You face unique grinding challenges when working with different brake disc materials. Each material, such as cast iron, carbon-ceramic, or steel, brings its own set of issues. For example, the way graphite forms in cast iron or the special elements in the metal can change how you approach grinding. Surface features and microstructures also affect results. You can solve many of these challenges by using specialized tools like Aimgrind’s Metal bond grinding wheels, which hold abrasive grains tightly for better control and longer use.

Key Takeaways

- Choose the right abrasive for each brake disc material to reduce tool wear and improve grinding efficiency.

- Monitor heat generation during grinding to prevent thermal damage, using coolants and high thermal stability wheels.

- Achieve a smooth surface finish by using multi-stage grinding and selecting appropriate abrasives for the material.

- Understand the hardness and microstructure of materials to tailor your grinding approach for better results.

- Regularly inspect and dress your grinding wheels to maintain performance and extend tool life.

Grinding Challenges in Brake Disc Materials

Tool Wear and Abrasive Selection

You will notice that tool wear is one of the biggest grinding challenges when working with different brake disc materials. Each material, like cast iron, carbon-ceramic, or steel, reacts differently during machining. Some materials, such as carbon-ceramic, contain silicon carbide (SiC), which has a hardness close to 9.5 on the Mohs scale. This high hardness can quickly wear down conventional abrasives. You may also face a composite microstructure in these discs, which causes uneven cutting resistance and vibration. Brittleness in some materials can lead to microcracks and chipping if you do not control the process well. Thermal sensitivity is another factor; localized heat can cause delamination or leave residual stress.

- High hardness of SiC wears down tools fast.

- Composite microstructure creates uneven resistance and vibration.

- Brittleness can cause microcracks and chipping.

- Thermal sensitivity may lead to delamination or stress.

To address these grinding challenges, you need to select the right abrasive. The table below shows some effective abrasive materials for brake disc grinding:

| Material Type | Key Attributes | Benefits |

|---|---|---|

| PCBN | Extreme hardness, wear resistance | High surface quality, improved efficiency, cost reduction |

| CBN Grinding Wheels | High hardness, thermal stability, durability | Long lifespan, reduced maintenance costs |

Choosing the right abrasive helps you reduce tool wear and improve grinding efficiency. You can achieve better results and lower your maintenance costs by using advanced abrasives like CBN or PCBN.

Heat Generation and Thermal Damage

Heat generation is another major grinding challenge. When you grind brake discs, friction creates heat. If you do not control this heat, it can cause thermal damage. Excessive heat can warp rotors, degrade brake fluid, glaze brake pads, and speed up component wear. It can even compromise safety.

| Consequence | Description |

|---|---|

| Warped Rotors | Prolonged heat exposure can warp rotors, causing uneven braking and vibrations, necessitating replacement. |

| Degraded Brake Fluid | High temperatures can break down brake fluid, reducing its effectiveness and increasing maintenance needs. |

| Glazed Brake Pads | Overheating leads to glazed pads, which lose effectiveness and may require replacement. |

| Accelerated Component Wear | Increased heat accelerates wear on all braking components, leading to higher maintenance costs. |

| Compromised Safety | Repeated overheating can lead to unreliable braking, increasing accident risk, especially in critical situations. |

You should always monitor temperature during grinding. Using coolants and selecting grinding wheels with high thermal stability, such as Aimgrind‘s Metal bond grinding wheels, can help you manage heat and avoid these problems.

Surface Finish and Accuracy

Surface finish and accuracy are critical for brake disc performance. You need a smooth surface to ensure optimal braking. High-performance vehicles have strict standards for surface finish. If you do not meet these standards, you may hear brake noise or feel vibrations. Achieving the right surface finish can be difficult, especially as tools wear out.

- Brake discs require a good finished surface for optimal braking performance.

- High-performance cars have strict surface finish standards.

- Surface roughness specifications vary by application.

- Achieving necessary smoothness can be challenging with traditional tools.

- Rough surfaces can cause brake noise or judder.

- Secondary grinding operations may be needed to meet tight specifications.

- Operators may struggle with achieving smooth surfaces, leading to noise or judder.

- Inconsistencies in surface finish can occur as tools wear.

- Grinding after turning is often needed for precision.

