Diamond Pellets Brief Introduction:

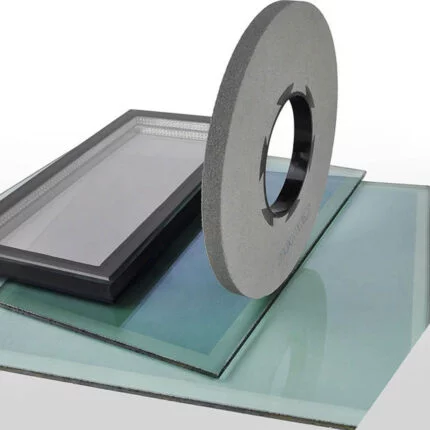

For the manufacturing of optical products like prism, lenses, and mirrors the use of diamond pellets is gaining importance in the glass industry. These pellets are preferred because of their cost-effectiveness, fast and reliable work. Their grinding action is very smooth. These pellets convert the rough surface into a smooth surface much faster and thus reduce the time required for polishing. These diamond pellets are also being used for making the components of imaging systems like objective lenses, microscope components, telescope mirrors, laser systems, and many other applications.

Features of Diamond Pellets:

- Consistency in performance

- Provide extra smooth and improve surface finishes.

- Increased lifespan with a strong bond and less damage

- Environmental friendly with less noise

- Cost-effective with high performance

- Future-oriented

- Optimal results with water-soluble cutting liquid

- Provide high excellent cutting with no scratch and abrasion resistance.

- High dimensional accuracy

- Very clean process

- High process repeatability

- Low subsurface damage

Detailed Description of Diamond Pellets:

-

Reason to use Diamond Pellets in the optical Industry:

Diamond pellets have now largely been used in the glass industry. When a new product is formed in the optical industry, this product has a damaged layer and rough surface due to the milling process. So to make this product eye-catching and durable surface grinding is done by using these pellets.

-

Types of Diamond Pellets:

There are two types of diamond pellets i.e. resin bond and metal bond. Each has specific usage and pros. You can choose the pellet type according to the nature of our work. A bond is a bonding material that holds the grain together with varying degrees of strength.

Metal Bond Diamond Pellets:

When the product comes from the milling process for the very first time it is treated with metal bond pellets. Metal bond has more strength than resin bond. So for initial finishing, it is preferred as we need to do much grinding. It removes the marks of roughness and layer damage left by the milling process. For making these pellet diamond powders, metal powder, and filler are mixed. Then cold pressing is performed, followed by sintering with hot pressing.

Features:

- Grinding action is smooth and controlled

- Optimal initial finishing

- Universal and multipurpose use

- Fast action with more strength and durability

Resin Bond Diamond Pellets:

Superfinishing is performed after 1st round of finishing by using resin bond diamond pellets. They remove the leftover damaged layer, improve the shape, size and give a shiny look to optical elements. For making these pellet resin powder, diamond powder, and filler are mixed. Then this mixed product undergoes cold pressing followed by sintering with hot pressing.

Features:

- Less strength than metal bond and provides extra smoothness

- Provides the shiny look to your optical elements

- High performance and time saving

- Cost-effective

-

Shapes of Diamond Pellets:

Depending on the type of use diamond grinding pellets are made in different shapes. These pellets are available in round, triangle, square and hexagonal shapes. Flat, flat-concave, flat-convex, double concave, double convex, and so on are the many types of diamond finish / super finish columns. The end face processing has two slots, four slots, six slots, and eight slots for chip removal.

-

Applications of Diamond Pellets:

Diamond pellets are widely utilized in the military, aerospace, transportation, and civil sectors, and are primarily used in the spherical and sphere grinding of optical glass, lenses, glassware, ceramics, gemstones, and other non-metallic hard brittle materials. Strong abrasive holding force, high wear resistance, good shape retention, high machining precision, high efficiency, good surface quality, and extended service life are all benefits of a diamond pellet.

-

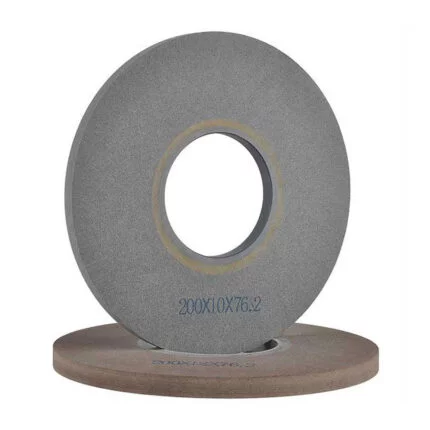

Specifications of Diamond Pellets:

| Product Name | Diameter | Thickness | Grit | Concentration |

| Metal bond Finishing, Grinding pellets | 3-20mm | 2.5-10 | 180-2000 | 75%-150% |

| Exceed Finish Grinding Pellets, Resin Bond | 3-20mm | 2.5-10 | 800-3000 | 75%-150% |

| Polishing Pellets (Resin) | 3-20mm | 2.5-10 | 75%-150% |

-

Benefits of Diamond Abrasive for Making Grinding Pellets:

The hardness of Diamond Abrasive:

Diamonds, coal, and graphite are all made up of the same chemical elements. The carbon atoms in coal and graphite are organized in sheets. Coal and graphite have a velvety feel because of this. Diamonds, on the other hand, are crystalline carbon. The carbon atoms in diamonds are organized in a tetrahedron. In three-dimensional space, this configuration indicates that each carbon atom is connected to five other carbon atoms. Carbon sheets in graphite and coal are substantially weaker than this. Diamond pellets are so hard because of the chemical structure that they can cut through any substance, including other diamonds.

Durability:

Resin diamond abrasives and metal bond diamond abrasives both are used preferably because the bond (metal or resin) gradually wears away, exposing fresh layers of diamond to polish the concrete. The tool’s durability is determined by the bond, not the diamond. The diamonds eventually fall out of the tool. Some of these are even ground down by the tool’s other diamonds. Diamond tools, on the other hand, endure longer than other abrasives due to their hardness. So diamond pellets are preferred to other types of pellets.

Speed Cutting:

Diamond’s hardness also implies that diamond abrasives grind more quickly than other abrasives. Part of this is related to durability – grinding tasks take less time when there are fewer tool replacements. Diamond tools’ quickness, on the other hand, is because they cut through any other substance. Diamond pellet tools will grind directly through a particularly tough stone, rather than grinding it repeatedly.

Cost-effective:

Industrial diamonds are a cost-effective tool material, despite their appearance. Other abrasives are more expensive than diamonds. They do not, however, cost so much more than they are prohibitively expensive. Diamond abrasives also allow for more work to be done with fewer tool changes because of their endurance. This implies that diamond tools are equivalent to other abrasives in terms of cost while having more grinding power. Diamond tools like diamond pellets are cost-effective tools for polishing and grinding because of their hardness, durability, and speed.

Summary:

Diamond pellets are one type of diamond tools which are widely used for grinding, finishing, and polishing in the optical industry. Diamond is used as an abrasive material that makes them more demanding in glass, ceramic, and many other industries. It is available in two types of bonds i.e. resin and metal bond pellets. They are available in different shapes; you can choose a suitable one according to the nature of your work. Metal bond pellets are used for initial finishing and resin bonded are used preferably for superfinishing. Specification of all types of diamond pellets has been provided in the table. You can order us product of the desired radian.

Contact Us

For More Grinding Solution or Customized Abrasive Tools