The best external grinding wheel material depends on what you need. Think about what you want to grind, the finish you want, and your budget. There are many materials for different jobs. Look at this table to see which material works best for each job:

Grinding Wheel Material | Typical Best-Use Scenario |

|---|---|

Aluminum Oxide | Grinding ferrous metals |

Silicon Carbide | Grinding non-metals and non-ferrous metals |

CBN | Hardened ferrous materials |

Diamond | Hard nonferrous materials like carbides, glass |

You should always check for ANSI certification on your grinding wheel. This helps keep you safe and makes sure the wheel works well. Picking the right wheel material, bond type, and hardness for your job gives better results. It also helps you get a smoother surface on your workpiece.

Key Takeaways

Pick the grinding wheel material for your workpiece. Use aluminum oxide for ferrous metals. Use silicon carbide for non-ferrous and non-metals. Use CBN for hardened steels. Use diamond for hard non-metal materials. Match the wheel’s bond type and hardness to your job. This helps you get better results. It also makes the wheel last longer. You will get a smoother finish. Use segment grinding wheels for tough jobs like concrete and stone. They remove material fast and stay cool. Take care of your grinding wheels. Check them for damage often. Dress them regularly. Use coolant to help them last longer. This also makes them safer. Always wear safety gear. Inspect wheels before you use them. Pick the right wheel size and type for your grinder. This keeps grinding safe and works well.

Grinding Wheel Overview

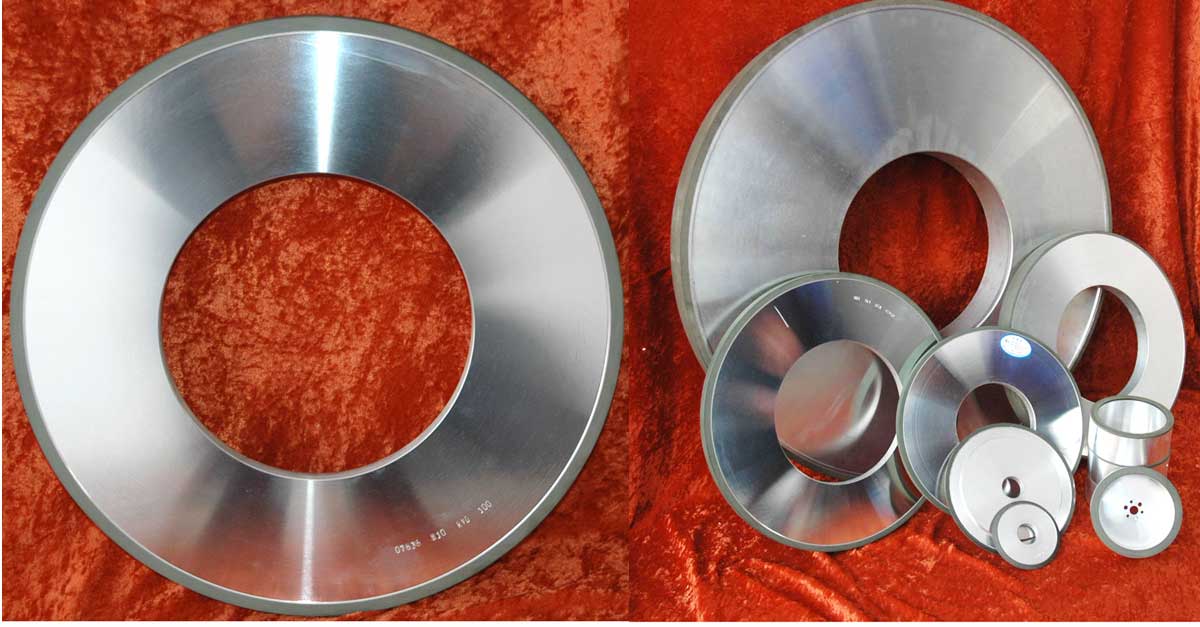

Types of External Grinding Wheels

You will find many types of external grinding wheel in shops and factories. Each type has a special shape and purpose. Here are the main types you might use:

Straight wheels: These are the most common grinding wheels. You use them for surface, cylindrical, and centerless grinding. They work well for shaping metal and other materials.