Several factors influence your ability to achieve high surface finish and accuracy:

- You must manage tolerances and coating thickness, especially for friction ring thickness and axial run-out.

- You need to control elastic deformation during grinding, as too much force can cause run-out and flatness issues.

- You should coordinate laser metal deposition and grinding processes to maintain quality and efficiency.

By understanding these grinding challenges and using the right tools and techniques, you can improve your machining results and extend the life of your brake components.

Material Properties and Their Impact on Grinding

Hardness and Toughness

You need to understand how hardness and toughness affect grinding. Hardness measures how well a material resists scratching or cutting. Toughness shows how much energy a material can absorb before it breaks. Brake disc materials have different hardness levels, which change how you approach grinding.

- Cast iron brake rotors usually have a hardness between H10 (1000 MPa) and H24 (2400 MPa). If the hardness goes above H21, you need heat treating or tempering. If it drops below H17, special annealing is needed.

- Carbon-ceramic materials are much harder than brake pads. They do not rust and use a transfer layer to create friction, which reduces physical wear.

When you grind harder materials, you need stronger abrasives and more careful control. Tougher materials can resist breaking, but they may also wear down your tools faster.

Thermal Conductivity

Thermal conductivity tells you how well a material moves heat away from the grinding area. This property is important because grinding creates heat, and too much heat can damage the disc.

- Gray cast iron brake discs keep the lowest peak temperature during braking. This helps prevent overheating.

- Carbon-ceramic discs also manage heat well, though the exact numbers can change.

- The design of the disc, such as ventilation holes, also affects how heat spreads.

If you choose a material with good thermal conductivity, you can control heat better during grinding. This helps you avoid warping or damaging the disc.

Tip: Always watch the temperature when grinding. Good heat management keeps your brake discs in top shape.

Microstructure Differences

The microstructure of a brake disc changes how it behaves during grinding. Microstructure means the way the tiny parts inside the material are arranged.

- Cast iron brake discs have a traditional structure. They resist wear well but are heavy and do not work as well at high temperatures.

- Carbon-ceramic discs use black silicon carbide. This makes them hard, stable in heat, and very resistant to wear. They lose less material and handle sudden temperature changes better.

- Steel brake discs are strong and bend without breaking. They may not handle heat as well as carbon-ceramic discs.

You need to match your grinding tools and methods to the microstructure of the disc. This helps you get the best results and keeps your tools working longer.

Comparative Overview: Cast Iron, Carbon-Ceramic, and Steel Brake Discs

Cast Iron Grinding Challenges

You often work with cast iron brake discs because they offer excellent friction properties and are cost-effective. However, you face several machining challenges when grinding these discs. Cast iron is both hard and brittle. This combination can cause your tools to chip or the workpiece to fracture. The abrasive microstructure of cast iron leads to rapid tool wear. High thermal stress during grinding generates intense heat, which can damage conventional tools. You also need to watch for micro-cracks that can weaken the disc.

| Challenge | Description |

|---|---|

| Extreme hardness and brittleness | Causes tool chipping and workpiece fracture. |

| High abrasiveness | Leads to rapid tool wear due to the abrasive microstructure of cast iron. |

| High thermal stress | Generates intense heat during cutting, which can degrade conventional cutting tools. |

| Tool and workpiece integrity | Cutting forces can induce micro-cracks in the workpiece, compromising its structural integrity. |

| Use of specialized tools | PCBN tools are employed to withstand the harsh conditions of machining hard cast iron. |

You can improve grinding results by using tools like Aimgrind’s Metal bond grinding wheels. These wheels resist wear and hold their shape, even under tough conditions.

Carbon-Ceramic Brake Discs Grinding

When you grind carbon-ceramic brake discs, you deal with some of the toughest machining challenges. These discs contain silicon carbide, which has a hardness close to 9.5 on the Mohs scale. This extreme hardness quickly wears down conventional abrasives. The composite microstructure creates non-uniform cutting resistance, causing vibration during machining. Brittleness can lead to microcracks and chipping if you do not control the process. Localized heat may cause delamination or leave residual stress in the disc.

| Challenge | Description |

|---|---|

| High hardness of SiC | Quickly wears conventional abrasives due to its extreme hardness (≈ 9.5 Mohs). |

| Composite microstructure | Causes non-uniform cutting resistance and vibration during machining. |

| Brittleness | Leads to microcracks and chipping if not properly controlled. |

| Thermal sensitivity | Localized heat can cause delamination or residual stress in the material. |

You need grinding wheels that can handle these conditions. Aimgrind’s Metal bond grinding wheels offer extreme hardness and wear resistance. Their high thermal conductivity helps move heat away from the grinding zone, protecting the disc and improving performance.

