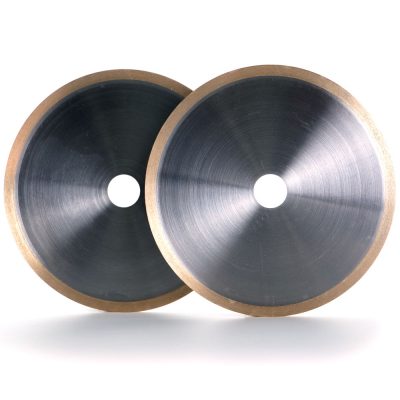

The metal bond cutting wheel is of two main types, including metal bond diamond cutting wheel and metal bond CBN cutting wheel. The former is used to cut wear-resistant and short-chipping (hard) materials such as ceramics, glass, carbide, ferrite, quartz, graphite, and semiconductor materials. The latter is used on materials that feature an affinity for carbon, such as iron-based alloys.

Feature of Metal Bond Diamond and CBN Cutting Wheels

Below are the unique selling propositions that inform every potential buyer why they should purchase metal bond diamond and CBN cutting wheels

- High deep cutting with a longer lifespan.

- Require low maintenance and feature longer maintenance of wheel sharpness.

- High wear resistance with more production output and better heat transfer from the workpiece.

- Utilized on many different material types, such as optical glass, tungsten carbide, steel, ceramic, quartz, titanium alloy, etc.

One of the prime importance and outstanding discoveries in the history of manufacturing is the invention of different blades that help with precision cutting. How great is it for an industry to have an acceptable blade bond type that could serve this unique purpose efficiently? With high-quality cutting wheels, you are guaranteed smooth, fast, clean operations while dealing with some specific workpieces.

Fortunately, metal bond cutting wheels are designed to offer the best service needed in different relevant places, including construction sites, tool shops, medical manufacturing industries, automotive shops, etc. They are undeniably great recommendations when it comes to cutting material. Therefore, it would be of great benefit to discuss the metal bond cutting wheels, their types, features, applications, and other vital details to help every potential customer.

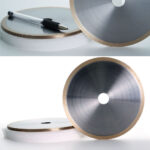

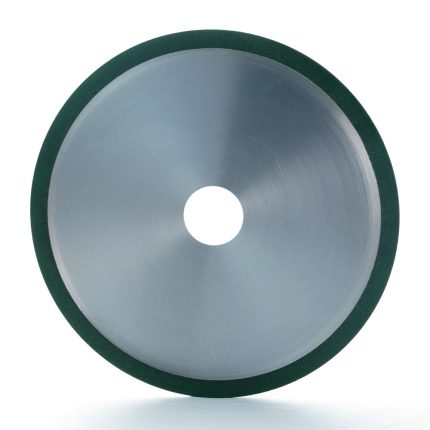

Metal Bond Cutting Wheels

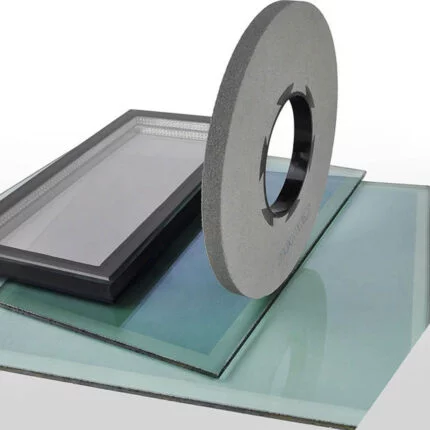

For those in need of standard wheels designed to meet several cutting requirements, metal bond cutting wheels are an ideal choice. They are made for a fantastic performance in cutting off several materials efficiently. They are abrasive tools that can maintain their superb form better than polyimide, resin, or conventional bonds while providing incredible free cutting

Metal bond cutting wheels are perfect for any application, be it wet cutting or dry cutting. Besides, they release heat via their metalcore and binder, which is proper for boosting material removal rates. These wheels also help extend the time that lies between dressing and truing.

If rightly applied, metal bond cutting wheels are one of the best precision cutting tools for glass, quartz, ferrite, etc. In addition, due to how these wheels feature high blade thickness and run-out accuracy, industries find it most suitable for processing precision molds of ceramics and cemented carbide.