Cylinder or wheel ring wheels: These wheels have a large, flat surface. You use them on vertical or horizontal spindle grinders. They grind with the end face, not the edge.

Tapered wheels: These wheels look like straight wheels but get wider at one end. They are strong and handle heavy loads. You use them for grinding threads and gear teeth.

Straight cup wheels: These wheels have a cup shape. They give you an extra grinding surface. Tool and cutter grinders often use them.

Dish cup wheels: These wheels have a dish shape. You use them for special grinding jobs.

You can also group grinding wheels by how you use them. Look at this table to see the main categories and what makes them different:

Category | Defining Characteristics |

|---|---|

Rough Grinding Wheels | Remove lots of material fast; use coarse abrasive material. |

Cutoff Wheels | Thin wheels for cutting, not grinding; made with special abrasive materials. |

Precision Grinding Wheels | Fine grit and strong bonds for smooth, accurate finishes. |

Diamond and cBN Wheels | Use diamond or cubic boron nitride abrasive; grind very hard materials like ceramics or carbides. |

Mounted Points | Small wheels on a shaft; good for detailed or small grinding jobs. |

The abrasive material, grain size, wheel grade, grain spacing, and bond type all affect how these wheels work.

Segment Grinding Wheel Uses

A segment grinding wheel stands out because it has separate abrasive segments with gaps between them. This design helps you remove material quickly and keeps the wheel cool. The gaps let air flow through, which stops overheating and makes the wheel last longer.

You often use a segment grinding wheel for heavy-duty jobs. These wheels work well for concrete grinding wheels and stone work. You will see them in construction when cutting or shaping bricks and concrete blocks. The segmented rim lets you grind hard materials fast without damaging the surface. When you use cooling fluids, the channels in the wheel help direct the liquid to the right spot. This keeps your grinding safe and efficient.

Segment grinding wheels are a top choice for tough jobs. They give you rapid material removal, long life, and strong performance in harsh conditions. If you need to grind or cut concrete, stone, or masonry, these wheels will help you get the job done right.

Aluminum Oxide Wheels

Pros and Cons

Aluminum oxide wheels are good for many jobs. They are tough and do not break easily. Their Mohs hardness is about 9.0. This makes them strong and helps them last longer. You can use them to grind most steels and ferrous alloys. They also work on wood and some other metals. The abrasive in these wheels sharpens itself. This means the wheel keeps cutting well for a long time.

Here is a simple look at the pros and cons:

Aspect | Advantages | Limitations |

|---|---|---|

Hardness | Tough and hard to break | Not good for very hard or brittle things like ceramics or glass |

Wear Resistance | Sharpens itself and lasts longer | Not as fast as superabrasives for removing material |

Corrosion Resistance | Stays strong even when hot | — |

Application | Works well on most steels, ferrous alloys, and wood | Not best for high-speed or very precise grinding |

Cost-effectiveness | Cheap and useful for many jobs | — |

Tip: Aluminum oxide wheels cost less than diamond or CBN wheels. They are a good deal for most metalworking jobs.

These wheels wear out faster on very hard materials. They are not the best for high-precision or fast jobs. If you need to grind very hard steel or want a perfect finish, try a different abrasive.

Best Uses

You can use aluminum oxide wheels for many grinding jobs. They work best on ferrous metals like steel and iron. Shops use them to make gears, threads, and thin parts. These wheels fit many grinders, like bench grinders and surface grinders.

Use them to sharpen tools, dress, and do fine grinding.

They work well on carbon steel, wrought iron, and bronze.

You can use them in car, plane, and metal shops.

These wheels give you a good mix of strength, finish, and price.

If you want a wheel for daily grinding, aluminum oxide is a smart pick. They help you finish your work and save money.

Silicon Carbide Wheels

Pros and Cons

Silicon carbide wheels give you a strong option for grinding hard materials. You will notice that these wheels cost less at first than diamond wheels, making them a good choice if you want to save money on smaller jobs. They handle heat well and do not crack easily, even when you use them for tough grinding tasks. You can use them for many types of materials, and they work well in jobs where you stop and start often.

