Electroplated Mounted Points Brief Introduction

Electroplated Mounted Points are the best abrasive mounted points and grinding tools for various materials. It comes in various point shapes and specifications which are expansively used for sculpturing, dressing, precision grinding, and internal grinding. Ceramics, carbide, sapphire, and glass materials are often used for Electroplated Diamond Mounted Points while for tough hard material like high carbon, high chrome hardens steels, Electroplated CBN Mounted Points are the best-recommended tools to use. Electroplated Mounted Points are specialized selected grades of blocky natural or synthetic materials like diamond and CBN, that are used as grinding pins.

Features of Electroplated Mounted Points

- High-grinding Efficiency and Precision. Hole processing, grinding, and polishing are easily done with their high-grinding efficiency in various materials.

- Wear resistance. Guarantees long service life and is wear-resistant with its optimum performance. Also, it offers low heat generation which is vital in its service life. You won’t worry about its strength and durability since it provides exceptionally high bond strength which reduces chances or risks of premature pull-out of the abrasive grains.

- Non-corrosive, no dust pollution. Very safe and reliable to use. Non-toxic material that can last for a longer period of time.

- Easy to use. Very easy to manipulate with its excellent manual labor and production cost.

- Applicable for metal or non-metal parts and various artwork. You can choose various shapes according to the machined part.

Detailed Description of Electroplated Mounted Points

There are two bond types of Electroplated Mounted Points, and both types have different application/usage, specification, and features. 1

Diamond Electroplated Mounted Points

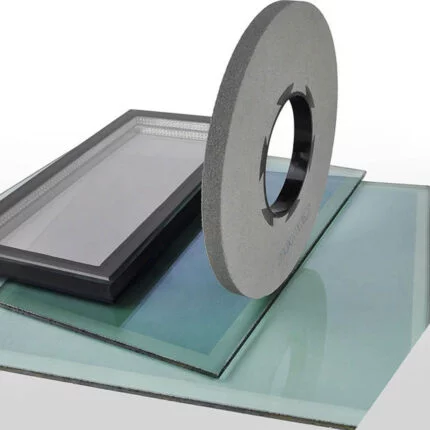

The Electroplated Diamond Mounted Points is a bond type that is composed of high-quality abrasive and synthetic material which is the diamond alloy. It is used in internal grinding, and precision grinding of various materials creating small holes in carbide, ceramic, sapphire, glass, superalloys, and other different hard nonmetal materials. The head of an Electroplated Diamond Mounted Points is a grinding tool that is used to bind abrasive materials together with a specific binding agent. Electroplated Diamond Mounted Points are usually installed in various machines for grinding, polishing, or for special installation tools.

-

Application of Diamond Electroplated Mounted Points

Most metal workers and those who work in industrial fields, use Diamond Electroplated Mounted Points as grinding pins externally or internally for a wide variety of materials. Dressing, internal grinding, precision grinding, are also common applications of Electroplated Diamond Mounted Points. Here are some applications of Electroplated Diamond Mounted Points in our industry.

- Precision Grinding. This ensures solidity and uniformity in the shape of the electroplated wheel. Precision grinding or rimming of aluminum oxide wheel electroplating process’ can produce different shapes of the wheel without deforming it.

- Cutting Tools Grinding. You may use a normal end-mill grinder and drill grinder with the electroplated wheel. Usually, carbides can be ground by Electroplated Diamond Mounted Points.

- Jig Grinding. Commonly used for ceramics grinding, precision grinding for quartz.

- Cutting and Machining Cement. Used for machining cement asbestos coating clutches.