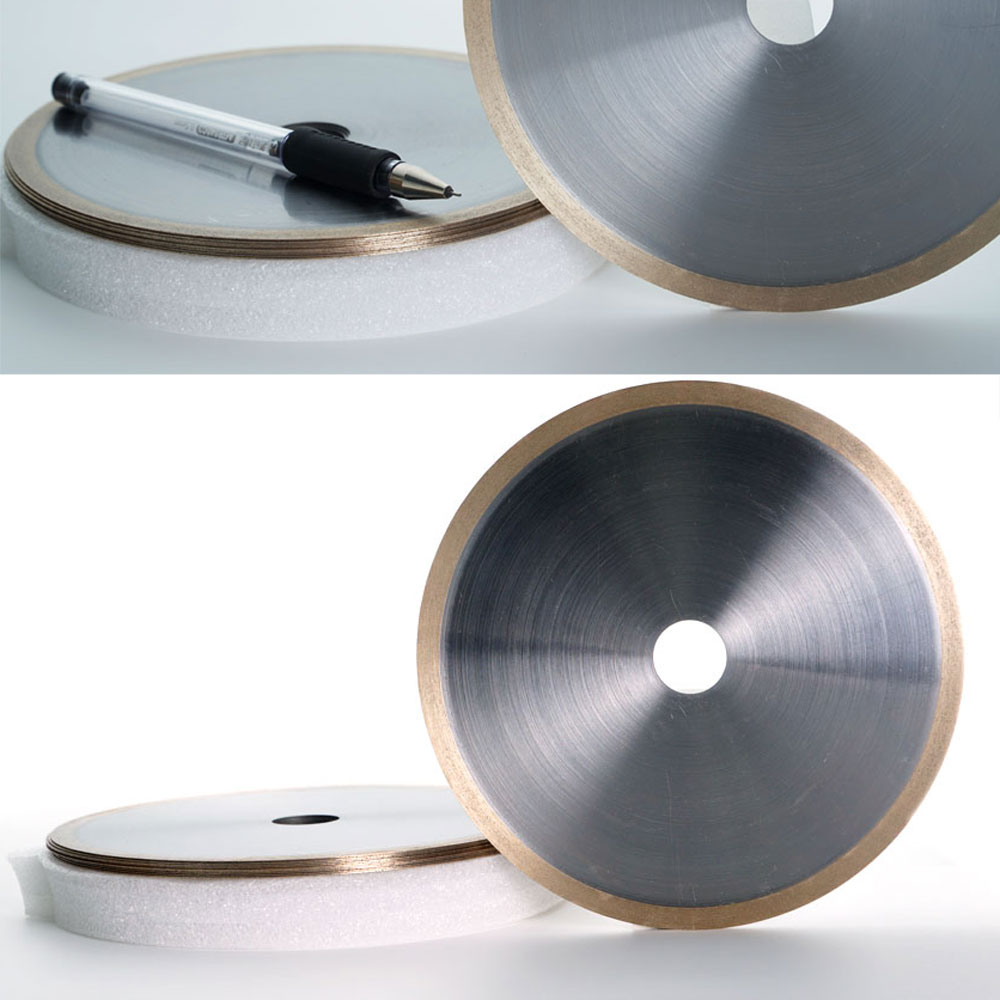

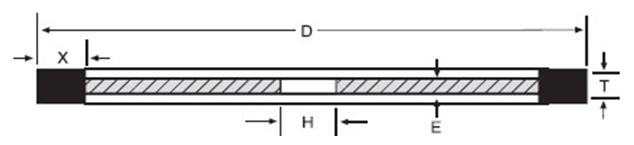

Specification of Metal Bond Cutting Wheel

|

|

||

| Hole | Diameter | Thickness |

| 12.7, 19.05, 20, 31.75, 50.8, 60, 127 | 50 – 400 mm | 0.2 -2.0 mm |

Types of Metal Bond Cutting Wheels

There are different types of metal bond cutting wheels. These include:

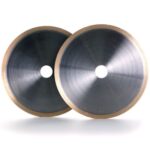

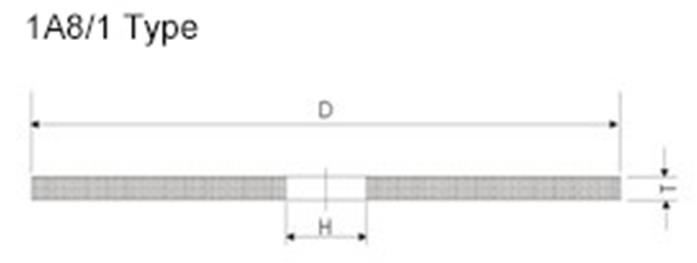

1a8/1: This is a type without a water slot.