However, silicon carbide wheels do not last as long as diamond wheels. You will need to replace them more often, which means more time spent on maintenance. These wheels wear down faster, especially if you use them on very hard surfaces. They also do not work well on soft stones like limestone. If you need a super smooth finish or have a high-volume job, you might want to look at other options.

Tip: Silicon carbide wheels offer great heat control and can handle high temperatures up to 1300°C. This helps you avoid cracks or damage when grinding hard, brittle materials.

Here is a quick list of the main points:

Easy to use and available in many sizes.

Not the best for soft stones or high-precision, high-volume jobs.

Applications

You can use silicon carbide wheels in many industries. They work well for grinding and shaping metal, such as steel, cast iron, stainless steel, copper, and aluminum. These wheels also help you polish ceramics, glass, and stones like marble and granite. If you work with composite materials like fiberglass or carbon fiber, these wheels will do the job.

Many industries rely on silicon carbide wheels. You will see them in automotive shops, aerospace factories, construction sites, and metalworking plants. Stonemasons use them to cut and shape natural stone. Tool makers and woodworkers also use these wheels for special tasks.

Some types of silicon carbide wheels fit certain jobs better. Green wheels work best for non-ferrous metals, rubber, and plastics. Black wheels handle very hard materials like optical glass and ceramics. You can choose the right wheel for your project based on the material you need to grind.

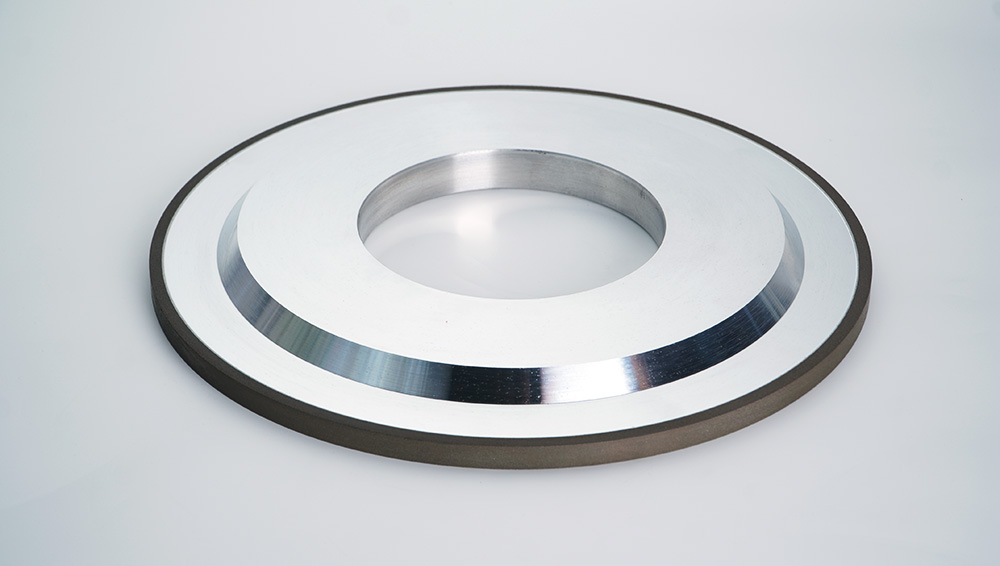

Diamond Grinding Wheels

Pros and Cons

Diamond grinding wheels are great for hard materials. They are very tough and stay sharp for a long time. Diamond is one of the hardest things on Earth. These wheels keep their shape and size well. This helps you get accurate results. Diamond cutting wheels are best for smooth finishes and high accuracy. The bond type changes how the wheel works. Resin bond wheels give fine finishes and good precision. Metal bond wheels last longer and are good for rough jobs. Vitrified bond wheels work at high speeds and handle heat well. Electroplated wheels cut fast and give fine finishes for special jobs.

Diamond wheels do not work well on ferrous metals. The carbon in diamond reacts with iron. This can hurt the wheel and your workpiece. Use these wheels for non-ferrous and non-metallic materials. If you need to grind steel, pick another abrasive. Diamond cutting wheels cost more than other types. But they last longer and save time on hard jobs.

Tip: Match the cutting speed to your material. High speeds remove more material but can make rough finishes and wear out the wheel faster. Low speeds give better surface quality.

