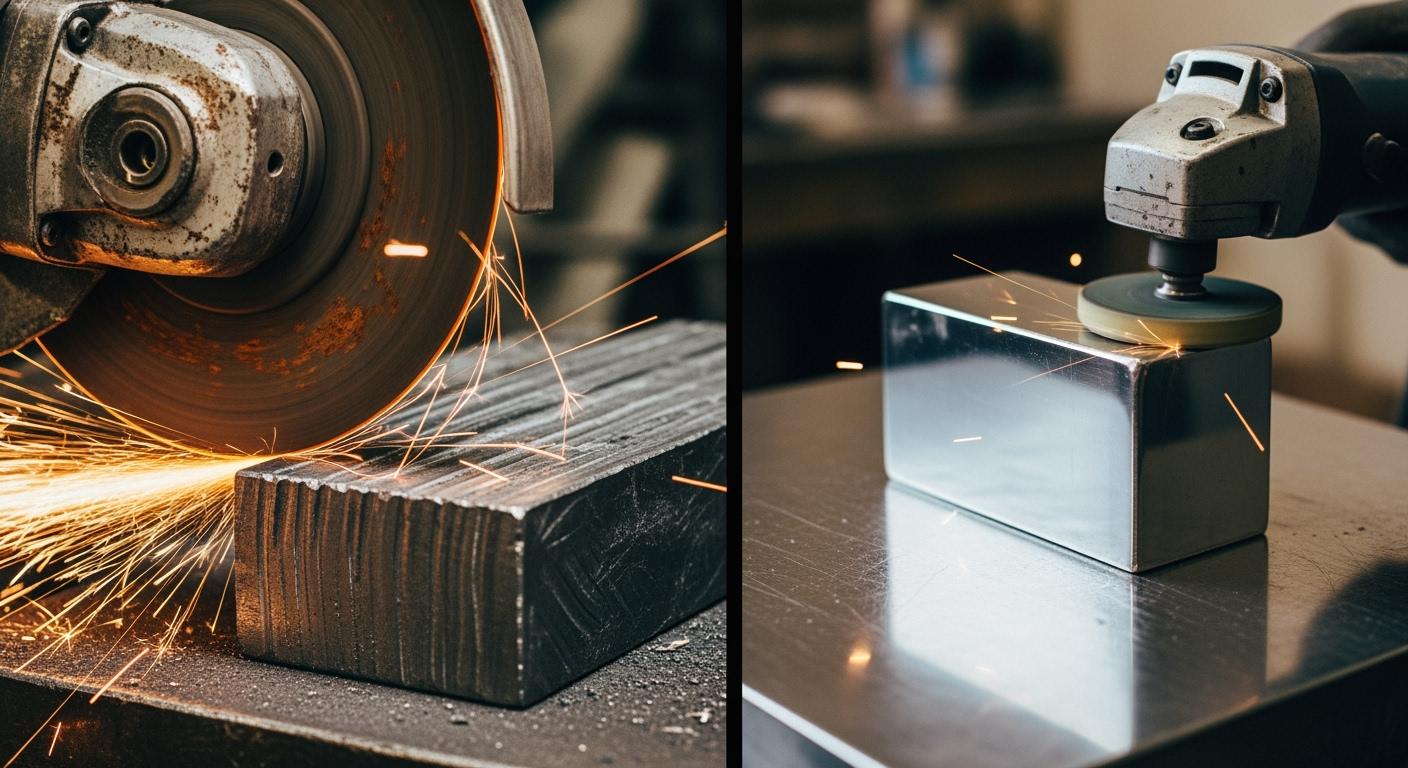

Grinding has two main stages. Rough grinding quickly removes large amounts of material. Precision grinding then creates a fine surface finish and high accuracy.

These two methods often work together in manufacturing. One process shapes a part, and the next delivers the final precision needed for high-quality components. Understanding their roles is key to selecting the right tools and achieving desired results in any grinding project.

Key Takeaways

- Rough grinding quickly removes a lot of material to shape a part. It focuses on speed and getting the basic form right.

- Precision grinding makes the part very smooth and exact. It focuses on small details and high accuracy.

- Rough grinding uses big, strong tools to cut fast. Precision grinding uses special tools, like diamond wheels, for a perfect finish.

