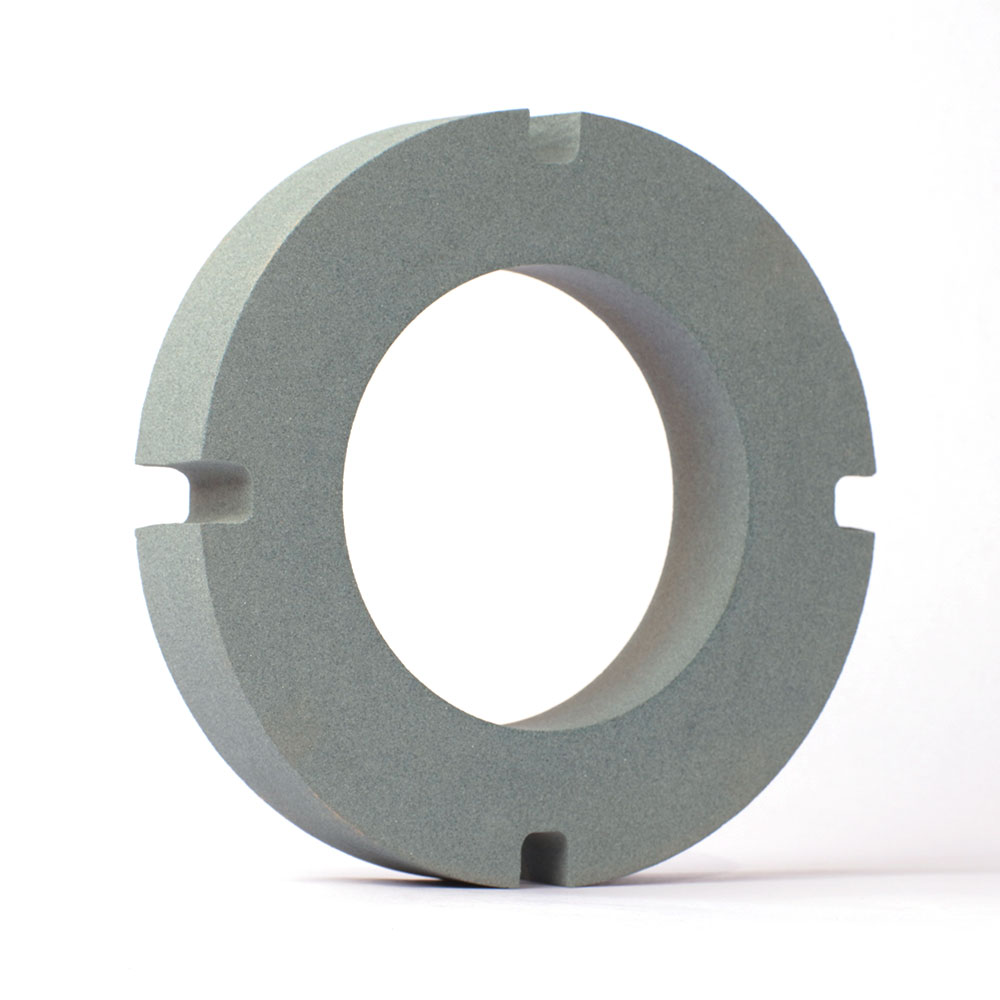

GC Dressing Tool for Surface Grinding Wheel

Professional-grade GC Dressing Wheel specifically engineered for restoring diamond/CBN surface grinding wheels. Our Surface Grinding Wheel Dresser utilizes premium Green Silicon Carbide (GC) abrasives to efficiently remove loaded material and re-sharpen dulled superabrasive wheels, ensuring optimal grinding performance.

