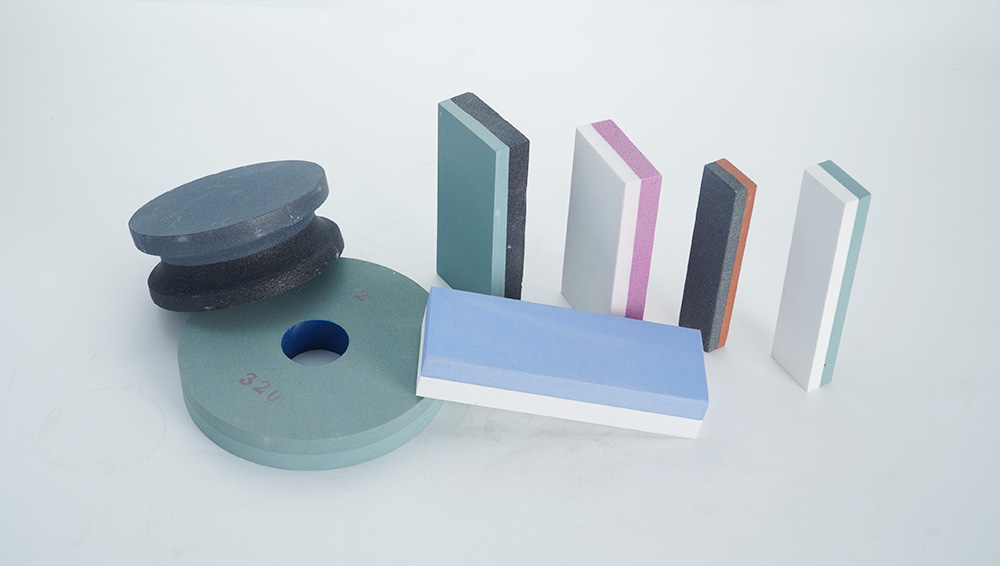

Aluminum oxide is best for steel and ferrous metals. A silicon carbide grinding wheel is better suited for non-ferrous and brittle materials. The best grinding wheels depend on the material you are working on and the finish you want to achieve. Many people in automotive and metalworking industries use aluminum oxide because it works well for many applications and is cost-effective. Silicon carbide grinding wheels are commonly used in woodworking and construction because they cut quickly and stay cool. Users should always consider their specific needs before choosing between aluminum oxide and a silicon carbide grinding wheel.

Key Takeaways

Aluminum oxide grinding wheels are good for steel and iron. They also work well on other strong metals. These wheels last a long time. They can handle hard jobs without breaking.

Silicon carbide wheels are best for hard and brittle things. They work well on glass, ceramics, and stone. These wheels make sharp cuts. They also give smooth finishes.

Pick your grinding wheel by the material you have. Think about the finish you want. Using the wrong wheel can give bad results. It can even break your work.

Always follow safety rules. Wear your safety gear. Check your wheels for cracks or chips. Use the right speed and pressure when grinding.

Clean your grinding wheels often. Dress them to keep them sharp. This helps them work better and last longer.

Quick Comparison

Key Differences

Silicon carbide and aluminum oxide are different in many ways. These differences come from how they are made and what they are made of. The table below shows how they compare:

Property/Aspect | Silicon Carbide | Aluminum Oxide |

|---|---|---|

Hardness (Mohs) | 9.0 (slightly less hard) | |

Crystal Structure | Sharp, brittle | Tough, self-sharpening |

Wear Resistance | Wears faster on tough metals | Lasts longer, better wear resistance |

Chemical Stability | Stable up to 1300°C | Stable at room and high temperatures |

Conductivity | Semiconductor properties | Insulator |

Toughness | More brittle, breaks down faster | Tougher, keeps cutting longer |

Dust Generation | More dust | Less dust |

Cost | Higher | More affordable |

Surface Finish | Fine, precise | Good for general sanding |

Best Use | Hard, brittle, non-metallic materials | Steel, iron, wood, general sanding |

Note: Silicon carbide costs more and can be harder to find in some places. Aluminum oxide wheels are easier to buy and cost less at first.

Best Uses

Picking the right abrasive depends on what you need to sand. Here are the best ways to use each one:

Silicon carbide is great for sanding hard and brittle things. People use it on glass, ceramics, stone, and some cast iron. It makes a smooth finish on surfaces that are not metal. It is not good for steel or strong metals because it wears out fast.