Steel and Alloy Disc Grinding

Steel and alloy brake discs present their own set of machining challenges. These materials are strong and can bend without breaking, but they may not handle heat as well as carbon-ceramic brake discs. You need to manage grinding heat to avoid warping. Steel discs can also cause tool wear, especially when you use high cutting speeds. CBN tools can last 5 to 25 times longer than carbide inserts when machining hardened steels or cast irons. You can achieve cutting speeds between 100 to 300 m/min for hardened steels and up to 1000 m/min for cast irons.

- You should use grinding wheels with excellent form holding and wear resistance.

- Aimgrind’s Metal bond grinding wheels maintain their profile over long use, which is important for tight tolerances.

- Their high thermal conductivity helps you manage heat during grinding.

Tip: Always match your grinding tool to the brake disc material. This helps you get the best results and extends tool life.

Grinding Process Optimization and Tool Selection

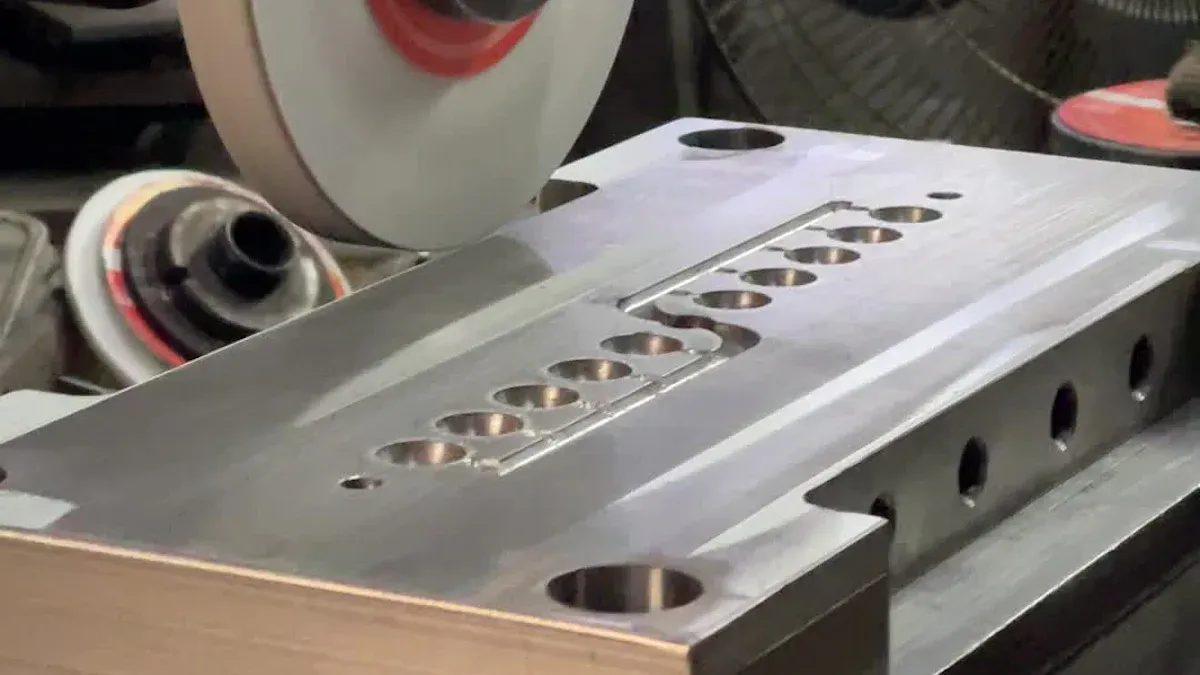

Aimgrind Metal Bond Grinding Wheels

You need the right tools to get the best results in machining. Aimgrind Metal bond grinding wheels help you achieve high precision and long tool life. These wheels use diamond or CBN abrasives, which makes them strong and stable. You can use them for hard alloys, ceramics, and superhard materials. When you work with a brake disc, you want a tool that keeps its shape and does not wear out quickly. Aimgrind offers custom solutions for your needs. You can talk to their experts to match the wheel to your equipment and process. This helps you save time and improve performance.