Precision Dressing

Our GC Dressing Tool maintains consistent wheel geometry and surface finish

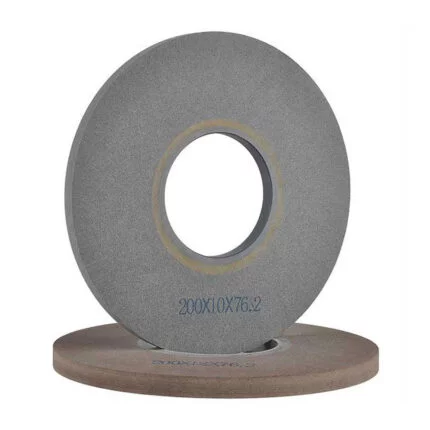

Extended Wheel Life

Effectively doubles the service life of your Surface Grinding Wheels

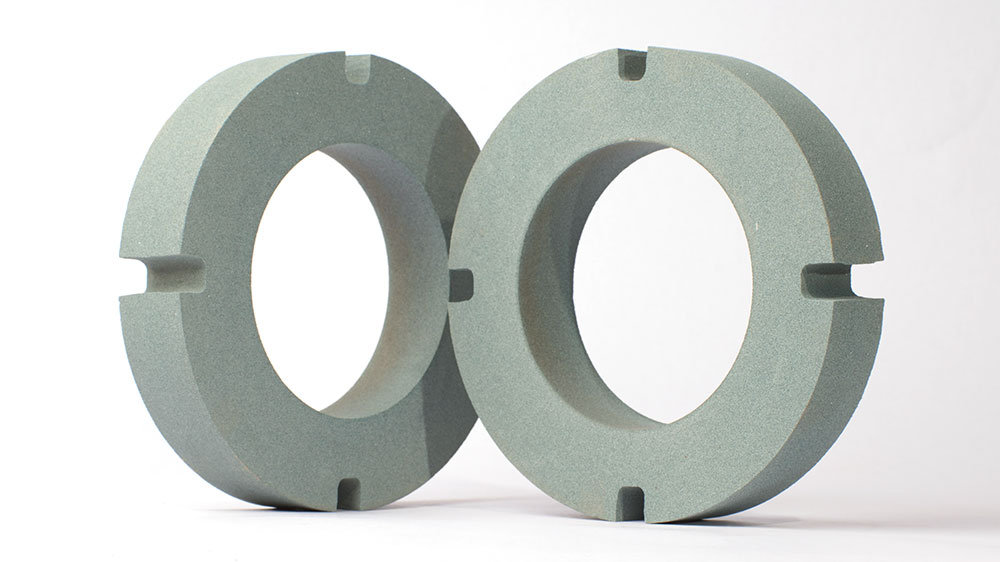

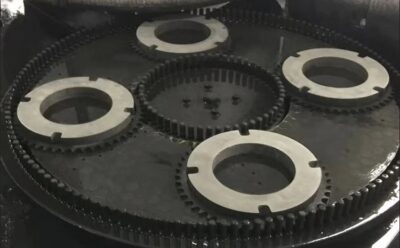

Multi-Wheel Configuration

GC Dressing Wheels can be stacked for simultaneous dressing operations

Technical Specifications

| Feature | GC Dressing Tool Advantage |

|---|---|

| Abrasive Material | High-purity Green Silicon Carbide (GC) – Ideal for Surface Grinding Wheel dressing |

| Standard Sizes | 205-330mm diameter GC Dressing Wheels (Custom sizes available) |

| Grit Selection | Optimally 1-2 grades coarser than your Surface Grinding Wheel |

| Dressing Efficiency | 30-50% faster than conventional Surface Grinding Wheel Dressers |

| Compatibility | All resin-bond diamond/CBN Surface Grinding Wheels |

Why Choose Our GC Dressing Tool?

Superior Dressing Performance

Our GC Dressing Wheel outperforms conventional dressers with:

- Faster cutting action – Reduces dressing time by up to 50%

- Precision grit alignment – Maintains optimal Surface Grinding Wheel topography

- Longer service life – 30% more durable than standard dressing tools

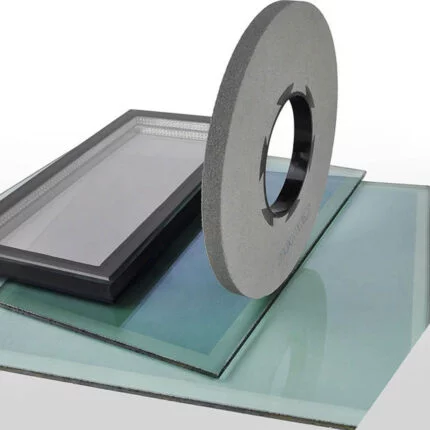

Industry-Leading Applications

The ultimate Surface Grinding Wheel Dresser for:

- Automotive: Gear, bearing and transmission component grinding

- Tool & Die: Carbide cutting tool and precision mold manufacturing

- Aerospace: Turbine blade and engine component finishing

Technical Support

- Grit matching service: Our engineers will recommend the ideal GC Dressing Tool grit for your specific application

- Custom configurations: Special sizes, profiles and mounting options available

- Dressing parameters: Complete technical guidance for optimal Surface Grinding Wheel performance

Contact Us

For More Grinding Solution or Customized Abrasive Tools