- Optical Processing Industry: Use for high precision grinding for glasses frame

- Artwork Industry: wood carving: stone carving, jade carving, ceramic artwork

- Gemstone Processing Industry: Producing super finished dental equipment, and precious metal parts

-

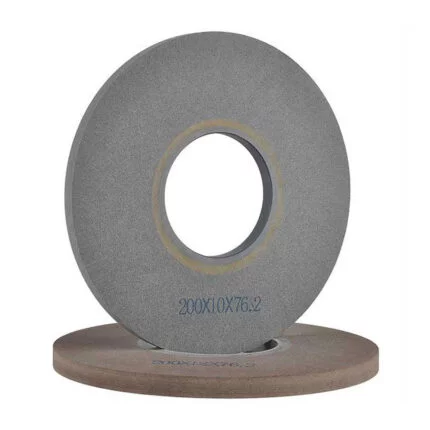

Diamond Electroplated Mounted Points Specifications:

There are various specifications available in the market regarding Diamond Electroplated Mounted Points. Applying the diamond-mounted points will be the main factor in selecting its accurate specifications. There is a range of standard shapes for Electroplated Diamond Points that will vary on the customer’s requirement. Standard shapes like the “A Shapes Mounted Points”, “B Shapes Mounted Points”, and “W Shapes Mounted Points”. Most Electroplated Diamonds Mounted Points are applied or can be mounted on a 1/8” shank which is 3 mm or 1/4″ shank which is 6 mm.

Here is a popular specification of Diamond Electroplated Mounted Points.

| Dia. D (mm) |

T (mm) |

L2 (mm) |

Dia Y (mm) |

Length L (mm) |

Grit |

| 1 | 3 | 6 | 3 | 35 | D126 |

| 2 | 4 | 13 | 3 | 45 | D126 |

| 3 | 4 | 18 | 3 | 45 | D126 |

| 4 | 5 | – | 3 | 57 | D126 |

| 5 | 6 | – | 4 | 57 | D126 |

| 6 | 7 | – | 4 | 57 | D126 |

| 7 | 7 | – | 4 | 57 | D126 |

| 8 | 8 | – | 6 | 57 | D126 |

| 9 | 8 | – | 6 | 57 | D126 |

| 10 | 10 | – | 8 | 70 | D126 |

| 12 | 10 | – | 8 | 70 | D126 |

| 14 | 12 | – | 10 | 70 | D126 |

| 16 | 12 | – | 10 | 100 | D126 |

| 18 | 15 | – | 14 | 100 | D126 |

| 20 | 15 | – | 16 | 100 | D126 |

| 1 | 3 | 6 | 3 | 35 | D126 |

| 2 | 4 | 13 | 3 | 45 | D126 |

| 3 | 4 | 18 | 3 | 45 | D126 |

| 4 | 5 | – | 3 | 57 | D126 |

| 5 | 6 | – | 4 | 57 | D126 |

-

Features of Electroplated Diamond Mounted Points

Here are some features of Electroplated Diamond Mounted Points which show how necessary and helpful it is.

- Has relatively large grit protrusion and higher abrasive concentration. Due to this, Electroplated Diamond Mounted Points provide free cutting properties and high-performance removal capacity.

- It allows the production of specialized shapes and profile tools even at short notice.

- Very much suitable for precision grinding since it only makes little changes in the wheel.

- Optimum performance, wear-resistant, and long service life.

- Corrosion-resistant, fine finish, smooth surface grinding.

- It provides aggressive cutting action due to its single layer of exposed diamond particles.

- It has mandrels that are made up of high-speed steel to withstand operating pressure.

- It provides a tough and durable bond due to its nickel alloy matrix.

- Jig grinding or internal grinding can be done for creating small holes.

- Applicable for granite, ceramics, glass, sapphire, and carbides

Electroplated CBN Mounted Points

Electroplated CBN (Cubic Boron Nitride) Mounted Points are usually used to create small diameter hole machining, high-speed precision grinding, or internal grinding, and dressing of hard-tough materials like high-speed steels, high carbon, high chrome steels, tools and die steels. They are highly recommended and helpful in providing high material removal rate. Also, Electroplated CBN Mounted Points are known for their free cutting characteristics and low heat build-up which are very applicable and usable in various conditions.