Aluminum oxide is best for sanding steel, iron, and other strong metals. It also works well on wood and for most sanding jobs. This abrasive lasts longer and works well on tough materials. Many grinding wheels use aluminum oxide because it is strong and saves money.

Each abrasive has its own good points. Silicon carbide cuts sharp and leaves a smooth surface on hard things. Aluminum oxide is strong and works for most metal sanding jobs. When picking between them, think about what you are sanding and the finish you want.

Aluminum Oxide

Properties

Aluminum oxide is a very common abrasive for grinding and sanding. It is very hard, with a Mohs hardness of 9. This means it does not scratch or wear out easily. It is also tough, so it can take hits without breaking. Aluminum oxide can handle a lot of pressure and bending. It keeps its shape even when grinding hard. When it is heat-treated, it gets sharper edges. This helps it cut faster and makes sanding easier.

Table: Key Properties of Aluminum Oxide

Property | Description | Effect on Grinding Performance |

|---|---|---|

Hardness | 9 on Mohs scale | Maintains sharp edges, resists wear |

Toughness | Absorbs energy, resists fracturing | Prevents premature breakage |

Compressive Strength | High resistance to crushing | Withstands heavy grinding pressure |

Flexural Strength | Resists bending forces | Maintains shape during sanding |

Heat-Treated Structure | Enhanced by heat treatment | Sharper edges, faster sanding |

Strengths

Aluminum oxide abrasives last a long time and do not break easily. They are good for tough sanding and grinding jobs. You can use them to take off rust, paint, and coatings from hard metals like steel and iron. Aluminum oxide sandpaper and wheels come in many grit sizes. This lets you pick the right one for rough or smooth sanding. Because it is tough, it can handle hard coatings and metals. That is why many factories use it.

Limitations

Aluminum oxide abrasives do not work well on everything. Soft metals like aluminum, brass, and copper can clog the wheel. This means you have to clean the wheel often to keep it working. Aluminum oxide is not as hard as some other abrasives. It may not be as good for very careful or heat-sensitive sanding. It sharpens itself but can wear down faster in some cases, especially when doing very fine work.

Soft metals can clog the wheel.

Not the best for very hard or heat-sensitive things.

You may need to clean the wheel often for best results.

Best Materials

People use aluminum oxide to grind ferrous metals. It works best on carbon steel, alloy steel, stainless steel, high-speed steel, and cast iron. It also works well on wood, plastic, and composites. This makes it useful for many sanding jobs. But for non-ferrous metals or stone, silicon carbide might be better.

Silicon Carbide Grinding Wheel

Properties

A silicon carbide grinding wheel is very hard and sharp. On the Mohs scale, it is about 9.5. This is a little harder than aluminum oxide. Because it is so hard, it can cut tough things easily. Silicon carbide does not react with most materials. It also moves heat away fast. This helps the wheel stay cool when sanding. It lowers the chance of heat damage. The grains in silicon carbide are brittle. They break off and show new sharp edges. This is called friability. It keeps the wheel sharp while you use it.

Property | Effect on Sanding and Grinding |

|---|---|

High hardness (Mohs 9.5) | Cuts hard, brittle, and non-metallic materials |

Sharp, brittle grains | Maintains sharpness, ideal for fine sanding |

Thermal conductivity | Reduces heat buildup during sanding |

Chemical inertness | Prevents reaction with most materials |

Strengths

Silicon carbide grinding wheels are great for hard and brittle things. The sharp grains cut fast and make a smooth finish. These wheels are good for glass, ceramics, stone, and some plastics. They move heat away well, so things do not get too hot. This protects delicate pieces. People use silicon carbide sandpaper and wheels in woodworking and building. They stay cool and cut quickly. The grains break and show new sharp edges. This makes them good for careful sanding.

Limitations

Silicon carbide grinding wheels have some problems. The grains are brittle and wear out faster than aluminum oxide. This happens more when used on steel and iron. You will need to change the wheel more often. This can cost more money. Silicon carbide is not good for grinding tough metals all the time. The wheel can break down and lose its shape. For soft metals or strong materials, pick another abrasive.

Wears out fast on steel and iron

Not good for grinding tough metals for a long time

Brittle grains can break if pressed too hard

Best Materials

A silicon carbide grinding wheel works best on hard and brittle things. People use it for glass, ceramics, optical glass, gemstones, and stone. It also works well on plastics and things that bend with heat. Green silicon carbide sandpaper is great for fine sanding these materials. The sharpness and hardness make it the best for smooth and careful sanding on non-ferrous and brittle surfaces.