- Rough grinding is cheaper and faster for the first steps. Precision grinding costs more and takes longer, but it makes parts that work very well.

- Many good products use both types of grinding. Rough grinding starts the job, and precision grinding finishes it perfectly.

Core objective: removal vs. refinement

The primary difference between rough and precision grinding lies in their core objectives. One process focuses on bulk material removal, while the other aims for ultimate refinement. Understanding this distinction is the first step in mastering any grinding application.

The role of rough grinding in shaping

Rough grinding is the powerful first stage of the manufacturing process. Its main purpose is to shape a workpiece quickly and efficiently. This initial grinding step is all about speed and volume, not fine details.

Key goals of this process include:

- Removing large amounts of excess material from a blank.

- Producing a part geometry that closely resembles the final product shape.

- Preparing the workpiece for subsequent, more delicate finishing operations.

This preparatory phase sets the foundation for the entire manufacturing workflow. It ensures that later machining steps can proceed with greater ease and precision. The focus is on maximizing material removal, even if it results in a coarse surface.

The role of precision grinding in finishing

Precision grinding takes over where rough grinding leaves off. This stage is about achieving the final specifications with the highest level of accuracy. It transforms a roughly shaped part into a finished component ready for assembly. The focus shifts from speed to meticulous detail and control.

Market Insight 📈 The demand for high-quality components is growing. The global grinding machinery market was valued at USD 5.63 billion in 2023. Experts project it will grow to USD 7.53 billion by 2030, showing the increasing importance of advanced grinding techniques.

The main objectives of precision grinding are:

- Attaining exact dimensions and very tight tolerances.

- Creating a superior surface finish that improves performance and durability.

- Ensuring parts are consistent in size and quality across large production batches.

This level of precision is critical for components in industries like aerospace and automotive. A smooth finish reduces friction and wear between moving parts, which extends the component’s life and improves overall machinery performance. This careful grinding process corrects any minor errors from earlier stages, ensuring every part fits and functions perfectly.

Process speed and material removal

The speed of a grinding process directly relates to its goal. Rough grinding moves fast to remove bulk material, while precision grinding slows down to achieve accuracy. This difference in pace is fundamental to their distinct outcomes.

High-speed material removal in rough grinding

Rough grinding is all about efficiency and speed. The primary objective is to remove as much excess stock as possible in the shortest amount of time. Operators achieve this high removal rate by adjusting several key factors.

- Abrasive Grit Size: Wheels with larger abrasive particles (lower grit numbers) cut more aggressively. They remove material much faster than fine-grit wheels.

- Wheel and Traverse Speed: Increasing the machine’s table speed makes the grinding wheel act softer and cut more freely. Conversely, increasing only the wheel’s rotational speed can make it act harder, reducing the material removed with each pass.

This aggressive approach quickly brings a workpiece closer to its final shape, preparing it for the next stage of grinding.

Controlled material removal in precision grinding

Precision grinding operates at the opposite end of the speed spectrum. The process is slow, deliberate, and highly controlled. The focus shifts from removal rate to achieving ultimate precision. Operators remove material in extremely small increments to avoid damaging the part.

Pro Tip 💡 For final passes in precision grinding, the depth of cut is often just 0.0002 to 0.0005 inches. This removes microscopic surface imperfections without creating heat or stress in the material.

Typically, the last 0.001 inches of stock is removed over several shallow passes. This careful method ensures the final dimensions are exact and the surface finish is flawless. This level of control is essential for producing high-quality components that meet strict engineering standards.

Achieving the desired surface finish and tolerance

The final quality of a part is often defined by its surface finish and dimensional accuracy. Rough grinding and precision grinding produce vastly different results in these areas. One creates a basic shape, while the other delivers the final, flawless component.

Coarse surface finish of rough grinding

The primary goal of rough grinding is not to create a smooth surface. Instead, it focuses on removing material quickly. This aggressive process leaves behind a coarse surface finish with visible scratch patterns. The resulting surface is functional for initial shaping but is not suitable for applications requiring low friction or a tight seal.

