You often see aluminum in many projects because it is lightweight and strong. When you need to shape or smooth aluminum, choosing the right abrasive wheels makes a big difference. Flap discs work well since they keep temperatures low and help prevent melting. Silicon carbide wheels also help you get a clean finish, especially when you use a lubricant. Diamond grinding wheels from Aimgrind give you precise results for tough jobs. These tools help you handle the challenges of aluminum grinding with ease.

Key Takeaways

- Flap discs are the top choice for aluminum grinding. They keep the metal cool, prevent warping, and provide a smooth finish.

- Silicon carbide wheels minimize heat and are ideal for achieving a fine finish on aluminum. Always use a lubricant to enhance performance.

- Diamond grinding wheels from Aimgrind offer precision and durability for tough jobs. They maintain their shape and work well for both wet and dry grinding.

- Choosing the right grit and hardness is crucial. Use coarser grit and softer grades to avoid clogging and ensure efficient grinding.

- Regular maintenance of grinding wheels extends their lifespan. Inspect for damage and clean them often to achieve the best results.

Types of Abrasive Wheels for Aluminum Grinding

When you work with aluminum, you need to choose the right abrasive wheels. Each type offers unique benefits for aluminum grinding. Let’s look at the main options and see how they help you get the best results.

Flap Discs for Aluminum

Flap discs stand out as the best abrasive for aluminum. You use flap discs when you want to keep your workpiece cool. These discs generate less heat than other grinding wheels for aluminum. This cooler cutting helps you avoid warping or discoloring the metal. Flap discs also last longer and give you a smoother finish. You can use them for deburring, cleaning, and shaping aluminum. Their versatility makes them a top choice for many tasks.

Tip: Flap discs help you finish your aluminum projects faster because you do not need extra steps for smoothing.

| Feature | Flap Discs | Other Abrasive Wheels |

|---|---|---|

| Efficiency | High | Varies |

| Cooler Cutting | Yes | No |

| Lifespan | Longer | Shorter |

| Surface Finishing | Better | Varies |

| Versatility | High | Limited |

You can see that flap discs offer high efficiency and versatility for aluminum grinding.

- Flap discs balance deburring and cleanup tasks.

- They reduce heat, so you protect soft metals like aluminum.

- Their design means you replace them less often.

- You get a smooth finish, so you save time.

Silicon Carbide Grinding Wheels

Silicon carbide grinding wheels work well for aluminum because they minimize heat. You start shaping with aluminum oxide, then switch to silicon carbide for a finer finish. These wheels help you avoid damaging your workpiece. You should use a lubricant to keep the temperature low and protect the abrasive.

| Feature | Silicon Carbide | Aluminum Oxide |

|---|---|---|

| Ideal for | Low-tensile strength metals like aluminum | General use, harder materials |

| Heat Generation | Minimizes heat during grinding | Can generate more heat |

| Precision | Offers precision without excess heat | Good for general precision |

- Begin with aluminum oxide for rough shaping.

- Use silicon carbide for a smooth finish.

- Add lubricant to prevent heat buildup.

Silicon carbide grinding wheels are effective for soft metals. They help you keep your aluminum cool and safe during grinding.

