which can cause more friction. This heat can burn your chain. You need to replace or fix these wheels more often.

Tip: If you sharpen chainsaws sometimes, aluminum oxide wheels save money.

CBN Wheels

CBN wheels are made with cubic boron nitride. This is a very hard material. You pick CBN wheels for sharpening steel chainsaw teeth. These wheels last much longer than aluminum oxide wheels. CBN wheels do not get hot easily and keep their shape. This means you get steady results. You do not need to fix CBN wheels often.

CBN wheels are best for professional jobs or if you sharpen a lot. They work well with fast grinding and tough steel.

Diamond Cut-Off Wheels

Diamond cut-off wheels are very hard and strong. You use diamond wheels to sharpen carbide-tipped chainsaw teeth. They also work for other non-metal materials. Diamond wheels make less friction and heat. This helps stop damage from heat.

Diamond wheels cost more at first. But they last much longer, so you save money later. Diamond wheels give clean, exact cuts, especially on hard things.

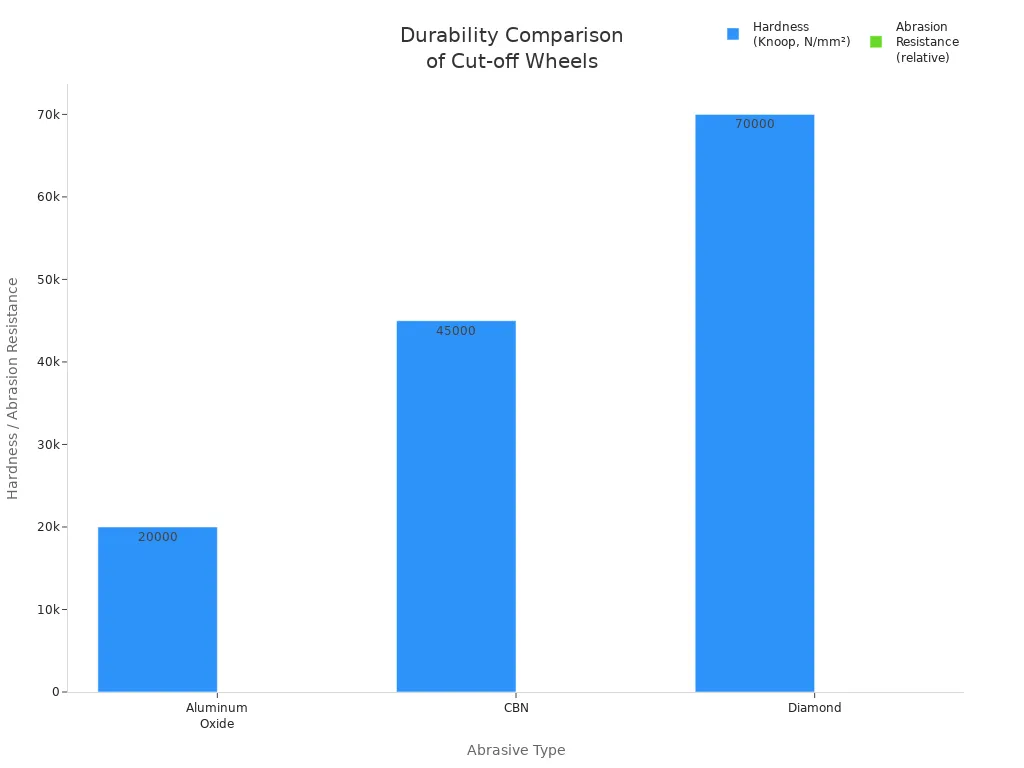

Here is a simple chart that compares the three types of abrasive wheels:

Abrasive Type | Hardness (Knoop, N/mm²) | Abrasion Resistance | Thermal Resistance | Typical Application Suitability |

|---|---|---|---|---|

Aluminum Oxide | ~20,000 | Baseline | Low | General purpose, less durable |

CBN | ~45,000 | ~4x Aluminum Oxide | High | Steel alloys, longer life |

Diamond | ~70,000 | Highest | Limited for steel | Carbide, ceramics, longest life |

Note: Diamond cut-off wheels are best for non-metal and carbide materials. CBN wheels work well for steel chainsaw teeth. Aluminum oxide wheels are good for basic sharpening but wear out faster.

Chainsaw Grinding Wheel Performance

Sharpening Speed

You want a chainsaw grinding wheel that sharpens fast and keeps your chain ready for cutting. Aluminum oxide wheels work well for basic sharpening, but they remove metal slower than other types. You may notice that you need to spend more time at the grinder when using these wheels. CBN wheels stand out for their speed. They grind steel chainsaw teeth quickly and do not require you to use the slow “tap-tap-tap” method. This means you can sharpen more chains in less time. Diamond wheels also offer fast sharpening, especially for carbide-tipped chains. They cut hard materials with ease and give you a clean edge. If you need to sharpen many chains or want to save time, CBN and diamond wheels give you the best cutting capabilities.