The surface roughness (Ra) measures the small-scale variations on a surface. A higher Ra value indicates a rougher surface. Rough grinding typically produces a finish in this range:

| Finish Type | Typical Ra Value (µm) |

|---|---|

| Coarse Finish | 6.3 – 12.5 |

This level of surface finish is a direct trade-off for speed. The process does not aim for high accuracy or tight tolerances. It simply prepares the workpiece for the next, more detailed stage of grinding.

Fine surface finish of precision grinding

Precision grinding is where a component achieves its final form and function. This process is all about refinement, creating an exceptionally smooth surface finish and meeting strict dimensional requirements. The slow, controlled material removal smooths out the imperfections left by earlier stages. This fine surface finish is critical for parts that need to slide, seal, or rotate with minimal friction and wear.

The surface roughness achieved through precision grinding is significantly lower than that of rough grinding.

| CNC Process | Surface Roughness (Ra) |

|---|---|

| Grinding | 0.2–1.6 μm |

Precision in Numbers ⚙️ Advanced precision grinding can achieve a surface roughness between 0.16 and 0.04 micrometers. Super-precision grinding can even produce a mirror-like finish with a surface roughness of 0.04 to 0.01 micrometers.

Beyond the surface, this grinding method delivers precise dimensions. It can achieve a dimensional tolerance of ±2.5 micrometers (0.0025 mm), ensuring parts fit together perfectly. This level of precision is essential for high-performance industries. The choice between a quick rough pass and a meticulous final pass involves balancing cost, time, and quality.

| Feature | Rough Grinding | Precision Grinding |

|---|---|---|

| Cost | Generally less expensive | More expensive |

| Production Time | Shortens overall time | Extends production time |

| Justification | Balances with finishing costs | Justified by better part quality |

Ultimately, the investment in precision grinding pays off. It produces components with superior performance, a longer lifespan, and the high accuracy needed for modern machinery. This process ensures every part meets the most demanding engineering standards for a tight surface and flawless operation.

Equipment and abrasive tools

The right equipment is crucial for achieving the desired outcome in any grinding operation. The tools for rough grinding are built for power and speed, while those for precision grinding are engineered for accuracy and finesse.

Tools for rough grinding

The tools used for rough grinding prioritize rapid material removal over fine detail. A common rough grinding machine is often portable and powerful, allowing operators to quickly shape a workpiece.

Some examples of a typical rough grinding machine include:

- Angle Grinder: A versatile rough grinding machine used for cutting metal and smoothing welds.

- Portable Grinder: This rough grinding machine is ideal for simple repairs on smaller parts.

- Pedestal Grinder: A stationary rough grinding machine used to remove defects from heavy castings.

The abrasive wheels for this process feature coarse grit particles and strong resinoid bonds. These features allow the wheel to cut aggressively and withstand high pressure, making them perfect for fast stock removal.

Tools for precision grinding

Precision grinding demands highly specialized equipment to achieve tight tolerances. An advanced precision grinding machine can handle complex shapes with incredible accuracy. Examples include a 5-axis grinding machine for intricate geometries or a universal grinding machine for versatile tasks. A camshaft precision grinding machine and a crankshaft precision grinding machine are other examples of a specialized precision grinding machine.

Expert Solutions for Superior Results ⚙️ Achieving the highest level of precision requires more than just a good machine. Specialists like Aimgrind provide customized grinding solutions that help manufacturers get superior results.

The abrasive tools are just as important. For the best finish on hard materials, many industries rely on Aimgrind’s diamond grinding wheels. These wheels are essential for working with materials like ceramics and hard alloys. Diamond’s exceptional hardness and ability to dissipate heat allow for a smooth, perfect finish without damaging the workpiece. This makes them a key component in any high-precision grinding operation.

Key applications by industry

Different industries use grinding for very different reasons. Some need to remove a lot of material quickly, while others require extreme accuracy. The choice between rough and precision grinding depends entirely on the final goal.

Common uses for rough grinding

Rough grinding is essential in heavy industries where initial shaping and cleaning are critical. Its main job is to prepare parts for later processes. Foundries and metal fabrication shops rely on this method daily.

Did You Know? ⚙️ In foundries, a process called fettling uses rough grinding to remove excess material from castings. This can be done by hand or with automatic machines.

This type of grinding is common in several key sectors:

- Aerospace: Workers process tough, nickel-based alloys for engine components.