Best Uses

Use diamond grinding wheels for hard, non-ferrous, or non-metallic materials. These wheels are good for grinding ceramics, glass, carbides, concrete, stone, and composites. Turbo row grinding wheels grind fast and give smooth finishes on concrete and masonry. Vacuum brazed grinding wheels cut quickly and last long on metal, stone, and fiberglass. Profile grinding wheels help shape and contour stone, marble, and granite. PCD grinding wheels remove coatings, glue, and paint from concrete floors.

Here is a table to help you pick the right diamond cutting wheel for your job:

Wheel Type | Best Application | Suitable Materials |

|---|---|---|

Turbo Row | Fast grinding, smooth finish | Concrete, masonry, stone |

Vacuum Brazed | Quick cutting, long life | Metal, stone, fiberglass |

Profile | Shaping, contouring | Stone, marble, granite |

PCD | Coating removal, floor prep | Concrete |

You get the best results when you use diamond wheels for hard materials. Do not use them on steel or iron. Pick the right wheel type and bond for your job. This helps balance cutting speed, finish quality, and wheel life.

CBN Grinding Wheels

Pros and Cons

CBN grinding wheels are strong tools for hard metals. They keep cool and do not cause much heat damage. These wheels hold their shape well. You do not need to clean or dress them often. Metal-plated CBN wheels do not explode easily. CBN wheels are balanced when you get them. You do not need extra balancing tools. You get sharp edges with no burrs. You spend less time finishing your work.

Here is a table to compare CBN, diamond, and aluminum oxide wheels:

Property / Feature | CBN Grinding Wheels | Diamond Grinding Wheels | Aluminum Oxide Wheels |

|---|---|---|---|

Hardness (Knoop) | 70,000 N/mm² | 20,000 N/mm² | |

Abrasion Resistance | ~4x aluminum oxide | ~4x aluminum oxide | Baseline |

Thermal Resistance | Up to 1000°C | Oxidizes above 600°C | Lower thermal resistance |

Chemical Stability | High with ferrous metals | Reacts with iron group metals above 700°C | Less chemically stable |

Suitable Materials | Hardened steels, tool steels | Carbides, ceramics, non-ferrous metals | General purpose |

Coolant Requirements | Needs oil-based coolants | Less sensitive to coolant type | Water-based coolants |

Limitations | Finite layer life in plated wheels | Not for steel at high temperatures | Lower abrasion resistance |

Note: CBN wheels last longer on hard steels like V10 and M2 HSS than diamond wheels. You do not need to change or fix the wheel often, so you save time.

Applications

CBN grinding wheels work best on hard steels and super-alloy steels. You use them to grind high-speed steels and tungsten carbide. They help sharpen end mills, milling cutters, and hobs. CBN wheels give sharp edges with no burrs. You can shape tools with good control.

Factories use CBN wheels to make and sharpen cold saw and friction saw blades. These wheels work on hard materials like HSS and tungsten carbide. You get accurate grinding and little heat damage. This keeps blades strong. Woodworkers use CBN wheels to sharpen chisels and plane blades made from tough steels. The wheels run smooth and do not clog. They keep tools sharp.

CBN wheels come in different bond types. Resin bonds work for wet or dry grinding but handle less heat. Vitrified bonds are good for fast, precise jobs with coolant. Electroplated bonds remove material quickly but do not last as long. You can pick the bond type that fits your grinding job. This helps you get the best results.

Bond Types

When you pick a grinding wheel, you need to check the bond type. The bond keeps the abrasive grains together. It changes how the wheel works. Each bond type is good for certain jobs and materials. Here is a table to help you see the main bond types:

Criteria | Vitrified Bonded | Resinoid Bonded | Metal Bonded |

|---|---|---|---|

Durability | High durability with long service life | Moderate durability, wears faster | Very high durability and wear resistance |

Form Retention | Excellent, retains shape well | Moderate, requires more frequent dressing | Excellent, holds shape over time |

Cutting Efficiency | High, balanced cutting performance | Very high, faster cutting action | Medium, slower but consistent cutting |

Thermal Resistance | Excellent, good heat dissipation | Fair, may soften under heat | Excellent, highly heat resistant |