Durability

Durability matters when you use your grinder often. Aluminum oxide wheels wear down quickly. You will need to replace or dress them after every few sharpenings. CBN wheels last much longer. Many users report that a CBN wheel can last up to five years with regular use. Diamond wheels are even more durable. Resin bond diamond wheels can last between 1,000 and 3,000 working hours, depending on how you use them and what you are cutting. This long lifespan means you spend less time changing wheels and more time sharpening. Both CBN and diamond wheels keep their shape, so you get steady performance over time.

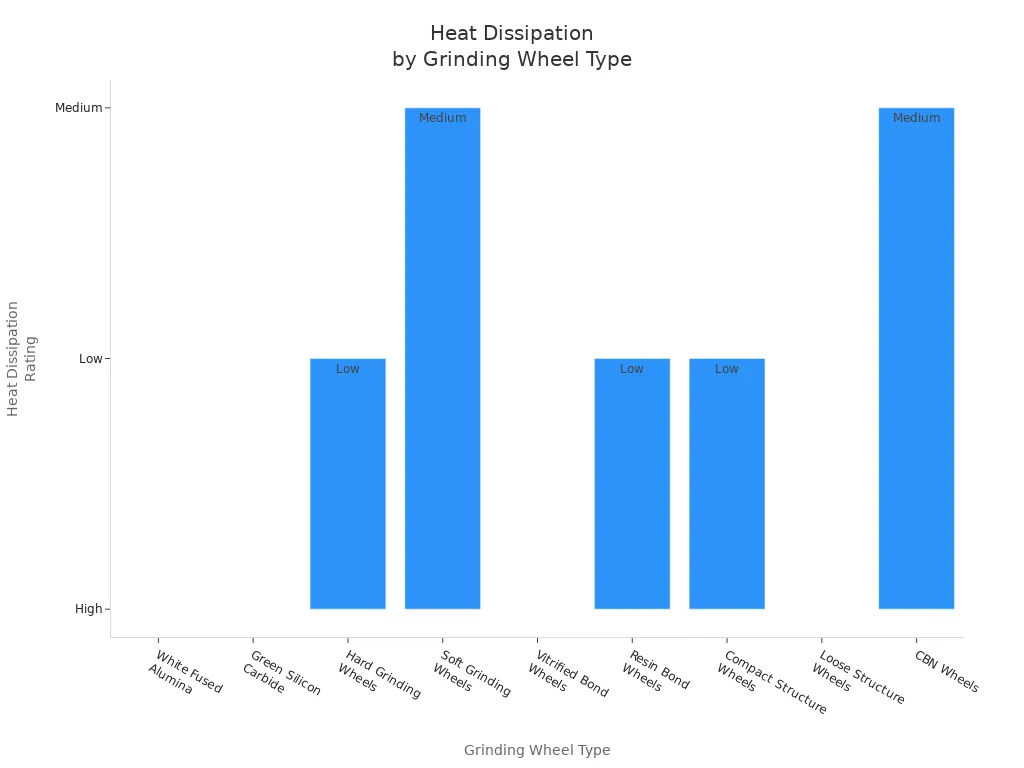

Heat Dissipation

Heat can damage your chain and affect cutting performance. Aluminum oxide wheels heat up quickly. This can burn your chain if you are not careful. You need to watch for sparks and slow down to avoid overheating. CBN wheels run cooler. They grind faster and remove metal without making the chain too hot. This reduces the risk of burning and keeps the metal strong. Diamond wheels also create less friction and heat. They work best at slow speeds and help protect your chain from heat damage. The chart below shows how different wheels handle heat:

Tip: CBN and diamond wheels help you avoid burning your chain, so you get better results and longer chain life.

Maintenance Needs

You need to take care of your chainsaw grinding wheel to keep it working well. Aluminum oxide wheels need the most maintenance. You should dress them with a dressing stone when new and then after every 2 to 5 sharpenings. This keeps the wheel in shape and exposes fresh abrasive grains. You also need to check for cracks, chips, and wear before each use. Cleaning is important, too. You can soak the wheel in a cleaning solution and scrub it with a brush to remove metal buildup.

CBN wheels need less maintenance. They keep their shape and do not load up with metal as quickly. You still need to clean them, but you will not have to dress them as often. Many users clean CBN wheels by soaking them in a solution and brushing off debris. Diamond wheels require the least maintenance. They stay sharp for a long time and rarely need dressing. You should use them on a slow-speed grinder and mount them properly for best results.

Here is a quick checklist for maintaining your grinding wheels:

Inspect for cracks, chips, and wear before each use.

Dress aluminum oxide wheels every few sharpenings.

Clean all wheels regularly to remove metal buildup.