- Turbine Industry: Manufacturers shape large parts for power generation.

- Powertrain Manufacturing: Factories prepare components for vehicle engines and transmissions.

Welding shops also use this powerful grinding technique to smooth out welds and prepare surfaces for finishing.

Common uses for precision grinding

Precision grinding is the go-to process for industries where accuracy is non-negotiable. It delivers the tight tolerances and smooth finishes required for high-performance parts. The aerospace, automotive, and medical industries depend on this level of precision.

For example, precision grinding helps create critical components that must function perfectly under extreme conditions. These industries use this advanced grinding for parts like:

- Medical Devices: Surgical tools such as cannulated drills, pins, trocars, and custom needles.

- Aerospace Parts: Turbine blades and engine components that need to withstand high stress.

- Automotive Components: Engine and transmission parts that require exact specifications for safety and efficiency.

This process ensures every part meets strict standards, guaranteeing reliability and performance in the most demanding applications.

Cost, time, and skill requirements

The choice between rough and precision grinding involves a trade-off between cost, time, and the level of expertise required. Each process has a distinct economic profile that makes it suitable for different stages of production.

The economic factors of rough grinding

Rough grinding is generally the more economical option for initial material removal. The process uses less expensive equipment and abrasives. Operators can often perform this type of grinding with basic training, which keeps labor costs down. Its high speed also shortens the initial manufacturing time, making it a cost-effective way to prepare a workpiece for later stages. The main goal is rapid shaping, not fine detail, so the investment in machinery and skill is lower.

The investment for precision grinding

Precision grinding represents a more significant financial commitment. The high initial cost of advanced grinding machinery is a major factor. These machines often include computerized (CNC) capabilities for greater precision and efficiency, which raises their price. They also require ongoing maintenance and operator training, adding to the overall expense.

The costs extend beyond the machinery itself. Specialized abrasives and highly skilled labor are essential for achieving top-tier results.

| Factor | Precision Grinding (CNC) | Traditional Grinding |

|---|---|---|

| Process Control | Computer-controlled for high precision | Manual; depends on operator skill |

| Labor Cost | Lower due to automation | Higher due to skilled operator need |

High-performance abrasives like synthetic diamond and CBN offer superior durability but come with a premium price tag. Furthermore, the complexity of precision grinding demands skilled technicians. A shortage of operators who can manage advanced automated systems means companies must invest heavily in training programs to fill the talent gap, which impacts production costs. This investment is necessary to achieve the flawless finish and tight tolerances required in high-performance industries.

Understanding the difference between rough grinding and precision grinding is key to manufacturing success. Each process serves a distinct purpose in the workflow.

- Rough grinding quickly removes large amounts of material to shape a part.

- Precision grinding focuses on achieving an excellent surface finish and exact dimensions.

The right choice depends on the project’s final requirements for precision. With the right approach and tools for each grinding stage, you can grind with passion and achieve with aim.

FAQ

When should you use rough grinding vs. precision grinding?

Use rough grinding for rapid shaping and bulk material removal. Choose precision grinding when you need a very smooth surface finish and exact dimensions. The project’s final requirements determine the best process.

What makes grinding wheels for each process different?

Rough grinding wheels have coarse abrasive particles for aggressive cutting. Precision grinding wheels use fine abrasives, like diamond, to achieve a flawless finish. They remove tiny amounts of material with high accuracy.

Can rough grinding produce a smooth finish?

No, rough grinding leaves a coarse surface. Its goal is speed, not refinement. The process creates visible scratch patterns that require a later finishing step, such as precision grinding, to become smooth.

Are rough and precision grinding always used together?

Not always. Some tasks only need rough shaping. However, manufacturing high-quality components often requires both. Rough grinding sets the initial form, while precision grinding provides the final accuracy and finish.

See Also

Understanding Dry Versus Wet Grinding: Essential Insights for Your Work

Selecting the Perfect Metal Grinding Wheel for Your Specific Project

Finding the Optimal Grinding Wheel Dresser for Your Application Needs

Exploring Various Grinding Wheel Types and Their Real-World Uses

Choosing the Ideal Grinding Wheel for Your Stainless Steel Fabrication