Ease of Dressing | Easy, regular dressing possible | Easy, quick and simple | Difficult, requires specialized tools |

Cost-Effectiveness | High, long-term value | High, low initial cost | Medium, higher upfront cost but longer life |

Best Applications | Heavy-duty, precision, long production runs | Precision grinding, finishing on softer materials | Grinding very hard or abrasive materials |

Resinoid Bond

Many grinding wheels use resinoid bonds. This bond uses synthetic resin to hold the grains. Resinoid wheels cut fast and give smooth finishes. They work with many abrasive materials. You can use them for wet or dry grinding. These wheels do not clog easily. The abrasive stays sharp. As you grind, new grains show up. This keeps the wheel working well and gives a steady finish.

Tip: Resinoid bonds are good for grinding softer materials. They help keep the wheel cool. You get less heat, so your workpiece stays safe.

Resinoid wheels cost less at first. They fit many jobs. You can use them for precision grinding and finishing. They work best on softer metals and ceramic parts. If you want a wheel that cuts fast and stays sharp, resinoid is a good pick.

Vitrified Bond

Vitrified bonds use a ceramic, clay-like material to hold the grains. These wheels are strong and last a long time. They resist heat and keep their shape. Vitrified wheels stay the same shape after many uses. They are best for heavy-duty and precise jobs. You can use them on hard metals and tough ceramics.

Vitrified wheels are easy to dress. You can refresh the surface with simple tools. These wheels cut well and work at high speeds. You will see them in long jobs and when you need tight sizes. If you want a wheel that lasts and gives a clean finish, pick vitrified bond.

Metal Bond

Metal bonds use a metal mix to hold the grains. These wheels are very tough and do not wear out fast. You can use them for grinding very hard or rough materials. Metal bonds last a long time and keep their shape. They are good for jobs that need a strong wheel.

But metal bond wheels are harder to dress. You need special tools to fix the surface. They also cost more at first, but last longer. If you grind hard ceramics or rough materials a lot, metal bond wheels save you time and money later.

Note: Metal bond wheels cut slower than resinoid or vitrified wheels. But they give steady results and last much longer.

Selection Tips

Matching Wheel Hardness

When you pick a grinding wheel, match its hardness to your material. The bond holds the abrasive grains together and sets the hardness. Hard wheels keep their shape and help you get exact sizes. But they might not remove enough material and can burn your work. Soft wheels let go of dull grains fast, which helps with hard materials. These wheels lose their shape quicker, so check your sizes often.

Here are some tips for matching wheel hardness:

Use hard wheels for soft metals like aluminum. This keeps the wheel’s shape and gives a smooth finish.

Pick soft wheels for hard materials like tool steel. Soft wheels sharpen themselves and remove material better.

If the wheel touches a big area, use coarse grit and a soft wheel. This keeps things cool and helps with heavy jobs.

For small areas, use fine grit and hard wheels. Hard wheels handle more pressure and keep their shape.

Think about your machine’s power. If your machine is weaker than the wheel size, use a soft wheel. If it is stronger, use a hard wheel.

Matching wheel hardness to your material helps you cut better and makes the wheel last longer. You change wheels less and get smoother finishes. New wheel technology helps control heat and keeps your work safe.

Tip: Always check your wheel for balance and dress it often. This keeps it sharp and stops vibration.

Choosing Bond Type

The bond type in your grinding wheel changes how it works and how long it lasts. Pick the right bond for your material and job. Each bond has special features and fits different tasks.

Here is a table to compare bond types:

Bond Type | Properties and Suitability | Limitations and Notes |

|---|---|---|

Ceramic (Vitrified) | Stable, heat and corrosion resistant, low cost, fits most wheels | Not for thin discs or high-speed grinding |

Resin | Strong, elastic, impact resistant, self-sharpening, good for high-speed grinding | Poor heat resistance (up to 300°C) |

Rubber | Strong, elastic, impact resistant, self-sharpening, good for polishing and thin discs | Poor heat resistance (up to 200°C) |

Metal | Tough, good form retention, fits diamond and CBN wheels | Poor self-sharpening |

Match the bond type to your grinding method. Metal bonds work well for tough jobs like concrete grinding. Resin bonds give you flexibility and smooth finishes, good for polishing. Vitrified wheels act harder in dry grinding and help with precise jobs. The bond type also depends on grit size and your goal, whether you want rough grinding or a shiny surface.

