Choosing the right metal grinding wheel starts with knowing your metal. If you pick the wrong abrasive or grit, you might see rough finishes, faster wheel wear, or even damaged parts. Here’s a look at some common mistakes people make:

|

Mistake |

What Happens |

|---|---|

|

Wrong abrasive type |

Poor finish, fast wear |

|

Incorrect bond or grit |

Glazing, rough surfaces |

|

Ignoring metal’s heat sensitivity |

Warping, cracks |

You can avoid these issues when you match your wheel to your metal and task. Always check the specs, pick the right size and bond, and think about safety first.

Key Takeaways

-

Match your grinding wheel to the metal type and task to avoid poor finishes and damage.

-

Choose the right abrasive material, wheel size, shape, and grit based on your project needs.

-

Check the wheel’s label for size, speed rating, bond type, and safety information before use.

-

Replace grinding wheels if you see cracks, glazing, or if grinding slows down to stay safe.

-

Always follow safety rules: use proper gear and never exceed the wheel’s maximum speed.

Project Needs

Metal Type

Before you pick a metal grinding wheel, you need to know what kind of metal you’re working with. Different metals have different hardness, heat sensitivity, and grinding needs. If you use the wrong wheel, you might end up with a poor finish or even damage your part. Here’s a quick guide to help you match the right abrasive to your metal:

|

Recommended Abrasive Material(s) |

Notes on Wheel Type and Application |

|

|---|---|---|

|

Steel |

Aluminum Oxide, Zirconia Alumina, Ceramic Alumina |

Aluminum oxide is versatile; Zirconia Alumina offers speed and durability; Ceramic Alumina for high accuracy and wear resistance |

|

Stainless Steel |

Zirconia Alumina, White Aluminum Oxide, Ceramic Alumina |

Zirconia Alumina performs well under heavy pressure and heat; White Aluminum Oxide is heat resistant and durable |

|

Aluminum |

Silicon Carbide/Aluminum Oxide Blend |

Blend ideal for soft metals, provides faster cut rates and longer wheel life |

|

Cast Iron |

Silicon Carbide |

Ultra-hard grain, quick cutting but less tough than others |

|

Titanium |

Ceramic Alumina, Zirconia Alumina |

High strength and wear resistance suitable for aerospace and medical parts |

|

Copper |

Silicon Carbide/Aluminum Oxide Blend |

Suitable for soft metals and alloys |

|

Alloys |

Aluminum Oxide, Silicon Carbide/Aluminum Oxide Blend |

Depends on hardness; blends used for softer alloys |

Tip: Always check the hardness of your metal. Harder metals like steel need tougher abrasives, while softer metals like aluminum do better with sharp, fast-cutting wheels.

Task Type

The job you need to do also shapes your grinding wheel choice. Are you cutting, deburring, or finishing? Each task needs a different approach:

-

Cutting or rough grinding: Use a coarse abrasive like aluminum oxide with a vitrified bond. These wheels remove material quickly and work well on hard metals.

-

Deburring: Pick a finer abrasive with a resin bond. Ball or bullet-shaped wheels help you reach tight spots and smooth out edges.

-

Surface finishing: Go for a fine abrasive, such as silicon carbide, with a softer bond. This setup gives you a smooth, polished look on softer metals.

You should also think about the size and shape of your workpiece, the pressure you’ll use, and if you need a certain finish. If you want a fast job, choose a wheel that matches your machine’s speed and horsepower. For detailed work, a finer grit and softer bond will help you get a clean finish.

Note: Always match your grinding wheel to both the metal and the task. This helps you get the best results and keeps your project safe and efficient.

Metal Grinding Wheel Types

Abrasive Materials

When you pick a metal grinding wheel, the abrasive material matters a lot. Each type of abrasive works best for certain metals and jobs. Let’s break down the main options you’ll see in stores and workshops:

