Features of Diamond CNC Profile Wheel for Edging Granite Marble Quartz Stone:

- Precise profiling

- High efficiency and several times better than electroplated products

- The excellent wheel in irregular shape stone processing

- Aggressive material removal rates

- Fit for angle grinder, marble machine, and other machines, easy to install

- Perfect for grinding on marble, granite, quartz, ceramics, artificial stone

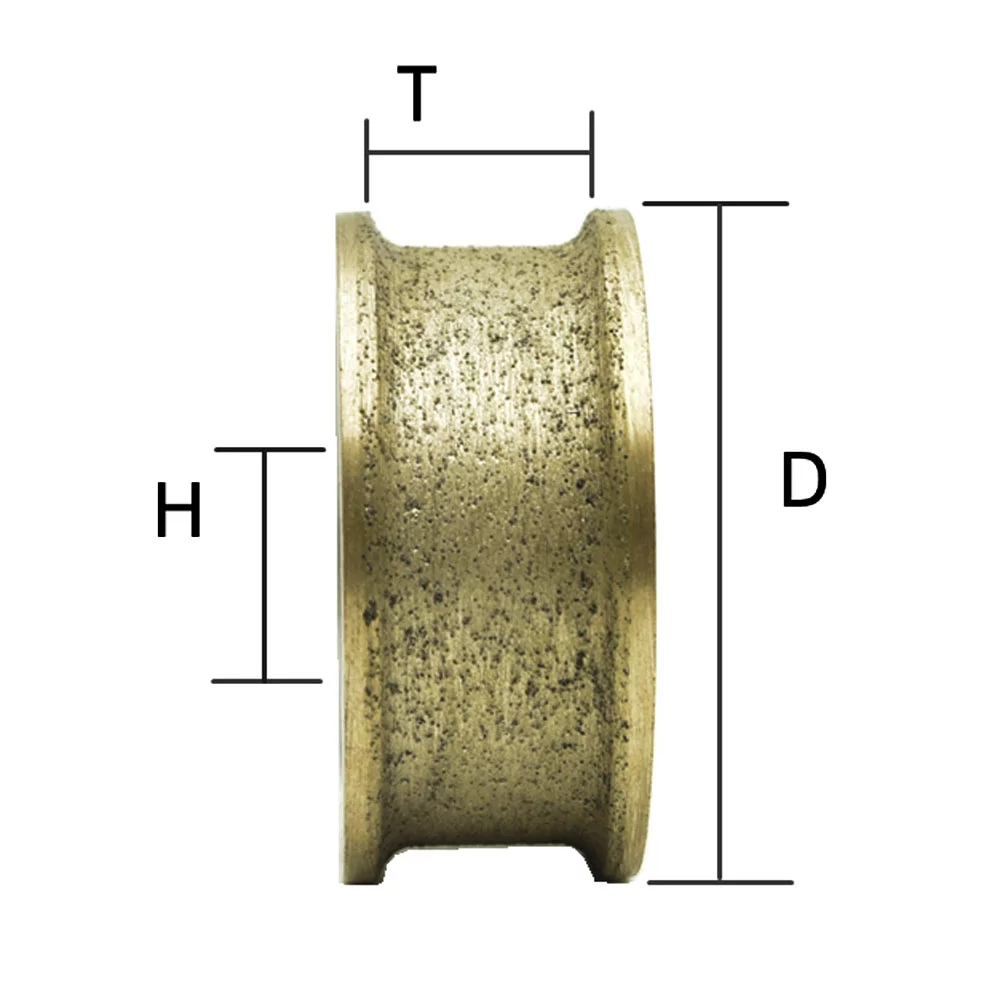

Detailed Description of Diamond CNC Profile Wheel :

Profile grinding wheel is used for grinding precise molds such as die, punch pin with complicated forms of irregular lines and curves. Profile grinding wheels carry diamond or CNC as an abrasive compound on its periphery.