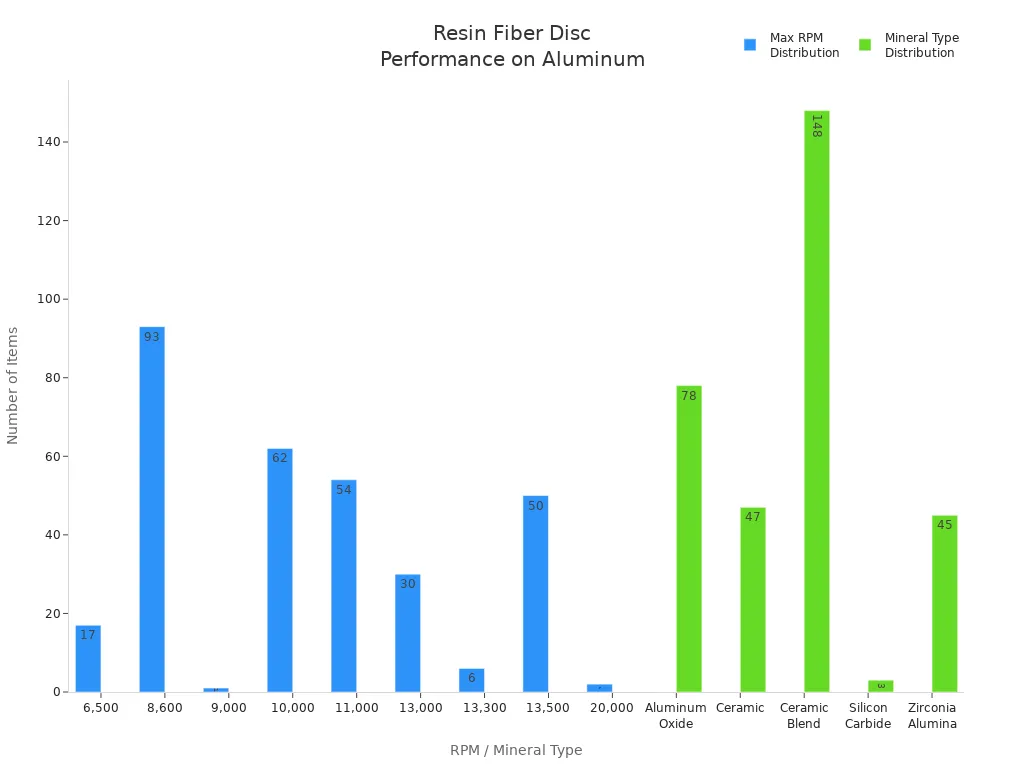

Resin Fiber Discs

Resin fiber discs give you strong performance on aluminum surfaces. You can use them for fast material removal and finishing. These discs come in many mineral types, such as aluminum oxide, ceramic, and zirconia alumina. You can choose the right disc for your needs. Resin fiber discs work at high speeds, so you finish your grinding tasks quickly.

You see that resin fiber discs are popular for aluminum grinding. They handle different RPMs and mineral types, so you get flexibility for your project.

Diamond Grinding Wheels by Aimgrind

Diamond grinding wheels from Aimgrind give you precision and durability. You use these wheels for tough jobs that need a high-quality finish. Diamond grinding wheels work well for hard alloys and composites, but they also help you achieve smooth results on aluminum. Aimgrind offers custom solutions, so you get the right wheel for your equipment and process. These wheels last longer and keep their shape, so you spend less time changing tools.

Note: Diamond grinding wheels from Aimgrind deliver consistent performance and help you reach your goals faster.

You can use diamond grinding wheels for both wet and dry grinding. They fit many types of grinding machines. Aimgrind’s expertise ensures you get the best match for your aluminum grinding needs.

Blended Abrasive Wheels

Blended abrasive wheels combine different materials to improve grinding results. You use these wheels when you want efficient metal removal and a uniform finish. The Aluminator wheel, for example, removes more aluminum and lasts longer than other wheels. Blended abrasive wheels keep a steady grinding rate, so you get consistent results. They also reduce vibration, which makes your work safer and easier.

- Efficient metal removal means you finish faster.

- Longer wheel life saves you money.

- Consistent grinding rates give you a smooth surface.

- Reduced vibration protects your hands and arms.

Blended abrasive wheels offer a cushion effect, so you avoid gouging mistakes. You get better control and safety during aluminum grinding.

