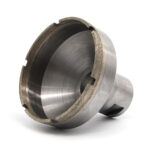

Diamond Drill Bits are commonly used tools for glass hole drilling and countering. Diamond Drill Bit hole processing can be applied on numerous materials like ceramics, porcelain, stones, limestone, gemstone, marble, granite, slate, shell, and bone.

Diamond Drill Bits Types:

As you will notice, Diamond Drill Bit also has the same feature as agate drilling or commonly known as core extraction. Diamond Drill Bit is consist of various type of shank like the straight shank, taper shank, internal and external threaded shank.

Diamond Section default size:

There are various specifications in the market that you can check for thin wall diamond drill bits or glass drill bits. The usual diamond-section wall thickness is 1 mm and has a height of 10 mm around it.

Dos and Don’t

Sintered Thin Wall Diamond drill bits are perfect for drilling holes on various materials like glass, stones, ceramic, porcelain, tiles, pottery, plates, shell, antler, bones, fossils, and hardwoods. A diamond drill bit is not recommended on metal, softwood, plaster, or soft plastics. These materials might clog the drill since they are too soft for the diamond drill bits. Materials like diamond and sapphire require patience in the drilling process since they are very hard materials. You might need a lot of drill bits when drilling a hole in it.

Features of Diamond Drill Bits:

- Works in Cool Water. Low heat generation makes the glass holes avoid breaking.

- High precision mechanism. This makes the drilling process much more efficient and effective.

- Good Sharpness. Drilling on the hardest materials like diamond, sapphire, etc. will not be a problem.

- Less Feature sensitivity. These glass drill bits have adapted less feature sensitivity like low noise, no tremors, and no broken edge

- High-wear resistance

- High-efficiency and long service life

Diamond Drill Bits Specifications:

| Item | Shank Type | Head Diameter | Wall Thickness | Diamond Height | Total Length |

| Diamond Drill Bits | Straight Shank | 5 mm – 100mm inner | 1 mm | 10 mm | 55 mm/65 mm/75 mm/95 mm |

| Tape Shank | |||||

| Threaded Shank | |||||

| Countersink | – – | – – | – – |

Things to Know about Sintered Thin Wall Diamond Core Drill Bit

1. Diamond Drill Bits Operation Tips and Installations Process

Before you can do any glass hole processing using sintered thin wall diamond drill bit, here are some tips you should remember during the installation process.

- First, tilt the device 45 degrees angle, then drill a crescent shape.

- Second, drill it for 90 degrees in the water

- Lastly, finish the process by drilling a smooth and perfect hole

After the installation of the diamond drill bit, thoroughly check it and observe if there are beating signs. Then, you proceed to normal operation. Keep in mind to do smooth drilling at all times. Avoid applying lateral pressure and curve spud. To reduce wear and coating products, you must add enough water specialized for lubrication and cooling. The process of dry drilling can create a big impact on its life span. And, to ensure safe operation throughout the whole work process, the operator must wear safety protective equipment.

2. Diamond Drill Bits Application:

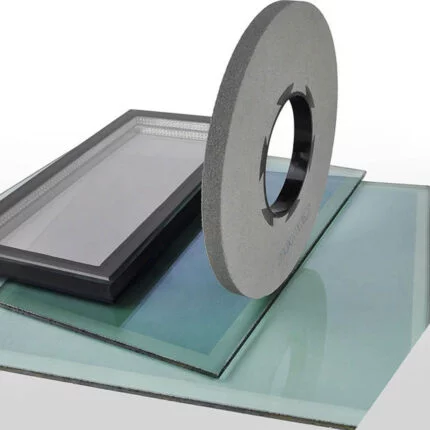

A diamond drill bit is commonly used for drilling holes through various hard materials such as glass materials (sea glass, beach glass, fused glass, sheet glass), stones (gemstones, rock, pebbles, minerals), ceramic, porcelain, tiles, glazed pottery, plates, shell antler, bone, fossil, and hardwoods.

Sintered thin wall diamond drill bits are a type of diamond drill bit that is bonded to the matrix at very high temperatures. It has several layers of diamond, so when you dress or clean it with aluminum oxide, the life of your drill bit or burr will not be extracted easily since it will reveal layers of diamonds around it. This is why the sintered diamond drill bits are known for their durability and extended life service. This feature also makes it more expensive than coated diamond drill bits or electroplated diamond drill bits, since it has several layers of diamonds that can last for a very long time.

