For most users, a diamond grinding wheel dresser gives you the best mix of versatility and performance. You can use this tool on almost any grinding wheel, so it works well in most home or shop settings. Your perfect grinding wheel dresser depends on your grinding wheel type, how often you grind, the finish you want, and your budget. Use our comparison guide to choose the right grinding tool for your needs.

Key Takeaways

-

Diamond grinding wheel dressers work well for most people. They are good because they can do many jobs and work well. Dressing your grinding wheel often keeps it sharp and clean. It also helps the wheel keep its shape. This makes cutting better and gives a smoother finish. Pick a dresser that fits your grinding wheel type. Think about how often you use it and how much you want to spend. This will help you get the best results. Always wear the right safety gear. Follow safe steps when dressing to stay safe and make your tools last longer. Check your grinding wheel and dresser often. Dress them often to keep them working well for a long time.

Grinding Wheel Dresser Types

Dressing Stones

Dressing stones are blocks made from rough materials like silicon carbide or aluminum oxide. You use them by rubbing the stone on the grinding wheel. This takes off old grains and shows new sharp parts. Dressing stones work best for fine-grained wheels and finishing jobs. They help make the grinding wheel smoother and sharper. These stones are easy to use and do not cost much. But they wear down fast and need to be replaced often.

|

Aspect |

Advantages |

Disadvantages |

|---|---|---|

|

Material |

Abrasive blocks (silicon carbide/aluminum oxide) |

Wears out quickly |

|

Function |

Removes worn grains, improves finish |

Produces dust and heat |

|

Suitability |

Great for fine-grained wheels, finishing |

Needs frequent replacement |

Dressing stones work with most regular grinding wheels, especially for finishing.

Diamond Dresser

A diamond dresser has strong diamonds on its tip or surface. You can pick a single-point or multi-point diamond dresser. The single-point type lets you control the shape and keep surfaces flat. It is good for small or medium jobs where you need to be exact. Multi-point dressers spread out the wear, so they last longer for big jobs and general use.

Tip: Use a single-point diamond dresser if you want your grinding wheel to stay flat and true.

Diamond dressers work with many grinding wheel types, like resin, vitrified, and metal-bonded wheels. They are very exact and can be used for many jobs, so both hobbyists and pros like them.

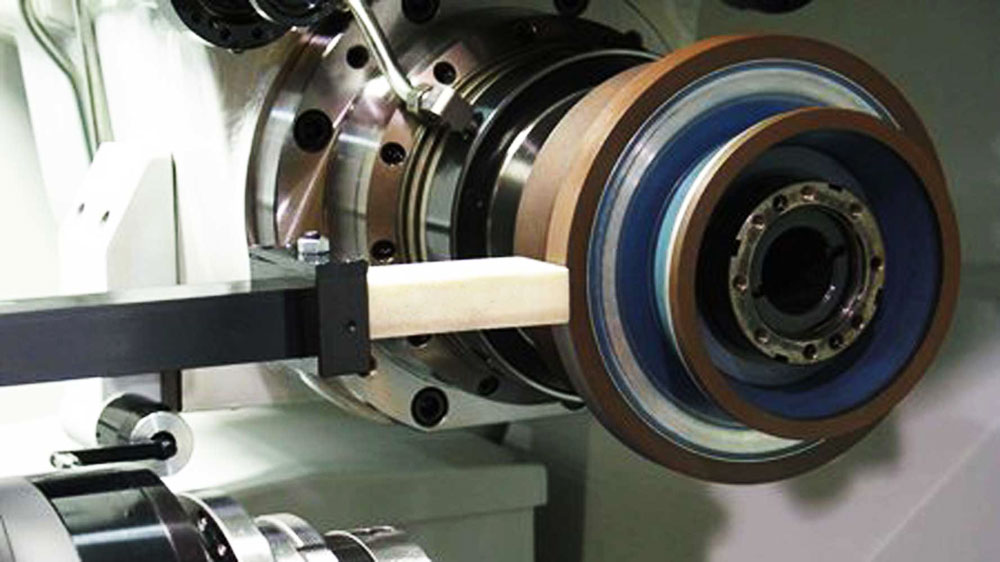

Diamond Rotary Dresser

Diamond rotary dressers look like spinning drums or discs with diamond bits. You use them for big grinding wheels or when you want a smooth, even surface. The spinning helps bring back the wheel’s shape and keeps it sharp. This tool is used in places like car, airplane, and medical factories, where you need very exact grinding.