|

Abrasive Type |

Performance & Features |

Best For |

Cost & Lifespan |

|---|---|---|---|

|

Aluminum Oxide |

Tough, durable, and versatile |

General-purpose grinding on steel, iron |

Affordable, moderate lifespan |

|

Zirconia Alumina |

Very tough, resists heat, lasts longer than aluminum oxide |

Heavy-duty jobs, stainless steel, alloys |

Higher cost, longer lifespan |

|

Ceramic Abrasives |

Self-sharpening, fast cutting, stays cool |

Hard-to-grind metals, precision finishing |

Expensive, longest lifespan |

|

Silicon Carbide |

Sharp, brittle, handles heat well |

Aluminum, copper, soft metals, plastics |

Moderate cost, good finish |

|

CBN (Cubic Boron Nitride) |

Super hard, stable at high temperatures |

Tool steels, nickel alloys, hard metals |

High cost, specialty use |

|

Diamond |

Hardest abrasive, cuts brittle materials |

Carbide, ceramics, stone |

Very expensive, specialty use |

You’ll find that aluminum oxide wheels are the most common. They work well for most jobs and don’t cost much. Zirconia alumina wheels handle tough jobs and last longer, so you might use them for stainless steel or hard alloys. Ceramic abrasives cut fast and stay sharp, but they cost more. Silicon carbide wheels shine when you work with soft metals like aluminum or copper. For the hardest jobs, like grinding carbide or ceramics, diamond and CBN wheels are your best bet.

Tip: If you want a wheel that lasts longer and cuts faster, try ceramic or zirconia alumina. For everyday jobs, aluminum oxide is a safe choice.

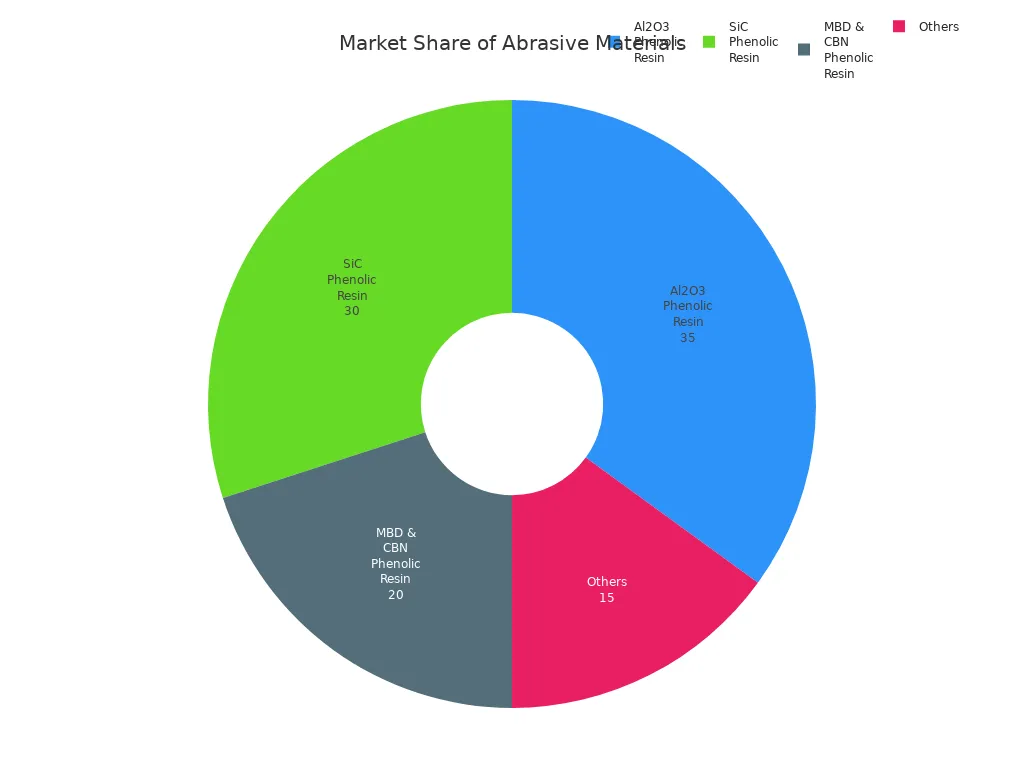

Here’s a quick look at the market share for each abrasive material in 2023:

Aluminum oxide and silicon carbide wheels make up most of the market. You’ll see these in almost every hardware store.

You’ll also notice different shapes and styles of metal grinding wheel. Here are some you might use:

-

Cutting Face Grinding Wheel – Great for making grooves or slots in metal.

-

Grinding Dish Wheel – Works well for curved surfaces and blending edges.