Tip: Choose a grinding wheel that matches your disc material for better machining results.

Diamond and CBN Abrasives

You will see better results when you use diamond or CBN abrasives for machining. Diamond abrasives work well for ceramics and hard materials. CBN abrasives are best for steel and alloy discs. These abrasives cut faster and last longer than traditional ones. You can reduce tool changes and keep your process stable. This means you spend less time on maintenance and more time on production. You also get a smoother finish on your brake disc, which improves performance.

Multi-Stage Grinding Strategies

You can use multi-stage strategies to improve your machining process. Start with a rough grinding stage to remove most of the material. Then, use a finer wheel for finishing. This method helps you control heat and avoid damage to the disc. You can also use coolants to keep the temperature low. By planning each stage, you make sure the disc meets quality standards. You get better surface finish and longer tool life.

Note: Always check your process and adjust the grinding wheel or parameters if you see problems.

Practical Solutions for Material-Specific Grinding Challenges

Segment Types and Applications

You need to choose the right segment type for each brake disc material to get the best results in machining. Different wheels work better for different materials:

- CBN wheels work best for ferrous metals like cast iron and steel. They give you thermal stability and high efficiency during machining.

- Diamond wheels are more effective for non-ferrous materials such as ceramics. They offer high hardness, which helps you cut and grind these tough materials quickly.

- Both types of wheels see use in industries like automotive and aerospace, where you often face a mix of materials and strict quality standards.

Selecting the right wheel helps you reduce tool wear and improve the quality of your grinding process.

Coolant Use and Heat Management

Managing heat is important when you work with different brake disc materials. You can use several techniques and products to keep temperatures low:

- Non-woven products allow air to flow through, cooling the workpiece during machining.

- Flap discs have overlapping flaps that act like a fan, moving air and reducing heat.

- Semi-flex discs use perforations and spiral patterns to channel heat away from the grinding area.

- Abrasive grease sticks help lower friction and heat, making your abrasives last longer.

- You should always use the recommended RPMs, apply light pressure, and keep the tool moving. These best practices help you avoid overheating and damage.

Tip: Good heat management keeps your tools sharp and your brake discs in top condition.

Surface Quality Improvement

You want a smooth surface after machining because it improves brake performance and safety. To get the best finish, you should:

- Use multi-stage grinding, starting with a rough pass and finishing with a finer wheel.

- Choose the right abrasive for the material. For example, use CBN for steel and cast iron, and diamond for ceramics.

- Apply coolants or lubricants to prevent heat buildup and surface burns.

- Check your work often to make sure you meet the required surface standards.

A careful approach to grinding helps you achieve a high-quality finish and extends the life of both your tools and brake discs.

You can overcome grinding challenges by choosing the right wheel for each brake disc material and following best practices. Material-specific strategies and process optimization help you get better results and save resources. To improve your grinding outcomes, remember these tips:

- Always select the correct grinding wheel for the task.

- Dress and inspect your wheel regularly.

- Use proper speeds and cooling to prevent overheating.

- Follow safety protocols and check for wheel wear.

Aimgrind’s Metal bond grinding wheels give you the precision and durability you need for every brake disc project. Apply these solutions to your work and see the difference.

FAQ

What grinding wheel should you use for carbon-ceramic brake discs?

You should use a metal bond grinding wheel with diamond abrasives. This type of wheel handles the extreme hardness of carbon-ceramic materials and gives you a smooth finish.

How do you reduce heat during brake disc grinding?

Always use coolants or lubricants. They help move heat away from the grinding area. You can also use grinding wheels with high thermal conductivity, like Aimgrind’s Metal bond wheels.

Why does tool wear happen faster with some brake disc materials?

Some materials, like carbon-ceramic or hard cast iron, have high hardness or abrasive microstructures. These features wear down your grinding tools quickly. You need to choose the right abrasive to slow this process.

Can you use the same grinding wheel for all brake disc types?

- No, you should match the grinding wheel to the disc material.

- Use CBN wheels for steel and cast iron.

- Use diamond wheels for ceramics.

- This choice gives you better results and longer tool life.