A diamond grinding pin is an indispensable tool for achieving precision on hard materials. Its unique diamond hardness and durability make it essential for modern manufacturing. The global market for diamond tooling is projected to reach US$27.78 billion by 2031, reflecting the industry’s reliance on these effective tools. The versatility of diamond tools, from grinding with electroplated diamond grit to finishing with various diamond files, is unmatched.

Types of Diamond Files Used in Manufacturing:

- Round diamond files

- Flat diamond files

- Square diamond files

- Triangular diamond files

- Half-round diamond files

- Custom diamond files

This grinding capability makes diamond tooling a cornerstone of high-quality production.

Key Takeaways

- Diamond grinding pins are very strong tools. They help make things precise from hard materials.

- These pins remove sharp edges and shape hard metals like carbide. They also finish inside parts.

- Diamond pins work well on glass, stone, and ceramics. They fix and engrave these materials.

- They improve engine parts and finish aerospace materials. This makes parts stronger and better.

- Using good diamond tools saves money. They last longer and make work faster and more accurate.

1. Deburring and Edge Breaking

Manufacturing processes like cutting, milling, and drilling often leave behind unwanted sharp edges called burrs. A single diamond grinding pin is an excellent tool for removing these imperfections safely and efficiently. These burrs can compromise part assembly, cause premature wear, and pose safety risks.

Removing Sharp Metal Burrs

Machining operations create several types of burrs through plastic deformation or material redeposition. Operators must address these defects for quality control. Common burrs include:

- Poisson Burr: Material elongates at the edges from compressive force.

- Roll-over Burr: Material bends instead of shearing cleanly.

- Tear Burr: A jagged edge forms from incomplete cutting.

- Cut-off Burr: Leftover material after a part is separated.

- Thermal Burrs: Molten metal solidifies on the edge from laser or plasma cutting.

Using diamond files provides a reliable method for removing these burrs without damaging the workpiece. The superior hardness of the diamond abrasive ensures a clean finish.

Creating Consistent Chamfers

Precision engineering requires consistent chamfers, or angled edges, for proper fit and function. These features are governed by industry standards like ASME Y14.5 and ISO 13715. A typical CNC default chamfer might be 0.5 mm × 45°. Achieving these exact specifications is critical. Diamond files give operators the control needed to create uniform chamfers on hardened steel, carbide, and ceramic components. The consistent cutting action of diamond files ensures every edge meets design requirements. Using these diamond files helps maintain tight tolerances.

Smoothing Surfaces with Diamond Files

Beyond deburring, diamond files are perfect for general surface smoothing. Their unique construction allows them to work effectively on complex contours and flat areas alike. The key advantage is that diamond files cut in all directions, which speeds up the finishing process significantly. This multi-directional cutting action makes these diamond files highly efficient. Operators can use various shapes of diamond files, such as flat or round profiles, to access tight spots. These versatile diamond files deliver a superior surface finish, preparing parts for their final application. The use of quality diamond files is essential for this task.

Pro Tip: For delicate work, start with a coarser grit of diamond files to remove bulk material and then switch to finer grit diamond files for a polished, smooth surface.

2. Shaping Carbide Tooling

Carbide is an extremely hard material used for cutting tools, dies, and wear-resistant parts. Its hardness makes it difficult to machine with conventional methods. Diamond grinding pins provide the necessary abrasive power to shape and finish carbide components with exceptional accuracy. This makes diamond tooling a critical asset in the tool and die industry.

Creating Complex Geometries

Manufacturers often need to create intricate shapes in carbide tooling. Diamond pins excel at this task. Their small diameters and various profiles allow operators to machine complex contours, internal radii, and detailed features that would be impossible with larger tools. The superior hardness of the diamond abrasive ensures clean cuts and precise material removal. This capability allows for the production of custom carbide tools for specialized manufacturing applications.