1a8/2: This is a type with a water slot.

Other types include:

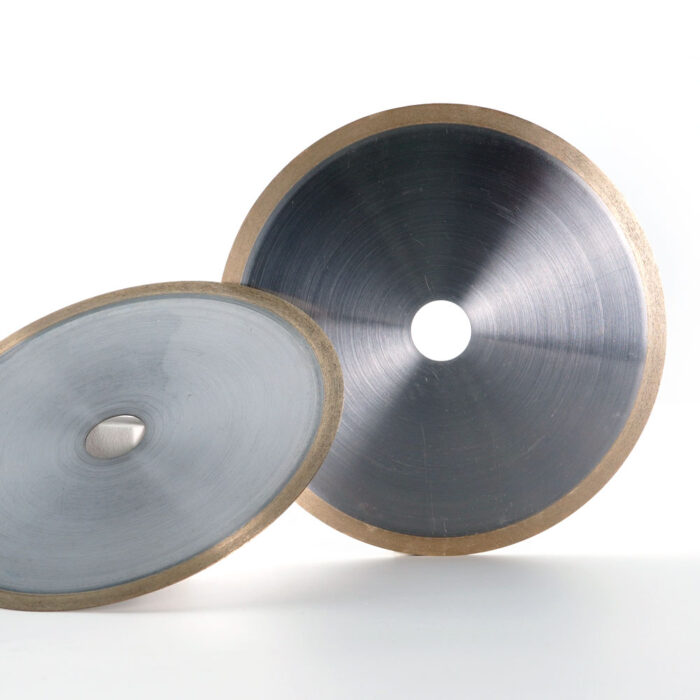

- 1a1 type: This is a type of metal bond cutting wheel characterized by the thickness of the work layer, which is very similar to steel plate. It’s a type designed specifically for precise cutting and grooving.

- 1a1r type: This is a type of metal bond cutting wheel characterized by a higher thickness of the work layer than the steel plate. It’s a type that helps with removing chips and cooling. They effectively work for grooving and cutting of components.

Features of Metal Bond Cutting Wheels

A metal bond cutting wheel comes with numerous benefits, which makes several industries prefer it to other tools:

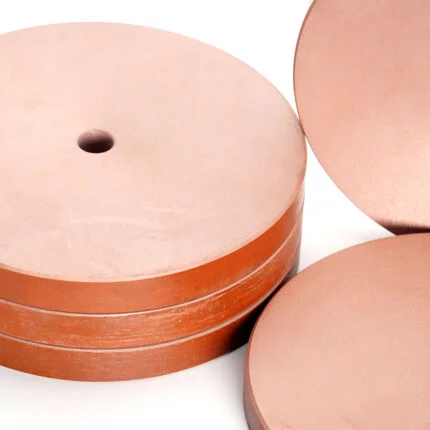

- Excellent performance and high-quality service: They are wheels sintered with sternum powder, silver, mill, copper, or cobalt, which helps enhance their performance on several surfaces such as semiconductors, ceramics, glass, silicon, refractories, and quartz.

The wheels are characterized by the longest and highest quality of service when used for tool cutting, even before any maintenance is required.

In addition, metal bond cutting wheels can make predetermined alterations to workpieces effectively. While this is being done, the wheels ensure that quality control issues are reduced, which may be inevitable with lesser quality wheels.

- Retention of the original dimensions: The tool’s original dimensions don’t change even with the most energetic cut-off applications.

- Better wheel retention properties or hardness: Resin bonds are used more than electroplated and vitrified bonds; however, metal bond cutting wheels provide better retention properties or hardness than resin bonds.

- Compatibility: Metal bond cutting wheels are compatible with numerous materials. They are sintered with a mill, copper, cobalt, sternum powder, or silver, making them ideal for refractories, glass, silicon, ceramics, quartz, semi-conductors, and other surfaces.

- Heat dissipation: Heat dissipates fast via the metalcore. The property of the wheels makes them appropriate for great material removal rate operation.

- Long life: Metal bond cutting wheels are known for a longer work life than those designed by other methods.

