Flawless HSS grinding demands a system of correct tools and techniques. The goal is to prevent wheel loading and achieve a perfect finish. Your cutting edge preparation determines the final quality. This preparation ensures a superior result from every grinding operation. This guide provides clear, actionable steps to master the process with the right grinding wheel. We will show you how to solve these common frustrations.

Key Takeaways

- Choose the right grinding wheel. CBN wheels are best for HSS. They cut cooler and last longer.

- Dress and true your grinding wheel often. Dressing cleans the wheel. Truing makes it perfectly round. This keeps the wheel working well.

- Use the right grinding technique. Apply light pressure. Keep the tool moving. This prevents overheating and protects the HSS.

- Always use coolant. Coolant removes heat. It also washes away metal chips. This stops the wheel from clogging and keeps the HSS strong.

Wheel Selection to Prevent Wheel Loading

Choosing the right grinding wheel is the first and most critical step to prevent wheel loading. The wheel’s composition directly impacts cut quality, heat generation, and tool life. Your selection sets the foundation for every subsequent grinding operation.

Abrasive Choice: Aluminum Oxide vs. CBN

Conventional grinding wheels for HSS often use aluminum oxide. This abrasive is effective for low-volume tasks and general-purpose grinding on softer metals. However, it is not ideal for high-speed grinding or achieving rapid material removal rates on hardened steels.

For professional results, Cubic Boron Nitride (CBN) is the superior abrasive. CBN is chemically stable and will not react with the carbon in steel. This makes it perfect for grinding ferrous metals like HSS.

Pro Tip: Aimgrind‘s CBN grinding wheels are the professional solution for high-performance HSS grinding. They cut cooler and last significantly longer, virtually eliminating wheel loading and the risk of burning the HSS temper.

The Role of Grit Size and Hardness

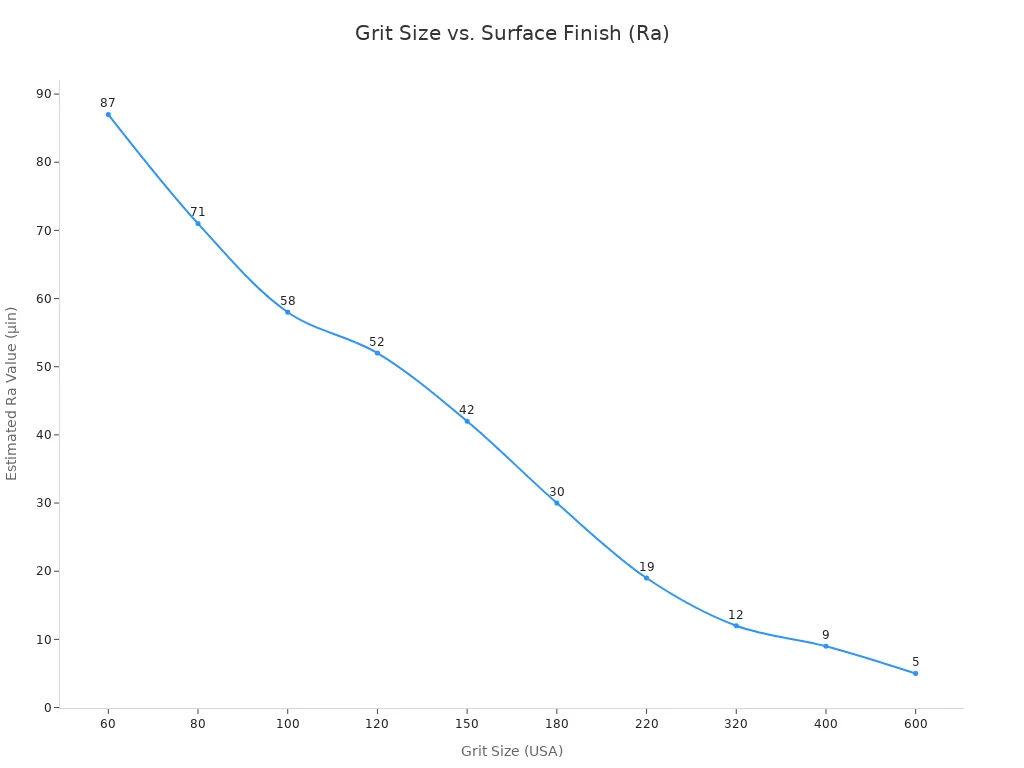

Grit size determines the surface finish of your tool. A lower number indicates a coarser grit for faster material removal, while a higher number means a finer grit for a smoother finish. For HSS, a 46-60 grit is a common starting point.