Sharpening Tungsten Carbide Dies

Tungsten carbide dies require regular sharpening to maintain their performance in stamping and forming operations. A sharp die ensures part quality and extends the tool’s life. Using a diamond pin for this process restores a keen cutting edge. For high-precision results, selecting the right grit size is crucial.

Note: Finer grits are recommended for finish grinding on carbide dies. This ensures a smooth, precise edge for high-performance stamping.

Recommended grit sizes include:

- Mesh sizes like 230/270, 270/325, and 325/400.

- Micron sizes from 40/60µm down to 0/1µm for lapping.

Achieving High-Precision Profiles

Modern manufacturing demands incredibly tight tolerances. The right diamond tooling enables machinists to achieve sub-micron levels of precision on carbide parts. This accuracy is essential for components used in aerospace, medical, and electronics industries. The stability and cutting efficiency of a diamond pin allow for the creation of profiles with minimal deviation. The following table shows examples of the tight tolerances achievable.

| Feature | Tolerance Type | Tolerance Value |

|---|---|---|

| Secondary Datum Feature (hole) | Perpendicularity | 0.05 µm |

| Tertiary Datum Feature (hole) | Position | 0.1 µm |

| 4-Hole Pattern | Position (at MMC) | 0.5 mm |

This level of control confirms why diamond tools are indispensable for high-precision work.

3. Internal Grinding

Internal grinding is a precision process for finishing the inner surfaces of components. Small-diameter diamond grinding pins are essential for this work, especially on hardened materials like steel, ceramics, and carbide. These tools enable manufacturers to achieve tight tolerances and superior surface finishes inside cylindrical parts.

Finishing Inner Diameters

Operators use internal grinding to refine the inner diameter (ID) of a workpiece. This process is critical for parts requiring a precise fit and smooth operation. The hardness of the diamond abrasive allows for efficient material removal while creating an excellent surface finish. The level of finish depends on the grinding stage, from roughing to super finishing.

