When you pick a carbide grinding wheel, you will see three main choices. These are diamond wheel, green silicon carbide, and CBN. Experts say diamond and CBN wheels are best. These abrasives are very hard and can handle heat well. This makes them great for grinding hard things like carbide. Regular wheels would not work for this. Green silicon carbide is special because it is very pure. It has sharp edges and keeps cutting edges sharp. You can use a diamond wheel for careful, detailed work. A carbide grinding wheel is good for tough jobs. These three types can do the hard work you need.

-

Green silicon carbide:

-

Has 97–99% purity

-

Has sharp, breakable edges

-

Works well on hard, breakable materials

-

Key Takeaways

-

Diamond grinding wheels are best for carbide. They cut quickly, last a long time, and make things smooth. – Green silicon carbide and CBN wheels are good for rough work or saving money. But they wear out faster than diamond wheels. – Picking the right wheel depends on grit size, bond type, wheel shape, and if it fits your machine. – Always dress your grinding wheel often. This keeps it sharp and safe for better results. – Follow safety rules. Wear protective gear, check wheels for damage, and use good ventilation when grinding carbide.

Carbide Grinding Needs

Why Special Wheels Are Needed

Carbide is a very hard material. You often see it in cutting tools because it can handle tough jobs. When you try grinding tungsten carbide, you face a big challenge. Regular wheels wear out fast and cannot cut well. You need a carbide grinding wheel that can handle the hardness and heat.

-

Carbide is much harder than steel, so normal abrasives do not work.

-

Diamond wheels are the hardest and can grind carbide without wearing down quickly.

-

Grinding creates a lot of heat. Special wheels have bonds that can take high temperatures and release new abrasive grains as needed.

-

Some wheels, like CDX, mix CBN and diamond to grind carbide efficiently and reduce heat damage.

-

The bond type, such as resin or metal, helps the wheel last longer and keeps its shape during grinding.

Tip: Polyimide bonds work well for grinding carbide tools because they can handle high heat and keep the wheel in shape.

Grinding Challenges

Grinding carbide is not easy. You must pay attention to many details to get good results.

-

Carbide tools are very hard but also brittle. They can chip or break if you are not careful.

-

Edges may chip or jump during grinding, so you need to handle the tools gently.

-

Grinding tungsten carbide needs special machines and skilled workers. Regular grinding centers may not have the right equipment.

-

Choosing the right wheel is important. Diamond wheels are best for carbide because they last longer and cut better.

-

You need to follow strict standards and use special tools to check your work. This helps you avoid mistakes and get a smooth finish.

Note: Skilled grinding mechanics make a big difference. They know how to avoid damage and get the best results from your grinding process.