-

Diamond rotary dressers give steady results every time.

-

They help keep shapes and sizes very accurate.

-

You can use them on vitrified, resin, and some metal-bonded grinding wheels.

If you need to fix superhard or very exact grinding wheels, a diamond rotary dresser is usually the best tool.

Grinding Wheel Dressing Basics

Why a Grinding Wheel need to dress

A grinding wheel needs dressing to work well. Over time, the grains on the wheel get dull. Dirt and bits can block the wheel’s surface. The wheel can also lose its round shape. When this happens, the wheel does not cut well. You may hear strange sounds or feel shaking. The workpiece might have marks or be the wrong size. Dressing takes away old grains and dirt. This makes the wheel sharp and round again. Grinding gets easier and more exact after dressing. Doing this often helps the wheel cut better and last longer. Studies show that good dressing keeps the wheel in top shape and gives better results.

-

Dressing a grinding wheel:

-

Makes the wheel sharp and round again

-

Cleans off dirt and bits

-

Fixes uneven spots

-

Helps grinding work better

-

Makes the wheel last longer

-

When to Dress

You should watch for signs that tell you to dress your wheel. These signs help you keep grinding safe and smooth.

|

Description |

Measurement Method / Indicator |

|

|---|---|---|

|

Grinding burn and clogging |

You can see marks or dirt on the wheel when it is worn out |

Look at the wheel after about 100 uses |

|

Dressing forces exceeding limits |

If it gets harder to dress, the wheel or tool is worn |

Use sensors to check how hard you push when dressing |

|

Force vacillations during dressing |

If the force goes up and down, the wheel may be broken |

Check the force and signals while dressing |

|

Surface roughness of grinding wheel |

If the wheel feels rougher, it is getting worn |

Use sensors to measure how rough the wheel is |

|

Acoustic emission and spindle load |

Sounds and motor strain can show the wheel needs dressing |

Use sound sensors and check the motor’s force |

These signs help you know when to dress your wheel. This keeps your wheel working well and your work looking good.

Do all grinding wheels need to dress

Most grinding wheels need to be dressed often to stay sharp. Some new wheels, like porous metal bond wheels, do not need it as much. These wheels are made to stop dirt from building up. For example, a porous metal bond wheel with glass fiber can grind some things without much dressing. This kind of wheel can be used dry, saves energy, and makes a smoother finish. But most wheels still need regular dressing. This helps them last longer, work better, and make your workpiece look good.

Dressing a Grinding Wheel – Step by Step

Conventional Grinding Wheels

There are a few ways to dress a conventional grinding wheel. The most common tools are a diamond dresser or a dressing stone. Here are the steps to keep your wheel sharp and safe:

-

Wear safety gear. Always wear safety goggles, a face shield, and hearing protection.

-

Secure the dressing tool. Hold the diamond dresser or dressing stone tightly against the grinding wheel.

-

Start the grinder. Turn on the grinder and let it get to full speed.

-

Apply the dressing tool. Gently press the tool on the wheel’s surface. Move it slowly across the wheel to cover all of it.

-

Control the feed. Keep the tool at a small angle, about 5°-15°. For a smooth finish, move the tool slowly and use a shallow cut.

-

Check your progress. Stop the grinder and look at the wheel. Repeat the steps if you need to.

Here is a simple guide to common dressing methods:

|

Dressing Method |

Description |

Common Tools Used |

Key Parameters and Notes |

|---|---|---|---|

|

Turning Dressing |

Shape and clean the wheel with a diamond dresser or block. |

Single-point diamond dresser, diamond block |

Use a 5°-15° angle, keep the contact point below the axis, and move slowly for a fine finish. |

|

Diamond Roller Dressing |

Use a diamond-coated roller for tricky shapes and big jobs. |

Diamond roller dresser |

This tool lasts a long time and is best for gears and blades. |

|

Dressing with Grinding Wheel |

Dress a wheel using a silicon carbide wheel. |

Silicon carbide grinding wheel |

The dressing happens by grinding one wheel with another. |

|

Rolling Dressing |

Use hard discs or rollers to shape the wheel. |

Corrugated iron disc, steel rollers |

You do this by hand, and it works well for simple shapes. |

Tip: Always turn off the coolant before you stop the grinder. This keeps the coolant from soaking into the grinding wheel.