Store wheels in a dry, safe place.

Follow the manufacturer’s guidelines for speed and pressure.

Note: Good maintenance helps your grinding wheel last longer and keeps your cutting sharp and safe.

Pros and Cons

Aluminum Oxide

Aluminum oxide cut-off wheels give you a basic option for sharpening chainsaw teeth. You find these abrasive cut-off wheels in most hardware stores. You can use them for general cutting and grinding tasks.

Pros:

You pay less for aluminum oxide cut-off wheels.

You can find this type in many sizes for different grinders.

You get a simple solution for occasional cutting and sharpening.

You can dress and reshape the wheel easily.

Cons:

You need to replace aluminum oxide cut-off wheels often because they wear down quickly.

You spend more time sharpening since these wheels remove metal slowly.

You risk burning your chain due to poor heat dissipation.

You must dress the wheel after every few uses to keep it working well.

You need to check for cracks and chips before each use for safety.

Tip: Choose aluminum oxide cut-off wheels if you sharpen chainsaws only a few times each year and want to save money.

CBN

CBN cut-off wheels use cubic boron nitride as the abrasive. You get a strong and long-lasting wheel for sharpening steel chainsaw teeth. You notice faster cutting and less heat when you use CBN abrasive cut-off wheels.

Pros:

You sharpen chains quickly with CBN cut-off wheels.

You get a wheel that keeps its shape for years.

You spend less time on maintenance.

You avoid burning your chain because CBN wheels run cooler.

You get steady results for every cutting job.

Cons:

You pay more for CBN cut-off wheels than for aluminum oxide.

You may not find every size in local stores.

You need to use CBN wheels only for steel chains, not carbide.

You must clean the wheel to remove metal buildup.

Note: Pick CBN cut-off wheels if you sharpen chainsaws often or work in a professional shop.

Diamond

Diamond cut-off wheels give you the hardest and most durable option. You use diamond wheels for sharpening carbide-tipped chainsaw teeth and other tough materials. You get clean and precise cutting with diamond abrasive cut-off wheels.

Pros:

You get the longest lifespan with diamond cut-off wheels.

You sharpen carbide chains and hard materials with ease.

You see less friction and heat during cutting.

You spend less time dressing and maintaining the wheel.

You get a smooth and accurate edge every time.

Cons:

You pay the highest price for diamond cut-off wheels.

You need to use diamond wheels only for carbide and non-metal chains.

You must use a slow-speed grinder for best results.

You may not find every size for your grinder.

Tip: Choose diamond cut-off wheels for specialty chains or if you want the best performance and longest life.

Wheel Type | Cost | Sharpening Speed | Maintenance Needs | Durability | Safety Risk | Best For |

|---|---|---|---|---|---|---|

Aluminum Oxide | Low | Slow | High | Low | Medium | Occasional use |

CBN | Medium | Fast | Low | High | Low | Professional steel |

Diamond | High | Fast | Very Low | Very High | Low | Carbide, specialty use |

Remember: Always check your cut-off wheels for damage before cutting. This helps you stay safe and get the best results.

Comparison Table

When you look at chainsaw grinding wheels, you want to know how each type works for sharpening and cutting. The best wheel depends on your chain, the wheel size, and what results you want. The table below shows how diamond, CBN, and aluminum oxide cut-off wheels compare for cutting, lasting, and maintenance.

Feature/Aspect | Diamond Wheel | CBN Wheel | Aluminum Oxide (AO) Wheel (Pink) |

|---|---|---|---|

Abrasive Material | Diamond (best for carbide chains) | CBN (best for steel chains) | Aluminum oxide (traditional) |

Chain Compatibility | Carbide chains | Steel chains | Steel chains |

Wheel Thickness (Chain Pitch) | 1/8″ for 1/4, .325, 3/8 Picco chains; 3/16″ for 3/8, .404 chains | Same as diamond, matched to chain pitch | Varies, often requires reshaping |

Wheel Shape | Full radius, no reshaping needed | Full radius, no reshaping needed | Often requires reshaping |

Heat Generation | Low heat due to metal core dissipating heat | Low heat due to metal core dissipating heat | Higher heat, risk of tooth burning |

Dust Generation | Virtually no dust (abrasive does not break up) | Virtually no dust | Produces dust during grinding |

Wheel Life | Lasts for thousands of chains | Lasts for thousands of chains | Shorter life, needs frequent replacement |

Cost Effectiveness | More cost effective over time | More cost effective over time | Less cost effective due to frequent replacement |

Sharpener Compatibility | Fits most sharpeners, same sizes as AO wheels | Fits most sharpeners, same sizes as AO wheels | Standard sizes |

Usage Notes | Do not use diamond on steel chains | Do not use CBN on carbide chains | Standard usage |

Tip: Always pick a grinding wheel thickness that matches your chain pitch. For example, a 1/8″ diamond cut-off wheel works well for 3/8 Lo Pro and .325 chains. Some people think a 3/16″ cut-off wheel helps with some .325 chains, but most guides say use 1/8″ for both 3/8 Lo Pro and .325 chains, and 3/16″ for 3/8″ chains.