Types of Carbide Grinding Wheel

Diamond Wheels

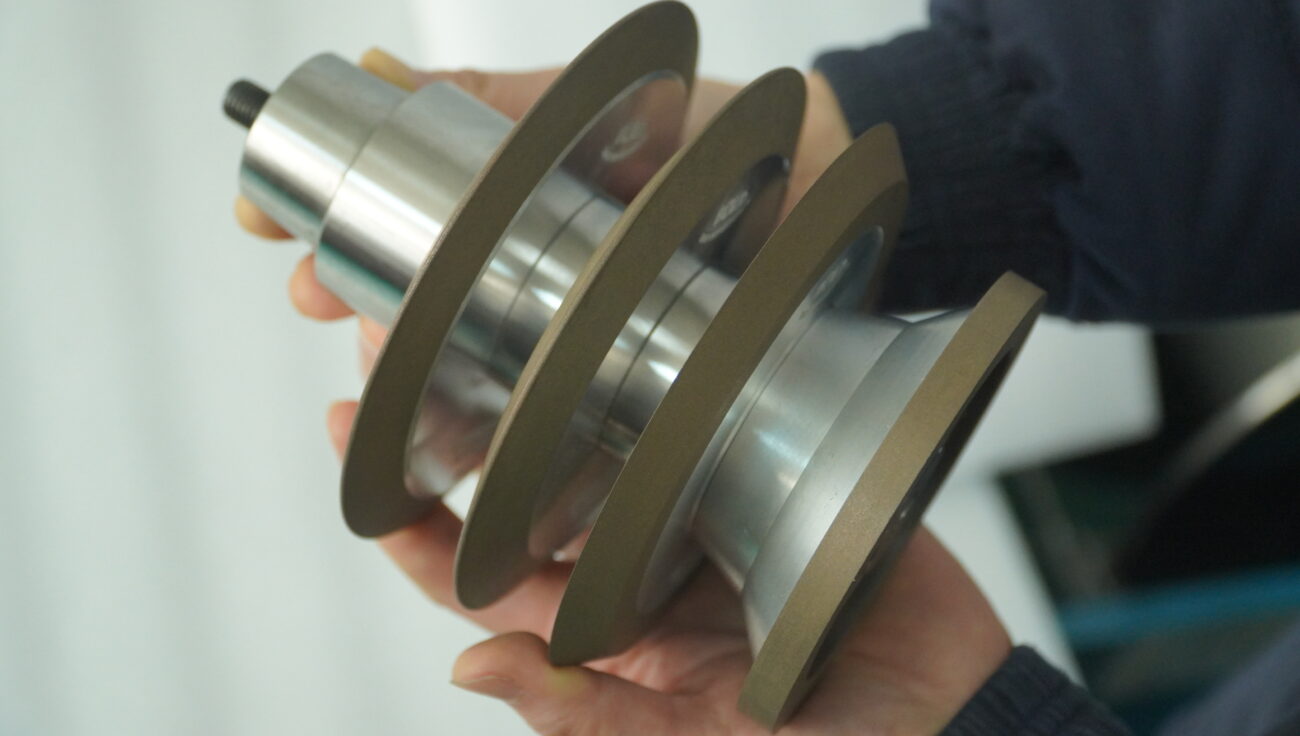

Diamond wheels are the best choice for grinding carbide. You can use them for rough or fine grinding jobs. These wheels have synthetic diamonds in different bonds. The bonds can be metal, vitrified, or electroplated. Each bond changes how the wheel works.

-

Metal bond diamond wheels use a metal like bronze or steel. They last a long time and do not wear out fast. They are good for grinding hard and brittle things.

-

Vitrified bond wheels use a glass-like bond. They keep their shape and handle heat well. This lets you grind with more accuracy at higher speeds.

-

Electroplated diamond wheels have one layer of diamond held by nickel. They cut sharply and give a smooth finish. But they do not last long for heavy jobs.

Pick the right bond for your material and finish needs. Hard materials like carbide need a hard bond. This keeps the wheel from wearing out too soon. Some diamond wheels have grooves or patterns on the surface. These help lower the grinding force and keep things cool. These designs make grinding easier and help the wheel last longer.

Diamond wheels work fast and give a smooth finish. They are used in many industries, like aerospace, mold making, and electronics. They are great for sharpening carbide tools and making clean edges. Using diamond wheels on tungsten carbide gives you the best speed and quality.

Tip: Always check the grit size and bond type before you start. Fine grits make a smoother finish. Coarse grits remove material faster.

Green Silicon Carbide Wheels

Green silicon carbide wheels are another choice for grinding carbide. These wheels are very pure and have sharp grains. You can use them for grinding hard and brittle things, like cemented carbide.

-

Green silicon carbide wheels cut well and move heat away fast. This keeps your workpiece cool and stops heat damage.

-

The grains are sharp and the wheel has tiny holes. This helps it grind quickly and remove chips easily.

But these wheels are very brittle. They do not keep their edge as long as diamond wheels. If you grind tough or bendy materials, the wheel may break down fast. You will need to dress the wheel often to keep it working well.

You can use green silicon carbide wheels for rough grinding. They are good when you need to remove a lot of material fast. They are not the best for fine sharpening or careful work on carbide tools.

Note: Green silicon carbide wheels do not work as well as diamond wheels. They also need more care and fixing.