A 46 grain is about 1/64inch so might make about a 1/64 corner with a fresh dress and perhaps a 1.0 Ra surface.

The chart below shows how a finer grit (higher number) produces a lower Ra value, resulting in a smoother surface.

A soft grade (G-I) grinding wheel is also recommended. The wheel’s friability allows dull abrasive grains to break away, exposing fresh, sharp cutting points. This self-sharpening action reduces loading.

Why a Porous Wheel Structure is Crucial

Porosity refers to the small, connected voids within a grinding wheel. These pores are essential for two reasons:

- Coolant Delivery: They act as channels, allowing coolant to reach the cutting zone. Better cooling prevents thermal damage to the workpiece.

- Swarf Clearance: They provide space for metal chips (swarf) to collect. This clearance is vital to prevent the wheel surface from clogging.

An open, porous structure is a key defense against wheel loading, especially when grinding tough materials. It ensures a stable and efficient grinding process.

Mastering Wheel Dressing and Truing

A new grinding wheel does not stay perfect forever. Over time, its surface becomes loaded with metal particles or glazed with dulled abrasives. Dressing and truing are two essential maintenance procedures that restore your wheel’s performance, ensuring a precise and safe grinding process.

Dressing to Restore a Sharp Cutting Surface

Dressing is the process of cleaning the grinding wheel’s surface. It removes loaded material and breaks away dull abrasive grains to expose a fresh, sharp cutting layer. For HSS grinding with conventional wheels, frequent dressing is non-negotiable.

Here is a simple guide to dressing your wheel:

- Select the Right Tool: Diamond dressers are the most efficient tools for aluminum oxide wheels. They use an industrial diamond to precisely remove material and sharpen the abrasive grains. Other options include star dressers and abrasive sticks.

- Secure the Dresser: Mount the dressing tool securely on a magnetic chuck or in a fixture. Ensure it is rigid to prevent chatter.

- Approach the Wheel: With the grinding wheel running at its operating speed, slowly bring the dresser into contact.

- Make Light Passes: Move the dresser across the wheel’s face in smooth, consistent passes. Remove only enough material to expose a clean surface.

Truing the Wheel for Geometric Accuracy

While dressing cleans the surface, truing corrects the wheel’s geometry. It ensures the grinding wheel is perfectly concentric with the spindle and its face is flat and true. An out-of-true wheel can cause measurable problems like chatter marks, poor surface finish, and even thermal damage from uneven pressure. Truing is critical for any precision grinding operation where dimensional accuracy is paramount.

When and How Often to Dress Your Wheel

You should dress your grinding wheel whenever you notice a decline in performance. Regular dressing not only improves results but can also extend wheel life by over 30%.

Look for Visual Cues: It’s time to dress your wheel if you see shiny spots or metallic streaks on its surface. This indicates loading or glazing, which means the wheel is rubbing instead of cutting.

Untimely dressing leads to increased grinding forces and higher temperatures, which accelerates wear. For optimal performance, many professionals recommend dressing the wheel lightly before each critical use.

Technique for Flawless Cutting Edge Preparation

Your technique is just as important as your tools. The right approach ensures a sharp, durable edge and a successful result. This cutting edge preparation involves controlling pressure, tool movement, and heat. Mastering this process is essential for professional outcomes.

Controlling Grinding Pressure and Speed

Apply light, consistent pressure during grinding. Forcing the tool against the grinding wheel creates excessive heat. This heat can ruin the HSS temper and accelerate wheel loading. Let the abrasive do the work.

The wheel’s surface speed also plays a major role. Adjusting the speed can make the wheel act harder or softer.

- Slower Speeds: The wheel acts softer. Abrasive grains break down faster, exposing a sharper surface. This creates a cooler cut and helps prevent wheel loading.

- Faster Speeds: The wheel acts harder. Grains are more durable, which is good for holding form but can increase heat if the wheel becomes dull.

Finding the right balance is key for effective cutting edge preparation.

Proper Tool Presentation and Movement

Proper tool presentation is a critical part of the preparation. Always present the tool to the wheel at the correct angle. This ensures the creation of effective clearance and rake angles for clean cutting.

Tool Angle Guide The correct angles depend on the material you plan to cut. Below are common starting points for lathe tools.