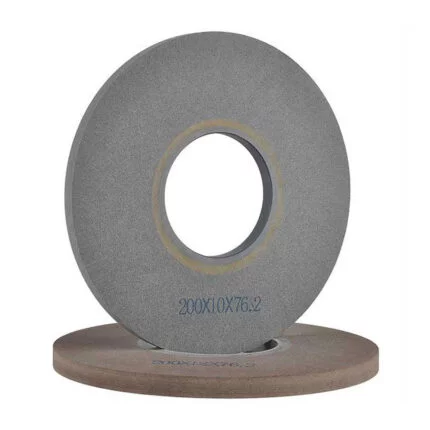

3. How do you sharpen Diamond Drill Bits?

Using aluminum oxide stone, dress and sharpen your diamond drill bit after each use. This is where a new and fresh layer of diamonds is revealed for the next work processing.

3. Life Span of Diamond Drill Bits and Required Number of Bits per Material

When it comes to Diamond Drill Bit, you have to consider so many factors like a lubricant, pressure, speed, and density of the material being used. It will be a good thing if you know the component of your materials first. Like when you are drilling a sea glass that is considered to be a thousand years older. It is important to know where it came from and its component particles.

Through glass drill bits processing, an average of 250 holes can be made in exactly one bit. Some materials like the China plates also apply the same procedure. An estimation of 15 holes or more can be done in one bit of processing. What about pebbles? Or gemstones? Gemstones take longer to drill, so you have to be very patient with them. While pebble drilling can be quite tricky. Pebbles have flint or quartz flecks in them. For an easy drilling process, pick pebbles that have no white or speckled bits around them.

The Mohs Mineral Scale of Hardness can be used for comparing various materials for the drilling process. This will serve as your reference in using your sintered thin wall diamond drill bits. Maintaining the resistance and efficiency of your tool plays a big role in its life. Make sure to gain the maximum life from your drill bit. Use little-to-no pressure to avoid getting your material cracked. Try to use the slowest level of speed on your diamond drill bits. Lastly, keep your thin wall diamond drill bits and materials at high temperatures using plenty of water.

4. Diamond Drill Bits on Glass, Stone, and Ceramic

Tools with diamond glass drill bits are also important in the drilling process. First, you have to know what kind of tool will be best for your diamond drill bit. Control, angle, and sensitivity will be affected by the chosen tool during the drilling process. Drill press and bench press do not offer angle drilling mechanisms but they can hold your material in place with a vice. You may use a handheld Dremel type of drill, flex shaft, pendant drill, or hand-held tool.

If you’re experiencing problems with your drill bits which are skittering across the surface of your material, try to angle your drill and start the drilling. Drill from a vertical position when the initial hole is made. This drilling process can be done through glass, smooth stone, and pebbles. If you are experiencing problems with sliding surfaces like tiles or glass bottles, then try to put a small piece of masking tape on the drilling area. This will be very helpful in keeping the diamond drill bit from sliding around, but you have to make use of the larger drill for about 6 mm upwards and not on drill bits as small as 0.75 mm to 3 mm for example.

5. Standard Speed for Diamond Drill Bits

It is important to know the standard speed of your diamond drill bit that you should be doing during the drilling process. In standard, using a low-speed setting, especially when starting to make holes, will prevent any cracks or breakages that will keep your diamond drill bits in their utmost performance.

Do you need to speed up at some point in the drilling process? Keeping your drilling speed at its lowest speed setting is very advisable. But if you are drilling a hole throughout the material, you may speed up. Just keep in mind that you have to slow it down when you are finally approaching the exit hole of the material. This will prevent damage like cracks and will make your drill last longer.

6. Safety Measures in using Diamond Drill Bits

There are things you have to know when you are using the diamond drill bits. To secure the safety of everyone who is dealing with the drilling process, remember some of these points.

High speed and high pressure can create a burning smell on your material. High speed can overheat the material and can damage it through visible cracks. This can also make the diamond drill bit to be quickly dull, which will shorten the life of your diamond drill bits.

Regularly check your drill bit’s temperature. Make sure it’s not hot to touch or not even warm. Starting your speed off on the lowest speed setting is the ideal phase. You may start slowly, then eventually increase the speed as you go through inside the material. Too much pressure can make the diamonds fall away. That is probably due to the shank on your diamond drill bits since it is made up of hardened steel and has breaking potential when under too much pressure.

Try to feel your material throughout its surface. If you are still unsure of the process, you can practice on a scrap piece of glass or on a pebble so you can get used to various techniques. Always remember these key points, when you have a smaller diameter, use a faster drill speed like 5,000 to 7,000 RPM. But if you have harder material, set your drill to its lowest speed setting. Slowest speed, minimum pressure, and coolant are vital factors in keeping your drill to its maximum potential and will prevent any damage to your material.

Contact Us

For More Grinding Solution or Customized Abrasive Tools