| Grinding Type | Ra Micron (µm) |

|---|---|

| Rough Grinding | 1.8 – 3.61 |

| Medium Grinding | 0.48 – 1.32 |

| Finishing | 0.23 – 0.38 |

| Super Finishing | 0.1 and below |

Grinding Bearing Races

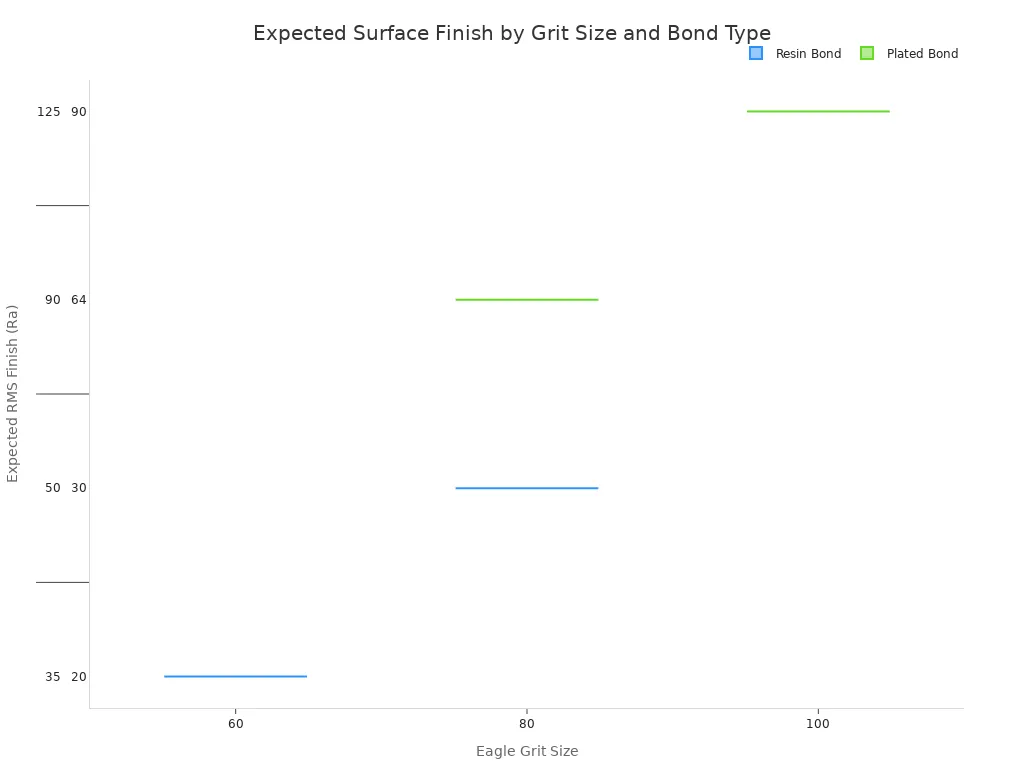

Bearing races demand exceptional geometric accuracy and surface quality to ensure low friction and long service life. A diamond grinding pin is the ideal tool for finishing these critical surfaces. The choice of diamond grit size and bond type directly impacts the final surface roughness. Plated bonds are often used for aggressive material removal, while resin bonds provide a finer finish.

As the chart illustrates, a finer grit size results in a smoother surface. This control is vital for high-performance bearings.

Correcting Bore Geometry

Heat treatment can cause parts to warp or distort. This often results in geometric errors like out-of-roundness, taper, or bell-mouthing in bores. Internal grinding corrects these imperfections. The process restores the bore to its exact specified geometry, ensuring that components fit together perfectly and function as designed. This corrective step is fundamental to quality control in high-precision manufacturing.

4. Practical Applications in Mold and Die Making

Diamond grinding pins have many practical applications in the mold and die industry. These tools are essential for finishing intricate cavities, cores, and surfaces in injection molds and stamping dies. The precision required in this field is exceptionally high. Manufacturers need tools that deliver flawless results on hardened tool steels.

Finishing Intricate Cavities

Mold cavities often feature complex designs with thin walls or undercuts. Diamond grinding pins allow operators to finish these detailed areas with great accuracy. The small size and varied shapes of the pins provide access to tight corners and complex geometries. Proper finishing prevents defects and ensures parts release cleanly from the mold. Case studies show significant improvements with the right techniques.

- A company producing polycarbonate dashboards used smaller pins to achieve a 97% defect-free release rate.

- Strategic pin placement near undercuts in injection molding reduced part sticking issues by 35%.

Polishing Mold Surfaces

The surface finish of a mold cavity directly impacts the final product’s appearance. The Society of the Plastics Industry (SPI) sets standards for these finishes. A glossy finish, or Grade A, requires a diamond buffing process. This level of polish is necessary for producing optically clear or high-gloss parts. Hardened steel, such as NAK80, is preferred for these molds because it polishes more effectively.

| SPI Standard | Description | Finishing Method |

|---|---|---|

| A-1 | High Glossy / Optically Transparent | Grade #3, 6000 Grit Diamond Buff |

| A-2 | High Glossy / Transparent | Grade #6, 3000 Grit Diamond Buff |

| A-3 | High Glossy / Transparent | Grade #15, 1200 Grit Diamond Buff |

Detailing Stamping Dies

Stamping dies must have sharp, precise edges to cut and form sheet metal cleanly. Over time, these edges wear down and require maintenance. Operators use diamond pins to resharpen and detail stamping dies, restoring their performance. This process extends the die’s life and ensures consistent part quality. For such high-stakes work, customized grinding solutions are critical.

Note: Aimgrind‘s customized grinding solutions are ideal for the high-precision requirements of mold and die finishing, ensuring every tool meets exact specifications.

5. Engraving Glass and Stone

The extreme hardness of diamond grinding pins makes them the perfect tool for working on brittle materials like glass and stone. These materials would shatter or chip with conventional tools. Diamond abrasives, however, allow for precise and controlled material removal. This capability opens up applications in both industrial and artistic fields.