CBN Wheels

CBN wheels are another option for grinding. CBN is almost as hard as diamond. It can cut hard materials well. These wheels have special features that help when grinding carbide.

|

Property |

Description |

Effect on Performance for Carbide Materials |

|---|---|---|

|

CBN is almost as hard as diamond. |

Gives strong cutting power and long life. |

|

|

Thermal Stability |

Keeps shape and cutting ability at high heat. |

Lowers risk of burning or cracking your carbide workpiece. |

|

High Thermal Conductivity |

Moves heat away from the workpiece fast. |

Protects carbide from heat damage. |

|

Wear Resistance |

Stays sharp longer than regular abrasives. |

Lets you grind with care and change wheels less often. |

|

Customizable Properties |

You can pick bond, grit size, and concentration. |

Lets you match the wheel to your job. |

|

Size Stability |

Holds its size and shape well. |

Keeps your grinding accurate over time. |

CBN wheels work for grinding carbide, but not as well as diamond wheels. They cost less than diamond wheels and last longer than regular wheels. But they may wear out faster on carbide. You can use CBN wheels for rough grinding or as a backup if you do not have diamond wheels.

Tip: CBN wheels are good if you want to save money. But diamond wheels still work best for carbide.

Comparison Table

Here is a table to help you compare the main types of grinding wheels for carbide:

|

Wheel Type |

Best Uses |

Pros |

Cons |

Cost-Effectiveness |

|---|---|---|---|---|

|

Diamond Wheel |

Sharpening, precision grinding, form grinding |

Highest efficiency, long life, best finish, strong abrasive grinding ability |

Most expensive, needs careful selection for bond and grit |

High performance, less cost-effective |

|

Green Silicon Carbide |

Rough grinding, fast material removal |

Good cutting, cool grinding, easy chip removal |

Brittle, wears quickly, needs frequent dressing |

Less efficient, less convenient |

|

CBN Wheel |

Rough grinding, backup for carbide, HSS tools |

Hard, stable at high heat, holds shape, less expensive than diamond |

Less efficient for carbide, wears faster on carbide |

More economical, but not best for carbide |

Remember: For most carbide grinding jobs, diamond wheels give you the best mix of speed, finish, and strength. Use green silicon carbide or CBN wheels if you want to save money or for easier jobs.

Choosing a Grinding Wheel for Carbide

Picking the right grinding wheel for carbide is very important. You need to think about what job you are doing. The material and machine you use also matter. Each thing changes how well your wheel works and how long it lasts. If you choose well, you will grind faster and get a better finish. Your tools will also last longer.

Here is a table that shows the main things to think about when picking a grinding wheel for carbide:

|

Factor |

Consideration for Carbide Grinding Wheel Selection |

|---|---|

|

Material Hardness |

Carbide is hard-to-grind; use mild, friable abrasive grains that fracture easily and stay sharp. |

|

Grit Size |

Finer grit sizes improve penetration and chip formation in hard materials like carbide. |

|

Wheel Grade |

Softer grades release dulled grains to prevent burning; harder grades hold form longer but may cause damage if too hard. |

|

Abrasive Grain Type |

Ceramic or superabrasive grains recommended for hard materials and high grinding pressures. |

|

Bond Type |

Select based on application: vitrified bonds for form holding and close tolerances; organic/resin bonds for fine finishes. |

|

Grinding Pressure |

Light pressure favors mild, friable grains and softer grades; heavy pressure requires tougher grains and harder grades. |

|

Required Finish & Form |

Fine finishes and close tolerances require finer grits and harder grades; softer bonds help maintain sharpness and prevent burning. |

|

Area of Contact |

Small contact areas need tough grains and harder grades; large areas allow milder grains and softer grades to self-sharpen. |

|

Wheel Speed & Machine |

Machine horsepower and spindle speed influence bond selection and wheel speed compatibility; high speeds may require special bonds. |

Tip: Always pick a grinding wheel that matches your job, material, and machine. This helps you get the best results.

Grit Size

Grit size tells you if your grinding wheel feels rough or smooth. It also changes how much you can grind off and how smooth your work looks. For carbide, grit size is very important.

-

Coarse grit, like 200 grit, is good for rough grinding. You can take off a lot of material fast, but the surface will feel rough.