Glass, ceramics, and stone

Optical glass and gemstones

Plastics and other non-metallic materials

Hard alloys and cast iron

Silicon Carbide vs Aluminum Oxide

Grinding Steel

Aluminum oxide is better than silicon carbide for grinding steel. It removes metal at a steady rate and does not wear out fast. This makes it great for steel and other strong metals. These wheels last a long time and give even results. The grains in aluminum oxide are tough and sharpen themselves. This helps them keep cutting well for a long time. Many workers pick aluminum oxide for steel because it can take a lot of pressure and heat without breaking.

Silicon carbide is very hard and sharp, but it wears out faster on steel. Its grains break easily, so you have to change the wheel more often. This makes the job slower and costs more money. For hard steel, soft wheels like white vitrified aluminum oxide work best. These wheels stay cool and protect the steel from getting too hot. Using grinding fluids and cleaning the wheel often helps keep it working well and stops it from overheating.

Tip: Use aluminum oxide wheels with water or coolant when grinding hard steel. This keeps the steel cool and helps the wheel last longer.

Grinding Aluminum

When grinding aluminum, you need to pick the right wheel. If you use the wrong one, it can get clogged or too hot. Aluminum oxide wheels are best for aluminum because they do not get clogged easily. They give a smooth finish and do not get too hot. People find that aluminum oxide works well for sanding and polishing aluminum. It gives good results every time.

Silicon carbide wheels are sharper and harder, but they break down faster if you push too hard. They can also make more heat, which can hurt the wheel and the finish. Silicon carbide can make a shiny finish at the end, but it is not as good as aluminum oxide for most aluminum jobs. It wears out fast and can give uneven results.

Clean the wheel often to keep it sharp and stop buildup.

Grinding Non-Metals

For things like glass, ceramics, and stone, silicon carbide is the best abrasive. Its grains break and stay sharp, which helps cut hard, brittle things. It also keeps things cool, so it works well on these surfaces. Silicon carbide wheels make clean cuts and nice finishes on concrete, marble, and glass. People use silicon carbide when they need a smooth finish on non-metal things.

Aluminum oxide does not work as well on non-metals. It is better for steel and other strong metals. For the best results on ceramics or stone, some people use diamond abrasives. Diamonds are even harder and move heat away better. But silicon carbide is still a good and cheaper choice for many non-metal jobs.

Surface Finish & Durability

How smooth the surface is and how long the wheel lasts are important. Silicon carbide wheels cut sharp and give a smooth finish on non-metals. They are great for making glass and ceramics look nice. For example, silicon carbide can make steel very smooth if you use fine grit.

Aluminum oxide wheels last longer, especially on steel and strong metals. They balance cutting speed and how long they last. Aluminum oxide can make steel smooth, depending on the grit and how you grind. Silicon carbide is harder, but it breaks more easily and does not last as long.

Abrasive Type | Best For | Typical Surface Finish (Ra, µm) | Durability |

|---|---|---|---|

Aluminum Oxide | Steel, ferrous metals | High | |

Silicon Carbide | Non-metals, glass, ceramics | 0.05 – 0.8 (non-metals) | Moderate |

Note: For the smoothest finish, use fine grit and good grinding methods. Aluminum oxide wheels last longer, but silicon carbide is better for finishing non-metal things.

Choosing the Right Grinding Wheel

Decision Checklist

Picking the right grinding wheel helps you get good results. The table below shows what to think about when choosing between silicon carbide and aluminum oxide:

Factor | Silicon Carbide | Aluminum Oxide |

|---|---|---|

Typical Use Case | Non-ferrous metals, ceramics, glass | Ferrous metals, general metalworking |

Hardness & Toughness | Very hard, brittle | Tough, less hard, durable |

Thermal Stability | High (up to 1400°C) | Good, stable at high temperatures |

Wear Resistance | High, but brittle | Good, lasts longer on tough metals |

Cost Considerations | Higher | More affordable |

Application Type | Precision grinding, fine finishes | Versatile, general sanding |

Finish Quality | Superior on hard/non-ferrous materials | Good, but less fine on hard materials |

Brittleness | Brittle, may chip | Tough, less prone to chipping |

Standards Compliance | Check ASTM, DIN, regional standards | |

Operational Conditions | High speed, high temperature | Performs well, may degrade at extremes |

Before you start sanding or grinding, look at this checklist:

Find out what material you have. Is it steel, iron, glass, ceramic, or aluminum?