Material Clearance Angle (degrees) Rake Angle (degrees) Machine Steel 10–12 12–18 Tool Steel 10 12 Stainless Steel 10 15–20

Keep the tool moving smoothly and constantly across the wheel’s face. This movement distributes heat evenly and prevents localized overheating. It also ensures even wear on the wheel surface.

Avoiding Overheating to Protect HSS Temper

Heat is the enemy of HSS. The final result of cutting edge preparation should be a sharp edge free from micro-cracks and heat damage. Overheating during grinding will soften (anneal) the steel, destroying its temper and ability to hold an edge.

M2 and M42 HSS begin to lose their hardness at temperatures above 540°C (1004°F). A visual sign of excessive heat is the color of the metal chips produced during grinding.

| Chip Color | Implication for HSS Edge |

|---|---|

| Blue | 🔵 Indicates excessive heat, burning the cutter. |

| Yellow | 🟡 Suggests too much heat is still present. |

| Silver | ⚪️ Ideal color, indicating proper heat management. |

A cool grinding preparation produces a stronger, longer-lasting cutting edge.

Using Coolant to Manage Heat and Swarf

Effective heat and swarf management is non-negotiable in precision grinding. A constant flow of metalworking fluid, or coolant, is the key to controlling the intense heat generated at the point of contact. It also plays a vital role in maintaining the efficiency of your grinding wheel.

Why Coolant is Critical for HSS Grinding

Coolant serves two primary functions in HSS grinding: heat reduction and swarf removal. It absorbs heat from the workpiece and the wheel, preventing the HSS from overheating and losing its temper. This ensures the tool’s cutting edge remains hard and durable.

Equally important, the metalworking fluid flushes away metal chips (swarf). High-pressure coolant acts like a power washer. It blasts chips out of the porous structure of the grinding wheel before they can clog it. This action keeps the wheel surface open and aggressive, preventing wheel loading and ensuring a clean, efficient cut.

Choosing the Right Coolant Type

Selecting the correct metalworking fluid is essential for optimal performance. The ideal choice depends on your specific grinding application. The three main types are:

- Synthetic Fluids: These water-based solutions offer the best cooling properties. They are transparent, which allows for good visibility of the workpiece.

- Semi-Synthetic Fluids: This type of metalworking fluid offers a balance of cooling and lubrication. It contains a small amount of oil mixed with synthetics.

- Soluble Oils: These fluids provide excellent lubrication and rust prevention. They are a good general-purpose choice for many grinding operations.

The proper interaction of metalworking fluid and grinding wheel is crucial for achieving a superior finish.

Effective Coolant Application Methods

How you apply coolant is just as important as which type you use. An inadequate flow will not manage heat or clear swarf effectively.

Pro Tip: Use a nozzle that delivers a high-volume, low-pressure flood of coolant directly into the grinding zone. The goal is to completely submerge the point of contact between the tool and the wheel.

Ensure the coolant stream is wide enough to cover the entire grinding area. Position the nozzle as close as possible to the wheel to prevent the fluid from being deflected by the air barrier created by the spinning wheel. Proper application ensures consistent cooling and a cleaner process.

Your HSS grinding success hinges on a complete system. Start with a superior wheel, like an Aimgrind CBN, to prevent wheel loading. Combine this with proper dressing, a light technique, and effective coolant. This cutting edge preparation is the key to a professional result. This dedicated preparation allows you to Grind with Passion, Achieve with Aim. Adopting these methods produces sharper, longer-lasting tools.

FAQ

Why are CBN wheels better for HSS grinding?

CBN wheels offer superior performance for HSS. They cut cooler and last much longer than conventional wheels. This prevents wheel loading and protects the steel’s temper. The result is a sharp, durable edge with every grind.

What is the main difference between dressing and truing?

Dressing cleans a wheel’s surface. It removes loaded metal and exposes fresh abrasive. Truing corrects the wheel’s geometric shape. It ensures the wheel is perfectly concentric and flat for any precision work.

How do I know if my grinding wheel is loaded?

Look for visual cues! Shiny spots or metallic streaks on the wheel’s surface indicate loading. A loaded wheel rubs instead of cuts. This generates excess heat and produces a poor finish, signaling it is time to dress the wheel.

Can I grind HSS without using coolant?

Grinding HSS without coolant is not recommended. The intense heat will quickly overheat the tool. This destroys the steel’s temper, softening the cutting edge and making it unable to hold its sharpness. Always use a proper coolant.