-

Fine grit, like 600 grit, is best for smooth grinding. You get a sharp edge that is great for careful cutting.

Here is a simple table to show how grit size changes your grinding:

|

Grinding Stage |

Recommended Grit Size |

Effect on Performance |

|---|---|---|

|

Rough Grinding |

200 grit |

Aggressive material removal, prepares surface for fine grinding |

|

Fine Grinding |

600 grit |

Produces smooth, sharp edge suitable for high-precision cutting |

-

Smaller grit sizes give a smoother finish but remove less material.

-

For jobs like end mill fluting, you might use about 240 grit. This helps keep shapes and corners tight.

Note: Grit size is not the only thing that controls how fast you grind. The bond and how the wheel wears down also matter a lot.

Bond Type

The bond holds the abrasive grains together in your wheel. The bond type changes how the wheel works, how long it lasts, and how easy it is to keep sharp.

-

Metal bonds are strong and last a long time. They are good for grinding hard things like carbide. Metal bonds keep their shape and handle heat, but they are hard to fix and cost more.

-

Resin bonds, like acrylate-based resins, help lower grinding forces and keep grains in place. They are easier to fix and can make tools last longer. Resin bonds are good for smooth finishes.

-

Vitrified bonds are easy to fix and cut well, but you see them more with iron-based materials.

-

Vacuum brazed and electroplated bonds hold grains tight and last long, but you cannot fix them. When they wear out, you need a new wheel.

Pick a bond that matches your grinding job, how hard your carbide is, and your machine. Metal bonds are best for tough jobs and high heat. Resin bonds are better for smooth work and easy fixing.

Tip: The bond type changes how well you grind, how long your wheel lasts, and how easy it is to keep sharp.

Wheel Shape

The shape of your grinding wheel changes what jobs you can do. Different shapes work best for different tasks. Here is a table of common wheel shapes for grinding carbide:

|

Wheel Shape |

Type Number |

Specific Advantages / Applications in Carbide Grinding |

|---|---|---|

|

Straight |

Type 1 |

Most common wheel for precision grinding; suitable for small parts and grooves |

|

Cylinder |

Type 2 |

Used for grinding cylindrical surfaces; reaches recessed areas precisely |

|

Tapered |

Type 4 |

Ideal for grinding gear teeth, threads, and tight spaces |

|

Recessed One Side |

Type 5 |

Minimizes contact with workpiece sides, reducing heat and wheel wear |

|

Recessed Two Side |

Type 7 |

Similar to Type 5, reduces side contact for specific grinding needs |

|

Flaring Cup |

Type 11 |

Used for tool grinding and modification |

|

Dish |

Type 12 |

Concave shape for grinding contours, edges, and complex shapes |

|

Saucer |

Type 13 |

Also used for tool grinding and modification |

Pick the wheel shape that fits your part and grinding job. Use a straight wheel for flat surfaces. Use a dish wheel for edges or tricky shapes.

Equipment Compatibility

Your grinding machine decides what wheel you can use. The machine’s power, speed, and accuracy all matter. If you use a wheel that does not fit, you may get bad results or break your tools.

-

Precision machines work best with softer bonds and finer grits. This helps you get a smooth finish and tight sizes.

-

Heavy-duty machines can use harder bonds and bigger grits for fast grinding.

-

The wheel shape and size must fit your machine’s spindle and guards.

-

Always check your machine’s speed rating and match it to the wheel’s top speed.

If you use the right wheel for carbide and match it to your machine, you will grind better, your wheel will last longer, and you will be safer.

Note: Always follow the maker’s rules for mounting, speed, and safety.

Dressing Wheels and Safety Considerations

To keep your grinding wheel sharp and safe, you need to dress it often. Dressing takes off dull grains and shows new, sharp ones. Here are some good tips:

-

Do not use diamond dressers on diamond wheels. This can hurt the wheel.

-

Dress the wheel gently and evenly while it spins.

-

Keep going until the wheel feels clean and sharp.

-

Always wear safety glasses and gloves when dressing.