1. Working Principle

The internal water holes in the profile wheel are designed for continuous water flow to keep the slab stone counter edges cool, wet, and lubricated while grinding. The top circular guide of the wheel is intended to regulate the longitudinal and lateral movement of the wheel while also providing greater flexibility and control over profile depth and width.

The profile is constructed using vacuum brazed technology, which is known for its stronger bonds, wear resistance, and durability. It has a long life and makes aggressive, efficient, clean, sharper, faster cuts on stones such as granite, marble, concrete, travertine, terrazzo, and quartz.

#40/50 grit diamonds are larger and are better suited for natural stones like marble and granite. #60/70 grit diamonds are finer and are better suited for ceramic materials to avoid chipping.

It is designed for the following usage –

- Stone (Quartz, Granite, Marble, others) Counter Edge Creation

- Concrete Countertop Edge Creation

- Wet or Dry Stone Edge Grinding & Shaping

- Full Bullnose, Miter, Demi / Roundover / Radius, Cove, Ogee, and Similar Profile Edge Creation

2. Types of Profile Grinding Wheels

Two types of abrasive materials are used for Profile Grinding Wheels:

Diamond: for grinding tungsten carbide, ceramic, and other hard to grind materials

CBN: for grinding tool steels such as SKH, SKD, SKS, and other ferrous materials.

- Diamond profile wheel

Diamond profile wheels, also referred to as diamond router bits are applicable for processing different stone edges and the edge surface like bevel, bullnose or half-bullnose, etc. In simple words, diamond profile wheels come to the rescue when you need to shape hard materials, marble or granite. Diamond wheels are one of the most popular stone profile grinding wheels available on the market. These give a great cutting effect and are known to have extended working life.

One of the most important diamond tools for profiling granite, marble, and other stones is a diamond profile wheel or hand router bit.

Diamond profile wheels come in a variety of shapes and sizes and are used to grind the surface of your materials and create the desired edge.

In general, we can divide traditional diamond profiles into two types:

- Segmented

- Vacuum Brazed

When compared to the segmented type, the vacuum brazed type is more aggressive and efficient, but it has a shorter lifespan. To ensure a longer lifespan, consider using the vacuum brazed profile wheel on soft stones such as marble.

Furthermore, vacuum brazed profile wheels are continuous and perform better. As a result, it is better suited for use on more expensive stones and where a high level of profile quality is required.

In short, a vacuum brazed profile wheel is an excellent choice for grinding marble and other soft stones. The segmented profile is more cost-effective for grinding granite and other hard stones.

There are numerous stone shapes to choose from, such as bevel, semi-bullnose edges, full bullnose, ogee, and so on.

There are 3 kinds of diamond profile grinding wheels:

- sintered diamond profile wheel

- vacuum brazed diamond profile wheel

- resin diamond profile wheel

Sintered profiling tools are designed for work on granite whereas the electroplated wheels are conceived for marble. Electroplated Diamond grinding wheels are mainly used for machining nonmetallic materials with high rigidity like ceramics, glass, tungsten carbide, ferrite, and so on.

Diamond profile grinding wheels are used for a variety of curved or oblique angle grinding on refractory materials.

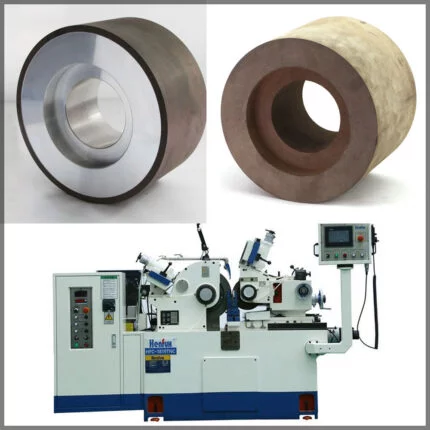

- CNC profile wheel

CNC machines were first used in stone fabrication. CNC profile wheel is equipped on CNC machine, which is good at irregular shape stone processing. CNC profile wheel has been developed to reduce production times, maximize tool life whilst providing excellent quality finishes. Electroplated CBN grinding wheels are mainly used for machining metallic materials such as chilled cast iron, founded alloy steel, titanium alloy, and so on.