Other Types of Grinding Wheels

You may also use hard grinding wheels, wire wheels, and non-woven grinding wheels for aluminum. Hard grinding wheels made from aluminum oxide or silicon carbide help you remove tough surfaces. Wire wheels clean aluminum dust and keep temperatures low. Non-woven grinding wheels resist loading and clogging, so you can polish and deburr aluminum easily.

| Type of Wheel | Characteristics | Applications |

|---|---|---|

| Hard Grinding Wheels | Made from aluminum oxide or silicon carbide; designed for heavy stock removal. | Effective for tough surfaces, including aluminum and other metals. |

| Wire Wheels | Efficiently remove aluminum dust; maintain lower temperatures during use. | Ideal for surface preparation and metal cleaning tasks. |

| Non-Woven Grinding Wheels | Constructed from nylon fibers; resist loading and clogging; flexible for contours. | Perfect for finishing tasks like deburring and polishing aluminum. |

You have many choices when it comes to types of grinding wheels for aluminum. Each type helps you solve different challenges and improve your grinding results.

Why These Abrasive Wheels Work for Aluminum

Aluminum’s Properties and Challenges

You face unique challenges when you work with aluminum. This metal is soft, but it has some tricky properties. Aluminum has porosity, which means it contains tiny holes inside. These small voids can make the metal weaker during grinding. You also find oxide inclusions on the surface. This oxide layer forms quickly and can make it hard to get a smooth finish.

Aluminum can also work harden. When you grind it, the surface gets tougher, which wears out your tools faster. The metal holds heat, so it can change shape if you do not control the temperature. You also see long, stringy chips when you grind aluminum. These chips can wrap around your tools and ruin the surface finish. You need to use special techniques to remove these chips and keep your work clean.

Here is a table that shows how some properties of aluminum affect your grinding process:

| Property | Impact on Machining |

|---|---|

| Work Hardening | Increases tool wear |

| Heat Retention | Affects dimensional accuracy |

| Chip Control Issues | Creates long, stringy chips that can entangle and affect surface finish |

- Long, stringy chips can lead to entanglement and poor surface finish.

- Chip evacuation requires specialized tooling and increased coolant pressure.

You must understand these challenges to choose the right grinding wheels for aluminum.

How Abrasive Wheels Address Aluminum Grinding Issues

You can solve many aluminum grinding problems by using the right abrasive wheels. Flap discs help you keep the workpiece cool. They do not let the metal overheat, so you avoid warping and color changes. Flap discs also give you a smooth finish, which is important for soft metals like aluminum.

When you use products made for aluminum, you reduce loading. Loading happens when bits of aluminum stick to the wheel. This can make the wheel stop cutting and damage your work. Flap discs and other grinding wheels for aluminum often have special coatings. These coatings stop aluminum from building up between the grains. You get better performance and a cleaner finish.

You also control heat by using moderate, steady pressure. Flap discs let you grind without pushing too hard. This keeps the temperature low and protects your workpiece. You can use lubricants with some abrasive wheels to help even more. These steps help you get the best results every time.

- Using products designed for aluminum helps reduce loading and manage heat generation.

- Coated abrasives and grinding wheels with inhibitors prevent aluminum from sticking to the wheel.

- Keeping a steady pressure while grinding reduces heat and protects your work.

Benefits of Using Specialized Grinding Tools for Aluminum Applications

You get many benefits when you use specialized grinding wheels for aluminum. Flap discs give you versatility. You can use them for shaping, smoothing, and finishing. They last longer than regular wheels, so you save time and money.

Diamond grinding wheels from Aimgrind offer high precision. You can use them for tough jobs that need a perfect finish. These wheels keep their shape and work well for both wet and dry grinding. You spend less time changing tools and more time getting your project done.

Resin fiber discs and blended abrasive wheels also help you finish your work faster. They remove material quickly and leave a smooth surface. You can choose the right tool for each step, from rough shaping to final polishing.

When you use the right grinding wheels, you protect your tools and your workpiece. You avoid overheating, reduce tool wear, and get a better surface finish. You also work more safely because these wheels reduce vibration and loading. You achieve the best results in your aluminum grinding projects by choosing the right tools for the job.