-

Check the wheel for cracks or damage before each use.

Grinding carbide can release harmful metals like cobalt and nickel. These can hurt your lungs and skin. Use dust collectors and good airflow. Filter your coolant to catch metal bits. Always wear safety gear and follow safety rules.

Safety First: Look for grinding wheels with the ANSI B7.1 mark. This means the wheel is safe for speed and use.

Common Mistakes: Do not use the wrong wheel, grit, or bond. Do not skip dressing your wheel. Always match wheel speed to your machine. Keep your area clean and store wheels in a dry place.

Application Tips

Tool Sharpening

When you sharpen carbide tools, you need to use the right method. Diamond wheels work best for sharpening carbide. You should avoid hand sharpening because it is hard to get a precise edge. Use a rigid setup, not a handheld grinder, to keep your tool steady. Composite diamond wheels that you can dress to run true will help you get a razor-sharp edge, especially on micro grain carbide. Plated wheels do not give the same sharpness. If you want to sharpen an endmill, make sure you use a machine that holds the tool firmly. This helps you keep the correct angle and shape.

Tip: Always inspect your grinding wheel before use. Look for cracks or damage to stay safe.

Surface Grinding

Surface grinding of carbide needs careful setup. Secure your workpiece so it does not move. Use the grinding wheel at the speed the maker recommends. This keeps you safe and helps the wheel last longer. Coolants help reduce heat and protect your carbide from damage. When you grind an endmill or other carbide part, use light pressure. Heavy pressure can cause chips or cracks. Stand to the side when you start the grinder. This protects you if the wheel breaks.

-

Use coolants to keep the workpiece cool.

-

Hold the workpiece firmly.

-

Apply steady, gentle pressure.

-

Check your grinding wheel for balance.

Maintenance and Safety

You can make your grinding wheels last longer with good care. Always train operators on safe handling and maintenance. Inspect wheels before each use for cracks or chips. Store wheels in a dry place and handle them gently. Dress the wheel often to keep it sharp and in shape. Clean the wheel to remove metal chips and debris. Use the right pressure and speed to avoid overheating. Follow the manufacturer’s guidelines for every grinding job.

Safety Reminder: Wear safety goggles, gloves, and hearing protection. Keep your workspace clean and dry. Always use the right personal protective equipment to prevent injuries from flying particles or wheel breakage.

If you want the best results when grinding carbide, use a diamond wheel. Diamond wheels help you work with accuracy and last a long time. Green silicon carbide and CBN wheels are good for rough jobs or if you want to save money. Look at the table below to help you pick the right grinding wheel for your job and machine:

|

Application / Metal Type |

Recommended Grinding Wheel(s) |

Key Characteristics / Notes |

|---|---|---|

|

Carbide |

Diamond wheel |

Best for precision, long life, smooth finish |

|

Hard-to-Grind Metals |

Tiger Ceramic |

Superior cut rate, long wheel life |

|

Aluminum |

Tiger Aluminum |

Non-loading, contaminant-free |

Always remember these safety rules:

Wear goggles, a face shield, and hearing protection.

Check your wheel for cracks or damage before using it.

Let the wheel spin for 60 seconds before you start grinding.

Pick the right diamond wheel for your job.

FAQ

What is the best grinding wheel for carbide tools?

You should use a diamond grinding wheel for carbide tools. Diamond wheels cut carbide quickly and last a long time. They give you a smooth finish and help you keep sharp edges.

Can you use regular grinding wheels on carbide?

No, regular grinding wheels do not work well on carbide. Carbide is very hard. You need a diamond or green silicon carbide wheel to grind it safely and effectively.

How do you keep a grinding wheel sharp?

You should dress your grinding wheel often. Use a dressing stick or tool to remove dull grains. This keeps your wheel sharp and helps you get better results.

Is it safe to grind carbide at home?

-

Grinding carbide at home can be safe if you follow safety rules.

-

Wear goggles, gloves, and a mask.

-

Use dust collection and good airflow.

-

Always check your wheel for cracks before you start.

Contact Us

For More Grinding Solution or Customized Abrasive Tools