Industrial Engraving on Quartz

Quartz is a very hard mineral used in many high-tech industries, including electronics and optics. Manufacturers use diamond grinding pins to engrave precise markings on quartz components. These markings can include serial numbers, alignment guides, or logos. The process requires extreme accuracy. The fine tip of a grinding pin creates clean, sharp lines without causing micro-fractures in the material. This precision ensures the structural integrity and functionality of the quartz part.

Artistic Carving on Granite

Artists and stonemasons use these versatile tools to carve intricate designs into hard stones like granite. The power and control offered by a grinding pin allow for incredible detail. An artist can create complex textures and patterns that would be impossible with traditional chisels. Common artistic applications include:

- Engraving detailed lettering on monuments

- Carving elaborate patterns on decorative tiles

- Creating fine textures on sculptures

- Shaping custom stone inlays

Detailing Glass Surfaces

Diamond grinding pins give artisans and manufacturers the ability to add fine details to glass surfaces. This process is essential for creating both functional and decorative glass products. Operators can etch intricate patterns, frost surfaces for privacy, or cut precise grooves in scientific glassware. The tool’s steady abrasive action removes glass material smoothly. This control prevents chipping and ensures a high-quality finish.

Tip for Glasswork: When detailing glass, using a constant stream of water as a coolant is crucial. It prevents heat buildup, reduces dust, and helps achieve a cleaner, smoother cut.

6. Modifying and Repairing Ceramics

Ceramic components offer excellent hardness and heat resistance but are notoriously brittle. Diamond grinding pins provide a reliable solution for modifying and repairing these delicate materials. Their precise abrasive action allows operators to work on ceramics without causing fractures or compromising structural integrity. This control is essential for post-production adjustments and maintenance.

Adjusting Component Dimensions

Ceramic parts can shrink or warp unpredictably during the firing process. This often results in components that are slightly out of specification. Operators use grinding pins to make fine adjustments to the dimensions of a finished part. This process allows them to achieve tight tolerances on critical features. The tool can carefully remove material from surfaces, bores, and slots, ensuring a perfect fit in complex assemblies.

Repairing Minor Surface Defects

Small chips, pits, or surface blemishes can render a ceramic part unusable. Instead of discarding the entire component, manufacturers can use a grinding pin for localized repairs. This tool can smoothly grind away the defect and blend the repaired area with the surrounding surface. This capability is especially valuable for high-cost ceramic parts, as it saves money and reduces waste. Common repairs include:

- Removing small edge chips.

- Smoothing out surface irregularities.

- Correcting minor casting flaws.

Machining High-Tech Ceramics

Modern industries rely on high-tech ceramics like alumina and zirconia for their superior strength and wear resistance. These materials possess a rigid atomic structure due to strong ionic or covalent bonds. This structure makes them incredibly hard but also brittle, causing them to fracture easily under stress. Advancements in superabrasive grinding wheels made the widespread use of these extra-hard materials possible.

Machining zirconia, for example, places high demands on equipment and consumes more diamond tools than other materials. This highlights the necessity of specialized abrasives for achieving precision on such challenging substrates.

7. Porting and Polishing Engines

Engine builders and performance enthusiasts use diamond grinding pins to optimize engine airflow. This process, known as porting and polishing, involves modifying the intake and exhaust ports of an engine’s cylinder head. The goal is to reduce air resistance and increase the volume of the air-fuel mixture entering the cylinders. This modification leads to more efficient combustion and greater engine power.

Smoothing Intake and Exhaust Ports

Engine ports often have rough surfaces and casting flaws from the manufacturing process. These imperfections disrupt airflow. Technicians use grinding pins to smooth these surfaces, which enhances airflow and can increase both horsepower and torque. While polishing the intake manifold alone may not yield large gains, a full port and polish job can be effective. One owner reported a 30 horsepower increase on a dyno after porting their engine, showing the potential of this modification.