Tip: Always match your grinding wheels to your aluminum application for top performance and safety.

How to Choose Grinding Wheels for Aluminum

Grit and Hardness Selection

You need to pick the right grit and hardness for aluminum grinding. Aluminum can load or glaze a wheel, making it stop cutting. You should use a coarser grit and a softer grade. This choice helps the grains break out and keeps your grinding efficient. The A-H soft hardness range works well for aluminum. These wheels stay sharp and do not clog easily.

| Material Type | Recommended Grit | Recommended Hardness | Reasoning |

|---|---|---|---|

| Aluminum | Coarser Grit | Softer Grade | Coarser grit cuts better, softer grade keeps the wheel clean and sharp. |

| Hard Materials | Finer Grit | Harder Grade | Finer grit and harder grade keep the wheel sharp for tough jobs. |

- Use a coarser grit wheel for aluminum to remove material fast.

- Pick a softer grade to avoid clogging and keep your grinding smooth.

Bond Types and Wheel Construction

You should know how bond types affect grinding wheels for aluminum. Softer bonds let abrasive grains break away, which helps the wheel stay sharp. Harder bonds hold grains tight, but they can cause loading with aluminum. Using a coolant or lubricant helps flush away swarf and keeps the wheel cool.

| Bond Type | Effect on Grinding Performance |

|---|---|

| Harder Bond | Holds grains tightly, keeps wheel shape, but can load with aluminum. |

| Softer Bond | Releases grains, self-sharpens, works well for aluminum. |

| Coolant | Lubricates and removes debris, improves performance. |

Matching Wheels to Grinding Tools and Machines

You must match your grinding wheels to your tools and machines. Flap discs are a top choice for aluminum grinding. They keep temperatures low and prevent melting. Use a T29 (conical) disc for removing lots of material. Use a T27 (flat) disc for a smooth finish. Always use the right pressure and technique. Overheating can make aluminum stick to the wheel or even cause accidents.

- Choose the right wheel for your machine and task.

- Flap discs give you versatility and help you get the best results.

Application-Specific Considerations

Think about your project needs before you choose a quality grinding wheel. Aluminum can clog standard wheels, so you need sharper abrasive grains and special bond formulas. Resin bonded cut-off wheels with finer grit work well. Non-loading wheels or those with wax or lubricant coatings improve performance.

| Consideration | Details |

|---|---|

| Material Loading | Aluminum clogs standard wheels. |

| Abrasive Grains | Sharper grains cut better. |

| Bond Formulations | Special bonds prevent clogging. |

| Optimal Wheel Type | Resin bonded, finer grit for aluminum. |

| Special Formulations | Non-loading, wax or lubricant coatings. |

If you want help, Aimgrind offers custom grinding wheels and support. You can get high-quality abrasives designed for your equipment and process. This service helps you achieve the best results in every aluminum grinding project.

Tip: Avoid common mistakes like using the wrong abrasive or grit size. Always follow the recommended settings for safety and performance.

Tips for Effective and Safe Aluminum Grinding

Preventing Loading and Clogging

When you grind aluminum, you often see the wheel clog or load up. This happens because aluminum is soft and sticky. You can stop this by using flap discs, which shed debris and keep the surface clean. Try a 46 grit wheel for fast removal. Many users find green wheels work better for aluminum. You should use silicon carbide wheels instead of aluminum oxide. Always apply a water-soluble coolant in a rich mix to keep things cool and prevent loading. You can also use a grinding paste from welding suppliers to keep your grinder clean. Remember to use light pressure and let the abrasive do the work. This helps you avoid thick chips that gum up the wheel.

Tip: Flap discs are the best disc for perfect results when you want to avoid clogging and get a smooth finish.

