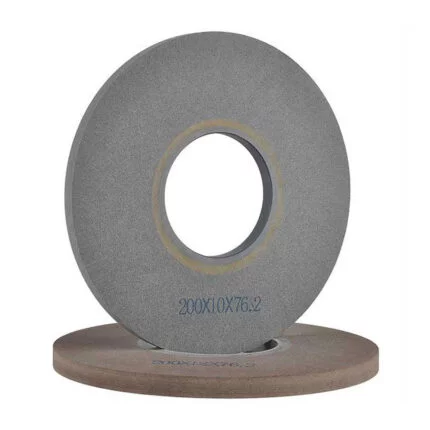

Worm Grinding Wheel

The worm grinding wheel is a specialized abrasive tool designed for precision grinding of worm gears and threads. Featuring high-grade abrasive grains and optimized bond structure, these wheels deliver exceptional accuracy and surface finish for critical gear applications in automotive, aerospace, and industrial machinery.

Detailed Description of Worm Grinding Wheel

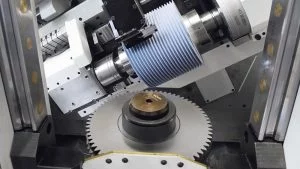

Precision worm grinding wheels are engineered specifically for manufacturing and refinishing worm gears – crucial components in power transmission systems that require extremely accurate tooth profiles and smooth surface finishes.

These specialized wheels typically use aluminum oxide or CBN (cubic boron nitride) abrasives with vitrified bonds to maintain precise form retention during the grinding process. The grain size and concentration are carefully selected based on the required surface finish and material removal rates.

Unlike standard grinding wheels, worm gear grinding wheels are precisely dressed to match the exact profile of the worm thread being produced. This requires specialized diamond dressing tools and often involves CNC-controlled dressing processes to achieve the necessary accuracy.

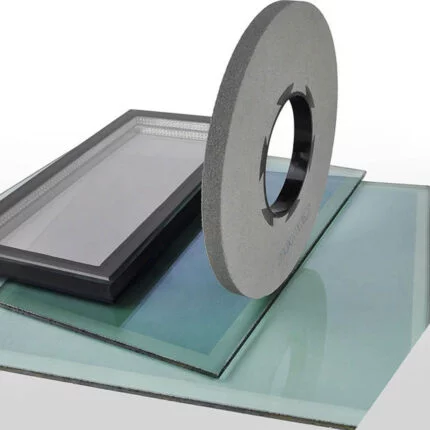

Key Applications

Worm grinding wheels are essential tools in gear manufacturing and maintenance across multiple industries:

Automotive Components

Precision grinding of steering system worm gears, transmission components, and other critical automotive parts requiring exact tooth profiles and smooth operation.

Industrial Machinery

Manufacturing and refurbishing of worm gears used in heavy machinery, conveyor systems, and precision positioning equipment.

Aerospace Systems

Production of high-precision worm gears for aircraft control systems, landing gear mechanisms, and other aerospace applications where reliability is critical.

Power Transmission

Grinding of worm gears used in speed reducers, elevators, and other power transmission systems requiring high reduction ratios.

Technical Specifications

| Standard Specifications | |

|---|---|

| Abrasive Material | Premium aluminum oxide or CBN |

| Bond Type | Vitrified (ceramic) or resin |

| Grain Size | 80-220 (standard), finer grades available |

| Diameter Range | 100mm-600mm (custom sizes available) |

| Width Range | 10mm-150mm |

| Bore Sizes | Standard from 20mm-100mm |

| Max Operating Speed | 35-60 m/s depending on specification |

Key Features

- Precision-formed abrasive profile

- Excellent form retention

- Consistent cutting performance

- Minimal vibration during operation

- Long service life

- Available in various hardness grades

Performance Advantages

Superior Accuracy

Maintains tight tolerances for precise worm thread profiles (±0.002mm achievable)

Excellent Surface Finish

Produces surface finishes down to Ra 0.2μm for smooth gear operation

High Productivity

Optimized abrasive formulation allows for faster material removal rates

Extended Wheel Life

Advanced bond technology provides longer service life between dressings

Selection Guide

Choosing the right worm grinding wheel depends on several factors:

Material Being Ground

- Steel alloys: Aluminum oxide wheels

- Hardened steels: CBN wheels recommended

- Non-ferrous metals: Silicon carbide options

Required Surface Finish

- Finer grits for smoother finishes

- Coarser grits for faster stock removal

Production Volume

- High volume: Premium CBN wheels

- Low volume: Conventional abrasive wheels

Our technical team can help select the optimal wheel specification for your specific application and machine parameters.

Summary

Worm grinding wheels are precision tools essential for manufacturing high-quality worm gears with accurate tooth profiles and excellent surface finishes. These specialized wheels are available in various abrasive types, grit sizes, and bond formulations to suit different materials and production requirements.

When properly selected and maintained, our worm grinding wheels deliver consistent performance, long service life, and exceptional results for critical gear applications across automotive, aerospace, and industrial sectors.

For custom worm grinding wheel solutions or technical consultation, please contact our engineering team.

Contact Us

For More Grinding Solution or Customized Abrasive Tools