Superhard Grinding Wheels

Dressing a superhard grinding wheel, like a diamond or CBN wheel, needs special care. These wheels are much harder than regular ones. You often need to shape and sharpen the wheel in two steps.

-

Put on your safety gear. Wear goggles, a face shield, and hearing protection.

-

Choose the right dressing tool. Pick a diamond pen, a silicon carbide wheel, or a diamond grinding wheel.

-

Shape the wheel. Use the dressing tool to make the wheel the right shape. Move slowly and press gently.

-

Sharpen the wheel. After shaping, use the tool to show new sharp grains.

-

Use advanced methods if needed. For tough jobs, you might use electrical discharge, electrolytic, or laser dressing.

-

Check the wheel. Look at the wheel to see if it is the right shape and sharpness. Repeat if you need to.

|

Aspect |

Conventional Grinding Wheels |

|

|---|---|---|

|

Dressing Process |

Shaping and sharpening, sometimes together |

Usually single-step mechanical dressing |

|

Dressing Methods |

Mechanical, electrical discharge, electrolytic, laser |

Mechanical (turning, rolling) |

|

Dressing Tools/Materials |

Diamond pens, silicon carbide wheels, diamond grinding wheels |

Abrasive wheels, diamond dressers |

|

Challenges |

High tool wear, long dressing time, need for precision |

Less complex, higher efficiency |

-

Superhard wheels need more advanced dressing methods because they are very hard and have special bonds.

-

You may need to use both mechanical and advanced techniques for the best results.

Note: Dressing a grinding wheel takes longer with superhard wheels. You must use the right dressing tool and method so you do not damage the wheel.

Choosing the Best Grinding Wheel Dresser

Wheel Type Compatibility

You need to match your grinding wheel dresser to the type of grinding wheel you use. The material and hardness of your wheel decide which dresser works best. Harder wheels need dressers with more diamond or tougher diamond types. The shape and size of the dresser must fit your wheel and machine. If you use a resin, vitrified, or metal-bonded wheel, a diamond dresser usually gives the best results. For superhard wheels, you may need a rotary dresser or a special diamond tool.

Here are some key points to consider:

-

The grinding wheel’s material and hardness affect which dresser you should pick.

-

The finish you want on your workpiece depends on the diamond grit size in the dresser.

-

Complex grinding jobs need dressers that offer more control and precision.

-

The dresser must fit your grinding machine and wheel setup.

-

The choice between natural and synthetic diamonds changes how long your dresser lasts.

-

Your dresser must handle the forces from your grinding machine without breaking.

Proper compatibility helps you remove dull grains, keep your wheel sharp, and improve efficiency. It also maintains the wheel’s shape, which leads to better dimensional accuracy and a consistent surface finish. Using a compatible dresser prevents uneven wear and reduces replacement costs.

User Needs and Budget

Your needs and how often you use your grinding wheel dresser play a big role in your choice. If you are a hobbyist or only use your grinder sometimes, a single-point diamond dresser or a dressing stone may be enough. These tools give you good control and are easy to use for small jobs. If you work in a shop or use your grinder every day, you may want a multi-point diamond dresser or a rotary dresser. These dressers work faster and last longer, making them better for frequent use.

-

Single-point diamond dressers give you high precision and control. They are best for fine wheels and detailed work.

-

Multi-point diamond dressers dress larger wheels quickly and wear evenly. They suit high-frequency use.

-

Rotary dressers, like diamond rolls, work well for complex shapes and heavy-duty grinding. They last a long time and keep your wheel sharp.

You should also think about your budget. High-quality grinding wheel dressers cost more at first, but they last longer and improve efficiency. This reduces replacement costs over time. If you only grind once in a while, a basic dresser may be enough. If you grind often or need top results, invest in a better dresser.

Tip: Choose a dresser that matches your grinding habits. This helps you get the best value and performance.

Finish Quality

The type of grinding wheel dresser you use affects the surface finish of your workpiece. Single-edge diamond dressers create sharp grains on the wheel, which leads to a smoother finish. Four-edge dressers can flatten the grains, making the surface rougher. The way you dress the wheel also matters. A slow, steady feed with the right depth gives you a better finish. If you move too fast or use too much pressure, the surface can become rough.

