A resin bond grinding wheel is special because it gives smooth finishes and works well on soft or heat-sensitive materials. Many industries use this wheel because it saves money and cuts very well. People get better results when they grind hard or breakable materials, like ceramics and glass.

Users often pick a resin bond grinding wheel for small jobs that need high accuracy.

This wheel also works well with CNC machines, giving better control and making the tool last longer.

Key Takeaways

Resin bond grinding wheels can bend a little and sharpen themselves. This makes them good for smooth finishes. They also work well on materials that get damaged by heat.

These wheels cost less money and do not need much care. This helps save both money and time on many grinding jobs.

Resin bond wheels work well on hard and soft materials. They are great for small and careful tasks. They also work well with CNC machines.

They can handle some heat but not too much. They are not the best for very hot or heavy grinding jobs. Metal or vitrified bonds work better for those jobs.

Picking the right bond type depends on the job. Resin bonds are good for quick and smooth grinding. Other bonds are better for tough or very exact jobs.

Bond Types Overview

Resin Bond Grinding Wheel

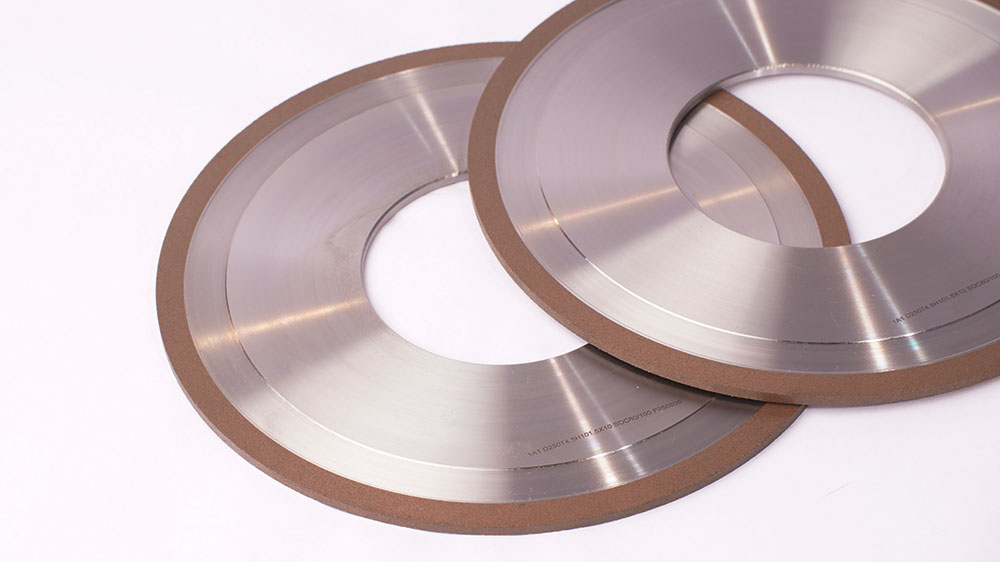

A resin bond grinding wheel holds abrasive grains with resin. Most makers use phenolic resin for this job. The resin bond makes the wheel strong and bendy. This wheel is good for many grinding jobs. It is best when you need a smooth finish and cool cutting. To make it, people mix, mold, press with heat, and finish the wheel. The bond layer is usually between 1/16″ and 1/4″ thick. It sticks to a metal hub. Green silicon carbide grains are often used in these wheels. They work best on cast iron, chrome rolls, and things that get hot easily.

Note: People use resin bond wheels a lot for cutoff, centerless, and superabrasive grinding.

Metal Bond

Metal bond grinding wheels use metal, like bronze, to hold abrasive grains. These wheels are very tough and last a long time. They keep their shape and work well for a long time. Metal bonds do not get damaged by chemicals and do not wear out fast. But, they do not let much coolant in, so they can get hot. You need special tools to dress these wheels. Metal bond diamond wheels are great for wet grinding hard things like ceramics, glass, and carbides.

Metal bond wheels cost more at first but last longer when used a lot.