Think about the finish you want. Should it be smooth or rough?

Check if the wheel is hard and tough enough.

Think about how hot or fast the job will be.

Look at the price and if you can buy the abrasive.

Make sure the wheel is safe and meets quality rules.

Pick a wheel that matches your sanding or grinding job.

Tip: Always read the label from the maker for safe use and best results.

Common Mistakes

People sometimes make mistakes with grinding wheels. These mistakes can make the job worse or even cause damage. Here are some common mistakes:

Picking the wrong wheel for the material. For example, using aluminum oxide on glass or ceramics, or using silicon carbide on steel.

Using a wheel that is old or broken. This can make sanding bad and is not safe.

Pushing too hard while sanding. This can break the wheel or hurt your project.

Not following safety steps. Not wearing gloves, goggles, or masks is risky.

Running the wheel at the wrong speed. This can break the wheel or give bad results.

Not cleaning the work surface. Dirt or oil can block the abrasive.

Using the wrong grit size. Coarse grit on soft things can scratch them. Fine grit on hard things can make sanding slow.

Storing wheels in wet or dirty places. This can cause rust or make them bend.

Pick the right wheel and grit for your material and finish.

Check wheels before using them. Replace if they are worn or cracked.

Use gentle, steady pressure. Let the wheel do the work.

Always follow safety rules and wear gear to protect yourself.

Clean the surface before you start sanding.

Keep wheels in a dry, clean place.

Note: Dress the wheel only when needed. This helps it last longer and keeps sanding smooth.

Performance Tips

Grinding and sanding work better if you follow these tips. These steps help your wheel last longer and work well:

Pick the right abrasive for the job. Use aluminum oxide for steel and iron. Use silicon carbide for glass, ceramics, and non-ferrous metals.

Choose the right grit size. Coarse grits take off material fast on soft things. Fine grits make hard or brittle things smooth.

Pick the right wheel grade. Softer grades cut faster but wear out sooner. Harder grades last longer and make a finer finish.

Change the wheel structure if needed. Dense wheels are good for hard things. Open wheels are better for soft things.

Set the right speed and feed rate. Too fast or too slow can cause heat or uneven sanding.

Dress the wheel when it gets dull, but not too much. This keeps it sharp and saves money.

Always check if the wheel meets safety and quality rules.

🛠️ Pro Tip: For the smoothest finish, use fine grit and press lightly. Let the wheel do the work for a better result.

Silicon carbide wheels are best for glass, ceramics, and non-ferrous metals. Aluminum oxide wheels work well for steel and iron. You should pick the right wheel for your project. Think about what material you have and the finish you want. Look at the wheel’s properties before you choose. If you are not sure, check the maker’s rules or ask an expert. Always stay safe when using grinding wheels. Wear the right safety gear, check the wheel for cracks, and follow the machine’s directions.

Key Safety Steps:

Put on safety glasses, gloves, and hearing protection.

Check the wheel for damage before you use it.

Hold your work tight and follow all instructions from the maker.

FAQ

What is the main difference between silicon carbide and aluminum oxide grinding wheels?

Silicon carbide wheels are harder and sharper. They work best on glass, stone, and ceramics. Aluminum oxide wheels are tougher and last longer. They work best on steel and iron.

Can you use aluminum oxide wheels on non-metal materials?

Aluminum oxide wheels can grind wood and some plastics. They do not work well on glass, stone, or ceramics. For those materials, silicon carbide gives better results.

Why do silicon carbide wheels wear out faster on steel?

Silicon carbide grains are very hard but brittle. They break down quickly when grinding tough metals like steel. This causes the wheel to wear out faster than aluminum oxide.

How can you prevent grinding wheel clogging?

Clean the wheel often. Use a dressing tool to remove buildup. Pick the right wheel for the material. For soft metals, use wheels made for non-ferrous materials.

Are both types of wheels safe for high-speed grinders?

Both wheels can work on high-speed grinders if they meet safety standards. Always check the label and follow the manufacturer’s speed rating. Wear safety gear every time.

Contact Us

For More Grinding Solution or Customized Abrasive Tools