Matching Gaskets and Manifolds

For optimal performance, the intake manifold, gaskets, and cylinder head ports must align perfectly. Misalignment creates “steps” that obstruct airflow. A technician uses a grinding pin to carefully remove material and match the port openings precisely. This process, called port matching, eliminates turbulence at the transition points. It ensures a smooth, uninterrupted path for the air-fuel mixture to travel from the manifold into the cylinder head.

Improving Engine Airflow

The primary goal of porting is to improve airflow. Engines with specially designed heads can see power gains of 20% or more compared to standard designs. The most significant improvements come from specific areas within the cylinder head.

Approximately 50% of airflow gains come from work on the valve seat area. Another 30-40% of improvement can come from reshaping the bowl area just behind the valve. A high-quality diamond tool gives technicians the control needed to make these critical adjustments.

8. Finishing Aerospace Composites

Aerospace manufacturing relies heavily on composite materials like Carbon Fiber Reinforced Polymer (CFRP) and fiberglass. These materials offer incredible strength-to-weight ratios but present unique machining challenges. Their abrasive and non-homogenous nature causes rapid tool wear and can lead to defects. Diamond grinding pins provide the necessary precision and durability to finish these advanced materials effectively.

Trimming CFRP Parts

Trimming CFRP components to their final dimensions is a difficult task. The material consists of hard carbon fibers embedded in a softer resin matrix. Conventional tools struggle because the fibers tend to fracture rather than cut cleanly. This process generates abrasive dust and can cause significant tool wear. A high-quality grinding pin with a diamond abrasive surface cuts through the tough fibers and resin with ease. This allows operators to achieve clean, precise trims without damaging the expensive workpiece.

Contouring Without Delamination

Delamination is a critical failure mode when machining composites. It occurs when the layers of the material separate due to mechanical stress or heat buildup. This defect compromises the structural integrity of the part. The controlled cutting action of a grinding pin is essential for preventing this issue.

By using the correct pin, operators can shape complex contours while minimizing cutting forces and thermal damage. This precision is crucial for maintaining the material’s integrity and ensuring the component meets strict aerospace safety standards.

Finishing Fiberglass Edges

Fiberglass parts also require careful finishing to prevent frayed edges and ensure a proper fit. After being cut or molded, fiberglass edges can have loose fibers that need to be removed. A grinding pin is perfect for this application. It smoothly grinds the edge to a clean, sealed finish. This process offers several key benefits:

- Creates smooth, burr-free edges.

- Prevents fiber fraying and splintering.

- Ensures dimensional accuracy for assembly.

- Improves the part’s overall appearance and safety.

9. Lapidary and Jewelry Making

The art of lapidary and jewelry making demands extreme precision and the right tools for difficult materials. Diamond abrasives are essential for working with both hard gemstones and precious metals. Jewelers and lapidaries rely on these tools for shaping, finishing, and detailing their creations. The unparalleled hardness of diamond makes these tasks possible.

Shaping Hard Gemstones

Lapidaries work with some of the hardest materials on Earth. Shaping precious stones requires an abrasive that is even harder. Diamond, with a Mohs hardness of 10, is the only material capable of cutting and shaping other hard gems like sapphires and rubies. Artists use these tools to transform rough stones into beautifully faceted jewels. The process requires careful material removal to achieve the desired cut and brilliance.

Pre-Polishing Precious Metals

Jewelers use grinding pins to prepare precious metals for their final polish. This step is crucial for creating a flawless, mirror-like finish. The tool smooths surfaces, removes file marks, and blends solder joints on metals like gold, silver, and platinum. This pre-polishing stage ensures a uniform texture. A perfectly prepared surface allows the final polishing compounds to work more effectively, resulting in a high-quality piece of jewelry.

Using a Diamond Grinding Pin for Detailing

Fine detail work separates exceptional jewelry from the ordinary. A diamond grinding pin gives jewelers the control needed for intricate tasks. They use it for engraving delicate patterns, cleaning up settings, and detailing ring shanks. The tool’s precision allows for sharp lines and clean finishes in very small areas. This level of detail adds significant value and beauty to the final product.