The precise profiling, high efficiency make it widely used in the edge processing of vanity top and counter-top, etc.

CNC Profile wheel don’t lose its shape during the entire life cycle and don’t need redressing.

3. Advantages of Diamond CNC Profile Wheel

- Five-step system

- Diamond layered technology

- Longest tool life

- Faster because of uniform diamonds and hardness of the bond

- All profile wheels are balanced & carefully inspected

- Standard 22mm bore

- Super sharp fitted with multi-blade, special formula, and exclusive technic.

- Stable quality gives you the best working effect.

- No bending plate. Precise cutting gives you a good slab with qualified flatness and verticality.

4. Profiles Offered

- Two Types Of Radius Profiles

- Ogee Straight

- Double Eased

- Bevel

- Full Bullnose

- Demi Bullnose

- Straight

5. Applications

- Grinding on marble, granite, quartz, ceramics, artificial stone, and glass.

- Especially for concrete outside walls in buildings or decorations.

- Partial flattening of floor and edging fine of marble or granite boards.

6. Dressing a Diamond CNC Profile Wheel

Profile grinding wheels are self-sharpening to some extent; however, for optimal performance, they should be dressed and trued using grinding dressers. Dressing the wheel means removing the current layer of abrasive from the work surface, exposing a new and sharp surface.

All wheels need to be dressed to ‘true’ them up. Truing the wheel makes the grinding surface parallel to the grinding table or another reference plane, resulting in an even and accurate surface across the entire grinding wheel.

When we profile grind, it is critical that the tracing pin/stylus we use and the width of the profile is exactly the same. It is important to dress the wheel from both sides.

The only true test of wheels integrity is to ’ring test’ prior to mounting on the machine.

7. Use Case

Profile grinding is used to grind precision molds with complicated forms of irregular lines and curves, such as die and punch for press, forming cutting tools, cutting tools, high precision plate gauge, an electrode for electric discharge grinding, and formed precision parts such as a template. Structural profile grinding wheels are used in dry, which is a significant feature that is handled by both a manual system and a full automatic Numerical Control system.

NC machines have recently become widely used in a variety of industries, and their use is rapidly expanding. The rigidity, horsepower, and machining accuracy of today’s machines have greatly improved, and profile grinding wheels are now required more than ever to generate high precision machining.

8. How to effectively use a Profile Grinding Wheel?

- When mounting, the wheel should be run-out at less than 0.005 to reduce wheel vibration as much as possible.

- Peripheral speed should be set between 1,000 and 2,000m/min.

- It is recommended that you do not exceed 90 strokes per minute.

- Grit sizes up to #800 are recommended for practical use, #1000 for a metal bond, and #1500 for a resin bond. Finishing is typically done with #600 abrasives.

- When a wheel becomes deformed or its cutting capability is reduced, it must be trued (formed) and then dressed back to its original form.

- Because of its sharp edge, the wheel must be handled and taken into custody with extreme caution. It is especially relevant to thin wheels.

- To get the best performance out of a wheel, experiment with the grinding conditions on the machine table with the workpiece until you find the setting that produces the best results.

Summary:

Profile grinding wheels are extensively used for stone processing. They are an efficient tool to create professional finished concrete edge profile shapes faster. Additionally, the profile wheels are regularly used to perform edge work in the fabrication of kitchen and bathroom tops. They are oftentimes used for stairs and funerary art. The design of diamond CNC profile wheel is geared toward reducing production times, maximizing tool life, and providing better quality finishes to maximize your investment.

Contact Us

For More Grinding Solution or Customized Abrasive Tools