Applications of Metal Bond Cutting Wheels

Based on the durable and hard-wearing qualities of metal bond cutting wheels, they are in several industries, especially glass, fine ceramics, semi-conductors packaging, hard metal, grinding materials, magnetic materials, electronic components, and other industries that know the importance of ultra-thin cutting disc.

The applications of metal bond cutting wheels can be streamlined to the two specific materials. These include metal bond diamond cutting wheels and metal bond CBN cutting wheels. Both cutting wheels are used in many cutting applications. These include (but are not limited to) deep cutting, glass cutting, wet or dry cutting, cut-off, and lots more.

Note: The cutting wheels that come in diamond and CBN materials can be seen in several outer diameters, including 3″, 4″, 5″, 6”, 7″, 8″, 10″, and 12″. Their thickness can vary, and the substrate core is made of steel.

Metal Bond Diamond Cutting Wheels

Metal bond diamond cutting wheels are cut off tools that are used effectively for various metalloid materials (wear-resistant and hard, short-chipping materials), such as oxide ceramic materials, semi-conductor materials, crystal, magnetic materials, gem, quartz, glass, printing circuit board, carbide, and so on.

Features of Metal Bond Diamond Cutting Wheels

Below are some of the features of metal bond diamond cutting wheels:

- Longer product life cycle: The wheels can be characterized by a long time of use, which enhances their productivity minimizing wheel changes and dressing frequency.

Moreover, they feature extreme wear resistance, which makes them last longer than other types.

- Work well on different workpieces: Metal bond diamond cutting wheels can work faster and excellently on ceramics, glass, quartz, semi-conductors, and other surfaces.

- Better heat transfers from the workpiece: There is a fast dissipation of heat via the metal core, which makes the wheels ideal for high material removal rate operations.

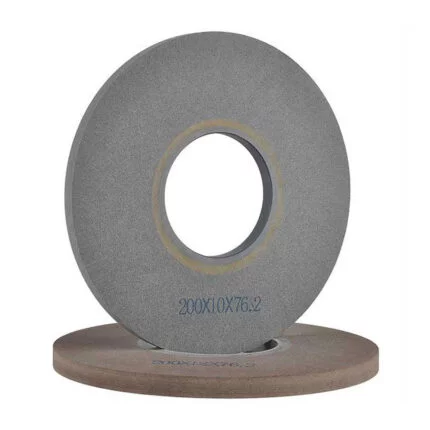

Metal Bond CBN Cutting Wheels

Metal bond CBN cutting wheels are cut-off tools used effectively for cutting materials characterized by an affinity for carbon, including iron-based alloys. In other words, these wheels are used for cutting different metal materials with high hardness, such as mold steel, cast iron, bearing steel, tool steel, and other ferrous metal materials.

Features of Metal Bond CBN Cutting wheels

Below are some of the features of metal bond CBN cutting wheels:

- The long service life of cutting pieces: Industries that prefer the use of metal bond CBN cutting wheels enjoy the cutting sharpness of the tool, which can be maintained for a long time.

- Strong ability to control abrasive materials: Unlike resin bond and vitrified bond cutting wheels, metal bond CBN is capable of bearing higher cutting pressure. The explanation provided by experts is that the overall abrasive pressure of the CBN cutting wheel on any workpiece makes the abrasive maintain close contact with the workpiece and ensure a strong relationship between the abrasive and its bond.

- Great impact resistance: Unlike a vitrified bond cutting wheel, a metal bond CBN cutting wheel is characterized by excellent impact resistance, which ensures that the structure of the bond stands up properly in interrupted cut applications.

- Good shape retention: The original shape of the tools doesn’t change even with the most energetic cut-off applications.

Summary

Based on the rapid development of ultra-precision cutting and high-speed cutting technology, there happens to be an emergence of more important requirements for cutting wheels. Metal bond cutting wheels are great for wet or drying cutting applications. With the metal bond diamond cutting wheels or metal bond CBN cutting wheels, users can have a faster and easy cutting process provided that they are properly applied.

Obviously, metal bond cutting wheels have become widely-used tools in numerous production environments due to their incredible features. Some of these remarkable features include outstanding performance, high-quality service, retention of original shapes, better wheel retention properties or hardness, impressive compatibility, the long service life of cutting pieces, and lots more.

We hope the details in this guide immensely help you make your purchase of the high-quality tools designed to meet your professional needs as far as the cutting process is concerned.

There are many other cutting wheels that can be customized, feel free to contact us.

Contact Us

For More Grinding Solution or Customized Abrasive Tools