Vitrified Bond

Vitrified bond wheels use clay and fluxes that are heated to about 2400°F. This makes a strong and stiff bond that stays strong even when hot. Vitrified wheels do not get hurt by water, oil, or acids, but they break if hit hard. Most grinding wheels are vitrified bond wheels. They work best where the temperature does not change much and there are no big shocks.

Bond Type | Properties | Typical Applications |

|---|---|---|

Vitrified | Strong, rigid, high-temp resistance | General grinding, precision work |

Resinoid | Flexible, cool cutting, moderate strength | Cutoff, rough grinding, heat-sensitive materials |

Metal | Durable, precise, chemical resistant | Hard materials, wet grinding, high-precision tooling |

Electroplated | Hard, high precision, reusable | Aerospace, medical, electronics, automotive |

Electroplated Bond

Electroplated diamond grinding wheels use a metal layer to hold diamond grains. This makes them wear out slowly and lose heat fast. The metal core helps keep the wheel cool while grinding. Electroplated wheels cut very clean and are very exact. They are used in aerospace, medical, electronics, and cars. These wheels last a long time and do not need to be changed often.

Electroplated wheels are best for special, very exact grinding, especially for hard things.

Resin Bond Features

Flexibility and Compliance

A resin bond grinding wheel is known for being flexible. This means it can bend a little during grinding. Because of this, it can handle small changes in the workpiece. The wheel’s flexibility helps stop cracks and damage. That is why people use resin bond wheels for smooth finishes and less heat.

Tests show that adding more Resin B makes the wheel up to 28% stronger than wheels with only Resin A.

Compression tests show the wheel can take four times more pressure than its tensile strength, so it resists cracks well.

When more Resin B is added, the wheel gets stiffer and less likely to break.

Field tests show wheels with more Resin B need 33–50% less grinding force, so they are more flexible and less likely to break.

Tool wear and G-ratio tests on hard steel show 2–3 times less tool wear and 2–7 times higher G-ratio for wheels with more Resin B, so they work better.

Surface roughness tests show up to 34% smoother surfaces, which means a better finish.

Note: Resin B helps the resin bond become less brittle and more flexible during grinding because it improves compressibility and friction.

The resin bond wheel can adjust to the workpiece. This helps lower heat and gives a better finish. But, if you want a very fine finish, a vitrified bond wheel might be better because it is stiffer and holds the grains in place.

Self-Sharpening and Cool Cutting

A resin bond grinding wheel can sharpen itself. As it grinds, old grains fall off and new sharp grains show up. This keeps the wheel cutting well for a long time. It means the wheel works well and lasts longer.

Experts say the hardness of the resin bond controls how fast grains come off. This helps the wheel stay sharp and work well. Studies show resin bond wheels are great at self-sharpening. The wheel stays sharp, so it works well and lasts longer.

Resin bond wheels also cut cool. The flexible bond helps control heat. This keeps the workpiece cooler and stops damage, especially on things that get hot easily. The result is a smooth surface and good shape.

Cost and Maintenance

Resin bond grinding wheels are a good deal for the price. They usually cost less than metal or vitrified bond wheels. They also do not need much care. Because they sharpen themselves, they last longer and do not need to be dressed often.

Lower starting cost than other bond types

Do not need to be dressed as much because they sharpen themselves

Less downtime and lower maintenance costs

Tip: Picking a resin bond grinding wheel can help save money and make grinding jobs faster.

Resin bond wheels are a smart pick for many jobs because they are cheap, easy to care for, and work well. They give steady grinding and high efficiency, especially when you need a smooth surface and good shape.

Phenolic Resin Bond Diamond Wheels

Thermal Stability

Phenolic resin bond diamond wheels can handle high heat very well. These wheels use phenolic resin to hold everything together. This resin has special chemical groups that help it stick to metal and stay strong in heat from 200°C to 400°C. Because of this, these wheels are safe and work well during hard grinding jobs.

The table below lists the main things that make these wheels work so well:

Property Type | Key Properties and Contributions to Performance |

|---|---|

Chemical Properties | High polarity, strong adhesion, withstands high temperatures, enhances binding strength |

Physical Properties | Good mechanical strength, heat resistance, wear resistance, works with hot-press processes, particle size matters |

Additional Notes | Resin quality affects safety and durability |

Makers check the resin quality very carefully. The amount of free phenol in the resin changes how the wheel cracks and how strong it gets after heating. The resin powder and hardener must be mixed evenly. If the powder is too rough, the wheel is weak. If it is too fine, mixing is hard and the wheel does not cut well. These steps help the wheels keep their shape and strength while grinding.