Note: Keep your discs dry and do not stack them. This keeps the bond strong and stops damage.

Angle Grinder Wheels

Angle grinder wheels come in many shapes and sizes. Pick the right discs for your material and job. The abrasive type, grit size, wheel hardness, and bond all matter. For steel and other ferrous metals, use aluminum oxide discs. For non-ferrous metals like aluminum, use silicon carbide or diamond discs.

Here is a table to help you choose:

Specification | Steel (Ferrous Metals) | Non-Ferrous Metals (e.g., Aluminum) |

|---|---|---|

Abrasive Material | Aluminum Oxide | Silicon Carbide or Diamond |

Grit Size | Coarse for rough grinding; fine for finishing | Fine grit for smooth surface |

Wheel Hardness | Harder wheels for shape retention; softer wheels for less heat | Softer wheels to prevent gumming |

Bond Type | Vitrified, Resin, or Metal | Non-loading bonds to avoid clogging and rust |

Special Notes | Use contaminant-free INOX discs for stainless steel | Use non-loading discs to prevent rust |

Type 27 discs are flat and work at angles between 25° and 35°. They are good for removing lots of material up to 45°. Type 28 discs have a curved shape and help you reach tight spots at low angles. For aluminum, use silicon carbide discs with non-loading formulas. This stops the discs from gumming up and keeps your surface clean. For stainless steel, pick INOX discs with less than 0.1% iron, sulfur, and chlorine. This stops contamination and keeps your metal strong.

Tip: Always balance your discs before using them. Dress them often to keep them sharp and stop vibration. Change discs when they wear out or look damaged.

Comparison

Performance

When you pick grinding wheels, you want good results. Each abrasive material works in its own way. Finer grits make smoother surfaces. If you want a shiny finish, use a wheel with fine grains. Resin bonds help make smooth finishes. Vitrified bonds are better for precise work. Coolant keeps the wheel cool and helps the finish look better. Fast speeds can stop the wheel from clogging. You get a better surface if the wheel is made for high speeds.

Cutting wheels work quickly and take off lots of material. They use coarse abrasives and need less force. Grinding wheels use finer abrasives and need more force. They remove material slowly and give a smoother finish. If you need to shape, smooth, or polish, grinding wheels are best.

Aspect | Cutting Wheels | Grinding Wheels |

|---|---|---|

Operating Speed | High speed | Slower speed |

Pressure Applied | Low pressure | Higher pressure |

Abrasive Structure | Coarse, porous | Fine, tightly packed |

Material Removal Rate | Fast, aggressive | Controlled, gradual |

Contact Area | Minimal (narrow line) | Larger area |

Surface Finish Quality | Rougher finish | Fine, polished finish |

Wear Rate | Faster | Slower |

Typical Applications | Fast cutting | Shaping, deburring, polishing |

Tip: Always pick the right abrasive type and grit size for your job. This helps you get the best results and finish.

Durability

Durability means how long your grinding wheels last. Some wheels wear out fast, others last longer. Aluminum oxide wheels last a medium amount of time. They work for many jobs but need to be replaced more often. Silicon carbide wheels wear out faster because they break more easily. You will need to change them more if you use them on hard things.

Diamond and CBN wheels last the longest. Diamond wheels work well on hard, non-metal things. CBN wheels are best for hard steels and keep their shape for a long time. These wheels resist heat and wear, so you do not have to change them often.

To help your wheels last longer, try these tips:

Clean your wheels after you use them with a soft brush.

Check for cracks, chips, or uneven wear.

Keep wheels in a dry, cool place.

Dress the wheel often to keep it sharp.

Use the right speed and pressure.

Use coolant to stop overheating.

Note: Taking care of your wheels and using special cooling methods can help them last longer and give better finishes.

Cost

Cost matters when you choose grinding wheels. Aluminum oxide wheels cost the least. They are strong and cheap, so many shops use them. Silicon carbide wheels cost even less, but they wear out faster. You might spend more money over time because you need to buy new ones often.