Wheel Maintenance and Longevity

You want your grinding wheels to last a long time and work well. Clean and inspect your flap discs and other wheels often. Look for cracks, chips, or any damage. Regular cleaning and checks help you get the best performance and keep your tools safe. When you take care of your wheels, you save money because they last longer. You also reduce waste and avoid accidents. Well-maintained tools give you the best results every time you grind aluminum.

Safe Grinding Practices

Safety matters when you use flap discs and other grinding tools. Always inspect your wheel before you start. Wear safety goggles, gloves, and hearing protection. Make sure the wheel’s RPM matches your tool. Use steady, controlled pressure and keep the right angle on your workpiece. Turn off coolant before stopping the wheel to prevent thermal shock. Keep your workspace clean and know what to do in an emergency.

| Regulation | Description |

|---|---|

| OSHA 29 CFR 1910.212 | Machine guarding to protect you from hazards like rotating parts and flying chips. |

| OSHA 29 CFR 1910.215 | Rules for abrasive wheel machinery, including proper guarding and maintenance. |

| OSHA 29 CFR 1910.94(b) | Ventilation requirements for polishing and buffing to control dust and fumes. |

| OSHA 29 CFR 1926.102 | Eye and face protection rules for workers exposed to flying particles and other hazards. |

| OSHA 29 CFR 1926.303 | Safety requirements for abrasive wheels and tools in construction, including guarding and use. |

Maximizing Performance with Aimgrind Solutions

You can boost your grinding performance by choosing the right flap discs and grinding wheels from Aimgrind. Aimgrind offers custom solutions for aluminum grinding. Their experts help you match the wheel to your machine and process. You can also find training resources that teach you about nonferrous materials like aluminum. These courses show you how to solve grinding problems and improve your skills. When you use Aimgrind’s support and products, you get the best performance and results for every aluminum project.

Note: Training in grinding best practices helps you avoid downtime and work more efficiently.

You can achieve great results in aluminum grinding when you choose the best abrasive for aluminum. Flap discs work well for aluminum because they keep the metal cool and help you finish faster. You can use T29 conical discs for removing stock and T27 flat discs for cleaning and smoothing. Silicon carbide and diamond grinding wheels also give you strong grinding performance on aluminum. You should match the wheel type to your aluminum application. This helps you pick the right abrasive, wheel grade, and grit size. Ceramic alumina grains and zirconia alumina work well for tough jobs. Aluminum oxide is good for rough shaping. You get better grinding, longer wheel life, and safer work when you follow these tips.

- flap discs help you avoid overheating and clogging.

- silicon carbide and diamond grinding wheels remove material quickly.

- matching your wheel to the job improves grinding and safety.

Tip: Always use Aimgrind’s support and products for the best grinding performance on aluminum.

FAQ

What makes flap discs the best choice for aluminum grinding?

You get great results with flap discs when you work on aluminum. Flap discs keep the metal cool and help you avoid loading. You can use flap discs for shaping, smoothing, and finishing. Flap discs also last longer and give you a smooth finish every time.

How do I prevent loading when grinding aluminum?

You should use flap discs because they shed debris and stay clean. Flap discs help you avoid clogging, which is common with aluminum. You can also use a lubricant or grinding paste. These steps keep your grinding tools for aluminum applications working well.

Can I use regular grinding wheels instead of an aluminum-specific option?

You should not use regular wheels for aluminum. Flap discs are an aluminum-specific option. Flap discs do not clog as easily. You get better performance and a smoother finish with flap discs. Always choose the right tool for aluminum.

How often should I replace flap discs when grinding aluminum?

You should check your flap discs often. If you see wear or damage, replace them. Flap discs last longer than many other wheels. You get more grinding time and better results with flap discs. Safe tools help you finish your aluminum project.

Do flap discs work for both rough and fine grinding on aluminum?

You can use flap discs for both rough and fine grinding. Flap discs come in different grit sizes. You pick a coarse grit for fast removal and a fine grit for smooth finishing. Flap discs give you control and top performance on aluminum.