-

Segmented Grinding Wheel – Removes material quickly and stays cool, perfect for heavy-duty jobs.

-

Large Diameter Grinding Wheels – Used for big, heavy pieces of metal.

-

Grinding Cup Wheel – Good for rough grinding and shaping before welding.

-

Straight Grinding Wheels – Versatile, used for sharpening and surface grinding.

-

Diamond Grinding Wheels – Best for super-hard materials like carbide or glass.

Note: Always match the abrasive and wheel shape to your project. This helps you get the best results and keeps your tools in good shape.

Wheel Structure

The structure of a metal grinding wheel affects how it performs, especially when you work with soft or clog-prone metals. Structure means how tightly the abrasive grains are packed together and how many spaces (pores) are between them.

-

Open Structure: These wheels have more space between the grains. This design lets chips and dust escape easily, so the wheel doesn’t clog up. Open wheels also help coolant reach the work area, which keeps things cool and improves the finish. You’ll want an open structure if you grind soft metals like aluminum or copper, which can clog a wheel fast.

-

Closed Structure: These wheels pack the grains tightly. They work well for hard metals because they hold their shape and last longer. But they can clog quickly if you use them on soft metals.

Here’s what you should do when working with soft or clog-prone metals:

-

Pick a wheel with an open structure. The extra space helps chips escape and keeps the wheel from loading up.

-

Use a softer grade wheel. This lets dull grains break away, so the wheel stays sharp.

-

Try a coarser grit for rough grinding. Bigger grains mean more room for chips.

-

For some ductile metals, consider a CBN wheel. These resist wear and stay sharp longer.

Tip: Some wheels have special coatings, like calcium stearate, that melt during grinding. This creates a barrier and stops chips from sticking, which helps prevent clogging and overheating.

If you use the right structure, you’ll spend less time cleaning your wheel and more time getting a smooth, clean finish. You’ll also make your metal grinding wheel last longer.

Size, Shape, and Grit

Wheel Size

When you pick a metal grinding wheel, size matters more than you might think. The diameter of the wheel changes how fast you can cut and how much metal you can remove. Bigger wheels cover more area, so they work faster and last longer. They also let you grind at higher speeds, which means you finish jobs quicker. Smaller wheels are great for tight spots or detailed work.

Here’s a quick table to show how wheel size affects your grinding:

|

Factor |

Effect on Grinding Process |

|---|---|

|

Grinding Wheel Diameter |

Larger wheels increase contact area and cutting speed, making grinding more efficient. |

|

Peripheral Speed |

Bigger diameter and higher RPM mean faster cutting, but never go over the wheel’s max speed. |

|

Wheel Wear and RPM |

As wheels wear down, you may need to adjust RPM to keep performance steady, but stay within safe limits. |

You’ll find most metal grinding wheels in sizes from 4.5 inches to 9 inches for hand grinders. For heavy-duty jobs, you might use wheels up to 20 inches. Smaller wheels work best for jobs like auto body repair, while big wheels handle thick steel beams.

Tip: Always check your grinder’s manual for the right wheel size and speed.

Wheel Shape

The shape of your grinding wheel changes how it works. Some shapes are better for flat surfaces, while others help you reach tricky spots. Here are the most common shapes you’ll see:

|

ANSI Type |

Description |

Typical Use |

|

|---|---|---|---|

|

Straight (Flat) |

Type 1 |

Flat disk, grinding on the edge |

General grinding, cutoff |

|

Depressed Center |

Type 27 |

Flat face with a center that dips down |

Heavy stock removal, weld grinding |

|

Cup |

Type 6/11 |

Bowl-shaped, grinding on the rim or sides |

Tool grinding, surface grinding |

|

Dish |

Type 12 |

Concave, prevents full contact |

Tool grinding, tricky surfaces |

Most people use Type 1 (straight) or Type 27 (depressed center) wheels for metalwork. Straight wheels are good for bench grinders. Type 27 wheels fit angle grinders and handle tough jobs like weld removal.

Note: Cup and dish wheels help you grind tools or reach hard-to-access areas.

Grit Selection

Grit size tells you how rough or smooth your grinding will be. Lower numbers mean bigger, rougher grains that cut fast but leave scratches. Higher numbers mean smaller, finer grains that make smooth finishes.

