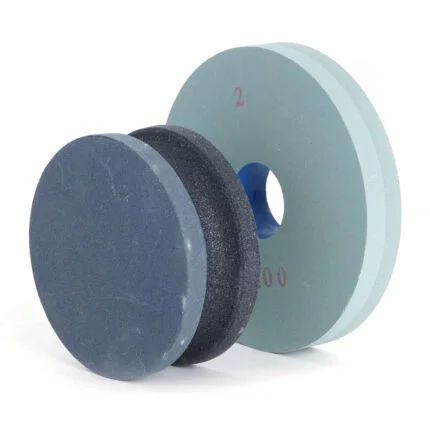

About Silicone carbide combination stones

Silicone carbide combination stones have both coarse and fine grit carbide surfaces. These fast-cutting stones are used to sharpen edges on tools to moderate tolerances quickly. Stones are very fast cutting and while a thin clear oil is usually sufficient. These softer stones have several advantages over harder stones. Because they are softer, they do not become glazed or loaded with detritus. Plus, they are lubricated effectively with water rather than oil, but can be used with either. There are a number of ways to sharpen knives and tools, but water stones are the preferred method because the user has absolute control during the sharpening process.

![]()

Silicone carbide combination stones

Detail Description

Combination sharpening stone (bench stone) is a flat stone used for sharpening tools on a bench. As a combination sharpening stone, it comes with two different grits on two different faces: one face is used to repair steel cutting edges while the opposite face is used to sharpen and maintain them. These two faces can be made of the same or different materials in different granularity. They can be made of silicon carbide and aluminum oxide, which can be used to sharpen knives, glass-wares and other kinds of related manufactures

Combination sharpening stone is ideal for producing durable and smooth-cutting edges. It helps sharpen and hone the edges of steel tools and implements such as knives, chisels, plane blades, and hand scrapers. The sharpening process is technically in two different ways. The first involves creating or re-establishing a cutting edge by grinding away parts of the metal to give the angle of the edge a proper adjustment and reforming the shape. The other process is honing, which involves removing small imperfections.

Common Uses:

Combination sharpening stone is an oilstone that is characteristically durable and wears slowly, with longer retention of flatness when compared to Waterstones. It is commonly used for some specific tasks. These include:

- For grinding away parts of the metal to adjust the angle of the edge and reform the shape

- Removing every small imperfection from the workpiece

Features of Silicone carbide combination stones

- Very user-friendly

- Perfect for a frequent sharpening of tools

- Restore cutting edge on straight-edged tools.

- Help maintain the swift slicing and overall usability of tools

- Feature two different types of stones in one

Below are the various specs of rectangular silicon carbide combination sharpening stone, featuring the grade, shape, and grit sizes:

| Type | Grade | Shape | Grit sizes |

| Combination Grit Sharpening Stone | Coarse | Rectangle | 80-100 |

| Combination Grit Sharpening Stone | Medium | Rectangle | 150-220 |

| Combination Grit Sharpening Stone | Fine | Rectangle | 280-320 |

Summary

Combination sharpening stones can be highly recommended for beginners. With this type of stone, users have two different types of stone in one at their disposal. Its silicon carbide and aluminum oxide combination sharpening stone can ensure the general sharpening and maintenance of kitchen knives and other regular steel tools such as plane blades, chisels, wood lathe cutters, precision tools, spokeshaves, and delicate instruments.

Getting a combination sharpening stone comes with numerous benefits. Aside from the fact that it’s very user-friendly, it’s ideal for frequent sharpening of knives. To cap it all, you can quickly restore the cutting edge on straight-edged tools with this sharpening stone, thereby maintaining the swift slicing and overall usability of such tools.

Contact Us

For More Grinding Solution or Customized Abrasive Tools