Pro Tip: 💎 When working on precious metals, use a light touch and keep the tool moving. This prevents heat buildup and avoids creating unwanted divots on the surface.

10. Sourcing Quality Diamond Tools from Aimgrind

Choosing the right supplier is as important as selecting the right tool. A reliable partner ensures you receive high-quality products tailored to your specific manufacturing needs. Aimgrind specializes in providing these exact solutions.

Understanding Aimgrind’s Diamond Tools

Aimgrind offers a wide range of diamond tools built for performance. These tools feature high-quality diamond grains and strong metal bonds. This construction ensures durability and precision when working with hard materials like glass, ceramics, and composites. The product line includes drill bits, reamers, and milling cutters designed for various industrial applications. Each tool provides superior cutting efficiency and a long service life.

Custom Solutions for Your Industry

Every industry has unique challenges. Aimgrind addresses this by offering customized grinding solutions. The brand works with customers in aerospace, woodworking, and glass processing to develop tools that match their equipment and processes perfectly. This tailored approach ensures optimal performance.

Aimgrind’s mission is to provide the correct diamond tooling for every job. This commitment to customization helps clients enhance productivity and achieve superior results in their specific applications.

The Value of Precision and Durability

Investing in quality diamond tooling pays off through precision and durability. Precision reduces material waste and the need for rework. Durability translates directly into significant cost savings. A single high-quality diamond tool can outlast dozens of standard abrasive tools, leading to major operational benefits. This extended lifespan means:

- Reduced Tool Purchases: You buy fewer tools over time.

- Minimized Downtime: You spend less time stopping machines for tool changes.

- Increased Production Efficiency: Your machines can operate faster and produce more parts.

These factors make high-quality diamond grinding tools a cost-effective choice. They improve your bottom line by delivering consistent, reliable performance day after day.

From engine porting to finishing aerospace composites, the diamond grinding pin proves its versatility. These tools are essential for achieving high precision on the toughest materials. The future of manufacturing demands even better performance, driven by advancements in superabrasive grinding technologies. This makes the selection of the right grinding tool more critical than ever.

Partnering with a specialized provider like Aimgrind ensures you get the right tool for the job. This enhances both quality and efficiency in your operations.

FAQ

### What are diamond grinding pins used for?

Operators use diamond grinding pins for precision work on hard materials. Key applications include deburring sharp edges, shaping carbide tooling, finishing internal bores, and detailing molds. Their versatility makes them essential in many manufacturing processes for achieving high-quality results.

### Can diamond pins work on materials other than metal?

Yes, they excel on hard, brittle materials. Diamond’s superior hardness allows these tools to effectively engrave glass, shape hard gemstones, and modify technical ceramics. This capability makes them valuable in industries ranging from aerospace to jewelry making.

### How should a user maintain a diamond grinding pin?

Proper maintenance extends tool life. Users should regularly clean the pin to remove debris buildup. Using a coolant like water during grinding prevents overheating and reduces wear. Storing the pins correctly prevents damage to the diamond abrasive surface.

### Why choose a diamond tool over a conventional one?

Diamond tools offer superior hardness and wear resistance. This durability means they last longer and require fewer replacements, reducing downtime. Their efficiency provides faster material removal and a better surface finish, making them a cost-effective choice for high-precision tasks.

See Also

Selecting The Optimal Grinding Wheel For Your Carbide Tooling Needs

Exploring Various Grinding Wheel Types And Their Real-World Uses

Mastering Safe And Effective Dremel Grinding Wheel Operation Techniques

Finding The Ideal Grinding Wheel Dresser To Suit Your Requirements

Selecting The Perfect Bench Grinding Wheel Material For Specific Tasks

Contact Us

For More Grinding Solution or Customized Abrasive Tools