Phenolic resins are made from phenol and formaldehyde. They do not burn easily and can stand up to chemicals and heat. They also stick well to other things. Some makers add things like molybdenum compounds or aluminum nitride to the resin. These extras make the wheel even stronger and more stable. The wheel then lasts longer and works better, even on hard or heat-sensitive things.

Note: Using the right mix of resin and extras helps these wheels stay safe and last longer, even when they get very hot.

High-Precision Applications

Phenolic resin bond diamond wheels are important for jobs that need high accuracy. These wheels help grind and finish parts that must be very exact and smooth. Many industries use these wheels because they work so well.

Aerospace companies use these wheels to shape and finish tough parts.

Car factories use them to grind carbide, ceramics, and hard steel.

Tool makers use them to make and sharpen tools that need to be very exact.

These wheels can do both surface and round grinding. This helps workers get the right shape and finish. The wheels also keep the workpiece from getting too hot, which is important for strong materials.

Some wheels have more holes, called porosity. Wheels with more porosity are good for dry grinding. They let heat out fast, so the workpiece stays cool and safe. This helps the wheel stay stable during careful work.

Tip: When workers need a diamond grinding wheel for very exact jobs, these wheels give the right mix of strength, heat resistance, and accuracy.

These wheels help keep the surface smooth and the size just right. They also last longer and do not need much care. Many industries pick these wheels because they give good results in hard jobs.

Resin vs. Metal Bond

Durability

Resin bond grinding wheels and metal bond grinding wheels are different in how long they last. Metal bond wheels are stronger and do not wear out as fast. They keep their shape for a long time and can handle hard jobs. Resin bond wheels are not as strong and wear out faster, but they need less force to use and do not get as hot. This makes resin bond wheels good for short jobs or when you want a smooth finish.

The table below shows how they compare:

Aspect | Resin Bond CBN Wheel | Metal Bond CBN Wheel |

|---|---|---|

Bond Strength | Lower bond strength | Higher bond strength |

Wear Resistance | Lower wear resistance | Better wear resistance |

Durability | Good for short runs | Excellent for long, tough jobs |

Grinding Force | Smaller grinding force | Higher grinding power |

Metal bond wheels are best when you need a wheel that lasts a long time and is very strong. They work well for hard jobs that need a tough wheel.

Heat Resistance

Heat resistance is important for grinding wheels. Metal bond wheels can handle high heat very well. They do not change shape or get soft, even if you use them for a long time. The metal inside helps move heat away from the grinding spot. This keeps both the wheel and the thing you are grinding safe.

Resin bond wheels can take some heat, but not as much as metal bond wheels. If they get too hot, they might get soft or break down. This means you should not use them for really hot or heavy jobs. Metal bond wheels also do not get hurt by strong chemicals and keep working with coolants.

Feature | Resin Bond Grinding Wheels | Metal Bond Grinding Wheels |

|---|---|---|

Thermal Resistance | Fair; may soften under heat | Excellent; highly resistant to heat |

Heat Dissipation | Limited | Effective through metal core |

Chemical Resistance | Susceptible at high temp | Resistant to chemical degradation |

High Wear Resistance | No | Yes |

Application Suitability

Resin bond and metal bond grinding wheels are good for different jobs. Resin bond wheels work on many materials and can remove a lot of material fast. They can also take in shocks from shaking. This makes them good for general grinding and quick jobs.

Metal bond wheels are great for grinding hard things like glass, ceramics, and carbides. They are the hardest type and last the longest. You need special tools to fix them because they are so strong.

Resin bond wheels are good if you want a wheel that is easy to use, flexible, and not expensive.

Metal bond wheels are best for hard jobs where you need a strong wheel that does not wear out fast.

Tip: Use resin bond wheels for quick, easy grinding. Pick metal bond wheels for tough jobs that need high accuracy and long life.