Diamond wheels cost a lot, but they last much longer. You pay more at first, but you save money if you grind hard things often. CBN wheels cost the most. They are best for grinding hard steels and alloys. Their long life and good performance can lower your total costs in busy shops.

Grinding Wheel Type | Cost Level | Durability / Service Life | Typical Applications / Notes |

|---|---|---|---|

Aluminum Oxide | Low | Moderate; limited service life | Most widely used; good for general grinding; low market cost |

Silicon Carbide | Low (cheaper than Al2O3) | Less durable; brittle, wears faster | Sharper and harder than aluminum oxide; best for non-ferrous materials and flat surfaces |

Diamond | High | Long service life | Superabrasive; best for fragile, hard materials; high-quality abrasives for glass, ceramics, and stone |

CBN | Very High | Very long service life | Superabrasive; ideal for hard steels and alloys; high upfront cost but saves money in demanding applications |

If you need strong abrasives for tough jobs, diamond and CBN wheels are worth the money. For daily grinding, aluminum oxide and silicon carbide wheels help you save money.

Decision Guide

How to Choose

Picking the right external grinding wheel can seem hard. You want your job to turn out well, so you need to think about a few things. First, look at what material you will grind. Different materials need different abrasives. Aluminum oxide is good for ferrous metals. Silicon carbide works for non-ferrous metals or cast iron. Superabrasives like diamond and CBN are best for very hard materials.

Here is a table to help you compare the main things:

Factor | What You Should Consider |

|---|---|

Type of Material | Use the right abrasive for your workpiece. Harder materials need superabrasives. |

Bond Type | Vitrified bonds are strong and accurate. Resinoid bonds take off material fast. |

Grit Size | Coarse grit takes off material quickly. Fine grit makes a smooth finish. |

Grinder Speed | Fast speeds work for easy materials. Slow speeds are better for hard materials. |

Coolant Use | Coolant keeps the wheel cool and helps it last longer. |

Wheel Shape | Straight wheels are for big surfaces. Cup wheels are for heavy things like granite. |

Size and Thickness | Make sure the wheel fits your grinder for safety and good results. |

Experts say you should always match the wheel to the material. Superabrasives like diamond and CBN last longer and work better for hard materials. Regular abrasives like aluminum oxide and silicon carbide are better for softer materials. Experts also say superabrasives help keep the wheel cool and in good shape.

To pick your wheel, follow these steps:

Figure out what material you need to grind.

Choose the abrasive that fits your material.

Pick the bond and grit size for your finish.

Check your grinder’s speed and wheel size.

Decide if you need coolant for your job.

Tip: Always look for cracks or damage on the wheel before you use it. Safety is most important.

Picking the right external grinding wheel material helps you do a better job. You work faster and save money when you match the wheel to your project, the finish you want, and your budget. Always make sure the wheel is safe and will last before you begin. Use this checklist to help you choose:

Make sure your workpiece is tight and use machine guards.

Clean up dust and keep your area neat.

Pick the wheel material and bond that match your grinding job.

If you follow these steps, you stay safe and your grinding goes well without wasting money.

FAQ

What is a cylindrical ring grinding wheel used for?

You use a cylindrical ring grinding wheel to shape and finish round objects. It works well on shafts, rods, and pipes. This wheel helps you get smooth, even surfaces on metal parts.

Can I use concrete grinding wheels for metal?

You should not use concrete grinding wheels on metal. These wheels work best on stone, brick, or concrete. If you use them on metal, they wear out fast and may not give a good finish.

How do I choose the right wheel for cutting?

You pick a wheel for cutting by checking the material you want to cut. Use a wheel made for that material. For metal, use a metal cutting wheel. For stone, use a stone or concrete wheel. Always check the label.

How often should I replace my grinding wheel?

You should replace your grinding wheel when you see cracks, chips, or uneven wear. If the wheel vibrates or does not cut well, get a new one. Always check your wheel before each use.

Are all grinding wheels safe for high-speed grinders?

Not all grinding wheels work for high-speed grinders. You must check the wheel’s speed rating. Never use a wheel with a lower speed rating than your grinder. This keeps you safe and prevents accidents.

Contact Us

For More Grinding Solution or Customized Abrasive Tools