-

Dressing removes worn grains and sharpens the wheel, which improves the surface finish.

-

Using a blunt dresser makes the wheel dull, which increases surface roughness.

-

Dressing depth and speed change the finish. Too deep or too fast can damage the wheel and make the finish worse.

-

Regular rotation of your diamond dresser keeps it sharp and helps you get a consistent finish.

You should always use enough coolant during dressing. This flushes away debris and keeps the wheel and dresser in good shape. After dressing, the grinding wheel may need a short break-in period before it gives the best finish. If you want high precision and a fine surface, use a single-point diamond dresser with careful technique.

Note: The right dresser and dressing method help you achieve the best surface finish and maintain efficiency in your grinding work.

Grinding Wheel Dressing Tips

Safe Use

You should always follow safety rules when you dress a grinding wheel. This keeps you safe and helps your tools last longer. Here are some important tips:

-

Wear the right personal protective equipment. Use safety glasses, a face shield, hearing protection, gloves, and safety shoes.

-

Make sure you have training for the grinding wheel and the dressing tool you use.

-

Check that all guards are in place and strong. Guards should cover as much of the wheel as possible.

-

Adjust the work rest close to the wheel. Keep the gap less than 3 mm to prevent accidents.

-

Inspect the grinding wheel before each use. Look for cracks or chips. Do not use a damaged wheel.

-

Fasten the grinder to a solid surface. This stops it from moving during dressing.

-

Stand to the side when you start the grinder. Let the wheel reach full speed before you begin.

-

Use light, even pressure when dressing. Let the wheel do the work.

-

Move the dresser smoothly across the wheel face. This prevents grooves and keeps the wheel even.

-

Clean your work area after you finish.

Tip: Dress your grinding wheel often with light passes. This keeps the wheel sharp and improves efficiency.

Maintenance

Good grinding wheel maintenance helps your dresser last longer and keeps your grinding safe. Follow these steps:

-

Inspect your dresser and grinding wheel before each use. Look for cracks, chips, or other damage.

-

Store grinding wheels and dressers in a dry, cool place. Avoid humidity and temperature changes.

-

Handle wheels and dressers carefully. Do not drop or bump them.

-

Dress your grinding wheel on a regular schedule. This keeps the wheel sharp and in the right shape.

-

Use the right dressing tool for your grinding wheel type. Check with the manufacturer if you are not sure.

-

Keep your grinding area clean. Control dust and keep the space dry to prevent rust.

-

Train everyone who uses the grinder on safe handling and basic maintenance.

Note: Regular inspection and dressing help you spot problems early. This keeps your grinding wheel and dresser working well for a long time.

Choosing the right dresser for your needs makes a big difference in your results. When you match your dresser to your application, you get better performance and save money over time.

-

Custom-fit dressers help you keep a steady finish and reduce waste.

-

The right tool also lowers how often you need to dress your wheel.

Regular dressing with the correct tools keeps your wheel sharp and helps it last longer.

1. You reduce surface loading and keep cutting effective.

2. Scheduled maintenance helps your wheel cut better and last longer.

Review the comparison guide before you buy to make the best choice for your shop.

FAQ

How often should you dress your grinding wheel?

You should dress your grinding wheel when you notice it cuts slower or feels rough. If you see burn marks or uneven surfaces, it is time to dress the wheel. Regular dressing keeps your wheel sharp and safe.

Can you use any dresser on any grinding wheel?

No, you cannot use every dresser on every wheel. Always match the dresser to your wheel type. For example, use a diamond dresser for hard wheels. Dressing stones work best for softer, conventional wheels.

What safety gear do you need for dressing a grinding wheel?

Always wear safety glasses, a face shield, and hearing protection. Gloves and safety shoes help protect your hands and feet. Safety gear keeps you safe from flying debris and loud noise.

Does dressing a wheel change its shape?

Yes, dressing can change the shape of your grinding wheel. You can use a dresser to make the wheel flat, round, or shaped for special jobs. Always check your wheel after dressing to make sure it has the right shape.

Contact Us

For More Grinding Solution or Customized Abrasive Tools