Resin vs. Vitrified Bond

Toughness and Ductility

Resin bond grinding wheels are strong and can bend a little. They can take hits and shocks while grinding. This makes them good for jobs where things might shake or move. The resin bond lets the wheel flex without breaking. Workers use these wheels when they want a smooth finish or work with fragile materials.

Vitrified bond grinding wheels are different. They are hard and break more easily. These wheels do not bend much at all. They keep their shape even when pressed hard. Vitrified wheels are best for jobs that need exact grinding and a steady surface. Their strength helps them last longer, especially when used all the time.

Stiffness and Wear

Stiffness matters in grinding. Vitrified bond wheels are very stiff and hard. This helps them keep their shape during long use. They do not change shape and keep the surface even. Resin bond wheels are more bendy. They can lose their shape if used too long or get too hot.

Wear is also important. Resin bond grinding wheels wear out faster if used a lot. They do not handle heat as well and can burn above 230°C. This means workers must change them more often. Vitrified bond wheels can take more heat and have tiny holes for air. They stay cool and do not wear out fast, even in hard jobs. Workers see that vitrified wheels keep their shape and last longer. This makes them great for tough jobs.

Tip: If you need a wheel that lasts long and keeps a steady surface, vitrified bond grinding wheels are a better choice than resin bond wheels.

Resin vs. Electroplated Bond

Grain Exposure

Resin bond grinding wheels and electroplated bond wheels show different ways of holding abrasive grains. In a resin bond wheel, the resin covers and supports the grains. As the wheel wears down during grinding, new grains become exposed. This process helps the wheel stay sharp and cut well. The wheel can keep working without losing its cutting power.

Electroplated bond wheels use a thin metal layer to hold the grains on the surface. Almost all the grains sit on top of the wheel. This design gives a very high grain exposure. The grains cut the material directly during grinding. Workers see fast and aggressive cutting with these wheels. The high grain exposure also means the wheel can make very precise cuts. Electroplated wheels work best for jobs that need exact shapes or fine details.

Note: Electroplated wheels do not have layers of grains. Once the top grains wear away, the wheel cannot expose new grains.

Reusability

Resin bond grinding wheels have a limited life. When the resin wears down, the wheel loses its shape and cutting ability. Workers must replace the wheel after it wears out. These wheels cannot be reused or recoated. Each new grinding job needs a fresh wheel.

Electroplated bond wheels offer better reusability. After the top layer of grains wears off, some wheels can be recoated with new abrasive grains. This process gives the wheel a second life. Workers save money and reduce waste by recoating instead of buying new wheels. Electroplated wheels also keep their shape well during grinding, so they work for many special tasks.

Resin bond wheels: single-use, not reusable

Electroplated wheels: can be recoated, longer service life

Tip: For jobs that need high precision and possible reusability, electroplated bond wheels give a clear advantage.

Comparison Table

Picking the best grinding wheel depends on many things. Each bond type has its own good and bad points. The table below shows how resin bond, metal bond, vitrified bond, and electroplated bond wheels compare. It looks at cost, how long they last, how well they work, and what jobs they fit best.

Bond Type | Cost Range | Durability & Wear | Grinding Performance & Suitability | Typical Applications |

|---|---|---|---|---|

Resin Bond | Medium-Low | Wears faster; flexible | Good self-sharpness; high processing efficiency; best for general grinding and smooth finishes | Cast iron, high-speed steel, heat-sensitive materials |

Metal Bond | High | Highly wear resistant | Slow grinding; generates high heat; best for hard materials and long runs | Ceramics, glass, carbide, wet grinding |

Vitrified Bond | Medium-High | High stock removal; rigid and porous; maintains form under heavy use | Precision grinding, large volume production | |

Electroplated | Low | Single-use; wears quickly | High material removal rate; no dressing needed; less smooth finish | Short runs, high-precision, special shapes |

Quick Reference:

Resin bond wheels are easy to use and bend a little, but they wear out faster than metal or vitrified wheels.

Metal bond wheels last a long time and can do hard jobs, but they cost more and grind slower.