Here’s how to pick the right grit:

-

Coarse Grit (40-80): Use these for rough grinding, weld removal, or shaping metal fast.

-

Medium Grit (100-180): These balance speed and finish. Great for smoothing and blending.

-

Fine Grit (220-400+): Choose these for polishing or when you want a shiny, smooth surface.

Each time you switch to a finer grit, you remove the scratches from the last step. If you want a mirror finish, start coarse and work your way up.

Tip: Coarse grits work fast but leave rough marks. Fine grits take longer but give you a smooth, polished look.

Bond and Compatibility

Bond Types

When you choose a grinding wheel, the bond type matters just as much as the abrasive. The bond holds the abrasive grains together and affects how the wheel performs. You’ll see two main types: vitrified and resin bonds.

Here’s a quick comparison to help you decide:

|

Feature |

Vitrified Bond |

Resin Bond |

|---|---|---|

|

Material |

Glass or ceramic |

Synthetic resin (phenolic, epoxy) |

|

Structure |

Porous, lets air and coolant flow |

Dense, less porous |

|

Grinding Speed |

Handles higher speeds |

Good for many jobs, but lower speed tolerance |

|

Durability |

Very durable, keeps its shape |

Softer, wears faster |

|

Heat Resistance |

High, resists heat and water |

Lower, can burn at high temps |

|

Application |

Precision, hard materials, high production |

Versatile, rough grinding, finishing |

Vitrified bonds work best when you need accuracy and a wheel that lasts. You’ll find them in jobs like tool sharpening or grinding hard metals. Resin bonds feel softer and give you a smoother finish. They’re great for rough grinding or when you want a wheel that’s easy to shape.

Tip: If you want a wheel for heavy-duty or high-speed grinding, vitrified or metal bonds are your best bet. Resin bonds work well for lighter jobs and finishing touches.

RPM and Safety

Safety always comes first when you use a grinding wheel. Every wheel has a maximum RPM rating. You must never go above this speed. If you do, the wheel can break apart and send pieces flying.

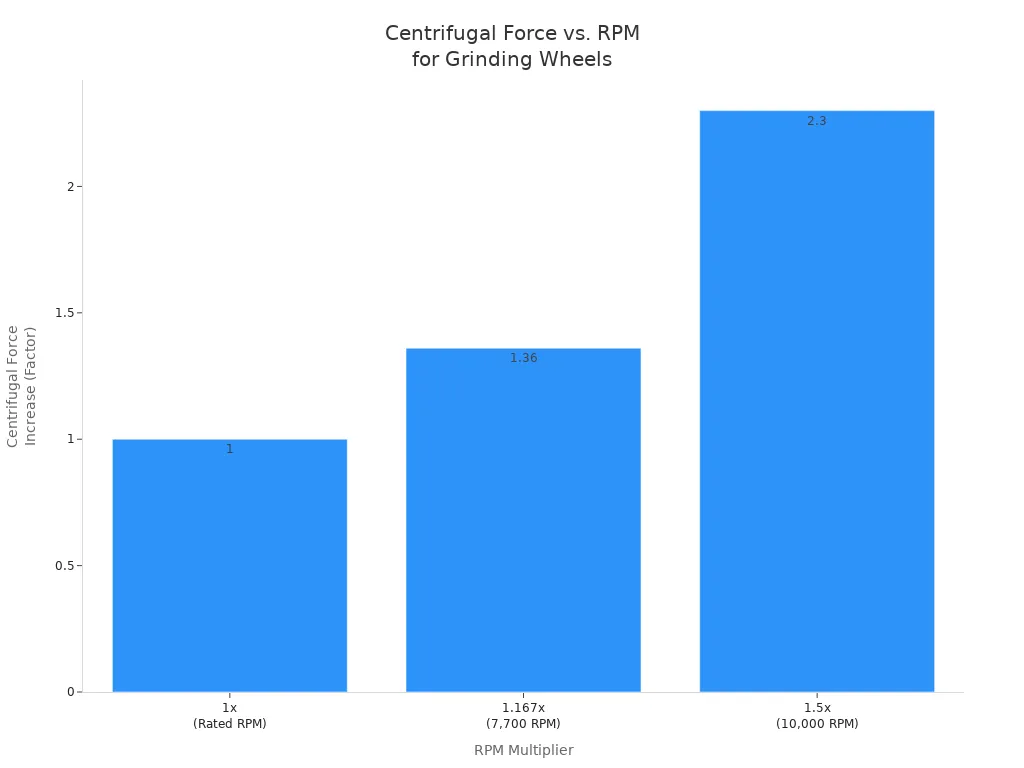

Check out this chart to see how fast the risk goes up when you exceed the rated RPM:

Here’s what you need to remember:

-

Always check the RPM marked on your wheel and compare it to your grinder’s speed.