-

Applications/Usage of Electroplated CBN Mounted Points

Electroplated CBN Mounted Points used for internal grinding of high-speed steels, tool & die steels, cast irons, and hardened steels. It can be used for steering pump, compressor, bearing races, and injection nozzles. Here are some industrial fields that apply Electroplated CBN Mounted Points in their work production.

- Automotive Industry: Cylinder processing, rounded corner of oil hole for crankshaft

- Mechanical Key Parts Industry: mold parts, mechanical parts, and many more

- Electrical Engineering Field: Use for superfinishing for burr of small parts

-

CBN Electroplated Mounted Points Specifications

Here’s a popular specification of CBN Electroplated Mounted Points.

| Order No. | Type | ØD | T | N | L | ØB | Grit Size |

| CBN | |||||||

| ICP-3003 | A | 0.3 | 2 | 4 | 35 | 3.0 | #600 |

| ICP-3004 | A | 0.4 | 2 | 5 | 35 | 3.0 | #400 |

| ICP-3005 | A | 0.5 | 2 | 5 | 35 | 3.0 | #400 |

| ICP-3006 | A | 0.6 | 3 | 5 | 40 | 3.0 | #200 |

| ICP-3007 | A | 0.7 | 3 | 8 | 40 | 3.0 | #200 |

| ICP-3008 | A | 0.8 | 3 | 8 | 40 | 3.0 | #200 |

| ICP-3009 | A | 0.9 | 4 | 8 | 40 | 3.0 | #200 |

| ICP-3010 | A | 1.0 | 5 | 8 | 40 | 3.0 | #200 |

| ICP-3015 | A | 1.5 | 5 | 8 | 45 | 3.0 | #150 |

| ICP-3020 | A | 2.0 | 5 | 12 | 45 | 3.0 | #150 |

| ICP-3025 | A | 2.5 | 5 | 15 | 45 | 3.0 | #150 |

| ICP-3030 | B | 3.0 | 5 | 15 | 45 | 3.0 | #150 |

| ICP-3040 | B | 4.0 | 5 | – | 50 | 3.0 | #150 |

| ICP-3050 | B | 5.0 | 8 | – | 50 | 3.0 | #150 |

| ICP-3060 | B | 6.0 | 8 | – | 50 | 3.0 | #150 |

| ICP-6040 | A | 4.0 | 10 | 22 | 80 | 6.0 | #100 |

| ICP-6050 | A | 5.0 | 10 | 22 | 80 | 6.0 | #100 |

| ICP-6060 | A | 6.0 | 10 | 22 | 80 | 6.0 | #100 |

| ICP-6070 | B | 7.0 | 10 | – | 80 | 6.0 | #100 |

| ICP-6080 | B | 8.0 | 10 | – | 80 | 6.0 | #100 |

| ICP-6090 | B | 9.0 | 10 | – | 80 | 6.0 | #100 |

| ICP-6100 | B | 10 | 10 | – | 80 | 6.0 | #100 |

| ICP-6120 | B | 12 | 10 | – | 80 | 6.0 | #100 |

| ICP-6140 | B | 14 | 10 | – | 80 | 6.0 | #100 |

| ICP-6160 | B | 16 | 10 | – | 80 | 6.0 | #100 |

| ICP-6180 | B | 18 | 10 | – | 80 | 6.0 | #100 |

The popular grain size and grit choice for Electroplated CBN Mounted Points is the 150# grit level. You can also choose various mounted point shapes. This can be applied to Electroplated Diamond and CBN Mounted Points.

-

Features of CBN Electroplated Mounted Points

Here are some features of Electroplated CBN Mounted Points which tell us how important and helpful it is in work production and industrial fields.

- Economically friendly

- Composed of a single layer of exposed CBN particles used for aggressive cutting action

- Can be applied for precision grinding, jig grinding, and internal grinding.

- Durable and high strength due to tough high carbon and high chrome steel applications.

- Composed of nickel alloy matrix to make it highly durable, and strong.

- Have superior cutting quality and fine finishing.

Contact Us

For More Grinding Solution or Customized Abrasive Tools