Vitrified bond wheels are strong and stiff. They do not get hurt by chemicals, so they are good for big jobs or when no one is watching the machine.

Electroplated wheels are great for short, exact jobs, but you cannot use them again after the top layer is gone.

People should pick the grinding wheel that matches the job and material. For example, resin bond wheels are good for most grinding and smooth finishes. Metal bond wheels are best for hard things and long jobs. Vitrified bond wheels are good for tough grinding and keep their shape. Electroplated wheels work best for short, very exact jobs.

Best Uses for Resin Bond

Ideal Materials

Resin bond grinding wheels work well on many materials. They can be used on both hard and soft workpieces. For hard things like ceramics and carbides, a softer resin bond wheel helps keep the edge sharp. These hard materials break into tiny pieces, so the wheel stays sharp and works fast. For softer things like steels and high nickel alloys, a harder resin bond wheel is better. Softer materials make long chips that can wear down the wheel quickly. Picking the right wheel hardness, grit size, and amount of grit helps match the wheel to the job. Harder materials need softer wheels with smaller grit. Softer materials need harder wheels with bigger grit.

Tip: Always pick the wheel based on what you are grinding and if you want a rough or smooth finish.

Industry Applications

Many industries use resin bond grinding wheels because they work well and can be used in many ways. These wheels are found in woodworking, mining, car making, airplanes, medical tools, glass, ceramics, oil and gas, and making things from different materials. Workers use them for tool grinding, grinding round parts, flat parts, and centerless grinding. Other jobs include cutting off pieces, grinding rolls, sharpening saws and knives, grinding PCD, and sharpening blades for surgery. Phenolic resin bonds are common in woodworking and mining. Polyimide resin bonds are used for very exact jobs in airplanes and cars. These wheels can be used on many materials like metals, ceramics, composites, tungsten carbide, and hard steels. They last a long time and work well for both rough and smooth grinding.

When Not to Use

Resin bond grinding wheels are not good for every job. They may not last long when grinding is very heavy or gets very hot. Metal bond or vitrified bond wheels are better for tough jobs because they are stronger and handle heat better. Resin bond wheels can also wear out fast on very soft materials if you pick the wrong hardness. If you need a wheel that is very stiff or keeps its shape for a long time, other bond types might work better. Do not use resin bond wheels when the job needs the best grinding under hard conditions.

Resin bond grinding wheels are special because they can bend a little, sharpen themselves, and save money. They work well for many jobs and make smooth surfaces. But, they do not handle heat as well and do not last as long as some other wheels. The table below shows how each bond type is different:

Bond Type | Main Strengths | Limitations |

|---|---|---|

Resin Bond | Gets hot fast, wears out sooner | |

Metal Bond | Very strong, keeps its shape | Slower, costs more |

Vitrified Bond | Hard, strong, stays cool | Breaks easily, not bendy |

Electroplated | Very exact, can use again | Only one use, not as smooth |

Pick resin bond wheels for fast, smooth grinding on things that get hot or break easily.

Use metal or vitrified wheels for tough jobs, high heat, or when you need the wheel to last a long time.

Always choose the right wheel for the material and job to get the best results.

FAQ

What makes resin bond grinding wheels different from other types?

Resin bond grinding wheels offer flexibility and self-sharpening. They work well on heat-sensitive and brittle materials. Many users choose them for smooth finishes and lower costs.

Can resin bond wheels handle high temperatures?

Resin bond wheels can handle moderate heat. They may soften or wear out if used in very high-temperature jobs. Metal or vitrified bond wheels work better for extreme heat.

How often should someone replace a resin bond grinding wheel?

Users should replace resin bond wheels when they lose shape or cutting ability. Frequent checks help prevent poor results. These wheels usually wear out faster than metal or vitrified types.

Are resin bond wheels safe for grinding glass or ceramics?

Yes, resin bond wheels work well on glass and ceramics. Their flexible bond helps prevent cracks and chips. Many industries use them for these materials.

Do resin bond grinding wheels need dressing?

Most resin bond wheels need less dressing because they self-sharpen. Some jobs may still require light dressing to keep the wheel in good shape.

Contact Us

For More Grinding Solution or Customized Abrasive Tools