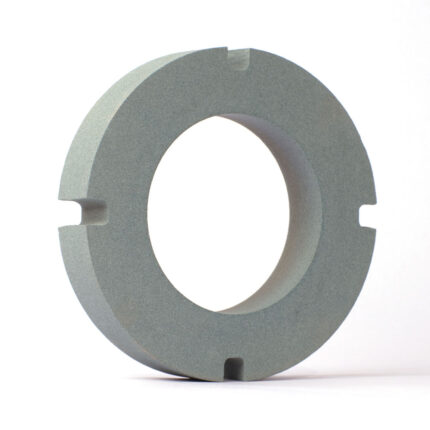

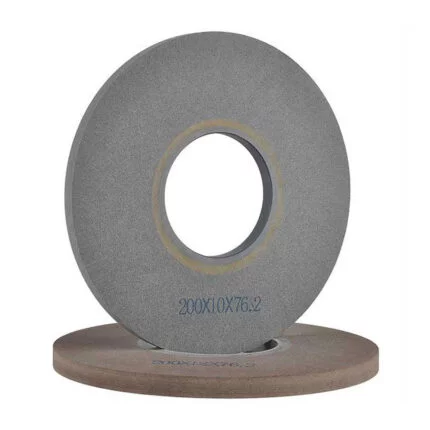

Resin Bond Knife Sharpening Barrel Grinding Wheel (WA46J7B)

The resin barrel grinding wheel (Model: WA46J7B) is manufactured with premium white aluminum oxide (WA) abrasive and high-strength resin bond, specifically designed for precision sharpening of woodworking tools, stainless steel knives, and paper cutting blades. The barrel structure with 6 bottom-mounted 8mm internal threaded positioning holes ensures machining stability and installation accuracy, making it the professional choice for tool maintenance in woodworking, papermaking, and related industries.

Key Advantages

| Parameter | Value |

|---|---|

| Outer Diameter (D) | 255mm |

| Thickness (T) | 100/120mm |

| Bore Diameter (H) | 205mm |

| Abrasive Type | White Aluminum Oxide (WA) |

| Grit Size | 46# |

| Bond Type | Resin (B) |

| Hardness Grade | J7 |

| Positioning Holes | 6×M8 Internal Thread |

- Applicable Materials: HSS/Stainless Steel/Alloy Tool Steel

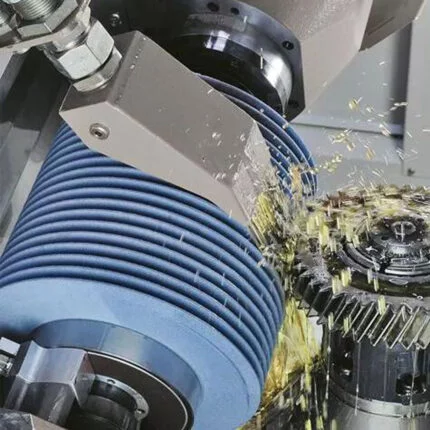

- Recommended Speed: 30-35m/s

- Balance Grade: G6.3

- Grinding Method: Wet/Dry Grinding

- Operating Temperature: ≤150℃

- Storage Conditions: Dry environment, avoid direct sunlight

Product Features

Precision Threaded Positioning

6 bottom-mounted M8 precision threaded holes ensure secure fastening during high-speed rotation, especially suitable for precision grinding of heavy-duty tools.

Premium White Aluminum Oxide

WA46 abrasive provides excellent cutting performance and self-sharpening, effectively reducing grinding heat and maintaining tool metal structure stability.

Special Resin Formula

Specially formulated resin bond offers strength with elasticity to buffer grinding impact, resulting in smoother edge surfaces.

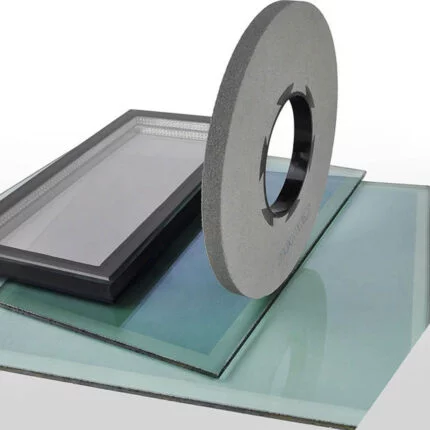

Applications

Woodworking Tools

- Planing Knives

- Peeling Knives

- Chipper Knives

Paper Industry

- Paper Cutting Blades

- Slitting Knives

- Guillotine Knives

Cutlery Manufacturing

- Stainless Steel Knives

- Industrial Blades

- Professional Cutlery

Panel Processing

- Plywood Tools

- MDF Tools

- Particleboard Tools

Usage Guide

1. Installation Requirements

- Use matching flange with 6 positioning bolts evenly tightened

- Inspect wheel for cracks/damage before installation

- Flange diameter ≥1/3 of wheel diameter

2. Grinding Parameters

| Tool Material | Speed (m/s) | Feed Rate (mm/pass) |

|---|---|---|

| Carbon Steel | 30-32 | 0.05-0.10 |

| Stainless Steel | 28-30 | 0.03-0.08 |

| HSS | 32-35 | 0.04-0.07 |

3. Maintenance

- Regularly dress wheel surface with diamond dresser

- Avoid stacking during storage

- Stop immediately if abnormal vibration occurs

- Check bolt tightness per shift

Technical Comparison

| Comparison | WA46J7B Resin Wheel | Standard Alumina Wheel | Ceramic Bond Wheel |

|---|---|---|---|

| Surface Roughness | Ra0.8μm | Ra2.5μm | Ra1.2μm |

| Sharpening Time | 2-3 min | 5-8 min | 3-5 min |

| Wheel Life | 300-400 tools | 100-150 tools | 200-250 tools |

| Heat Affected Zone | Minimal | Significant | Moderate |

| Installation Stability | Excellent (6-point) | Average | Good |

Contact Us

For More Grinding Solution or Customized Abrasive Tools