You should also think about how well the wheel works when you choose cut-off wheels for cutting. Here are some things to look for:

Many grinding wheel sizes let you sharpen different chain pitches and tooth sizes.

Angle guides help you set the right cutting angle for each tooth.

High speed (up to 3,150 rpm) lets you sharpen fast, but you need a strong diamond or CBN wheel to handle the heat.

Wear indicators show you when to change your cut-off wheels, so your cutting stays sharp.

Most chainsaw brands work with diamond, CBN, or aluminum oxide cut-off wheels.

Diamond cut-off wheels work best for carbide chains. CBN cut-off wheels are best for steel chains. Aluminum oxide cut-off wheels are a basic choice for steel chains, but you need to reshape and replace them more often. Wheel size and shape change hook and side plate angles, which affect your cutting speed and how long the wheel lasts.

Note: Always check your cut-off wheels for cracks and wear before you start cutting. This keeps you safe and makes sure your chains are ready to work.

Choosing a Wheel

Occasional Use

If you sharpen chainsaws only a few times a year, you want a wheel that is easy to use and affordable. Look for a simple electric or handheld sharpener that fits your workspace. Choose a reputable brand for better results. Adjustable grinding angles and speed control help you get a sharp edge without much effort.

Pick a wheel that matches your chain size and fits your grinder.

Make sure the sharpener has blade guards and secure clamping to boost the safety factor.

For grit size, a medium grit (60-80) works well for most home users.

Tip: Do not force the wheel. Let it do the work to avoid overheating and burning your chain.

Professional Use

If you sharpen chainsaws daily or run a shop, you need a wheel that lasts and works fast. CBN wheels give you long life and steady performance. They keep their shape and run cooler, which helps you avoid downtime.

Use a bench-mounted grinder for better control and speed.

Choose a wheel that matches your chain pitch and tooth size.

Clean the wheel often to prevent metal buildup.

Flip or rotate the wheel every 20-30 chains to keep it sharp.

Note: High-quality brands like Oregon or Tecomec offer better cutting and durability.

Specialty Chains

Carbide-tipped chains need diamond wheels. These wheels cut hard materials and last a long time. Always check that your grinder supports diamond wheels.

Use a slow-speed grinder to reduce heat.

Pick a fine grit (100-120) for carbide chains to get a smooth edge.

Make sure the sharpener has adjustable angles for best results.

Remember: Using the wrong wheel size or width can lead to poor sharpening and unsafe chains.

Budget

Your budget affects your choice. The table below shows how cost and lifespan compare:

Wheel Type | Initial Cost | Longevity | Maintenance Frequency | Budget Impact Summary |

|---|---|---|---|---|

Premium Super Abrasive | High | Low | Higher upfront cost, saves money over time | |

Aluminum Oxide (Pink) | Low | Shorter lifespan | Frequent replacement needed | Cheaper at first, costs more in the long run |

If you want to save money now, aluminum oxide wheels cost less but need more upkeep. Super abrasive wheels cost more at first but last much longer.

Safety matters most. Always check for cracks, use guards, and secure the chain before sharpening.

CBN or diamond chainsaw grinding wheels sharpen chains best. CBN wheels are good for steel chains and last a long time. Diamond wheels work great for carbide-tipped chains. If you are new, use softer bonded wheels with bigger grit sizes. This helps stop burning the cutters. Always pick a wheel that matches your chain pitch and skill level. After you choose, use safe sharpening steps. Keep your tools clean and store them right for good results.

FAQ

What wheel should you use for sharpening steel chainsaw teeth?

You should use a CBN wheel for steel chainsaw teeth. CBN wheels last longer and sharpen faster than aluminum oxide wheels. You get better results and save time.

Can you use a diamond wheel on regular steel chains?

No, you should not use a diamond wheel on steel chains. Diamond wheels work best for carbide-tipped chains. Using them on steel can damage the wheel and waste money.

How often should you dress an aluminum oxide wheel?

You should dress an aluminum oxide wheel every 2 to 5 sharpenings. Dressing keeps the wheel sharp and helps you avoid burning your chain.

What grit size works best for home chainsaw sharpening?

A medium grit size, like 60 or 80, works best for most home chainsaw sharpening jobs. You get a sharp edge without making the chain too rough.

How do you check if your grinding wheel is safe to use?

Tip: Inspect your wheel for cracks, chips, or wear before each use. Spin the wheel by hand and listen for odd sounds. Replace the wheel if you see any damage.

Contact Us

For More Grinding Solution or Customized Abrasive Tools