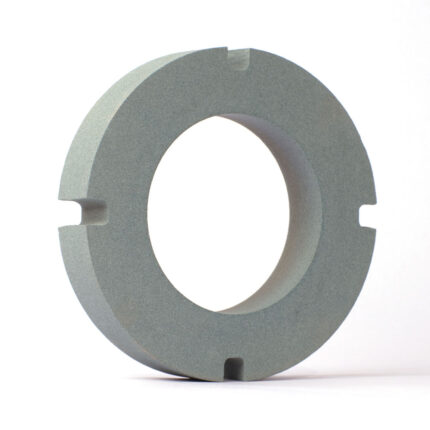

Silicon Carbide Grinding Wheel

![]()

The silicon carbide grinding wheel is a harder grinding wheel compared to its standard aluminum oxide counterpart. It features a highly sharp abrasive grain and is designed with a versatile material. This grinding wheel is typically used for grinding soft metals (such as cast iron and aluminum) and extremely hard materials (such as cemented carbide).

Detailed Description of Silicon Carbide Grinding Wheel

![]()

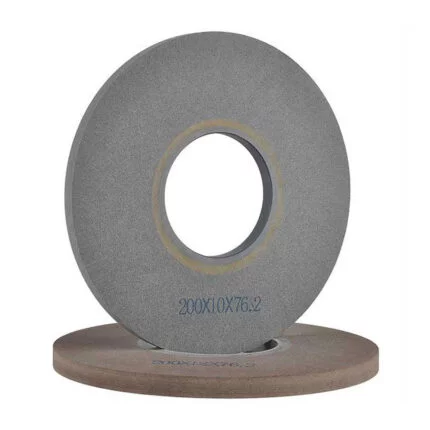

Generally, grinding wheels are designed with abrasive grit and made for grinding, cutting, and machining applications. They help remove material from glass, wood, concrete, metal, and brick.

Silicon carbide grinding wheels as one of the invaluable types of grinding wheels are produced by mixing petroleum coke, pure white quartz, and small amounts of salt and sawdust and by firing the combination in an electric furnace.

The production process of the grinding wheel is called synthesizing sand and coke. The resulting crystalline mass is graded and crushed by particle size, just as in the production of aluminum oxide abrasive.

Moreover, the grinding wheels are more brittle and harder than aluminum oxide wheels. These wheels are available in two main types, including black and green silicon carbide grinding wheels.

The black types are ideal for grinding non-ferrous metals (such as brass, copper, magnesium, and aluminum) and non-metallic (such as gemstones and ceramics). The green types are used for grinding cemented carbide. They are also more friable when compared with their black counterparts.

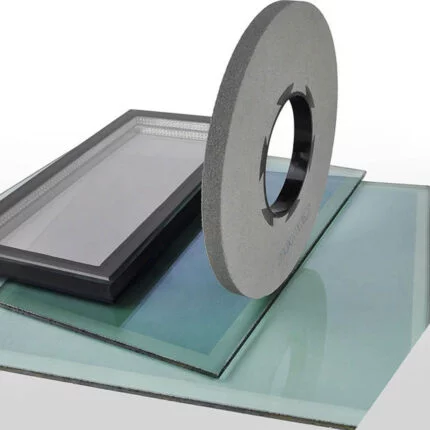

Application of Silicon Carbide Grinding Wheel

![]()

Silicon carbide grinding wheels are widely used in the metalworking and commercial construction industry. They are tools designed for grinding steel, carbide, cast iron, plastics & rubber, and aluminum & non-ferrous metals. Check below to see the application examples of silicon carbide grinding wheels:

· Grinding

Grinding needs fast removal of materials, and silicon carbide grinding wheels are a perfect option because of their abrasive properties when used on ferrous and non-ferrous metals, welding, construction, foundry, pipework, and metallurgy markets.

· Cutting

The grinding wheels are great for cutting work pieces due to their superior hardness and toughness (silicon carbide is often found in cut-off grinding wheels).

· Coated

The grinding wheels are used in the coated market for different applications, including (but not limited to) sanding of non-ferrous metals, glass, plastics, enamels, and fibrous woods.

· Polishing

The grinding wheels are usually used to smoothen and shine work pieces. They are also well suited for a wide variety of polishing applications.

· Lapping

The grinding wheels are used for various lapping applications, making them great for softer materials. They are designed to create flat, smooth, and unpolished surfaces.

Types of Silicon Carbide Grinding Wheel

![]()

Silicon carbide grinding wheels are of two types:

- Green Silicon Carbide Grinding Wheels: These are designed for grinding cemented carbide. They are more friable tools than black silicon carbide grinding wheels.

- Black Silicon Carbide Grinding Wheel: These are perfect for grinding non-metallic (such as gemstones and ceramics) and non-ferrous metals (such as brass, copper, magnesium, and aluminum).

| Silicon Carbide | |||

| Name | Coloration | SiC contents | Machined materials |

| Black silicon carbide 98C | black | 98,26% | non-ferrous materials, hardened and grey cast iron, cemented carbides, plastics, glass, leather, and rubber |

| Green silicon carbide 99C | dark green | 99,66% | HSS cutting tools, ceramics, cemented carbides, and for truing and dressing |

Note: The two varieties of silicon carbide are insignificantly different as chemical composition and physical properties go. Nonetheless, green type comprises a small number of admixtures, giving it higher abrasive features and making it more brittle than the black type.

Features of Silicon Carbide Grinding Wheels

![]()

- The wheels offer high productivity and excellent surface finish

- The wheels are designed with burn-free components.

- The wheels provide lower grinding cost and dressing frequency

- The wheels offer a shorter grinding time

- The wheels offer excellent heat conductivity

Summary

Silicon carbide grinding wheels are ideal for harder materials such as cemented carbide. But they can also be used on soft materials such as copper, cast iron, or fused alloy steels. The wheels come with very sharp abrasive grain and are made with a versatile material. Silicon carbide grinding wheels are available in two types: green and black, each with its peculiar features.

They are widely used in the metalworking and commercial construction industry for grinding, cutting, polishing, etc. Several operators prefer them because the wheels are capable of dressing themselves, depending on their desired finish, leaving a fantastic working surface, which may need no polishing. Besides, the cutting speed of the grinding wheels can vary based on the ground material.

Contact Us

For More Grinding Solution or Customized Abrasive Tools