-

The wheel’s RPM rating should be equal to or higher than your grinder’s max speed.

-

Never use a wheel on a machine it wasn’t made for.

-

Keep your grinder in good shape. Worn bearings or spindles can cause vibration and make the wheel break.

-

Wear safety gear like goggles and gloves every time.

Note: Even a small increase in speed can make the wheel much more dangerous. Doubling the RPM can make the force on the wheel four times higher!

If you follow these steps, you’ll stay safe and get the best results from your grinding wheel.

Buying and Using Tips

Reading Labels

When you pick out a grinding wheel, always check the label first. The label gives you important details that help you stay safe and get the best results. Here’s what you should look for:

-

Find the speed stripe. This shows the maximum safe speed for the wheel. Make sure your grinder does not go faster than this.

-

Check the size. Look for the diameter, thickness, and bore size in millimeters. This helps you pick a wheel that fits your tool.

-

Look for the mark of specification. This tells you the grit size, hardness, bond type, and structure. You want these to match your job.

-

Review the code for manufacturing details. This can help with quality checks or if you need to reorder.

-

Confirm the highest possible speed of operation. Never use a wheel above this speed.

-

Follow the installation guide. This helps you mount the wheel safely.

-

Note any limitations on use. Some wheels are not made for certain jobs.

-

Check for test documents. These show the wheel passed safety inspections.

-

Look for ISO type markings. These mean the wheel meets international safety standards.

-

Observe the expiration date. Old wheels can be unsafe, so use them before they expire.

Tip: Understanding the label helps you choose the right wheel and keeps you safe while working.

Replacement Timing

You should replace your grinding wheel before it becomes a hazard. Here are some signs that tell you it’s time for a new one:

-

You see the wheel wearing down or the abrasive surface looks thin.

-

The surface looks shiny or glazed, which means it won’t grind well.

-

The wheel gets clogged with metal or other material.

-

You spot cracks or chips. Never use a damaged wheel.

-

Grinding feels slow or takes longer than usual.

-

You hear strange noises or feel extra vibration.

-

The wheel or workpiece gets too hot.

-

Your finish looks rough or uneven.

Regular checks help you spot problems early. Always follow the manufacturer’s advice for mounting, speed, and care. This keeps your work safe and your results sharp.

Here’s a quick look at how long grinding wheels usually last:

|

Usage Context |

Lifespan Range |

|---|---|

|

Industrial Grinding Rolls (Mining/Industrial) |

|

|

High-Volume Production |

Note: If you use your wheel for light jobs, it might last months. Heavy-duty work wears it out much faster.

Choosing the right metal grinding wheel gets easier when you follow a few simple steps:

-

Check your project needs and pick the right wheel type, size, grit, and bond.

-

Always match the wheel to your metal and grinding task.

-

Read the label and follow manufacturer guidelines for safety and best results.

Remember, using the correct wheel and staying safe helps you avoid common mistakes and keeps your work smooth.

FAQ

What happens if you use the wrong grinding wheel for your metal?

You might see poor finishes, faster wheel wear, or even damage to your part. Always match the wheel to your metal type for the best results.

How do you know when to replace your grinding wheel?

Look for cracks, chips, or a glazed surface. If grinding feels slow or you hear odd noises, it’s time for a new wheel.

Can you use one grinding wheel for all metals?

No, you shouldn’t. Different metals need different abrasives. Using the wrong wheel can cause clogging, overheating, or poor performance.

What safety gear should you wear when grinding metal?

-

Safety goggles or a face shield

-

Gloves

-

Hearing protection

-

Long sleeves

Always protect yourself. Flying sparks and debris can cause injuries.

Contact Us

For More Grinding Solution or Customized Abrasive Tools